Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

229results about How to "Solve the scratch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polishing liquid for grinding and polishing lithium niobate optical wafer

InactiveCN1858131AEasy to break awayIncrease viscosityOptical surface grinding machinesAqueous dispersionsLithiumLiquid viscosity

The present invention discloses polishing liquid for grinding and polishing optical lithium niobate wafer. The polishing liquid consists of silica sol 30-90 vol%, organic amine alkali 1-10 vol%, inorganic alkali 1-5 vol%, activator 0.5-5 vol%, chelating agent FA / O 0.5-5 vol%, and deionized water for the rest. Under CMP and high pH condition, lithium is formed into stable complex and water soluble niobate to raise polishing efficiency and surface quality. The present invention has organic alkali and lithium niobate surface matter to form soluble amine salt easy to separate from the reaction surface, and this avoids the increase in the abrasive granularity and polishing liquid viscosity to ensure no scoring, high flatness and no adsorbate.

Owner:HEBEI UNIV OF TECH

Manufacturing method of circuit board

InactiveCN105407653ASolve the problem of not being oxidized and scratchedSolve the scratchNon-metallic protective coating applicationPrinted circuit boardEngineering

The invention belongs to the field of printed circuit board equipment, and particularly relates to a manufacturing method of a circuit board. The method comprises the following steps: carrying out cutting and board baking; fabricating an inner-layer line; carrying out lamination; drilling an outer layer; carrying out outer copper deposition; carrying out full-plate electroplating; fabricating an outer-layer line; carrying out pattern plating; carrying out appearance etching; carrying out resistance welding; carrying out a test; carrying out molding and milling; and the like, and also comprises a step of attaching a protecting adhesive film to the surface of the circuit board and windowing before the molding and milling step, wherein the windowing position of the protective adhesive film is a milling path through which an end-mill passes in the milling process. The protecting adhesive film is attached to the surface of the circuit board and is windowed, so that the target that the golden finger surface of the circuit board is not oxidized or scratched is achieved.

Owner:FAIR RAYS ELECTRONICS TECH SHENZHEN LTD

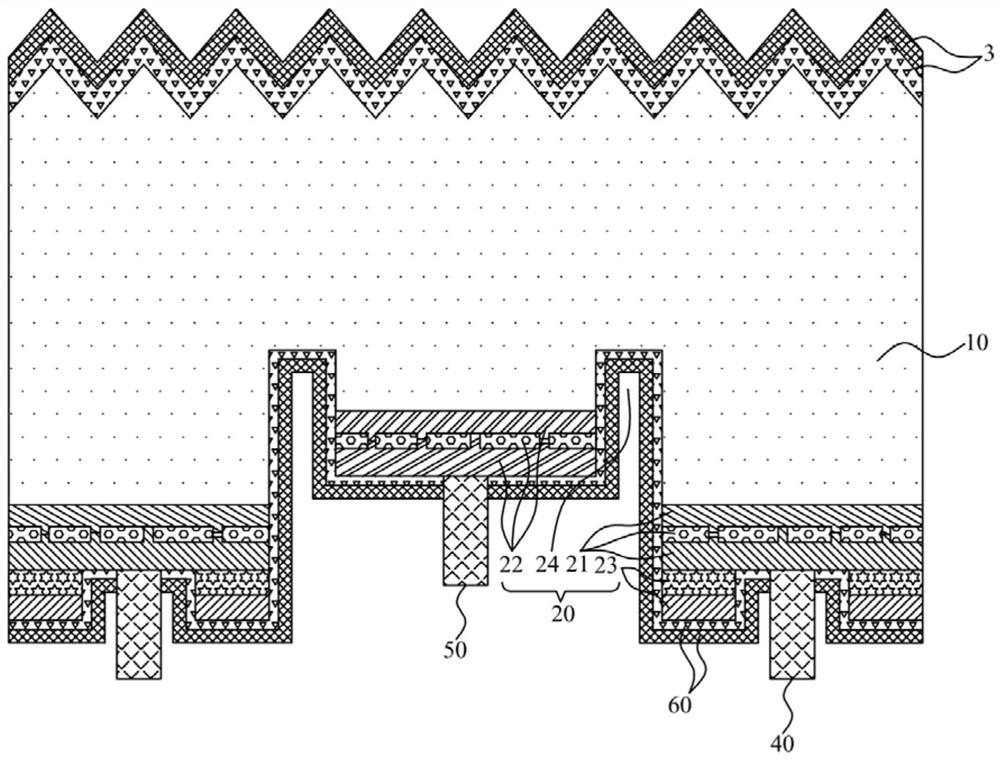

Tube type PERC single-sided solar cell, preparation method thereof and special equipment thereof

ActiveCN107256894AReduce the ratio of scratchesReduce impact forceFinal product manufactureSemiconductor/solid-state device manufacturingScratchingSilica membrane

The invention discloses a tube type PERC single-sided solar cell, which comprises a main silver back gate, an all-aluminum back electric field, a back-side composite film, a P-type silicon, an N-type emitting electrode, a front-side passivation film and a positive silver electrode. The back-side composite film is composed of one or more selected from an aluminum oxide film, a silicon dioxide film, a silicon oxynitride film and a silicon nitride film and is deposited at the back of a silicon chip by adopting tube type PECVD equipment. The tube type PECVD equipment comprises four gas pipelines of silane, ammonia, trimethyl aluminum and laughing gas. The appliance of the tube type PECVD equipment, used for loading and unloading silicon chips, is a graphite boat. The depth of a sticking point groove of the graphite boat is 0. 5-1 mm. The invention also discloses a preparation method and special equipment of the tube type PERC single-sided solar cell. According to the invention, the photoelectric conversion efficiency is high. Meanwhile, the appearance yield and the EL yield are high. The problems of scratching, winding and plating can be solved.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH +1

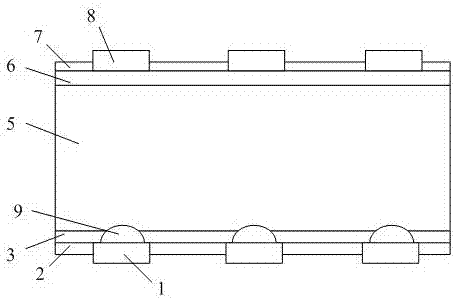

Manufacturing method of plastic sealed solar photovoltaic assembly

The invention discloses a manufacturing method of a plastic sealed solar photovoltaic assembly. The manufacturing method comprises the following steps: arranging a first EVA material layer on a glassy layer, arranging a cell layer on the first EVA material layer, arranging a second EVA material layer on the cell layer, and arranging a back plate material layer on the second EVA material layer, wherein all the parts are laminated and shaped into laminates by a laminating machine, and plastic frames with the plastic sealing function are arranged at the circumferences of the laminates and are subject to plastic sealing by ultrasonic hot melting. The invention thoroughly solves the problems that the conventional aluminum alloy frame is easy to oxidize and scratch, too much time is spent in waiting for the curing of silica gel and the like, raises the production efficiency, and lowers the cost.

Owner:HANWHA SOLARONE QIDONG

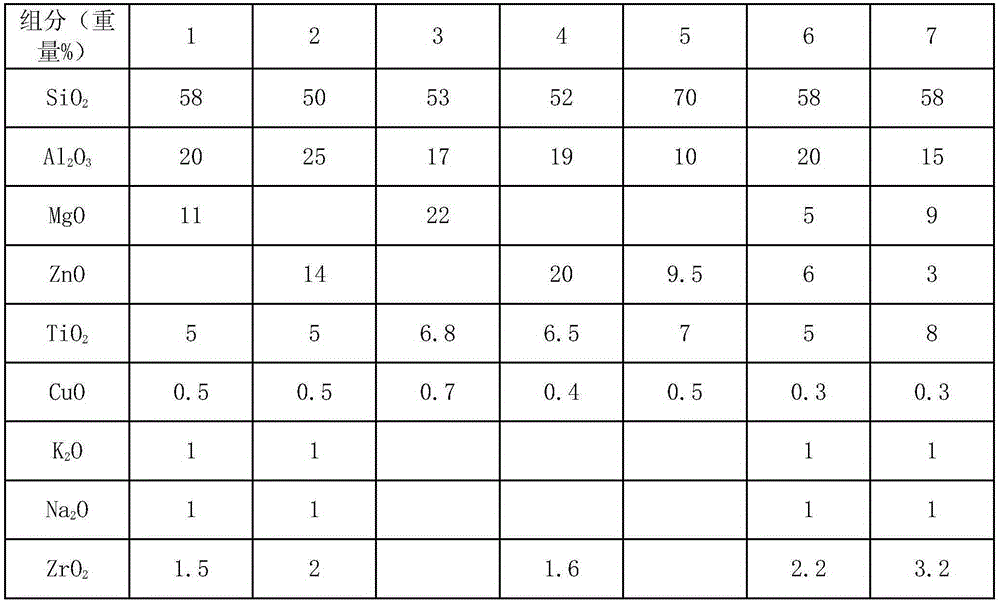

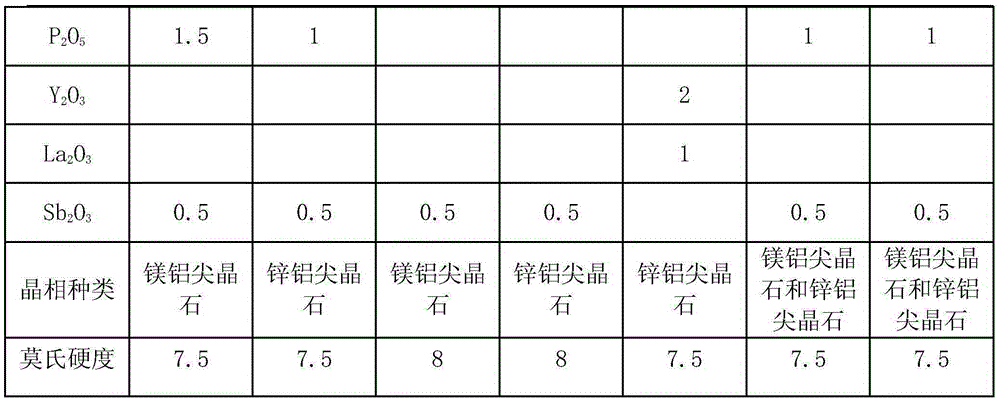

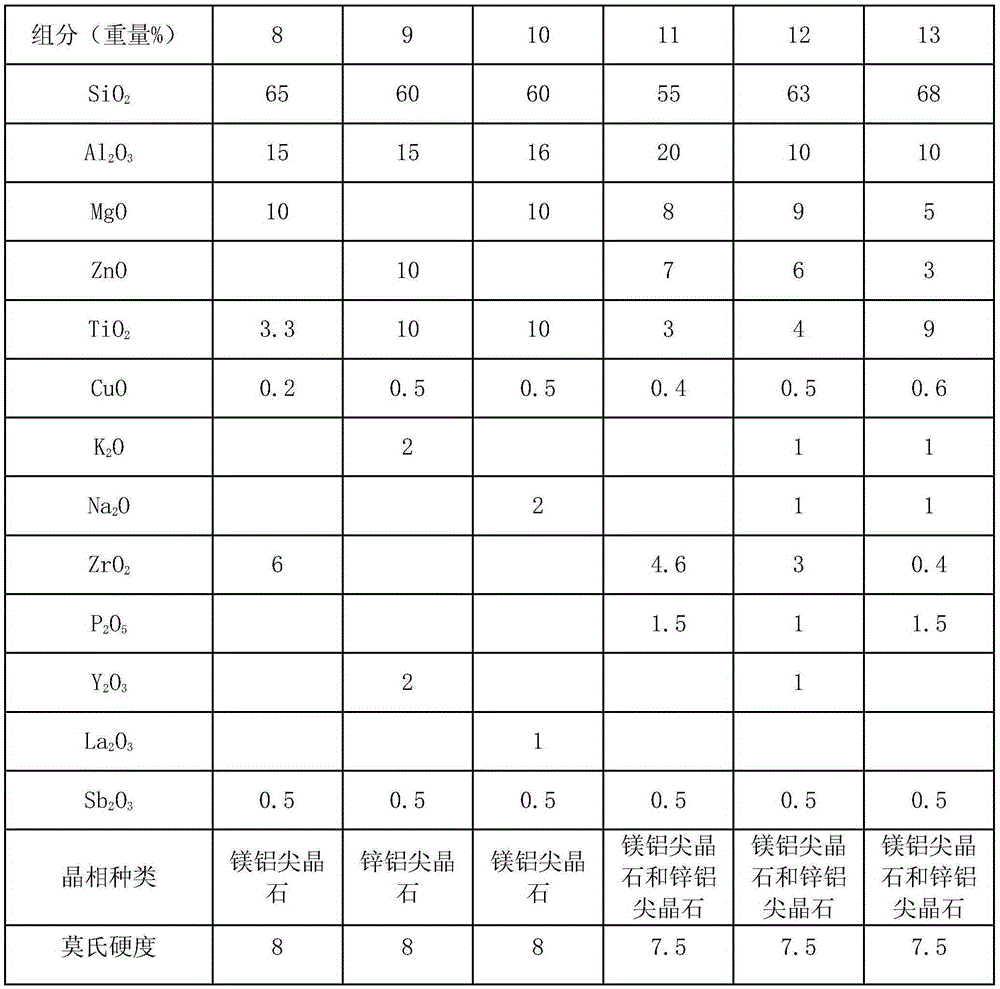

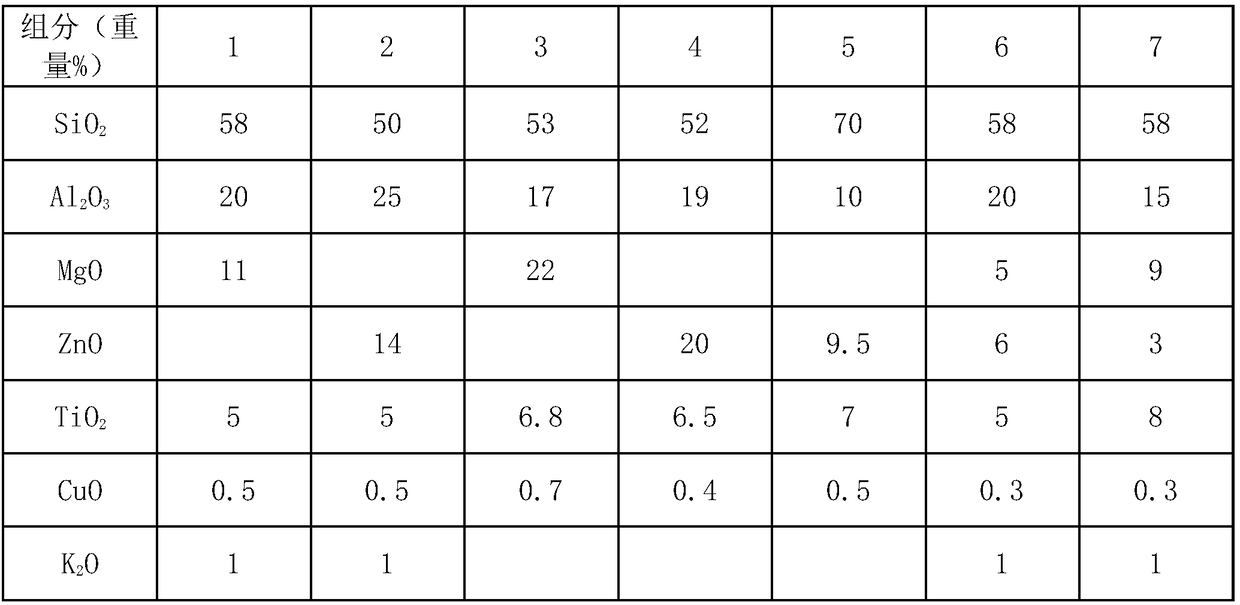

Glass ceramic and preparation method thereof

The invention provides an amber glass ceramic which is relatively high in hardness and resistant to high temperature. The amber glass ceramic comprises the following ingredients by weight percent: 50-70 percent of SiO2, 10.0-25 percent of Al2O3, 3-10 percent of TiO2, 0.2-0.7 percent of CuO, 0-22 percent of MgO and 0-20 percent of ZnO, and comprises at least one of MgO and ZnO. The glass ceramic has the Moh's hardness of 7.5-8 H, can be applied to decorative materials and ornaments, can solve the problem of scratching of ordinary amber glass, is not softened at the high temperature of 1150 DEG C, therefore, is high-temperature resistant and can be further processed under the high-temperature condition. The glass ceramic is high in mechanical strength, hardness and thermal stability, and excellent in chemical stability, wearing resistance and electric insulativity, and can be used for decorative materials, building inner and outer walls, grounds, gallery-column and other high-grade decoration projects.

