Acidic glass detergent

A glass cleaning agent, acid technology, applied in the direction of surface active detergent composition, detergent composition, detergent compounding agent, etc., can solve the problems of empty drum, trouble of production enterprises, difficult cleaning of polishing powder, etc., to improve cleaning Effect, solve the cleaning unclean, solve the effect of glass scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

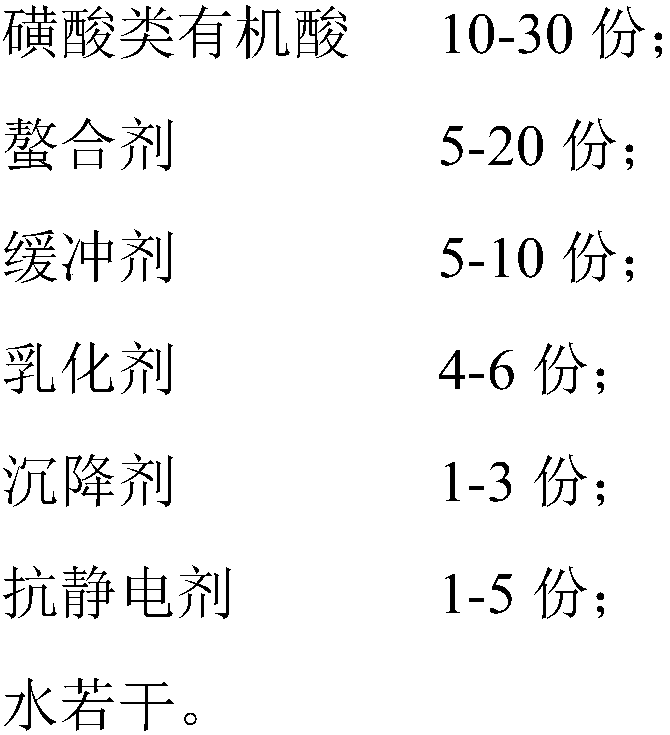

[0022] A kind of acidic glass cleaning agent, its mass percentage consists of: 10 parts of methanesulfonic acid, 5 parts of ethylenediaminetetraacetic acid, 10 parts of glycine, 4 parts of isomeric alcohol ether (XP-90), nonionic polyacrylamide ( Molecular weight 6000) 1 part, TX-10P phosphate ester 1 part, appropriate amount of water.

Embodiment 2

[0024] A kind of acidic glass cleaning agent, its mass percentage consists of: 25 parts of p-toluenesulfonic acid, 10 parts of sodium citrate, 10 parts of phthalic acid, 10 parts of alkyl glucoside (APG0810), nonionic polyacrylamide (molecular weight 2000 ) 2 parts, TX-10P phosphate ester 1 part, appropriate amount of water.

Embodiment 3

[0026] A kind of acidic glass cleaning agent, its mass percentage consists of: 20 parts of sulfamic acid, 5 parts of sodium citrate, 5 parts of gluconic acid, 8 parts of phthalic acid, 8 parts of fatty acid methyl ester ethoxylate (FMEE), 3 parts of non-ionic polyacrylamide (molecular weight 3000), 1 part of TX-10P phosphate ester, appropriate amount of water.

[0027] Dilute the cleaning agent in Example 1-3 with water to a pH value of 0.5-4, add it to an ultrasonic cleaning machine solvent tank respectively, use the cover glass as a cleaning test piece, put it into the ultrasonic cleaning machine solvent tank for cleaning, The temperature is set to 60°C, and the time is set to 120S. After cleaning, observe the cleanliness of the surface of the test piece and the number of scratches. The comparative example is Guangdong Shanzhifeng Win-76 alkaline cleaning agent. The cover glass is used as the cleaning sample, which is placed in the solvent tank of the ultrasonic cleaning mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com