Rotary compressor and crankshaft thereof

A technology for rotating compressors and crankshafts, which is applied in the field of compressors, and can solve the problems of increasing the running resistance of compressors, strict requirements on magnetic permeability, and increased wear of crankshafts and bearings, so as to reduce gas resistance, reduce weight, and rotate Effect of Eccentric Inertial Force Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

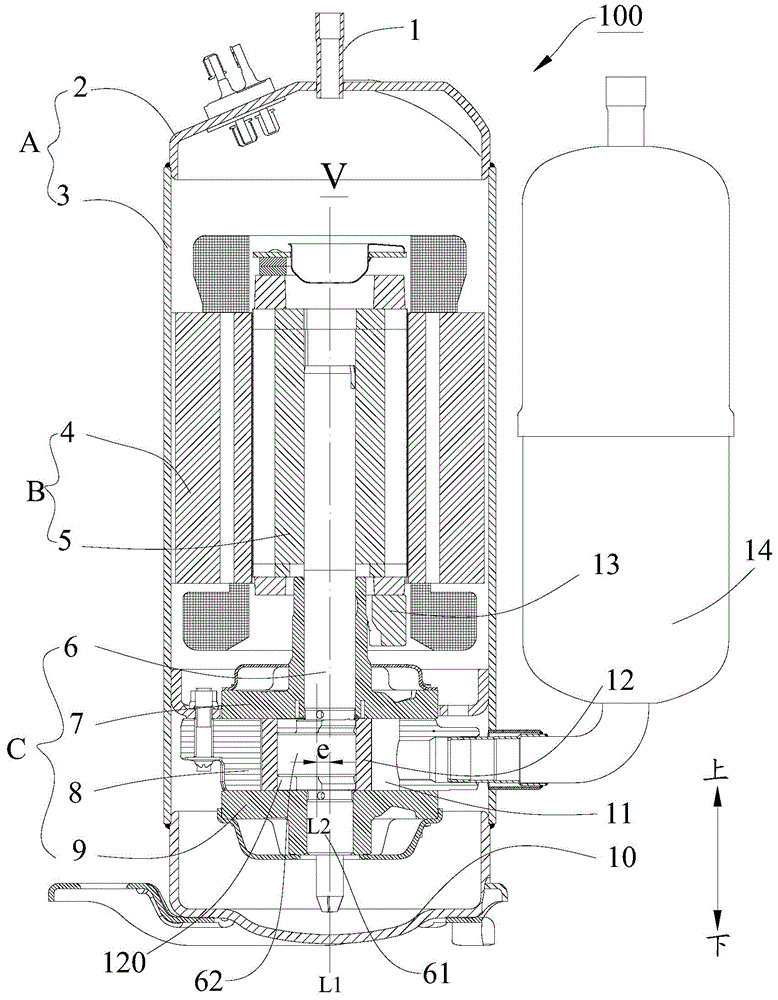

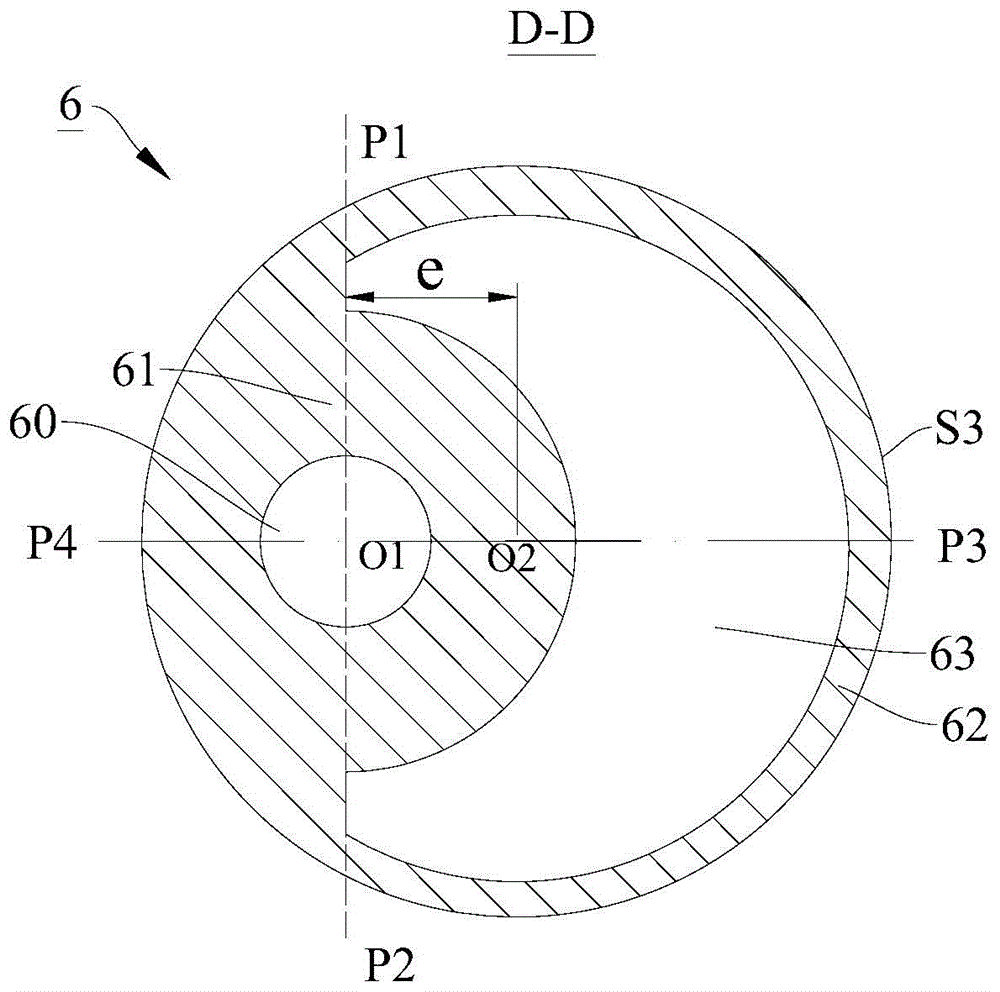

[0076] In this example, if figure 2 and image 3 As shown, the weight-reducing balance hole 63 is a through hole through the eccentric portion 62 up and down, thus, the processing of the weight-reducing balance hole 63 is more convenient, the production cost of the crankshaft 6 is lower, and the eccentric mass of the eccentric portion 62 can be greatly reduced. .

[0077] Specifically, such as image 3 As shown, the cross-section of the weight-reducing balance hole 63 is generally fan-shaped, and the center of the fan-shaped coincides with the central axis L1 of the main shaft portion 61 . In this way, the mass center of the eccentric portion 62 can be moved to the central axis L1 of the main shaft portion 61 as much as possible, so that the mass center of gravity of the crankshaft 6 is close to the central axis of rotation, which is beneficial to reduce the vibration and noise of the compressor, and is convenient to reduce or even avoid the use of balance. Block 13.

[0...

Embodiment 2

[0081] In this example, if Figure 7 and Figure 8 As shown, the structure of the crankshaft 6 is substantially the same as the structure of the crankshaft 6 in the first implementation, and this will not be repeated.