Owner:CDGM GLASS LLC

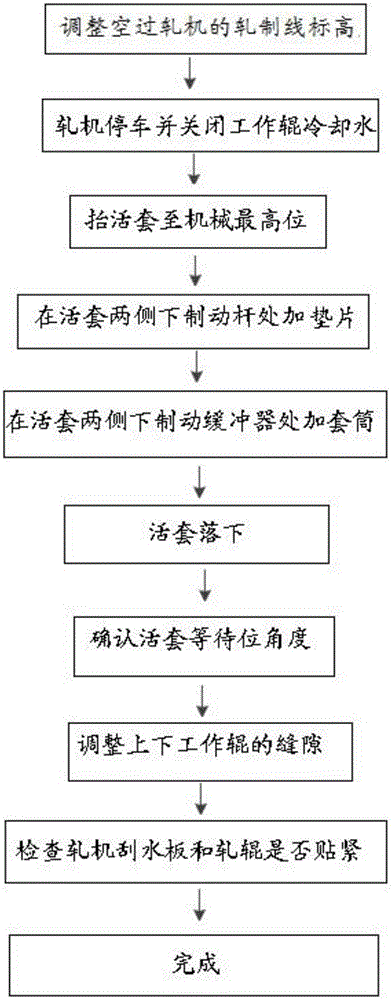

Method of preventing heavy gauge strip steel from being scratched among finishing mill racks

ActiveCN105728460AAvoid compressionSolve the scratchMetal rolling stand detailsFlexible work arrangmentsPosition angleStrip steel

The invention provides a method of preventing heavy gauge strip steel from being scratched among finishing mill racks. The method comprises the following steps of: adjusting the elevation of a rolling line of an idle rolling mill to right elevation; and adjusting the mechanical position of a downstream loop of the idle rolling mill, to be specific, lifting the loop to the mechanical highest position, arranging a gasket on a brake bar below the loop and a sleeve on a buffer below the loop, dropping down the loop, and identifying the waiting position angle of the loop. The method has the beneficial effects that the rolling line is in the right elevation, and strip steel is lifted; the waiting position angle of the loop is increased by adjusting the mechanical position of the downstream loop of the idle rolling mill, thereby preventing the lower surface of the strip steel from scratching a lower guide plate of a rolling mill outlet, completely solving the surface scratching problem of the strip steel, greatly increasing the percent of pass of strip steel quality and ensuring the smooth production.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

WMT solar cell module and preparation method thereof

InactiveCN103258888AImprove moisture resistanceAging resistantFinal product manufacturePhotovoltaic energy generationEngineeringSolar battery

The invention discloses a WMT solar cell module. The WMT solar cell module is formed by upper layer glass, a first hot melt adhesive film layer, a MWT solar cell string, a conductive adhesive layer, a second hot melt adhesive film layer, a conductive foil layer and lower layer glass in a sealing mode, wherein the upper layer glass, the first hot melt adhesive film layer, the MWT solar cell string, the conductive adhesive layer, the second hot melt adhesive film layer, the conductive foil layer and the lower layer glass are sequentially stacked. The pattern of the conductive foil layer is matched with the pattern of the electrode at the back side of the MWT solar cell string. A hole is formed in the position, corresponding to the conductive foil layer, of the second hot melt adhesive film layer, and the conductive foil layer is enabled to be capable of being contacted with the electrode at the back side of the MWT solar cell string. The conductive adhesive layer is arranged between the conductive foil layer and the electrode at the back side of the MWT solar cell string. The invention further discloses a preparation method of the MWT solar cell module. A two-layer-glass structure is adopted, and the glass has good functions of being moisture-resisting, ageing-resisting, ultraviolet-resisting, and not prone to be ageing. Compared with a rear panel of conventional molecular materials, the WMT solar cell module is very good in weather resistance, and therefore the service life of the module can be prolonged.

Owner:CECEP SOLAR ENERGY TECH (ZHENJIANG) CO LTD

Microcrystalline glass mainly containing spinel and preparation method thereof

The invention provides microcrystalline glass taking spinel as a main component. The microcrystalline glass comprises the following components in percentage by weight: 47.5-70.0% of SiO2, 10.0-20.0% of Al2O3, 0-22.0% of MgO, and 0-12.5% of ZnO; wherein the total content of MgO and ZnO is 6% or above, and the crystallized glass contains microcrystals of spinel crystals. By using a proper precursorglass for heat treatment, microcrystal is separated out from a glass matrix through crystallization, so that the microcrystal glass mainly containing spinel is prepared, the Moh's hardness of the glass is 7.5-8, the glass can have different colors, the scratching problem of building microcrystal glass mainly containing wollastonite is solved, and the service life is prolonged. The microcrystallineglass mainly containing spinel has the characteristics of high mechanical strength, high hardness, favorable wear resistance, favorable electric insulativity and the like, and can be used as architectural decoration materials, chemical and anticorrosive materials, mine wear-resistant materials and the like.

Owner:CDGM OPTICAL GLASS

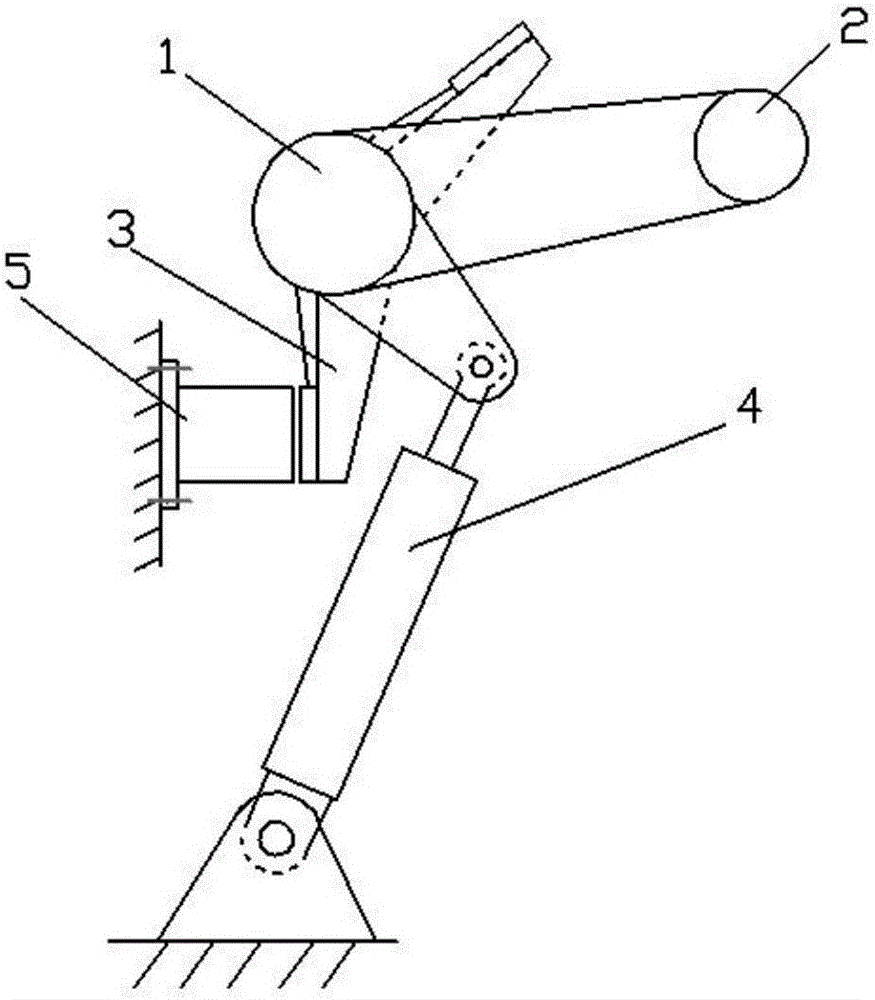

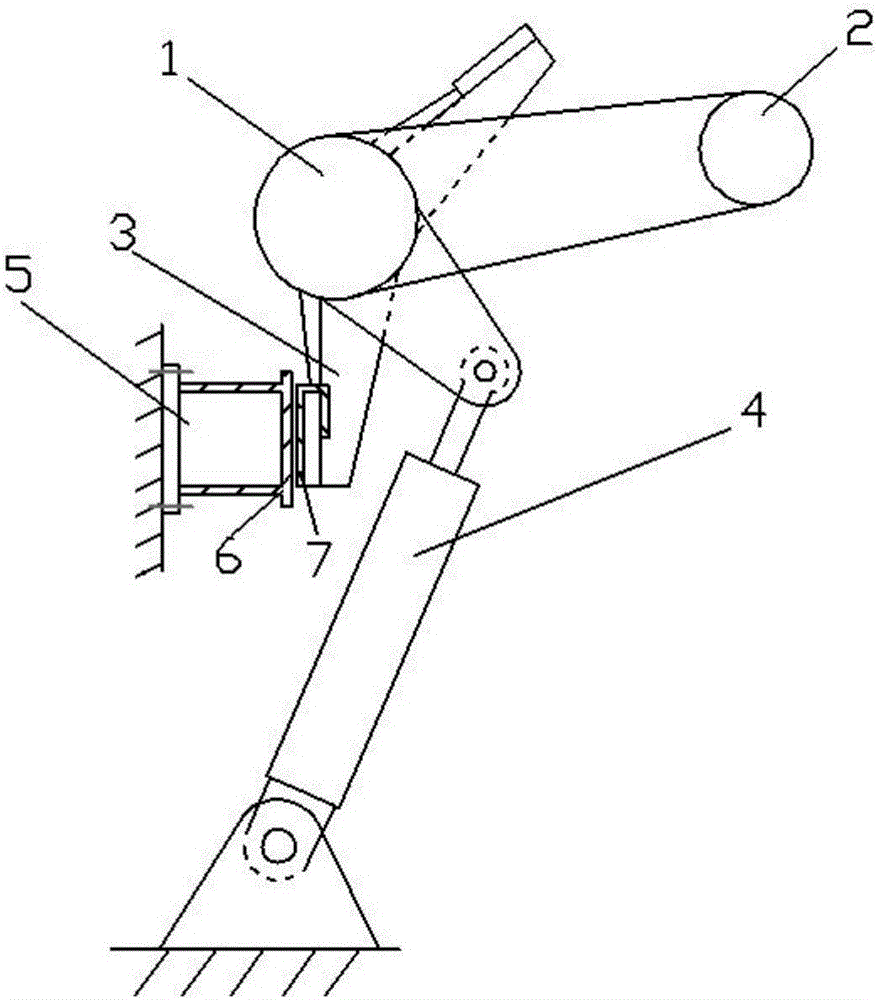

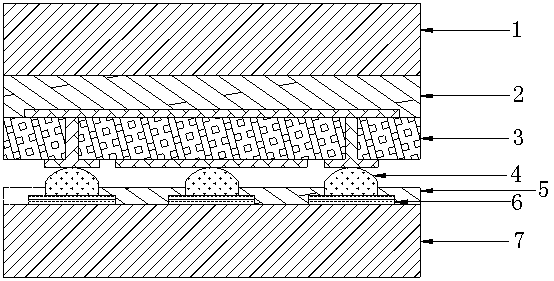

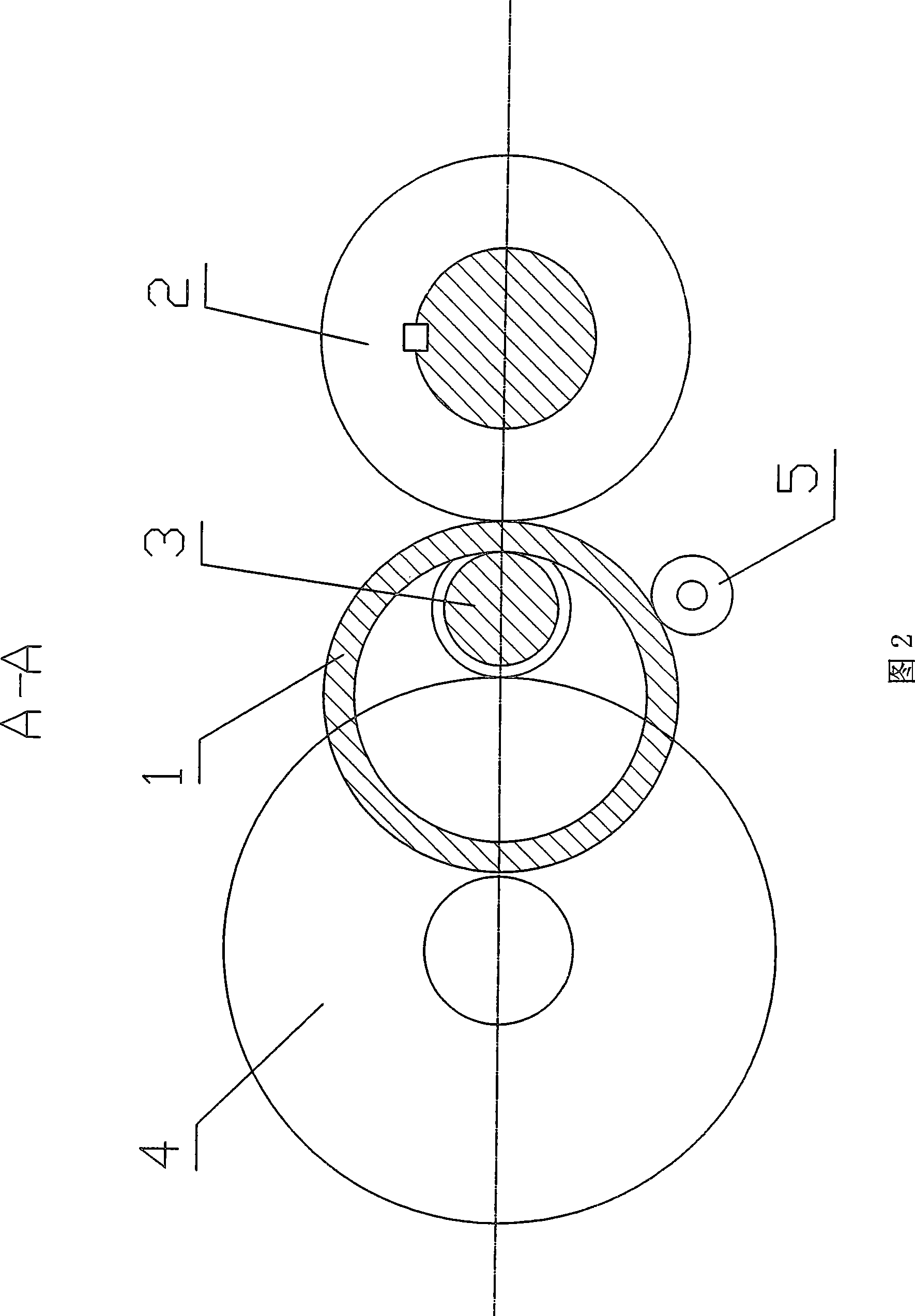

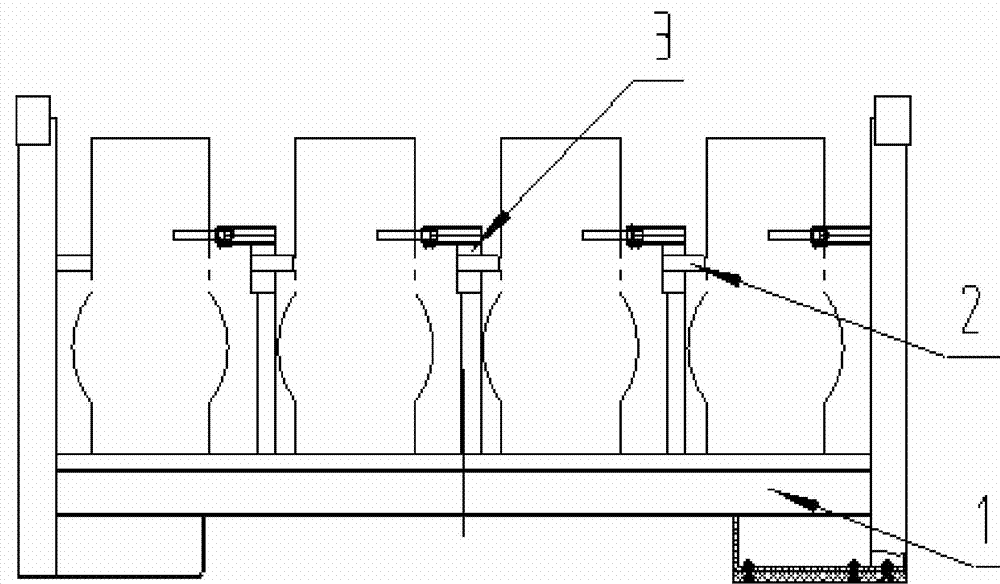

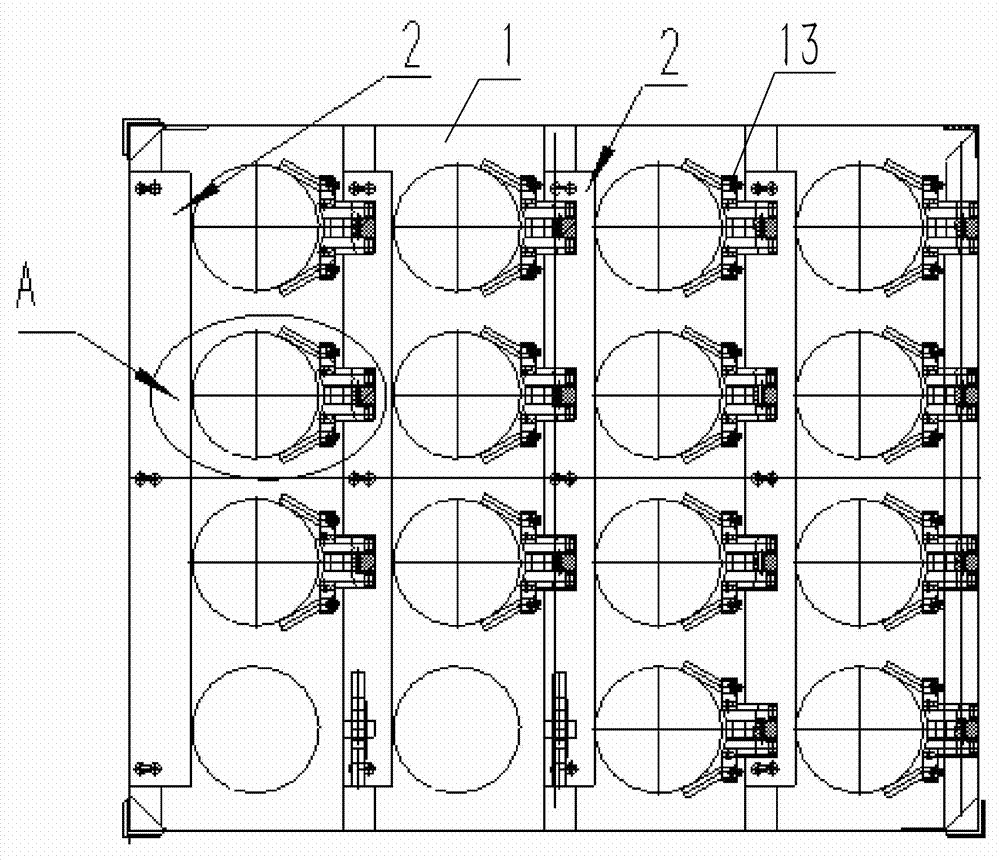

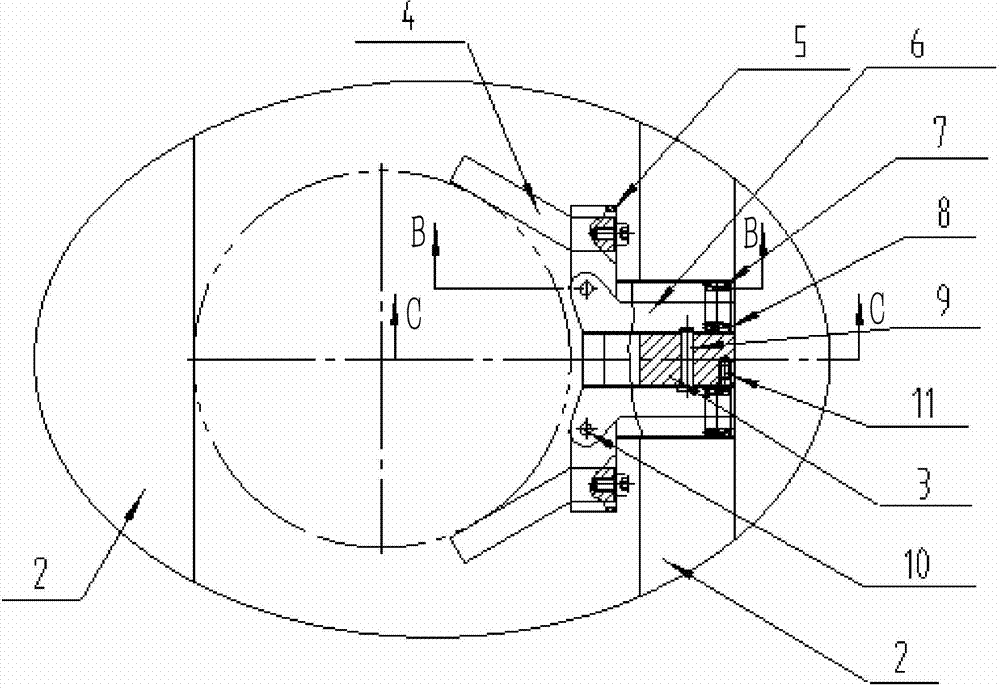

Mandrel power mechanism for cold rolling machine

InactiveCN101433916AReduce wearExtended service lifeRolling mill drivesMetal rolling arrangementsControl systemEngineering

The invention relates to a mandrel power unit for a cold roller, which is provided with a rolling wheel, a supporting wheel, a core roll which is arranged between the rolling wheel and the supporting wheel, and a control system of the core roll. The mandrel power unit is characterized in that the core roll is provided with a driving rotary power unit, and the unit consists of a hydraulic oil cylinder, a motor, a position detecting device and a connecting body which are integrated into a whole and used for driving the core roll and the supporting wheel. The mandrel power unit for the cold roller not only improves the service life of the core roll but also solves the problem of scrape of the furrow bottom of a bearing ring, improves the finish degree of the processed curved surface of cold-rolling pieces, reduces the production time of abrasive machining, and greatly improves the price performance ratio of the cold roller.

