Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

236 results about "Closed angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

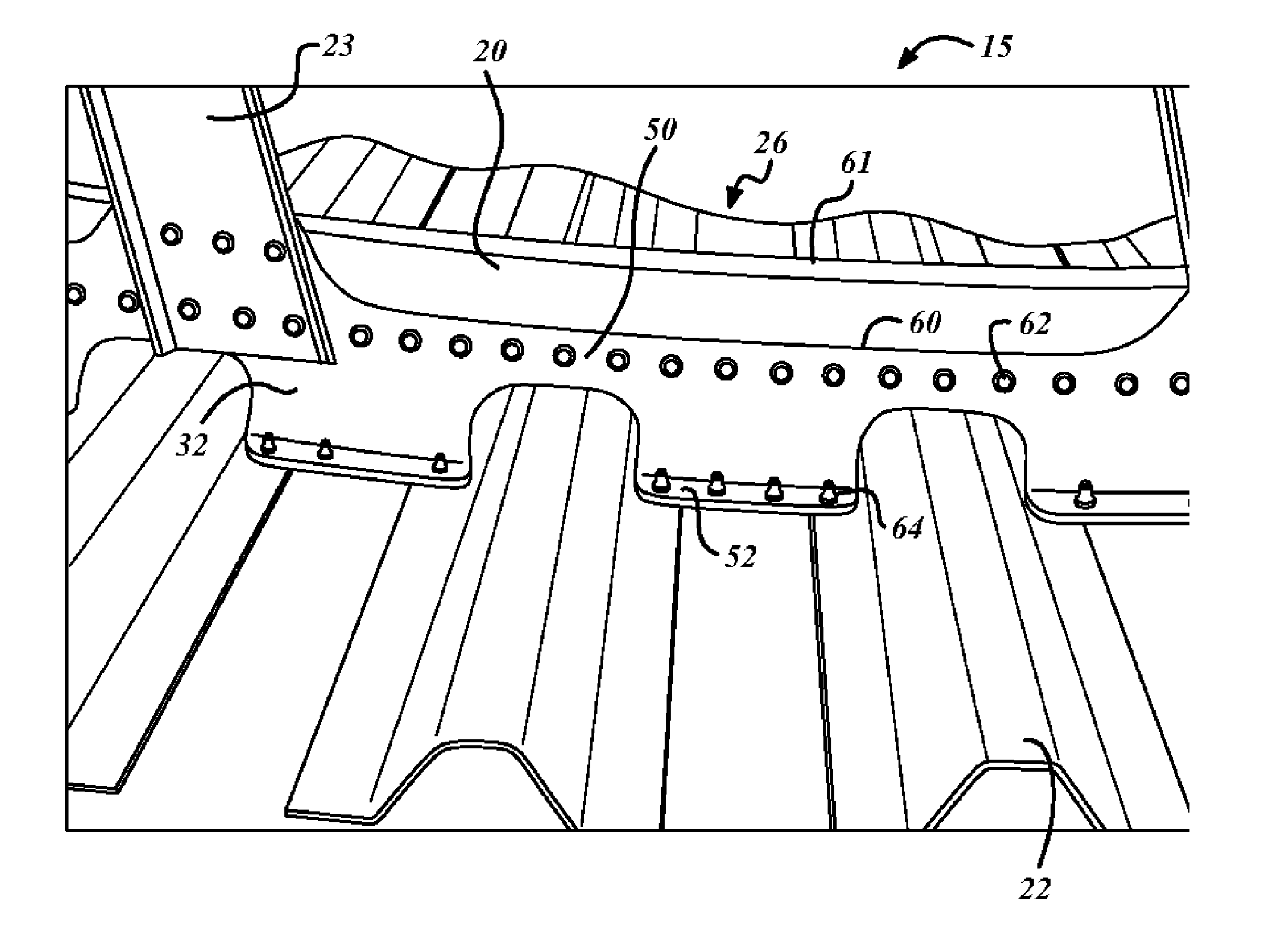

