Gas-solid separator

A gas-solid separation and air duct technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of difficulty in solving the dust collection efficiency of separation devices and the limitation of the height and diameter of the gas resistance loss system. Simple structure, reduced system height and diameter, and high dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

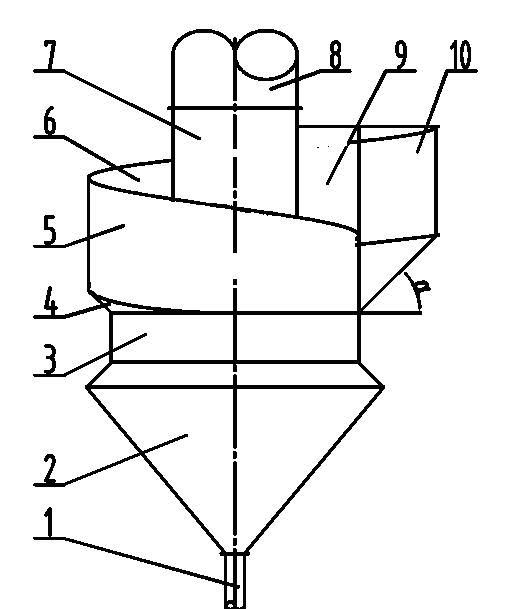

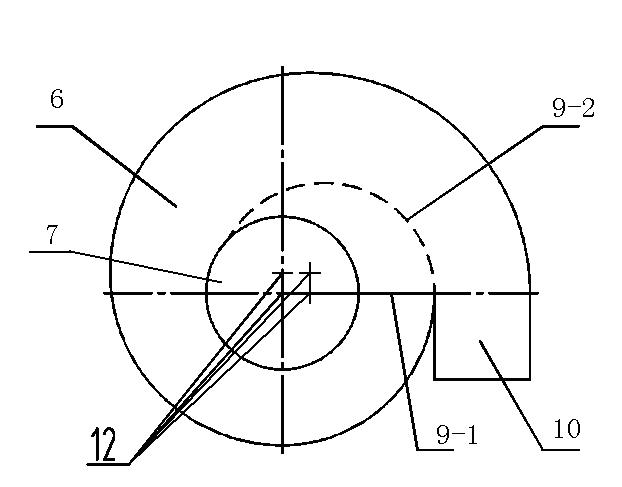

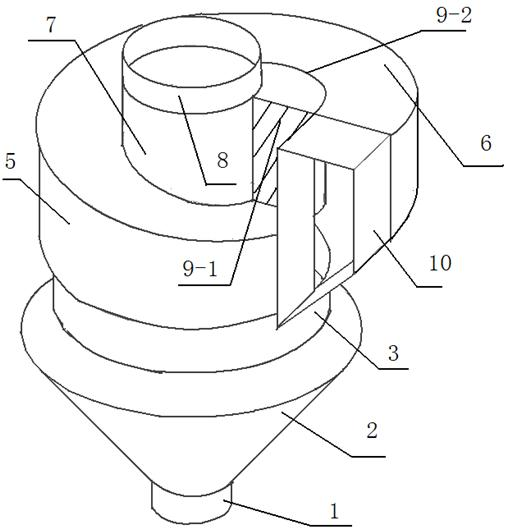

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] Such as Figure 1-3 As shown, the present invention includes a sudden expansion cone 2, a cylinder 3, a conical plate 4, an air duct 5, an air guide tube 7 and a sealing plate, and a sudden expansion cone 2, a cylinder 3, a tapered plate 4, and an air duct 5 are connected sequentially from bottom to top, and the air duct 5 is coiled on the air guide tube 7; the air duct 5 adopts the existing four-core large volute type; the four-core large volute type means that the center circle of the volute has Four center points 12, and the wrap angle of each center is 90°; the uppermost opening of the air duct 5 is an air inlet 10, and the top surface of the air duct 5 is a spiral cover plate 6 with a downward spiral structure; the air guide tube 7 The top is provided with an air outlet 8, and the bottom is connected with the column body 3 and the sudden expansion cone 2; the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com