Owner:金凯岷 +1

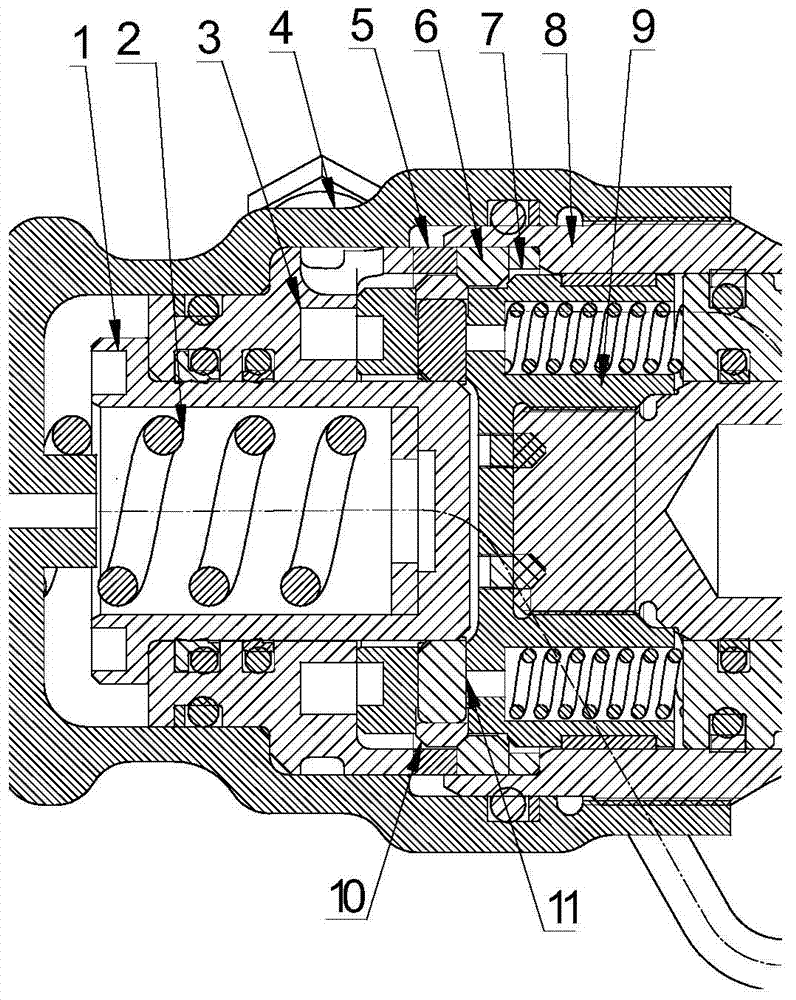

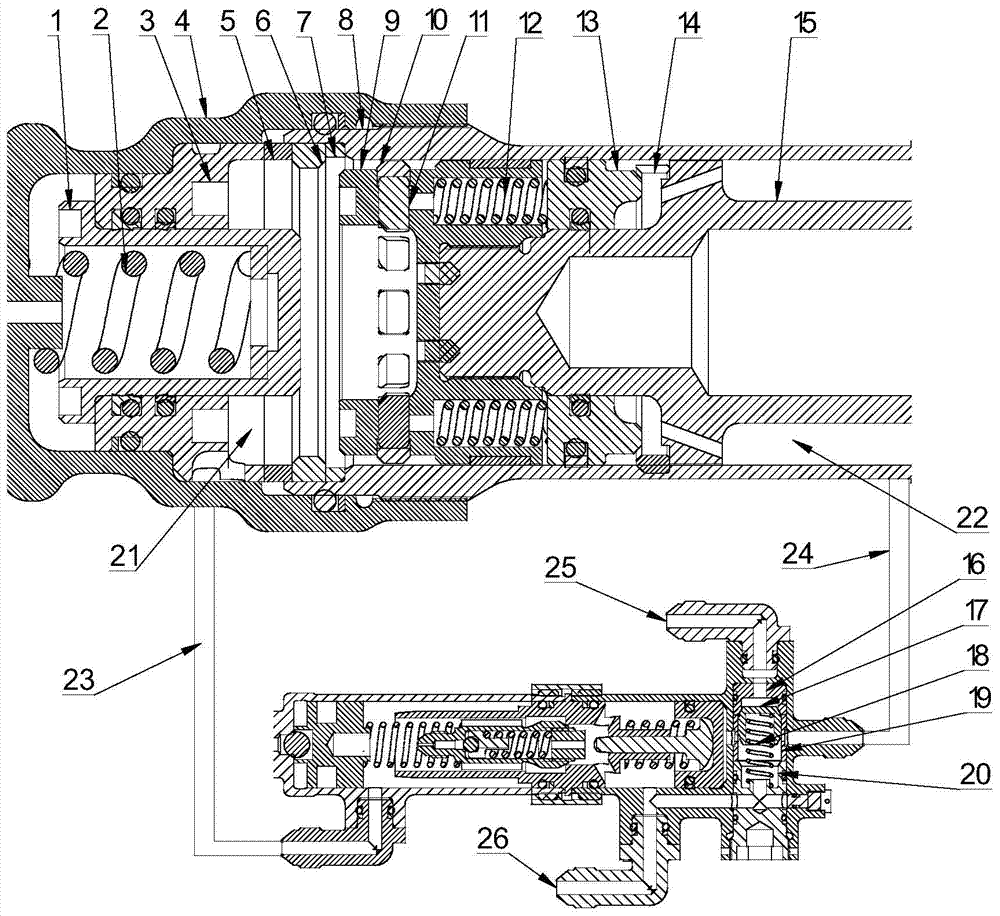

Hydraulic floatingsnap ring lock

ActiveCN104500501ASolve the scratchSolve the problem of realizing the fast release function of the actuatorFluid-pressure actuatorsEngineeringActuator

The invention discloses a hydraulic floating snap ring lock and aims to provide a snap ring lock capable of solving the problem of unreliable performance of a steel ball lock due to scratch of a steel ball on an unlocking or locking surface caused by unlocking or locking. According to the technical scheme of the hydraulic floating snap ring lock, on a hydraulic lock housing of an actuator cylinder, a first shuttle valve seat is connected with a second shuttle valve seat through a shuttle valve sleeve; a shuttle valve element moving in the shuttle valve sleeve and a spring for pushing the shuttle valve element to be reset are integrated in theshuttle valve cavity of the cavity body of thehydraulic lock housing to form a shuttle valve for communicating the raising cavityof the actuator cylinderwith the lowering cavity of the actuator cylinder during extension of the actuator cylinder and separating the raising cavity of the actuator cylinder from the lowering cavity of the actuator cylinder during retraction of the actuator cylinder; when a first spring ring (10) is driven by a retainer (9) to completely pass through a snap ring seat (6), the floating snap ring lock is completelyunlocked, a seal cavity is formed in the conical surface of the first shuttle valve seat (16), the raising cavity is separated from the oil return passage of a system, and return oil in the raising cavity enters the lowering cavity of the actuator cylinder through the shuttle valve to realize a quick lowering function.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

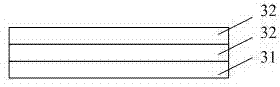

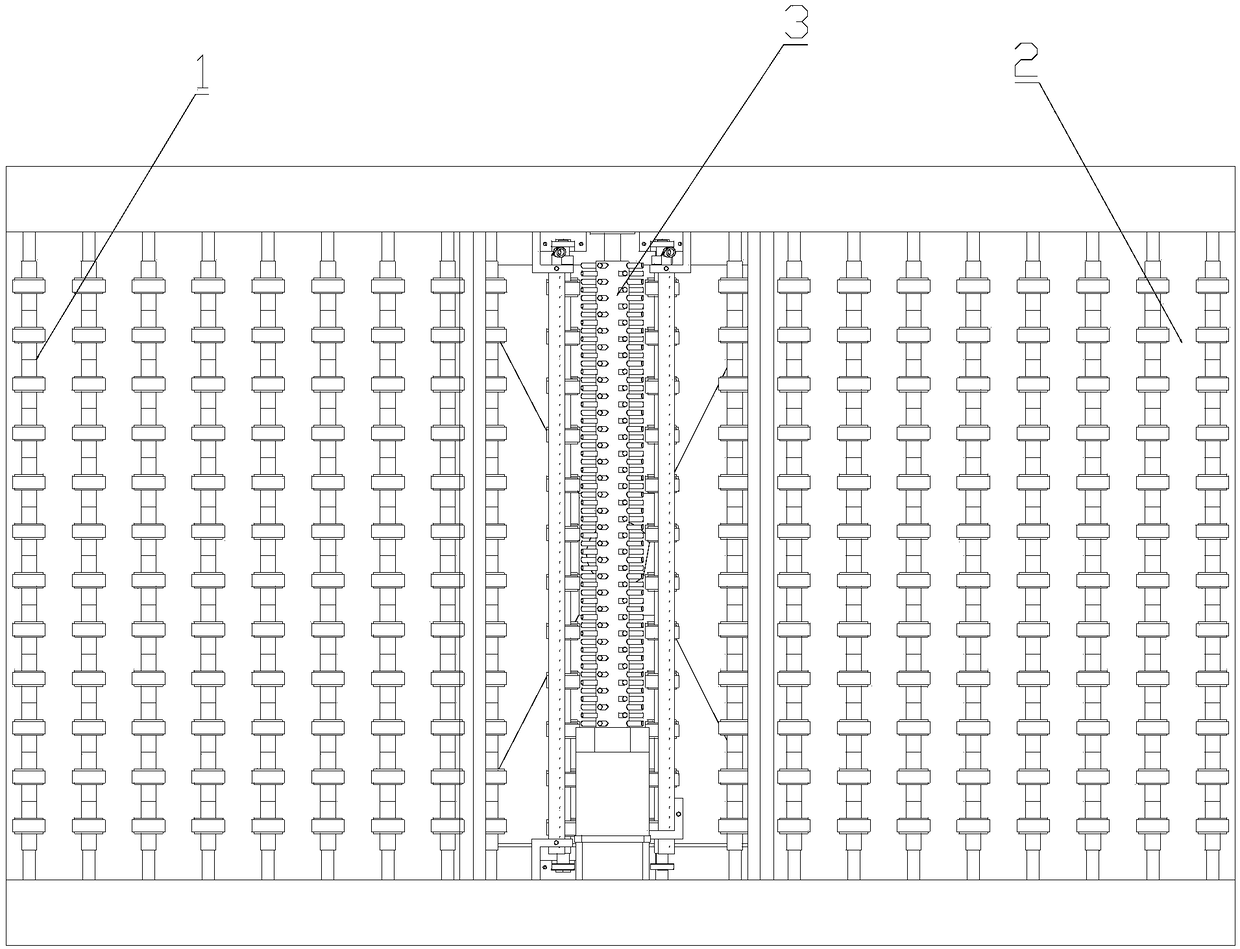

Repair technology and preparation technology of tubular PERC solar cell

ActiveCN107331730AEL yield improvementIncrease power generationFinal product manufactureSemiconductor/solid-state device manufacturingNitrogenRoom temperature

The invention discloses repair technology of a tubular PERC solar cell. The repair technology is set after annealing of a silicon wafer and before film coating of a back face of the silicon wafer. The repair technology comprises the following steps: (1) a semi-finished silicon wafer which stays over 4 hours after the annealing and before the film coating is placed into a repair furnace, nitrogen having a flow rate of 5-10slm is introduced into the repair furnace to achieve self-cleaning, and inlet time of the nitrogen is 1-5min; (2) nitrogen having a flow rate of 5-20slm is introduced to blow and sweep dust on the silicon wafer; (3) temperature of the repair furnace is raised from room temperature to 500-650 DEG C, and nitrogen having a flow rate of 1-5slm is introduced at the same time; and (4) the temperature of the repair furnace is kept at 500-650 DEG C for 5-30min, and nitrogen having a flow rate of 5-20slm is introduced at the same time. Correspondingly, the invention further discloses a preparation technology of the tubular PERC solar cell. Through adoption of the repair technology and the preparation technology, the problem of efficiency reduction brought by too long semi-finished product stay time is solved, and the EL yield rate is improved.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +1