Secure herringbone arrangement for the armrest of a seat, seat and two seat assembly provided with such an arrangement

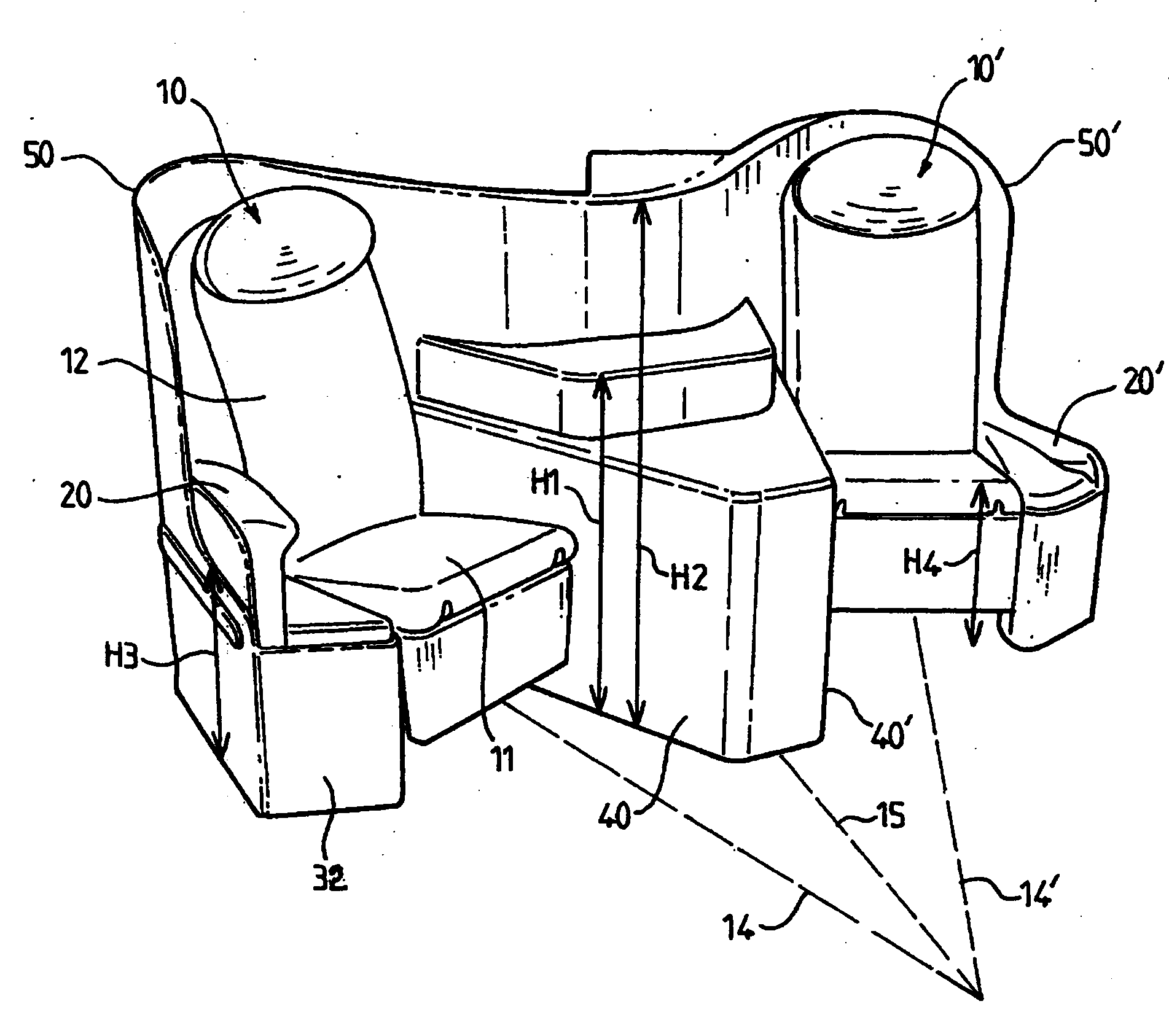

