Filtering device with electrostatic spinning nanofiber cloth and mask

A technology of electrospinning and nanofibers, which is applied in the field of filter devices and masks with electrospinning nanofiber cloth, which can solve the problem of poor ventilation capacity, unsatisfactory filtering effect of melt-blown non-woven masks, and failure to achieve high Efficiency filtration, low resistance use standards and other issues, to achieve the effect of small gas resistance and excellent filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

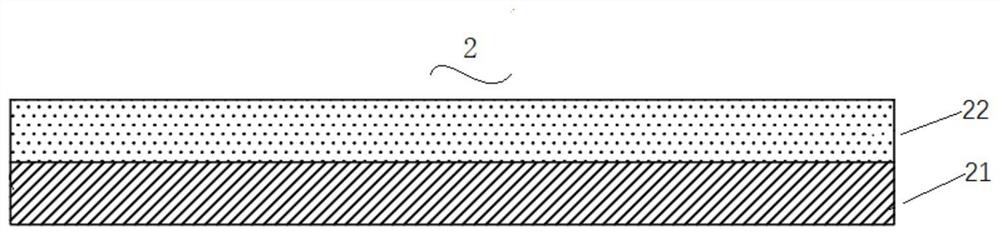

[0050] See attached Figure 1-2 , is a filter device 2 with electrospun nanofiber cloth, comprising:

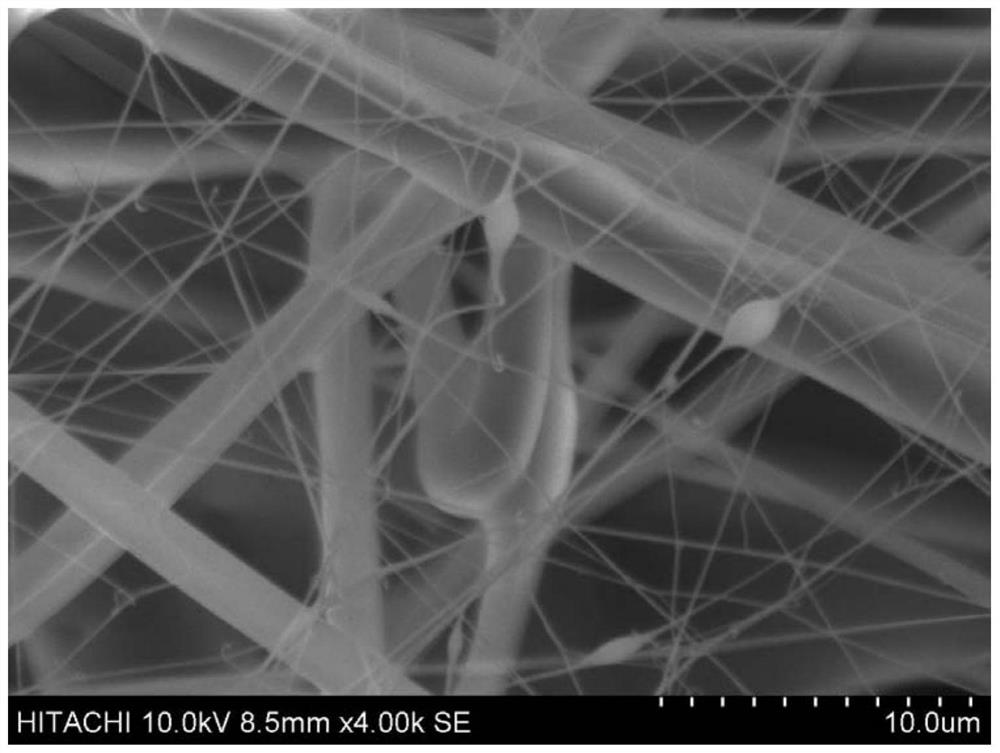

[0051] Electrospun nanofiber cloth 22;

[0052] Melt-blown non-woven fabric 21, melt-blown non-woven fabric 21 is arranged on at least one side of the electrospun nanofiber cloth 22 and forms a filter structure with more than two layers with the electrospun nanofiber cloth 22;

[0053] The relationship between the fiber diameters of the electrospun nanofiber cloth 22 and the meltblown nonwoven fabric 21 is inversely correlated;

[0054] The percentage of filtration efficiency of melt-blown non-woven fabric 21 for particles with a particle size of 0.02-10 μm is M; the percentage of filtration efficiency of electrospun nanofiber cloth 22 for particles with a particle size of 0.02-10 μm is N; then satisfy: M / N=1.05-1.6, M / N=1.05-1.6, M is 80-96%, and N is 70-93%.

[0055] Such as figure 1 Shown is a preferred embodiment, the melt-blown non-woven fabric 21 is disposed on one...

Embodiment 2

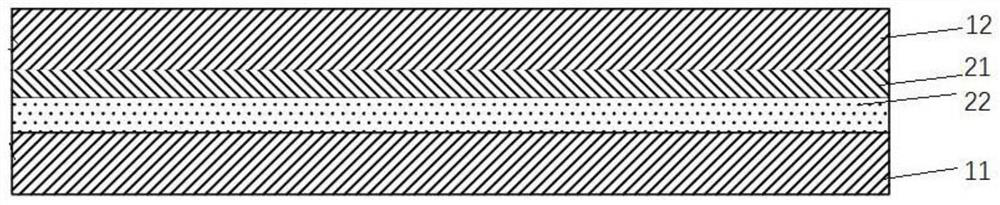

[0079] See attached Figure 1-4 , is a mask with electrospun nanofiber cloth 22, including a mask main body 1 and a filter device 2. Mask main body 1 comprises outer layer 11 and inner layer 12, inner layer 12 and outer layer 11 are non-woven fabrics in the present embodiment. The inner layer 12 is used to fit the user's face, and the filter device 2 is arranged between the inner layer 12 and the outer layer 11 . Specifically, the filter device 2 includes an electrospun nanofiber cloth 22 and a melt-blown non-woven fabric 21 , and the melt-blown non-woven fabric 21 is disposed inside the electrospun nanofiber cloth 22 to support the electrospun nanofiber cloth 22 . The relationship between the fiber diameter of the electrospun nanofiber cloth 22 and the melt-blown non-woven fabric 21 is inversely correlated; the percentage of the filtration efficiency of the melt-blown non-woven fabric 21 to particles with a particle size of 0.02-10 μm is M; The filtration efficiency percent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com