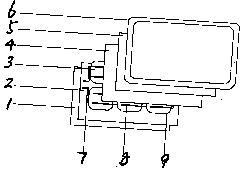

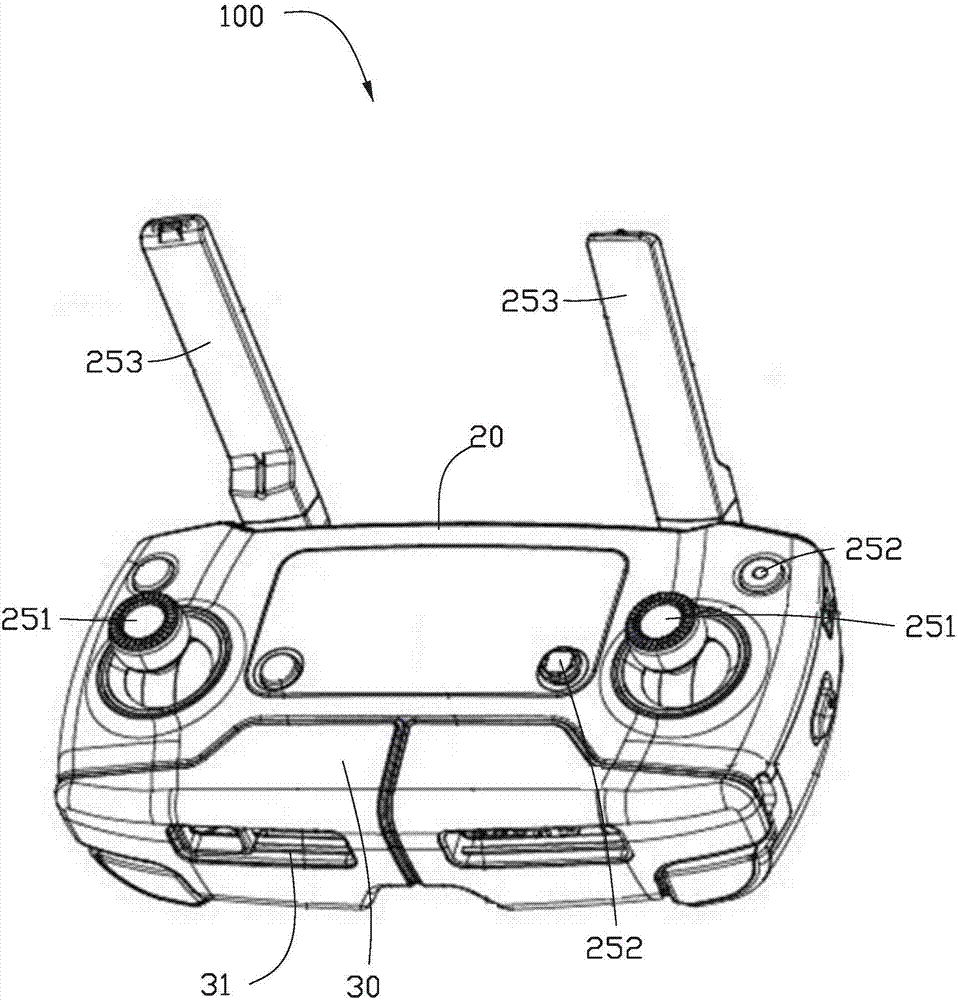

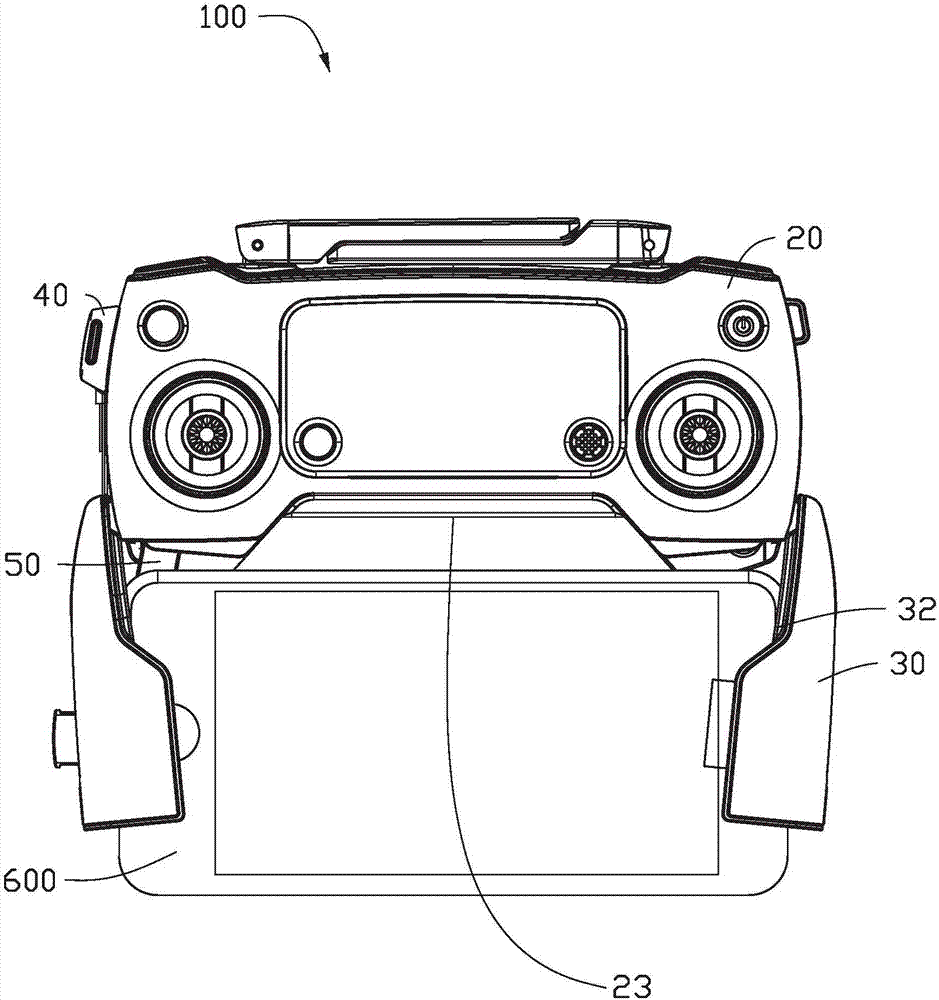

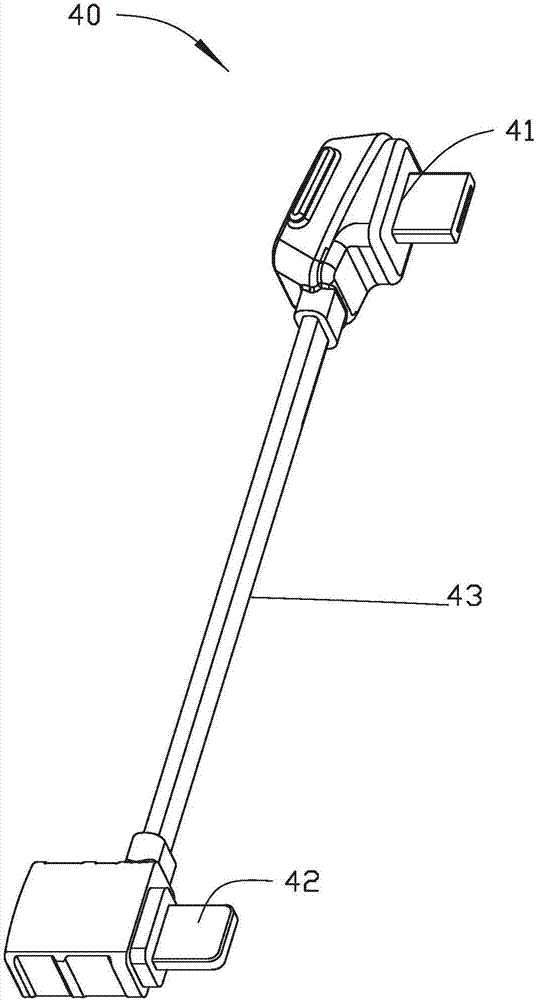

Remote terminal

ActiveCN107111929AKeep a clean lookSolve the messTelevision system detailsTransmission systemsRemote controlComputer terminal

A remote control terminal (100) comprises a remote controller body (20) and a holding mechanism (30) connected with the remote control main body (20). The side surface of the main body (20) of the remote controller is provided with an electric connecting interface which is matched with the first connecting terminal of the connecting lead (40). The holding mechanism (30) is used for holding the mobile terminal (600), and the second connecting terminal of the connecting wire (40) is matched with the interface of the mobile terminal (600). The holding mechanism (30) with respect to the remote controller main body (20) for holding activities, in the mobile terminal (600) out of state, or in facilitating the remote terminal (100) carrying the contraction. The holding mechanism (30) is used for positioning the connecting wire (40) positioning mechanism second connection terminals, when the holding mechanism (30) is in the extended state, the positioning mechanism of the connecting wire (40) of the second connecting terminal with the mobile terminal (600) the interface of electric. When the holding mechanism (30) is in the contraction state, the connecting wire (40) can be set around the side of the remote controller body (20).

Owner:SZ DJI TECH CO LTD

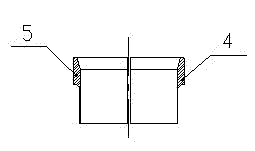

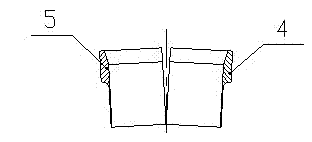

Piston installing tool of hydraulic oil cylinder piston rod

InactiveCN103286743ASolve the scratchReduce the difficulty of assemblyMetal-working hand toolsHydraulic ramPiston rod

The invention discloses a piston installing tool of a hydraulic oil cylinder piston rod. The installing tool is a smooth thin sleeve and machined by surplus materials of a cylinder barrel of an oil cylinder. The piston installing tool of the hydraulic oil cylinder piston rod is simple in structure, easy to machine, and convenient to use, and the problem that a piston sealing ring is easily scratched by threads of the cylinder barrel of the hydraulic oil cylinder when the piston machine piston rod is placed into the cylinder barrel of the oil cylinder through the hydraulic oil cylinder is simplified and solved.

Owner:WUXI INST OF COMMERCE

Rock wool belt heat preservation fireproof composite board cutting device

InactiveCN109047925AEasy to operateHigh degree of automationLarge fixed membersMetal working apparatusWoolEngineering

The invention discloses a rock wool belt heat preservation fireproof composite board cutting device. The rock wool belt heat preservation fireproof composite board cutting device comprises a supporting mechanism, a cutting mechanism and a pushing mechanism, wherein the supporting mechanism is composed of a base, a first supporting column, a first cutting table, a second cutting table and a secondsupporting column, the cutting mechanism is composed of a first motor, a guide rail, a first sliding block, a threaded block, a first hydraulic telescopic rod, a second motor and a cutter, the pushingmechanism is composed of a pushing plate, a second hydraulic telescopic rod, a second sliding block and a third hydraulic telescopic rod, the first cutting table and the second cutting table are located at the same height, the first sliding block is connected with the guide rail in a sliding mode, the threaded block is in threaded connection with the rotating shaft, the second motor is fixedly connected to the lower end of the first hydraulic telescopic rod, an output shaft of the second motor is fixedly connected with the cutter, the pushing plate is in a U shape, the second sliding block isin sliding connection with the base, and the second sliding block is fixedly connected with the third hydraulic telescopic rod. According to the rock wool belt heat preservation fireproof composite board cutting device, the operation is convenient, the automation degree is high, the labor resources are saved, the working intensity of workers is relieved, and the product quality is guaranteed.

Owner:合肥神舟建筑集团有限公司

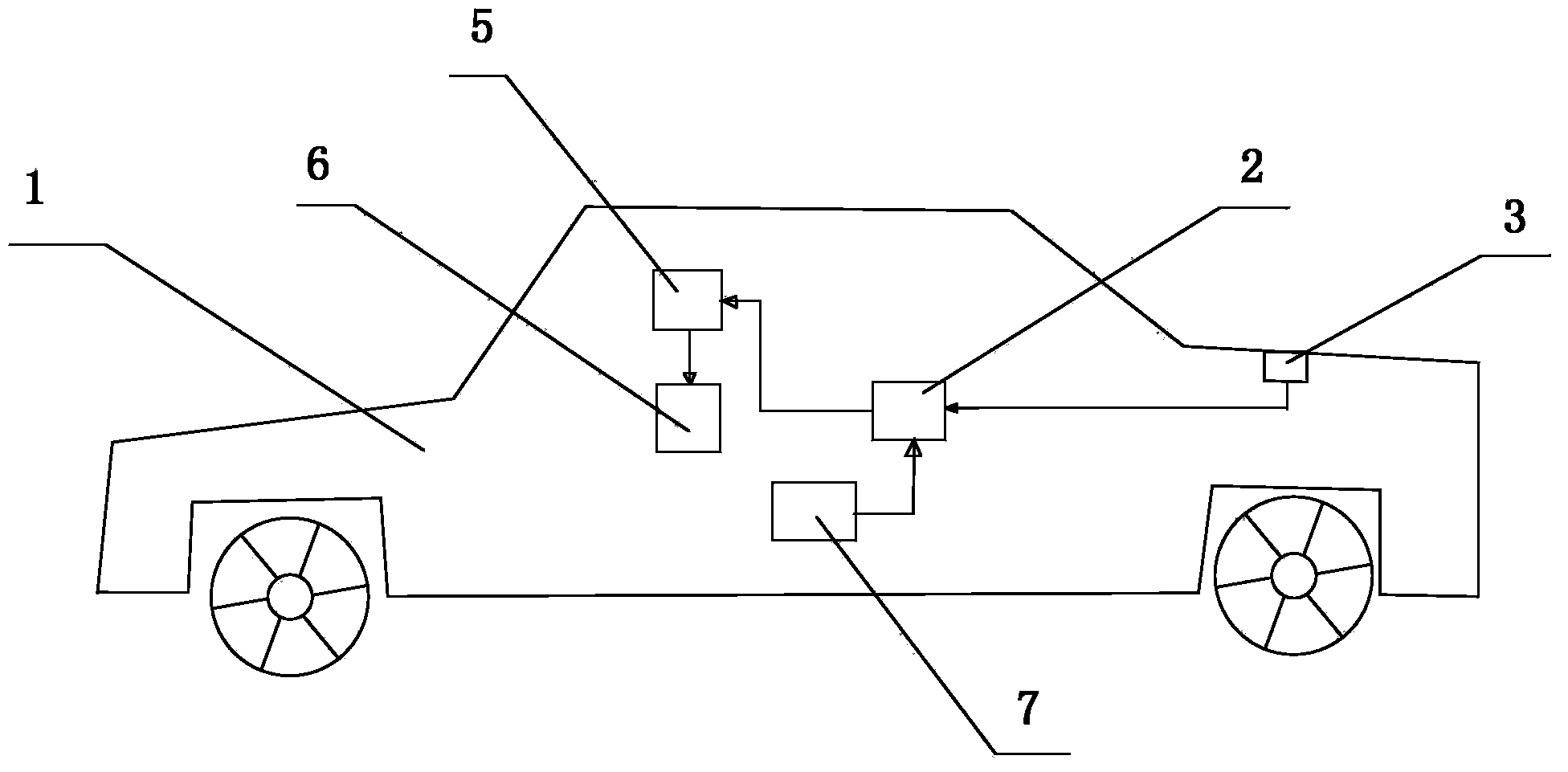

Automobile scratch monitoring device based on vibration

InactiveCN103802787ASimple structureReasonable designAnti-theft devicesBattery packMicromonas micros

The invention discloses an automobile scratch monitoring device based on vibration. The automobile scratch monitoring device comprises a vibration sensor, a control unit, a camera, a storage medium and a battery pack, wherein the vibration sensor is installed on an automobile and used for detecting the vibration condition of the surface of the automobile, the control unit is arranged in the automobile, the camera is installed in the automobile and used for taking pictures when the surface of the automobile is scratched, the storage medium is connected with the camera and used for storing the pictures taken by the camera, and the battery pack is connected with the control unit and supplies power to the control unit. The vibration sensor is connected with the input end of the control unit. The output end of the control unit is connected with the camera and controls work of the camera. The control unit and the storage medium are installed in the automobile. The vibration sensor is a miniature microphone. The automobile scratch monitoring device is simple in structure, reasonable in design, good in use effect, capable of effectively solving the problem that automobile owners do not know when the automobile is scratched in the prior art, small in size, light in weight, high in precision and capable of monitoring the time of occurrence of scratching.

Owner:XIAN JINHE OPTICAL TECH

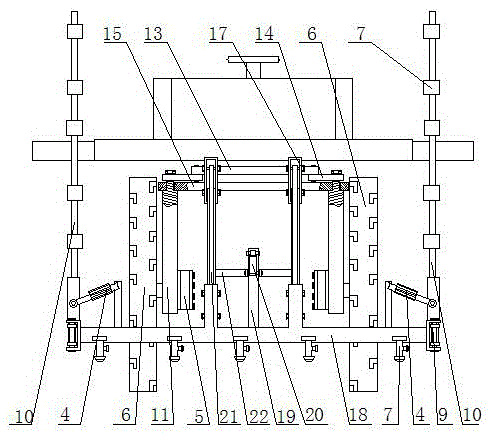

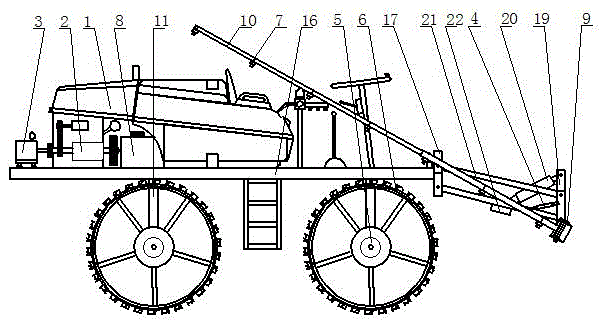

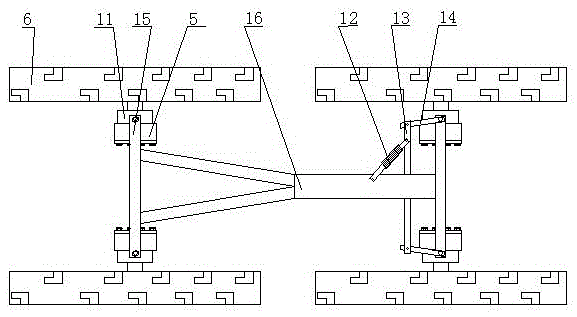

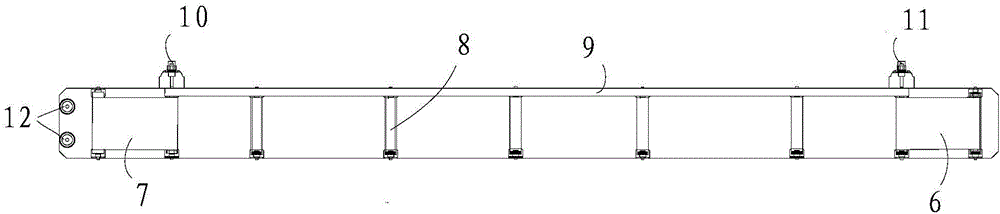

Farmland pesticide spraying vehicle

InactiveCN105454199ASufficient powerSimple structureManure treatmentLiquid fertiliser regulation systemsHydraulic motorVehicle frame

The invention relates to a farmland pesticide spraying vehicle, and belongs to the technical field of pesticide machinery. The pesticide spraying vehicle comprises a pesticide box, a vehicle frame, a spraying rod adjusting mechanism, a hydraulic pump, a delivery pump, spraying rods, hydraulic motors, wheels and nozzles. The wheels are symmetrically arranged at the lower portion of the vehicle frame through the hydraulic motors. The pesticide box is mounted on the vehicle frame. The hydraulic pump, the delivery pump and a power device are mounted on the vehicle frame and on one side of the pesticide box. A hydraulic oil tank is arranged on one side of the hydraulic pump. The spraying rod adjusting mechanism is arranged on the other side of the pesticide box and at the end of the vehicle frame. The spraying rods are movably mounted on the two sides of the spraying rod adjusting mechanism through pins, and the multiple nozzles are mounted on the spraying rods. The pesticide spraying vehicle is simple in structure and high in working efficiency, can be widely applied, can automatically adjust the spraying height of the spraying rods, and solves problems that a conventional pesticide spraying vehicle has a small application range and crops can be easily damaged or scratched by the vehicle. The pesticide spraying vehicle is quite suitable for spraying pesticide and applying fertilizer for crops.