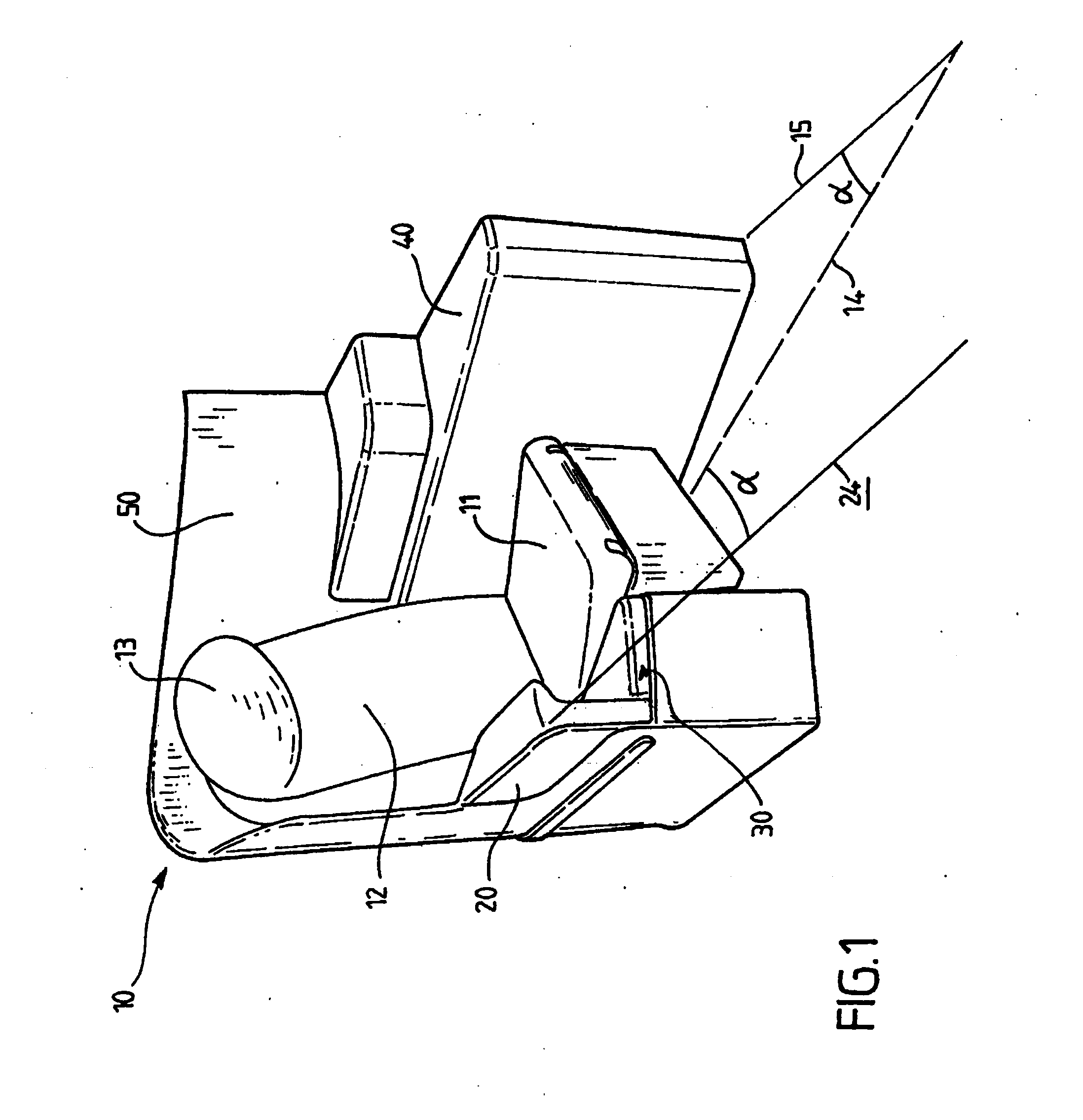

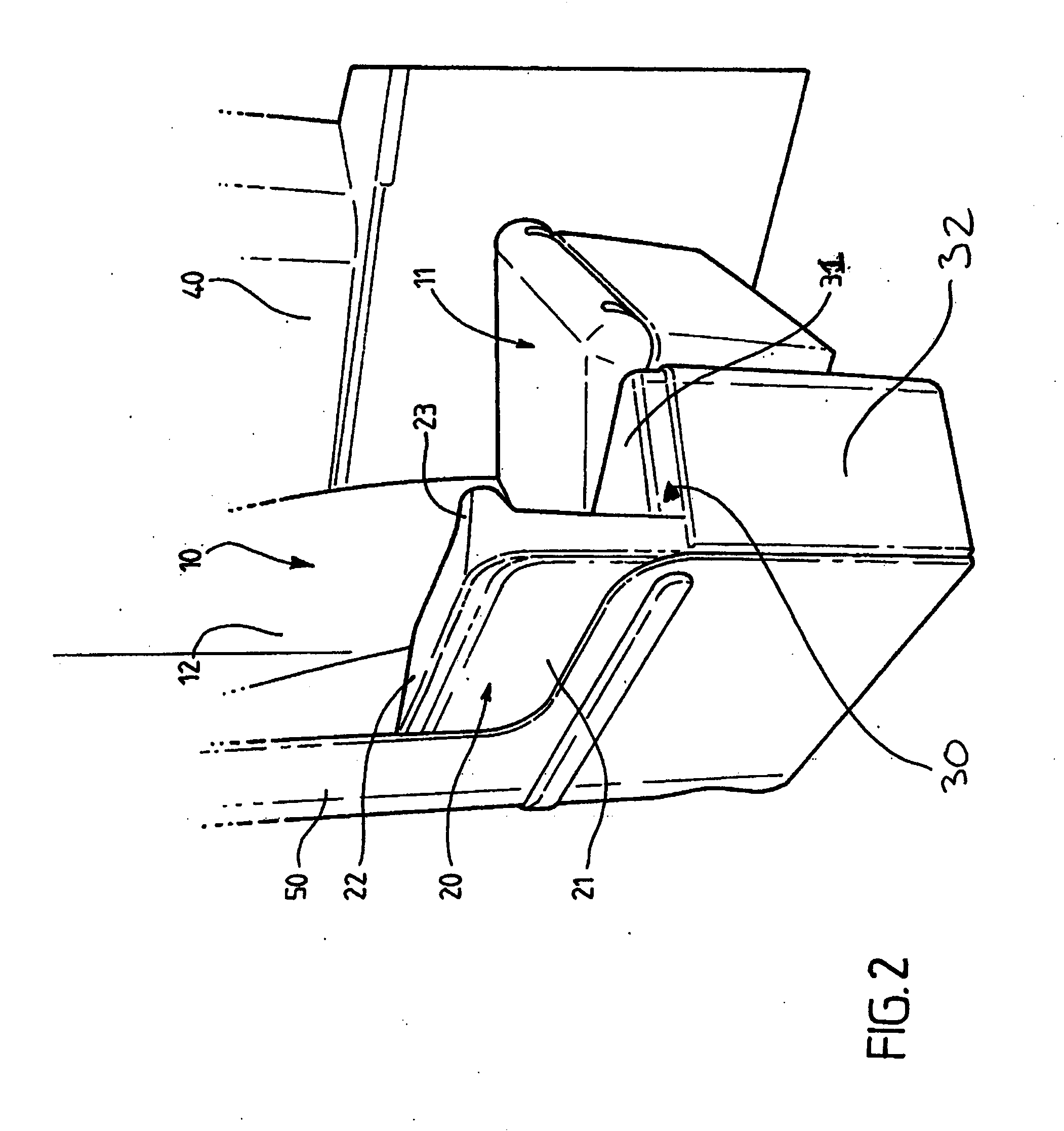

