Solar cell, back contact structure thereof, cell assembly and photovoltaic system

A technology of solar cells and back contact, applied in the field of solar cells, can solve problems such as belt transmission scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

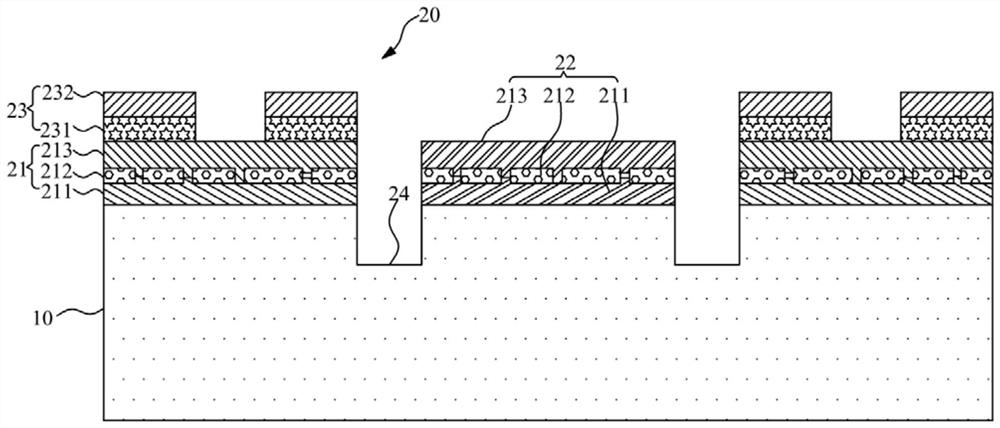

[0057] An embodiment of the present invention provides a back contact structure of a solar cell. For ease of description, only the parts related to the embodiment of the present invention are shown. Refer to figure 1 As shown, the back contact structure 20 of the solar cell provided by the embodiment of the present invention includes:

[0058] A first doped region 21 with a polarity opposite to that of the silicon substrate 10 and a second doped region 22 with the same polarity as that of the silicon substrate 10 are arranged at intervals on the back of the silicon substrate 10, and the first doped region 21 is provided with There are protected areas 23;

[0059] Both the first doped region 21 and the second doped region 22 include a first doped layer 211, a passivation layer 212, and a second doped layer 213;

[0060] The protection region 23 includes an insulating layer 231 and a third doped layer 232 having the same polarity as the second doped region 22;

[0061] An isol...

Embodiment 2

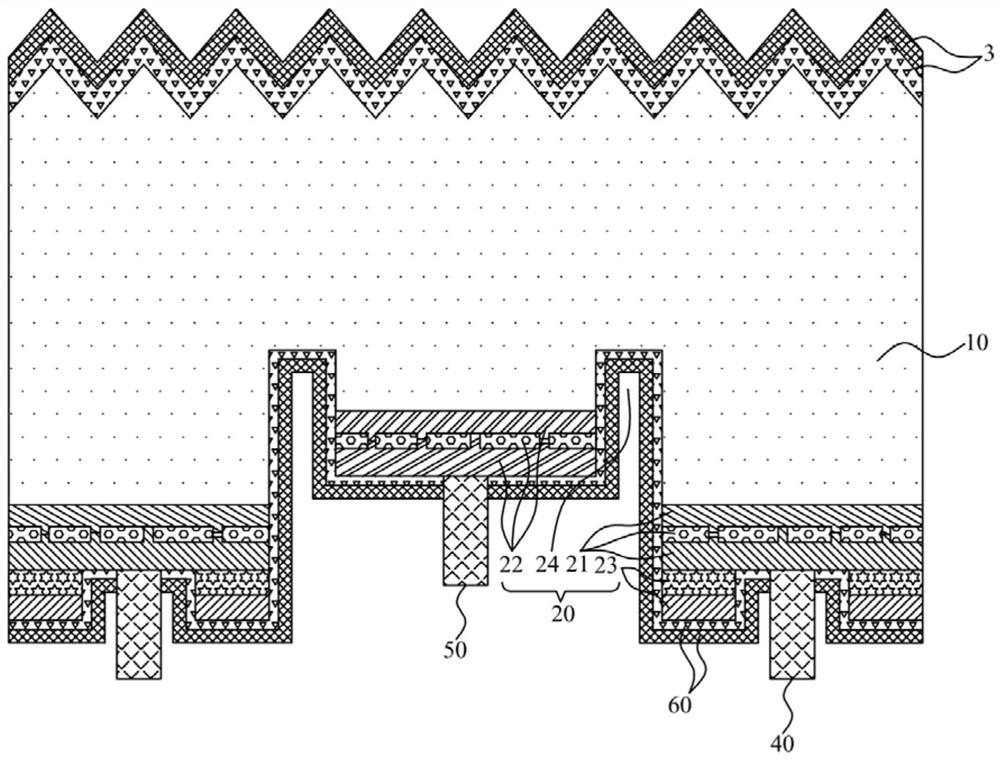

[0089] The second embodiment of the present invention provides a solar cell. For the convenience of description, only the parts related to the embodiment of the present invention are shown. Refer to figure 2 and image 3 As shown, the solar cell provided by the embodiment of the present invention includes:

[0090] silicon substrate 10;

[0091] The back contact structure 20 described in the foregoing embodiments disposed on the back of the silicon substrate 10;

[0092] a first dielectric layer 30 disposed on the front side of the silicon substrate 10;

[0093] a first conductive layer 40 disposed on the first doped region 21 in the back contact structure 20 and a second conductive layer 50 disposed on the second doped region 22 in the back contact structure 20; and

[0094] The second dielectric layer 60 is disposed on the back contact structure 20 and disposed between the first conductive layer 40 and the second conductive layer 50 .

[0095] Wherein, in one embodiment...

Embodiment 3

[0109] The third embodiment of the present invention also provides a battery assembly, which includes the solar cell described in the second embodiment above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com