Owner:HUBEI JINGJIANG AGRI CO LTD

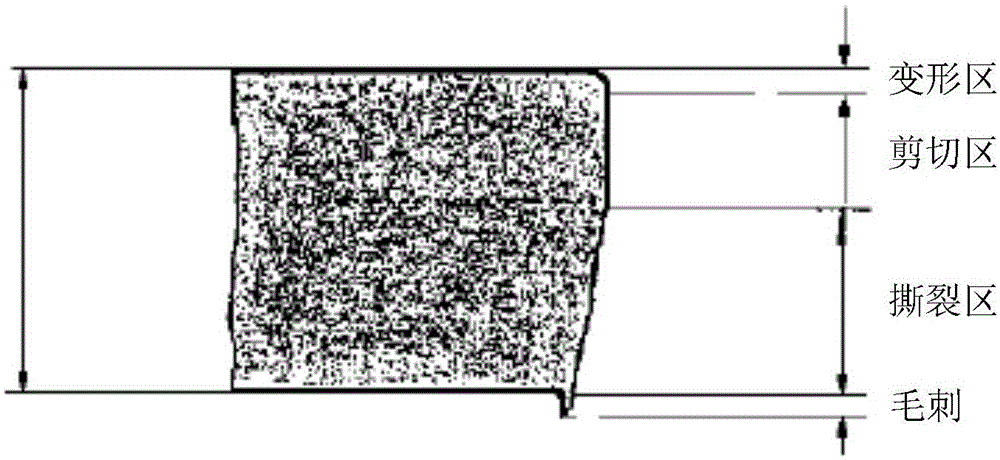

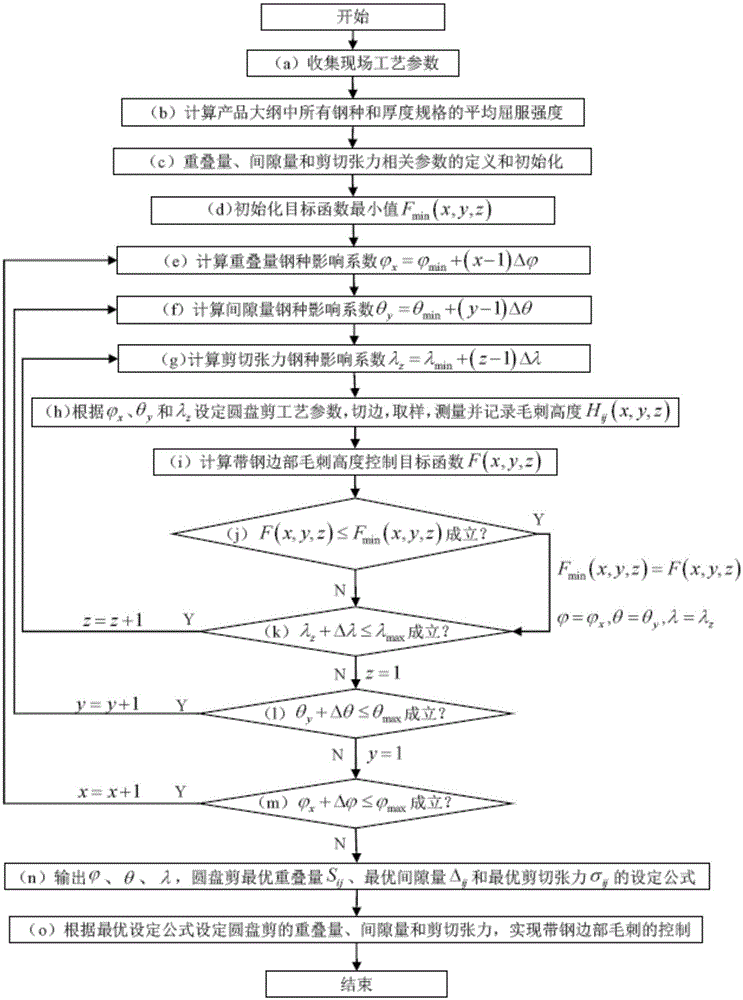

Strip steel scrap edge rag control method suitable for rewinding unit circle shear

ActiveCN106552963ASolve the scratchMeet the requirements of trimming qualityShearing machinesStrip steelSteel ball

The invention provides a strip steel scrap edge rag control method suitable for a rewinding unit circle shear. The overlap amount S, the gap amount delta and the shear tension sigma of the circle shear are controlled to control the scrap edge rag of strip steel. The method is characterized in that the optimal overlap amount influence coefficient phi, the optimal gap amount influence coefficient theta and the optimal shear tension influence coefficient lambda of a group of strip steel are used to calculate the optimal overlap amount Sij, the optimal gap amount deltaij and the optimal shear tension sigmaij of the i-th kind of steel ball and the strip steel of the j-th thickness in the group of strip steel. The method takes into account the influence of the overlap amount, the gap amount and the shear tension of the circle shear on the scrap edge rag of the strip steel, and controls the scrap edge rag of the strip steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for processing complex large-sized plastic rubber panel appearance surface decoration

The invention discloses a processing method for surface decoration of a large complex plastic panel which includes the following steps: a film is manufactured according to the appearance sculpt, pattern and character of a product; a film blanking die is manufactured, the film is blanked and the film in need of shaping is remained; a film shaping die is manufactured for shaping the film and obtaining the shaped film with the needed shape; an injection die is manufactured for injection and shaping; the injection die is designed and developed according to the structure of the product, the shaped film is arranged, positioned and arranged, then is injected and shaped to obtain an injection piece. The processing method for surface decoration of a large complex plastic panel solves the problems of tearing and scuffing easily appearing during the closed angle transition of the surface decoration of the large complex plastic panel as well as the pre-shaping of an injected sheet in the die, avoids the phenomena of drapes, bad wrapping and serious color difference generated at the crossed location, improves the yield of the product and enhances the appearance effect of the product.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

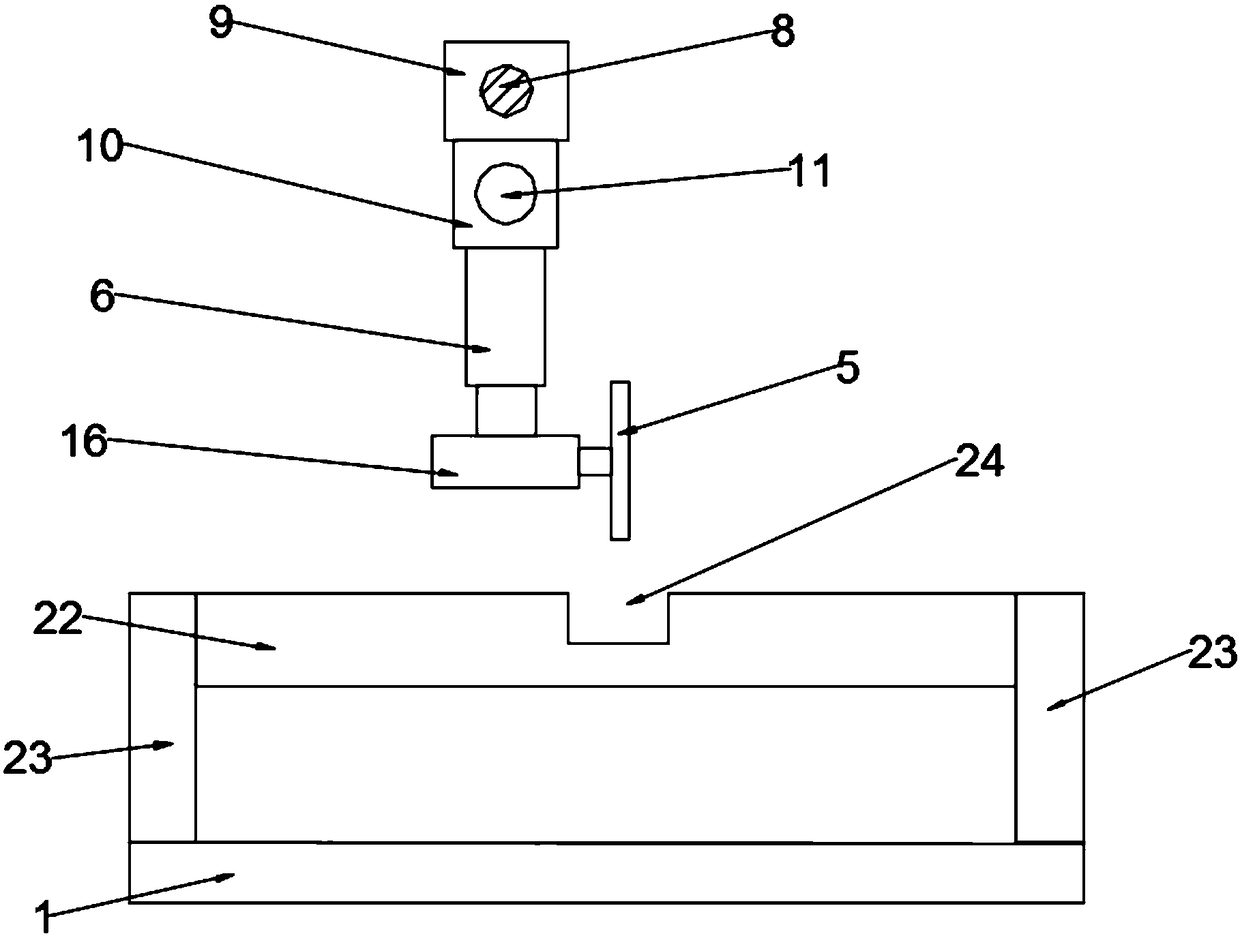

Universal printer

InactiveCN105690994AFast dryingResolve blurOther printing apparatusEngineeringMechanical engineering

The invention discloses a universal printer. The universal printer includes a rack, a printing platform, a printing mechanism and an operation panel; the rack is provided with a base; the base is provided with racks; the printing mechanism is provided with sliding blocks which can slide on the tracks; the sliding blocks are provided with lifting rods; the printing mechanism is arranged on the lifting rods; a drying device is arranged above the printing platform; and the drying device is supported on the printing mechanism through supports. According to the universal printer of the invention, the lifting type printing mechanism is designed, so that the universal printer can be applied to printing of materials with different natures and different thicknesses; and the drying device is arranged on the printing mechanism, so that printing and drying can be carried out simultaneously, and the drying rate of ink can be improved, and therefore, printing efficiency and the quality of printed products can be improved, and the problem of the fuzziness and scratch of printed images which is caused by a situation that the ink cannot be dried timely with the increase of printing speed can be solved. The universal printer has the advantages of simple structure and convenient operation.

Owner:张丹

Transfer case

ActiveCN104495031AThe solution is easy to be hung up or scratchedPlay a supporting roleInternal fittingsTransfer caseTransfer procedure

The invention discloses a transfer case. Mechanical claws are assembled in a case body of the transfer case, so that components can be clamped in the case body by the mechanical claws when transferred; clamping force can be applied to two reverse sides of each component by two claw bodies of the corresponding mechanical claw, accordingly, supporting effects can be realized for the components in the case body by the mechanical claws, and the components can be prevented from being toppled over along with jolting of the case body; the two claw bodies of each mechanical claw can be oppositely opened and closed from the periphery of the corresponding component to clamp the component when the two claw bodies of the mechanical claw are operated to clamp the component, so that the claw bodies of the mechanical claws can be prevented from frictionally sliding on the surfaces of the components when the components are clamped by the mechanical claws, and the surfaces of the components can be prevented from being scratched. The transfer case has the advantages that the components can be clamped under the oppositely opened and closed actions of the claw bodies of the mechanical claws and can be prevented from being toppled over owing to the component supporting effects of the claw bodies, and accordingly the problem that the front and rear surfaces of components can be easily suspended or scratched in transferring procedures in the prior art can be solved.

Owner:HENAN PINGGAO ELECTRIC +2

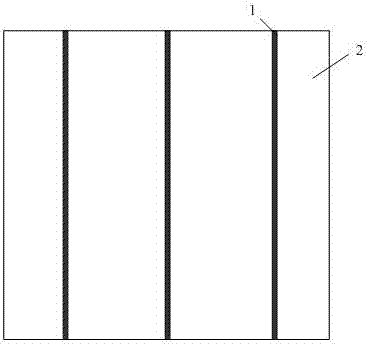

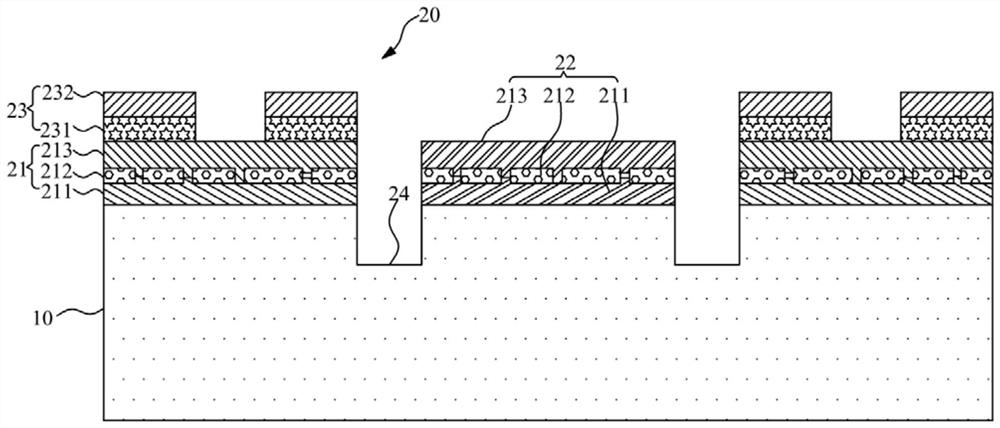

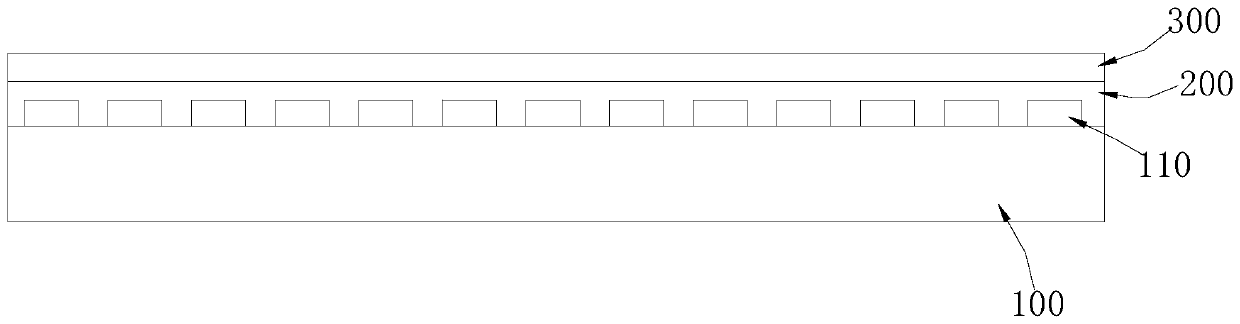

Solar cell, back contact structure thereof, cell assembly and photovoltaic system

PendingCN113394304AAvoid scratchesSolve the scratchPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention is applicable to the technical field of solar cells, and provides a solar cell and a back contact structure thereof, a cell assembly and a photovoltaic system, the back contact structure comprises first doped regions which are arranged on the back of a silicon substrate at intervals and have polarities opposite to the polarity of the silicon substrate, and second doped regions which have the same polarities as the polarity of the silicon substrate. Protection regions are arranged on the first doped regions; each of the first doped region and the second doped region comprises a first doped layer, a passivation layer and a second doped layer; each protection region comprises an insulating layer and a third doped layer with the same polarity as the second doped region; isolation regions are arranged between the first doped regions and the second doped regions; the protection regions are provided with openings, so that a first conductive layer is connected with the first doped region; and the heights of the first doped regions and the second doped regions are both higher than the heights of the isolation regions. According to the back contact structure provided by the invention, the problem of scratches caused by belt transmission in the existing battery preparation process is solved.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +3

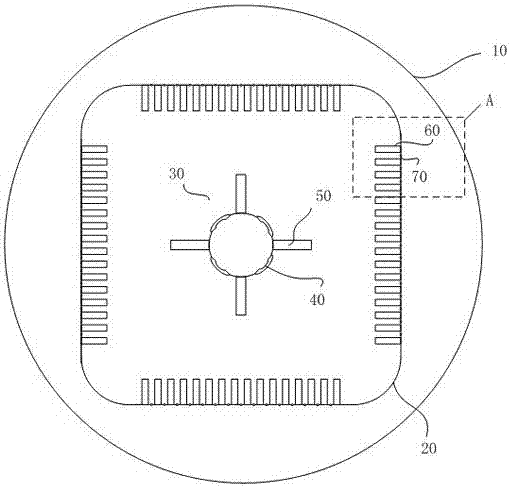

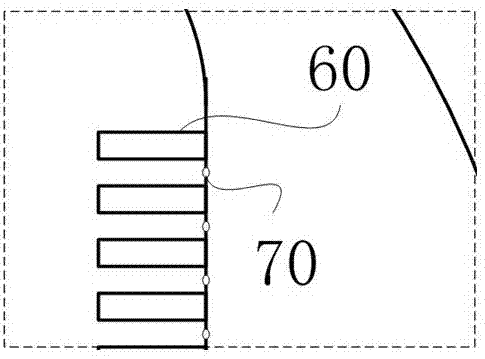

LED display screen

ActiveCN110148361AImprove waterproof, dustproof and shockproofHigh impact strengthIdentification meansLED displayEngineering

The invention discloses an LED display screen, which is provided with a lamp face. A protection resin layer and an elastic resin layer are sequentially arranged on the lamp face of the LED display screen, and the protection resin layer is located between the elastic resin layer and the lamp face. According to the LED display screen, the properties such as water prevention, dust prevention and impact prevention of the lamp face of the LED display screen can be improved through the protection resin layer, the properties of scratching resistance and edge breakage resistance of the protection resin layer can further be improved through the elastic resin layer, and thus the lamp face of the LED display screen is not prone to the phenomena of scratching and edge breakage; by arranging the protection resin layer and the elastic resin layer simultaneously and meanwhile retaining an original protection resin layer to protect lamp beads against being damaged by external force, the problems of scratching, edge breakage and the like of the surface of a current glue filling LED display screen can be effectively solved; and meanwhile, the high-toughness elastic resin layer on the outermost layerfurther has certain elasticity, external impact can be effectively buffered, and thus the lamp face of the LED display screen is good in impact-resistance strength.