[0082] The difference is that, in the second embodiment, the weight-reducing balance hole 63 is provided with a reinforcing rib 64, and the setting of the reinforcing rib 64 is equivalent to dividing the weight-reducing balance hole 63 into two or more sub-weight-reducing The more reinforcing ribs 64 are provided for the holes 630, the more the number of sub-weight-reducing holes 630 divided by the weight-reducing balance hole 63 will be. The purpose of this design is to prevent the eccentric part 62 from breaking due to excessive decrease in stiffness during the weight reduction process by strengthening the reinforcing effect of the rib plate 64 .

[0083] It should be noted that if the stiffness of the eccentric portion 62 of the crankshaft 6 decreases too ...

Embodiment 3

[0089] In this example, if Figure 9 to Figure 13 As shown, the structure of the crankshaft 6 is substantially the same as the structure of the crankshaft 6 in the first implementation, and this will not be repeated.

[0090] The difference is that in the third embodiment, as Figure 9 As shown, the crankshaft 6 also includes: a horizontal partition 65, which is perpendicular to the central axis L1 of the main shaft portion 61 and is arranged in the weight-reducing balance hole 63, and the outer peripheral surface of the horizontal partition 65 and the weight-reducing balance hole The inner peripheral surface of 63 is at least partially attached in the circumferential direction. The horizontal partition 65 is supported on the thin wall of the eccentric part 62 to form the weight-reducing balance hole 63, which is conducive to improving the rigidity of the eccentric part 62 of the crankshaft 6, and avoiding gas leakage caused by excessive deformation of the eccentric part 62 u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com