Owner:UNILUMIN GRP

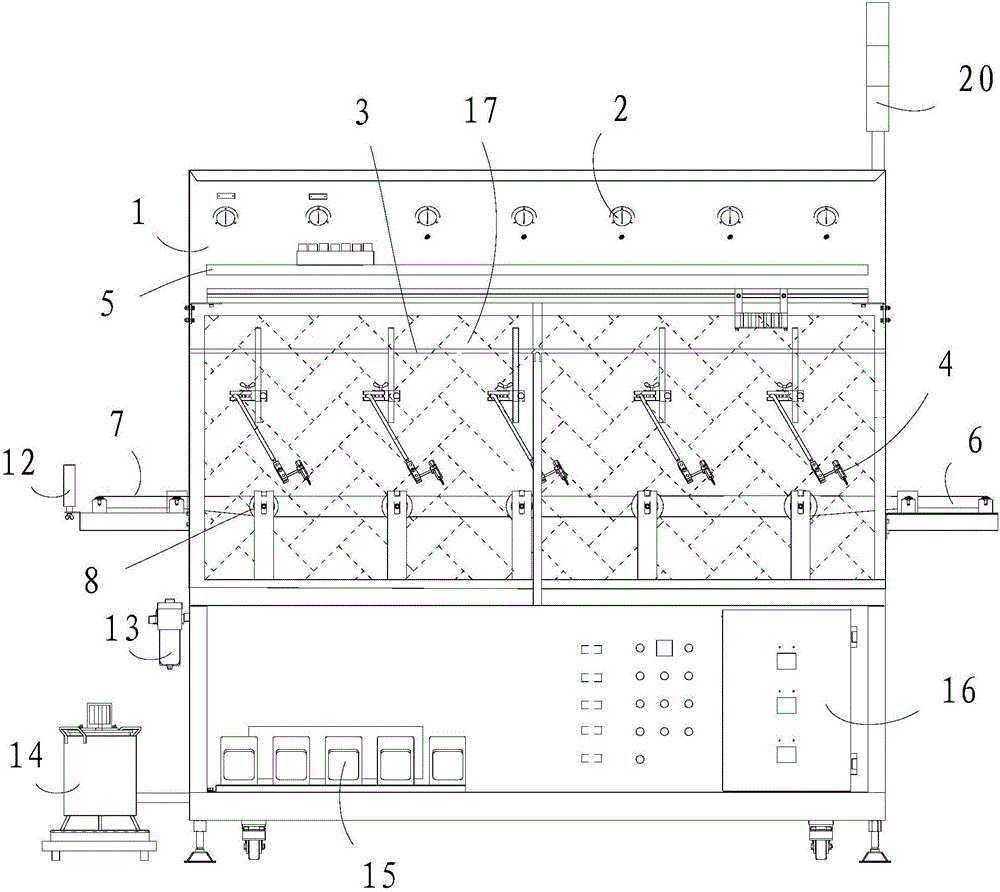

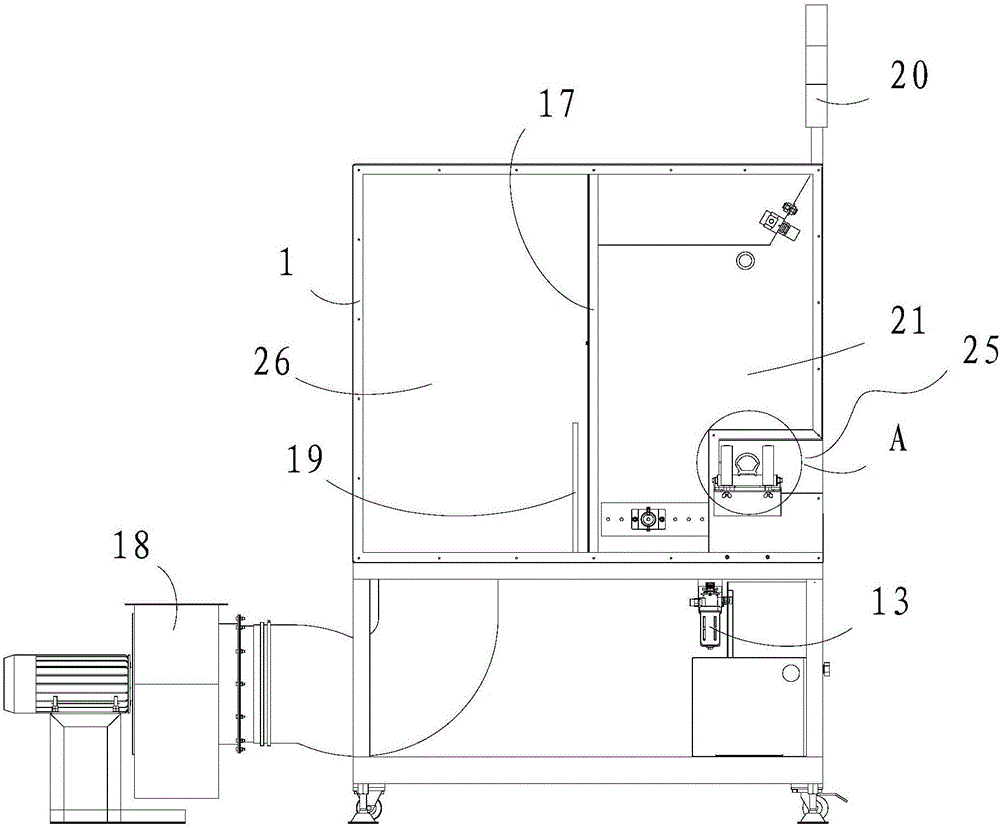

Reciprocating type dust removal device and method used after PCB drilling

InactiveCN108326944AReduce the number of manual operationsHigh precisionInsulating layers/substrates workingCleaning using gasesEngineeringManipulator

The invention discloses a reciprocating type dust removal device used after PCB drilling. The device comprises a reciprocating type dust removal mechanism, a drilling cleaning mechanism, a turnover plate cooling mechanism, a hole site precision testing mechanism and an automatic plate collection machine which are sequentially connected. The dust removal mechanism is connected with a dust removal feeding mechanical hand, and the hole site precision testing machine is connected with a testing feeding mechanical hand. Automatic dust removal and cleaning operation after drilling is achieved, the manual operation frequency of personnel in the cleaning and detection process is reduced, the processing efficiency is improved, the processing period is shortened, and the problem that a plate face isscraped in the manual repeated carrying process is solved. The reciprocating type dust removal mechanism can carry out dust removal treatment on plates repeatedly back and forth, the cleaning effectis more thorough, dust in holes can be effectively removed, and therefore follow-up hole site precision detection results are higher in accuracy. The invention further discloses a dust removal method.The dust removal method is wired type automatic dust removal method and is high in dust removal efficiency, good in cleaning effect and applicable to batch treatment on dilled plates.

Owner:江西景旺精密电路有限公司

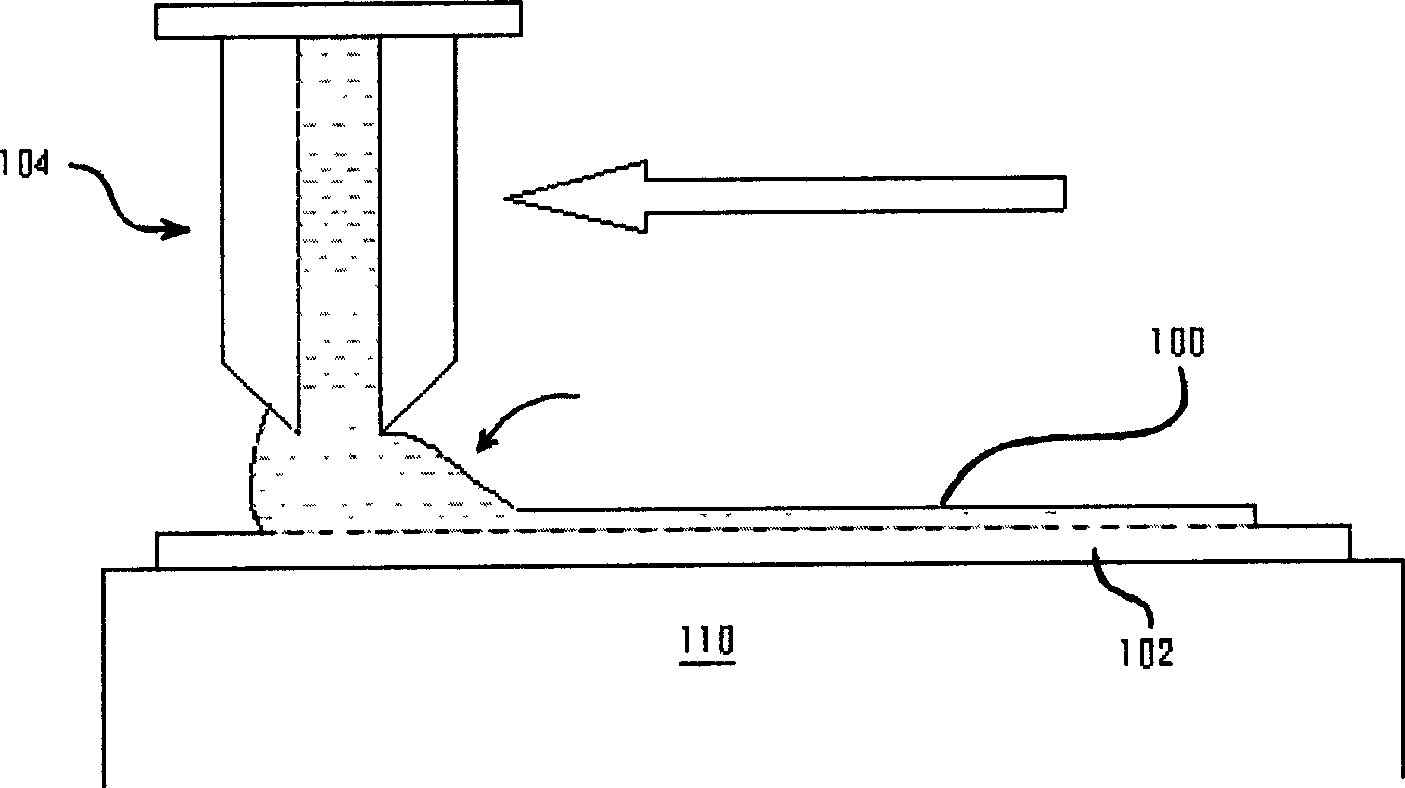

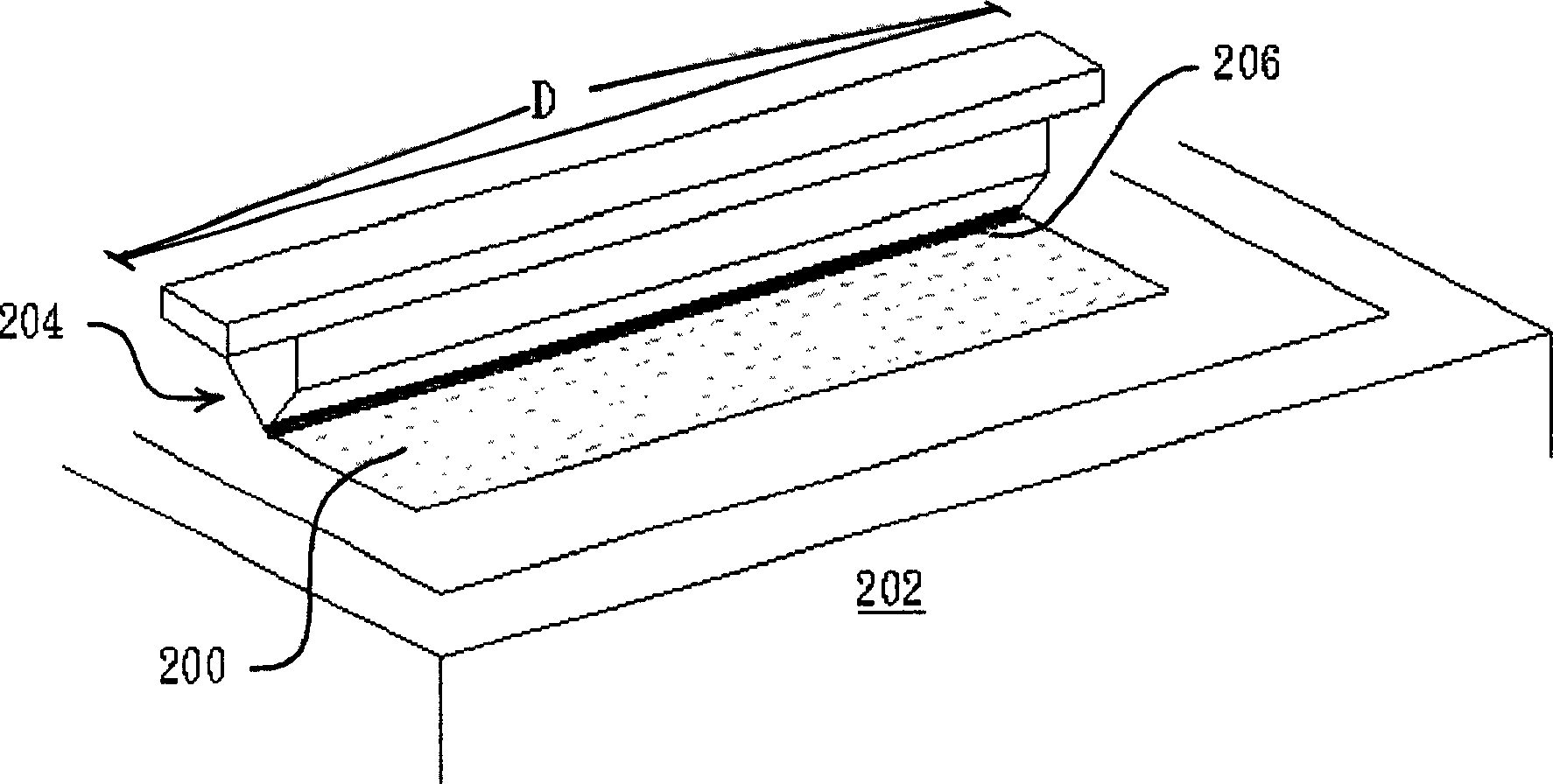

Fine seam type coating device

InactiveCN1824392ASolve the scratchExpand the adjustment rangeLiquid surface applicatorsCoatingsBiochemical engineeringRelative motion

The present invention relates to an improved fine-slot type coating equipment. It includes base seat, fine-slot type coating nozzle and diaphragm. The fine-slot type coating nozzle is positioned on the base seat, the diaphragm is fixed on the fine-slot type coating nozzle, and said diaphragm is outwards extended from the fine-slot type coating nozzle, and the width of said diaphragm can cover the spraying range of said fine-slot type coating nozzle. When the fine-slot type coating nozzle and base seat are sued for driving coating material and making it be moved onto base material by means of their relative movement, the diaphragm can raise stability of coating process.

Owner:ALLIED MATERIAL TECH CORP

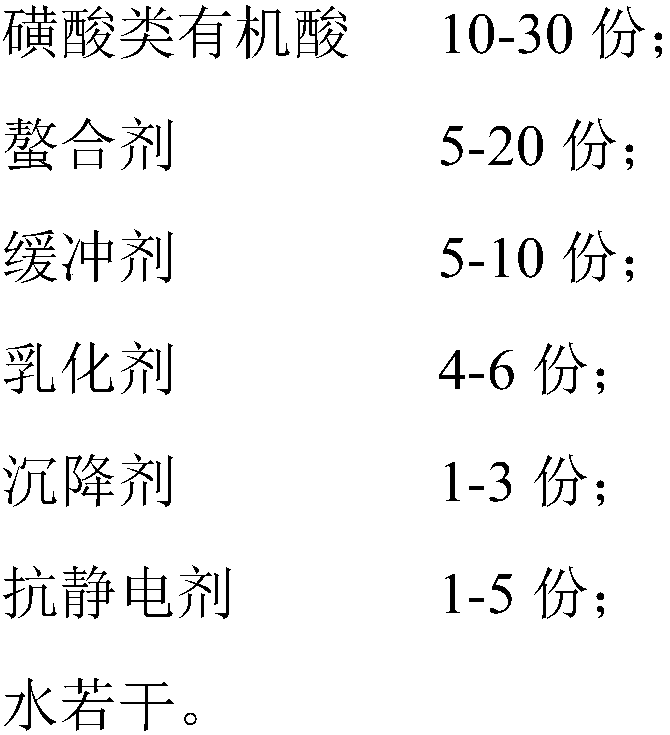

Acidic glass detergent

ActiveCN108949374AEasy to cleanSolve the scratchOrganic detergent compounding agentsPolymeric surface-active compoundsOrganic acidAntistatic agent

The invention discloses an acidic glass detergent which is prepared from the following components in parts by weight: 5-40 parts of a sulfoacid organic acid, 3-30 parts of a chelating agent, 3-15 parts of a buffer agent, 2-9 parts of an emulsifier, 0.5-5 parts of a settling agent, 0.5-8 parts of an antistatic agent and some water. By adopting an acidic cleaning system, the problem that glass cleaned by an alkaline cleaning system is likely to scratch and is not cleaned clearly is solved effectively, and meanwhile, by adding the buffer agent, the settling agent and the antistatic agent, the cleaning effect of the acidic glass detergent is further improved.

Owner:深圳市海风润滑技术有限公司

Front spraying device for automobile sealing strip

InactiveCN106607290ASolve the scratchPrevents sagging buildupLiquid surface applicatorsSpraying apparatusEngineeringBinding force

The invention provides a front spraying device for an automobile sealing strip. The front spraying device comprises a box body. A spraying channel is formed in the box body. An air exhaust mechanism communicates with the spraying channel. The front spraying device further comprises a spraying mechanism with a spraying gun. Two transfer parts capable of operating synchronously are arranged at an inlet and an outlet of the spraying channel separately. A plurality of rotary supporting parts are arranged in the spraying channel at intervals, and the distance between every two adjacent rotary supporting parts is 20-30cm. A constraining guide part capable of applying constraining force to guide the movement of a rubber tape of the sealing strip is arranged at the outlet of the spraying channel. According to the front spraying device for the automobile sealing strip disclosed by the invention, the rubber tape of the sealing strip can pass through the spraying channel according to a set position, the problem of scratching due to overturning in the passing process of the rubber tape of the sealing strip can be prevented, the problems of drooping accumulation and deformation happening to the rubber tape of the sealing strip due to excessively-large space between the rotary supporting parts can also be prevented, and therefore the effect that the soft rubber tape of the sealing strip passes through the spraying channel smoothly so as to complete a front spraying technology can be guaranteed.

Owner:NUOBO RUBBER PRODION

Discharge device of capacitor nailing machine

PendingCN108074754AGuaranteed not to forceFast and smooth transferTerminal applying apparatusCapacitorBiomedical engineering

The invention discloses a discharge device of a capacitor nailing machine. The discharge device comprises a discharge hopper, a rotating plate, a feeding mechanism, a needle taking clamp and a drivingmechanism, wherein the discharge hopper is provided with a guide needle inlet and a guide needle outlet, the guide needle outlet is located at the bottom of the discharge hopper, the rotating plate is provided with a station groove for magnetically attracting a guide needle and rotationally conveys the guide needle. The station groove is located in the circumference of the rotating plate. The feeding mechanism comprises a needle ejecting plate. The top face of the needle ejecting plate is located at the guide needle outlet of the discharge hopper. The needle ejecting plate moves up to send the guide needle to a groove opening of the station groove of the rotating plate to be magnetically attracted into the station groove. The needle taking clamp is located at the position, at the tail endof the rotating trajectory of the rotating plate, of the guide needle and used for taking down the guide needle in the station groove of the rotating plate. The driving mechanism is connected with the needle ejecting plate and the needle taking clamp and used for driving the needle ejecting plate and the needle taking clamp to move. The discharge device is rapid and stable in guide needle conveying, and twelve stations are used for conveying during the intermittent movement of the plate so that the guide needle can be corrected and completely positioned.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

Microcrystalline glass and preparation method thereof

The invention provides amber microcrystalline glass with high hardness and high-temperature resistance. The microcrystalline glass comprises, by weight, 50 to 70% of SiO2, 10.0 to 25% of Al2O3, 3 to 10% of TiO2, 0.2 to 0.7% of CuO, 0 to 22% of MgO and 0 to 20% of ZnO, wherein the microcrystalline glass contains at least one selected from the group consisting of MgO and ZnO. The microcrystalline glass of the invention has a Mohs hardness of 7.5-8 H, can be applied to decorative materials and decorative articles, and overcomes the problem of scratching of ordinary amber glass. The microcrystalline glass is not softened at a high temperature of 1,150 DEG C, has resistance to high temperatures, and can be further processed under high-temperature conditions. The microcrystalline glass of the invention has high mechanical strength, hardness and thermal stability, and good chemical stability, wear resistance and electrical insulation performance, and can be applied to decorative materials andused for high-grade decoration projects for interior and exterior walls, floors and pillars of buildings, etc.

Owner:CDGM GLASS LLC

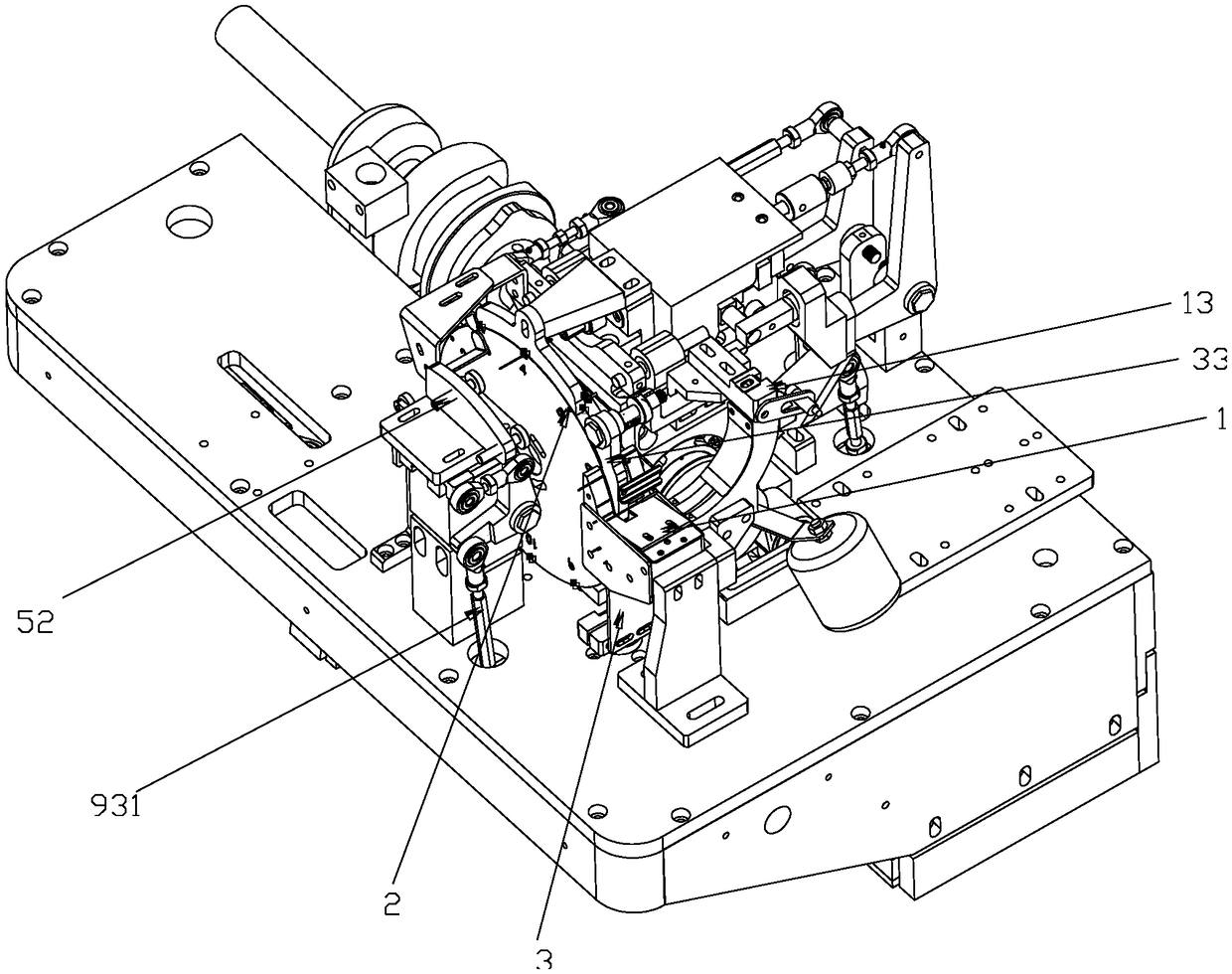

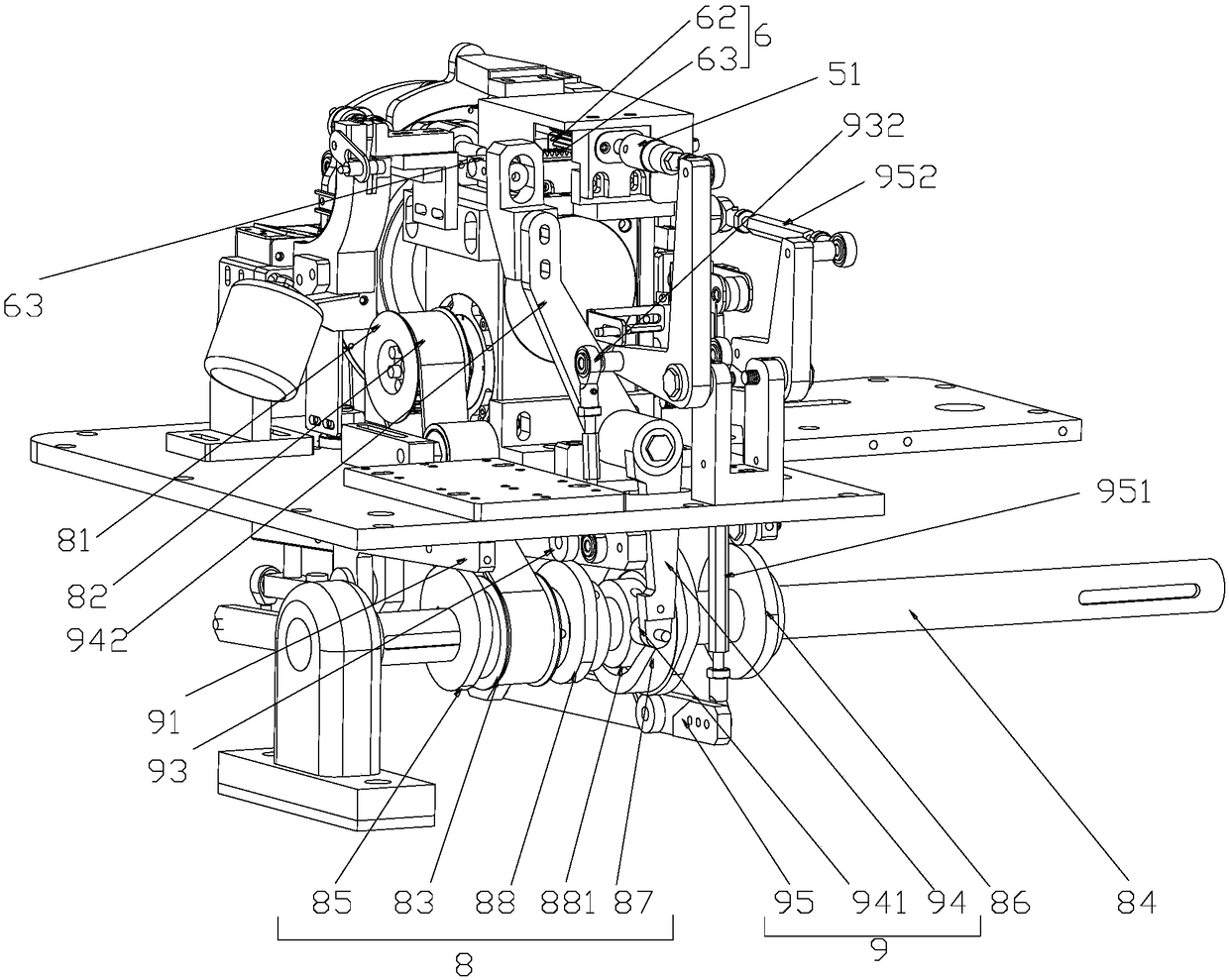

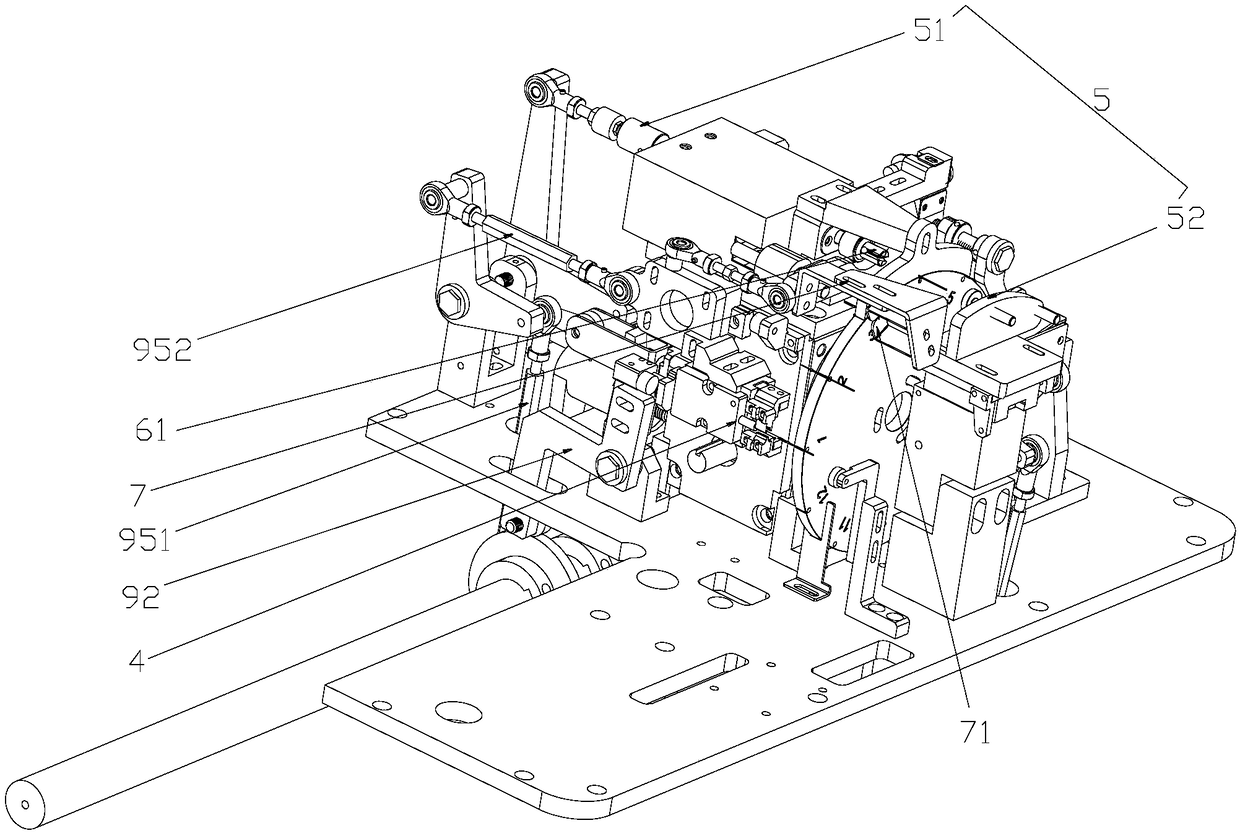

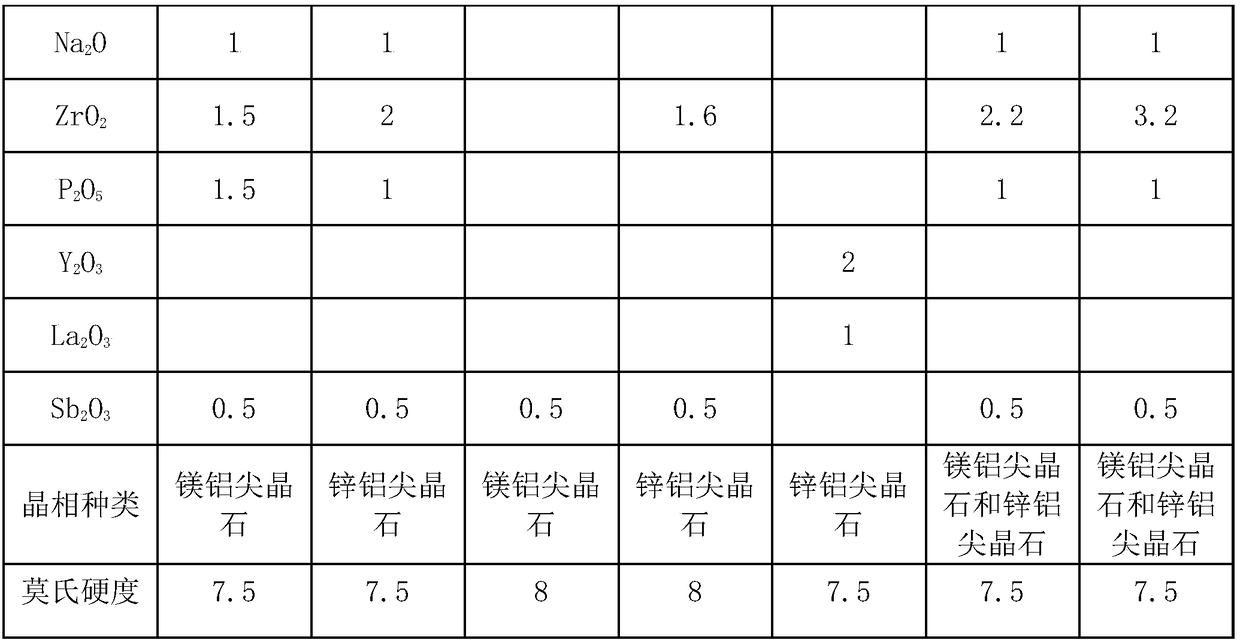

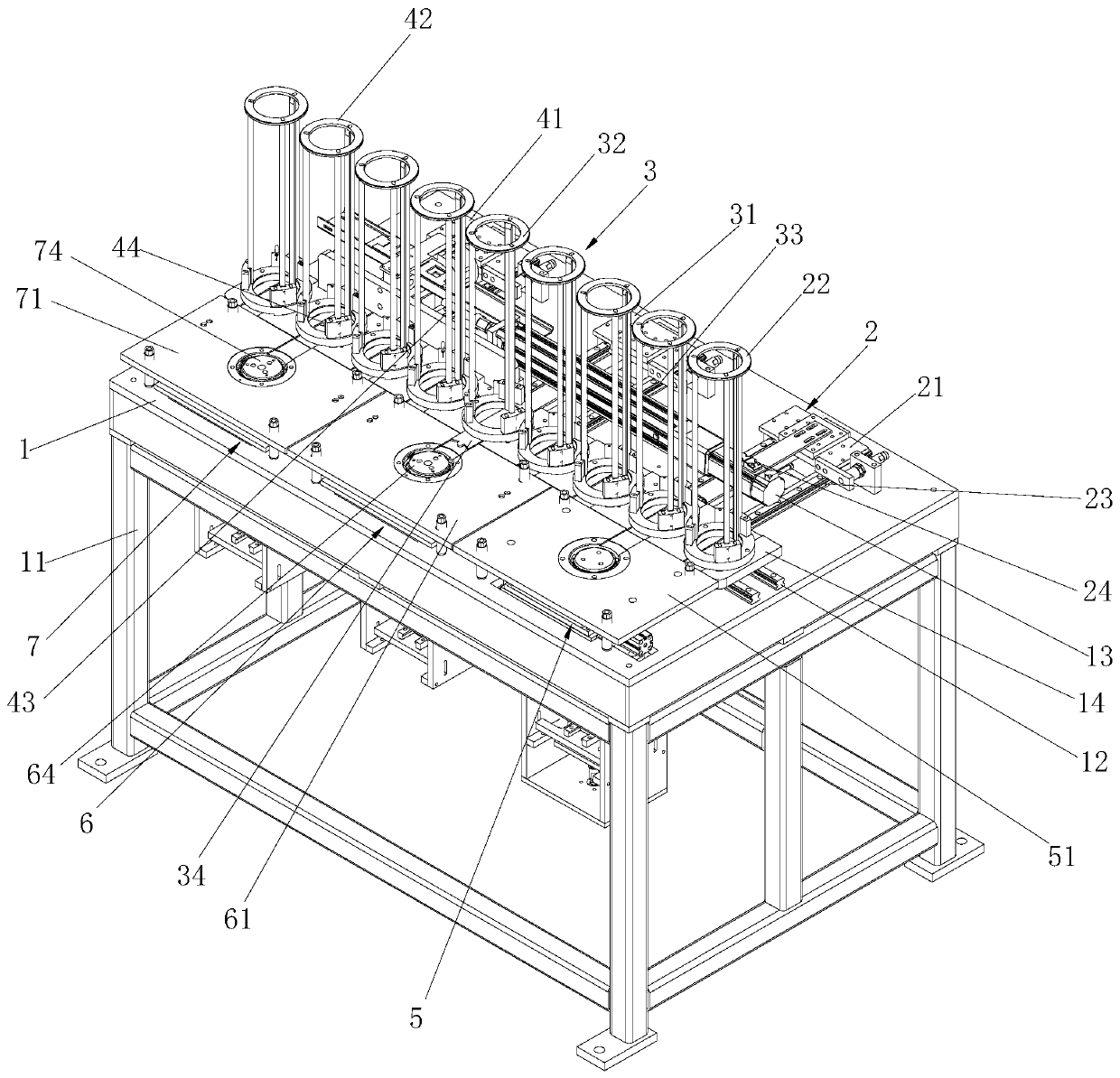

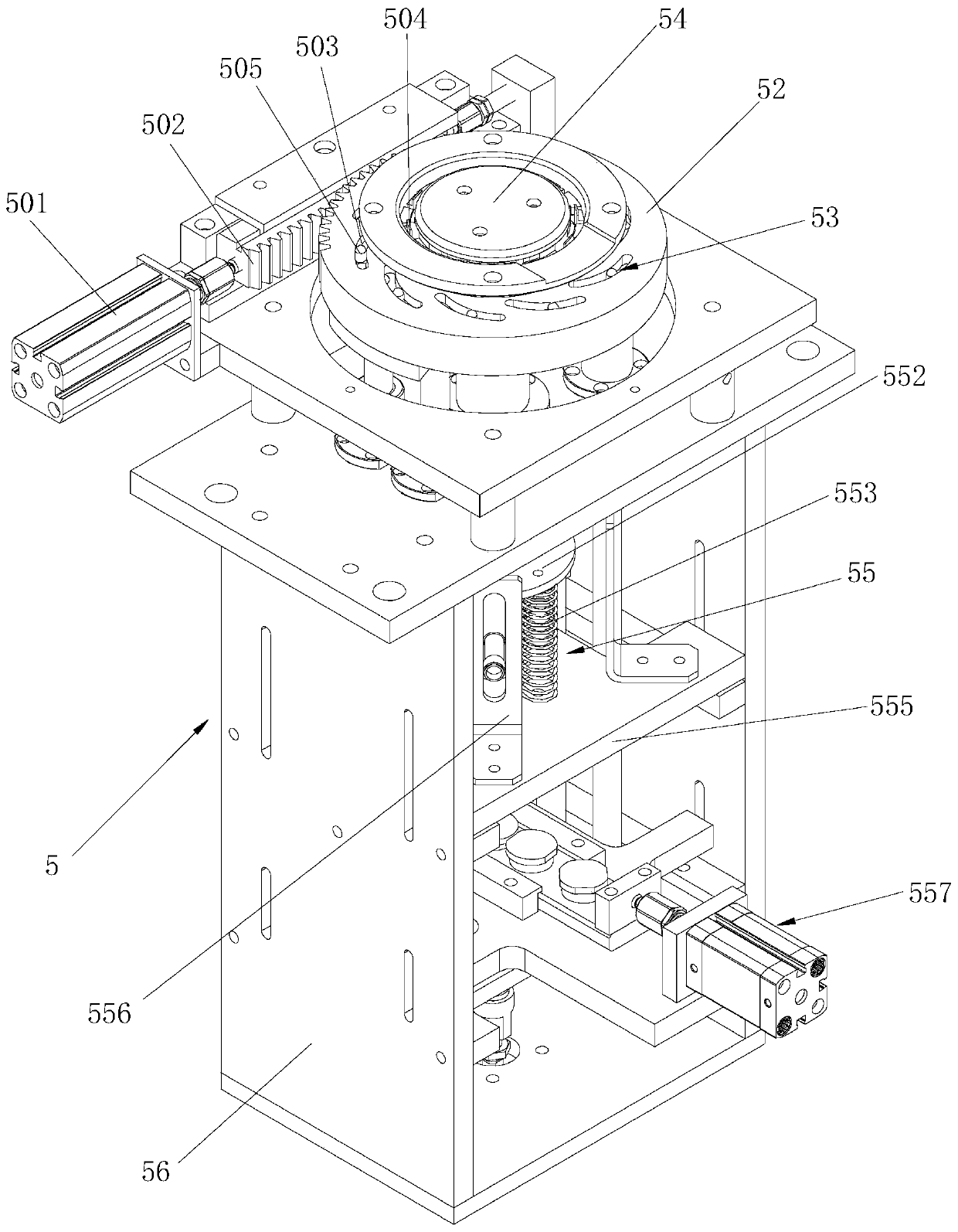

Intelligent detecting installing equipment for multiple types of piston rings

PendingCN109909723AAccurate installation controlImprove assembly efficiencyMetal working apparatusPiston ringPetroleum engineering

The invention discloses intelligent detecting installing equipment for multiple types of piston rings. The intelligent detecting installing equipment for the multiple types of piston rings comprises an installing platform, an oil ring positioning device, a conical surface gas ring positioning device and a barrel surface gas ring positioning device are connected to the installing platform, and first longitudinal slide rails, a first switching electric cylinder and a first material bin supporting plate are transversely arranged in the middle of the installing platform; the oil ring positioning device comprises first pushing mechanisms, oil ring material frames and oil ring expanding devices, and the oil ring material frames are connected to the first material bin plate; each oil ring expanding device comprises a first material receiving plate, a first transmission gear ring and a first expanding mechanism, a first piston supporting block is arranged in each first material receiving plate, and a first buffering reset mechanism and a first buffering support are connected to the lower end of each first piston supporting block; each first transmission gear ring is located at the lower end of the corresponding first material receiving plate and arranged outside the corresponding first piston supporting block in a sleeving mode; and the conical surface gas ring positioning device and the barrel surface gas ring positioning device are arranged on the portion, on the right side of the oil ring positioning device, of the installing platform. According to the installing equipment intelligent installing of the piston rings can be achieved, operation is easy and convenient, and the installing efficiency is high.

Owner:QINGDAO BESTONE IND EQUIP

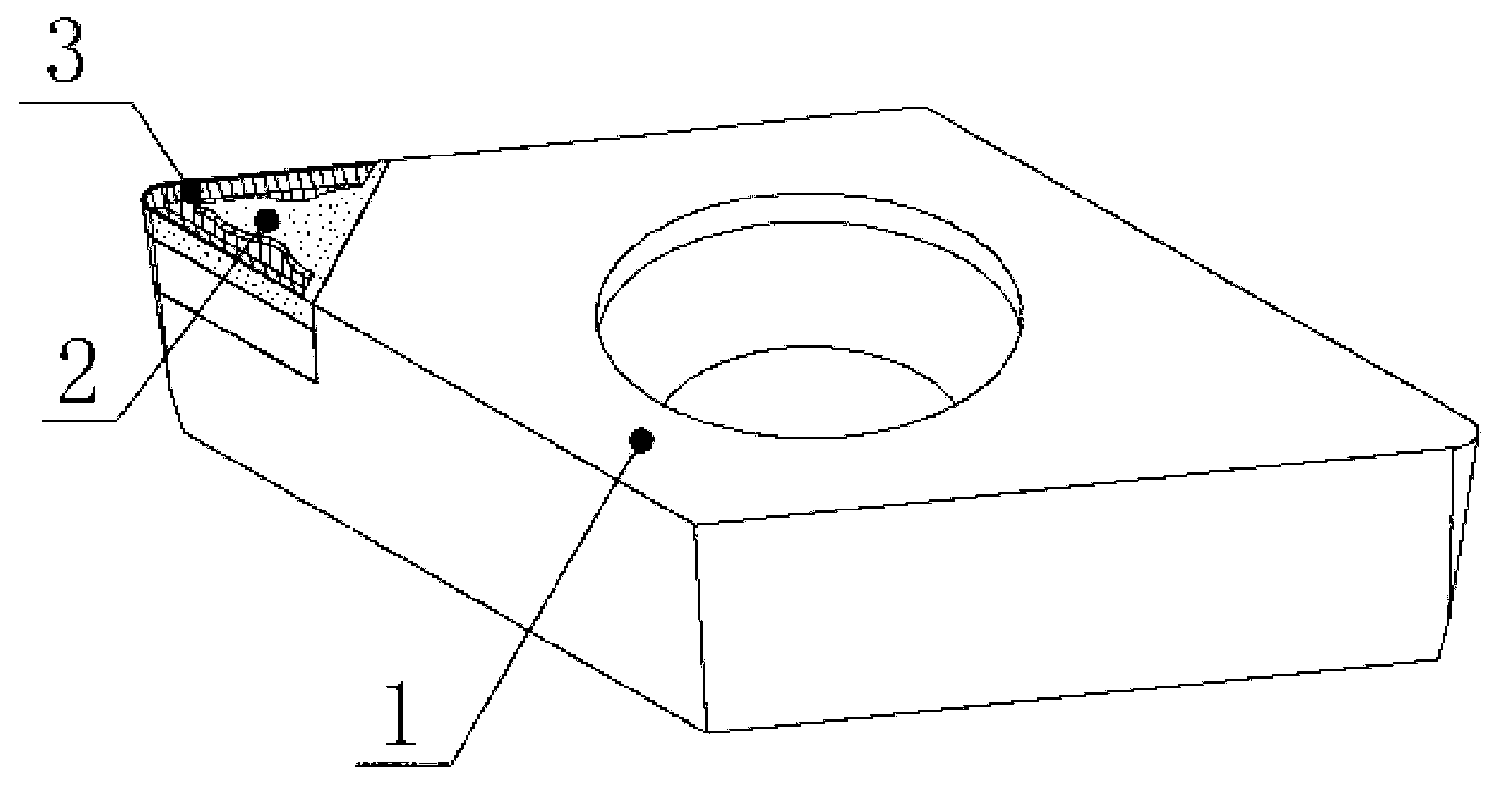

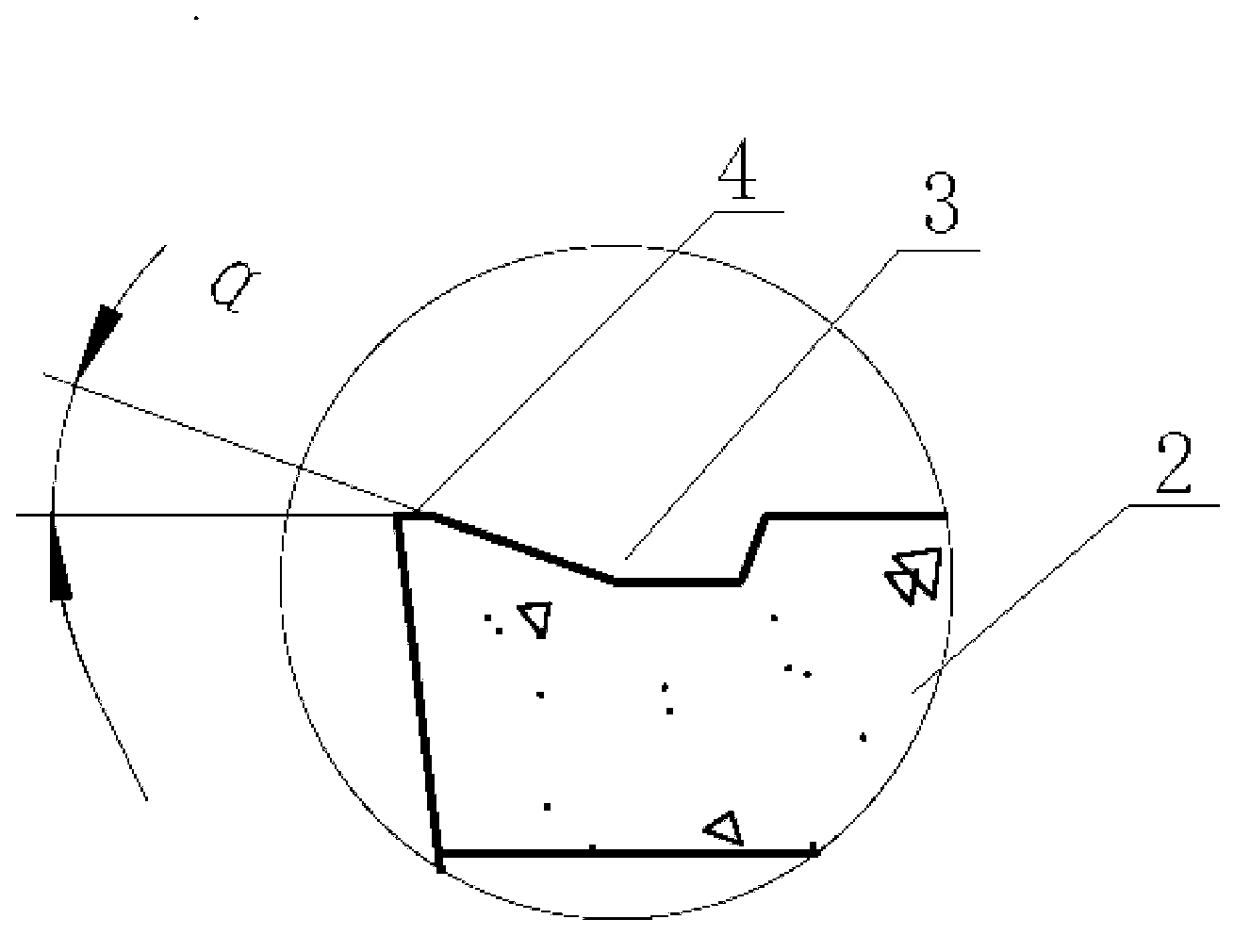

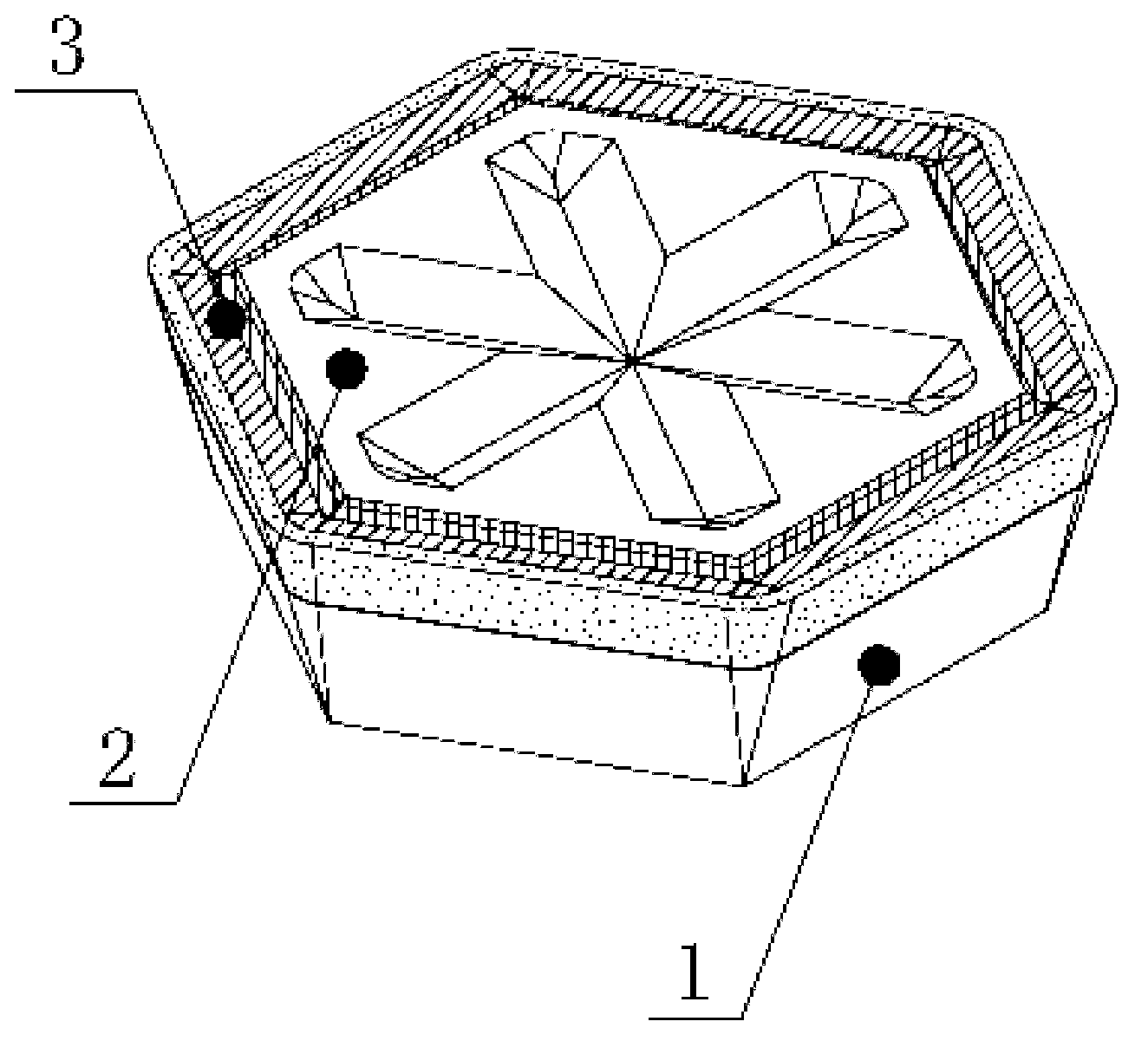

Superhard blade with chip breaking groove

ActiveCN103192102ASolve the scratchSolve the problem of winding knivesTurning toolsTool bitHardened steel

The invention relates to a superhard blade with a chip groove. A tool bit is welded on a base, and the chip groove lower than a surface cutting edge is arranged on the tool bit. The blade can be of any type in the ISO (International Standardization Organization) standards, and can be of customized special shape and special type, the blade is designed with a single tool bit or multiple tool bits, the chip breaking groove can be processed on the surface of each tool bit, and different angles and shapes of the chip breaking groove can be designed according to the blade of different types to meet requirements on use and processing in actual working conditions. By the superhard blade with the chip breaking groove, the problem that workpieces are scratched or a tool is wound caused by continuous cutting during production is effectively solved, probability of abnormal damages caused by abrasion of the tool is lowered, and requirements on high-speed efficient cutting are met. The superhard blade with the chip breaking groove is mainly used for processing of non-ferrous metal products and hardened steel products in industries like aerospace, automobiles, machinery manufacturing, ships and chemistry.

Owner:BEIJING WORLDIA DIAMOND TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com