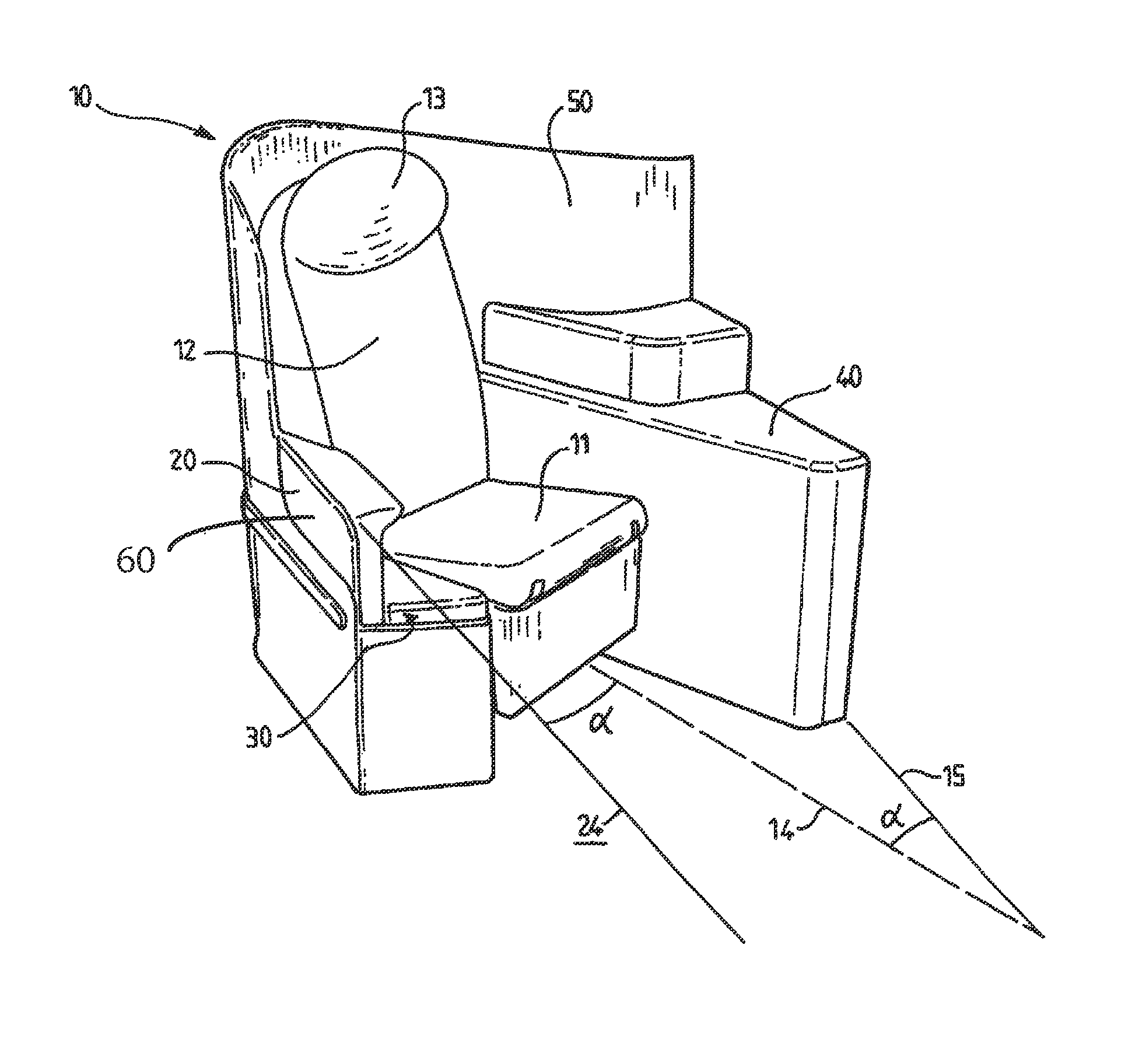

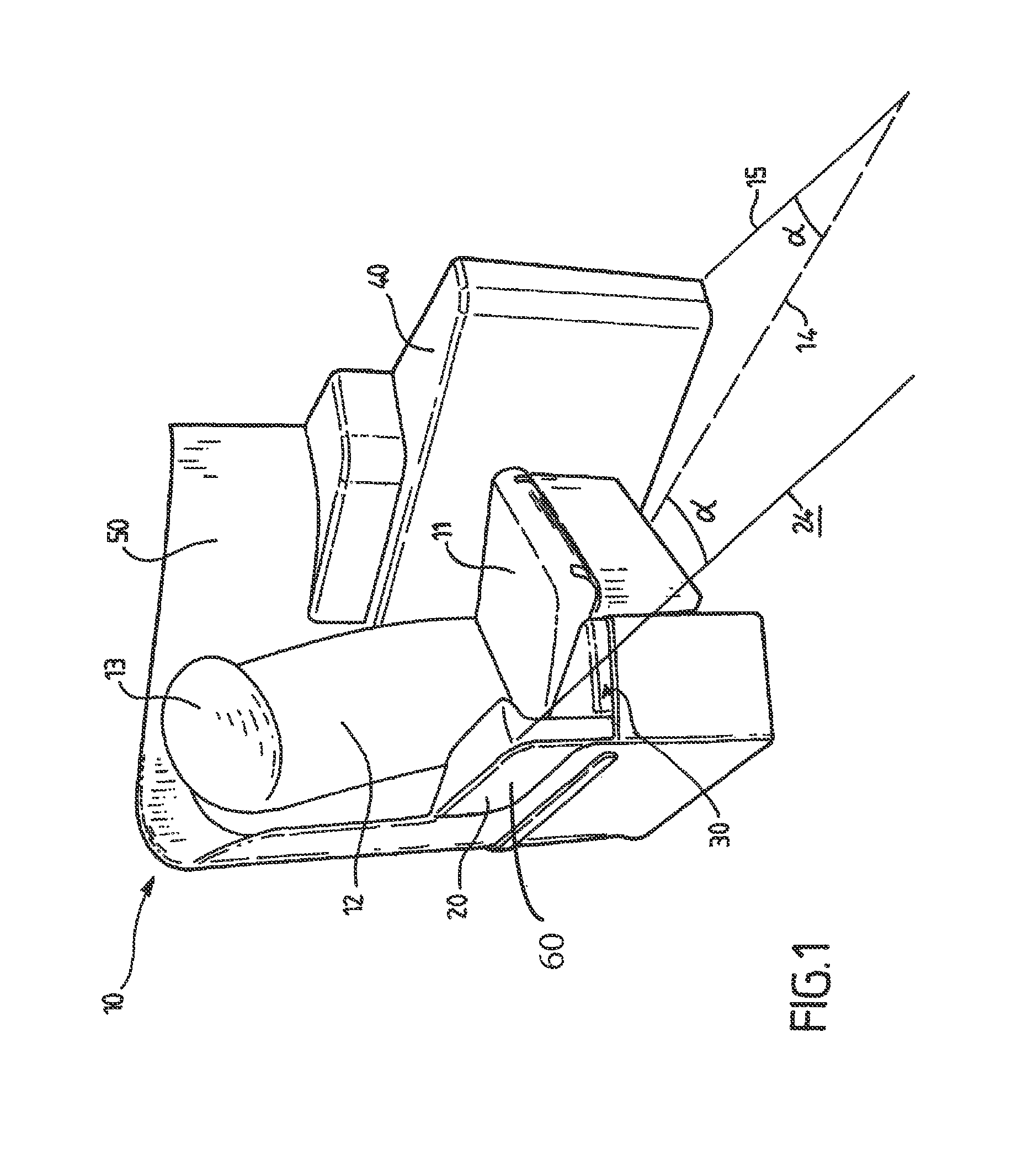

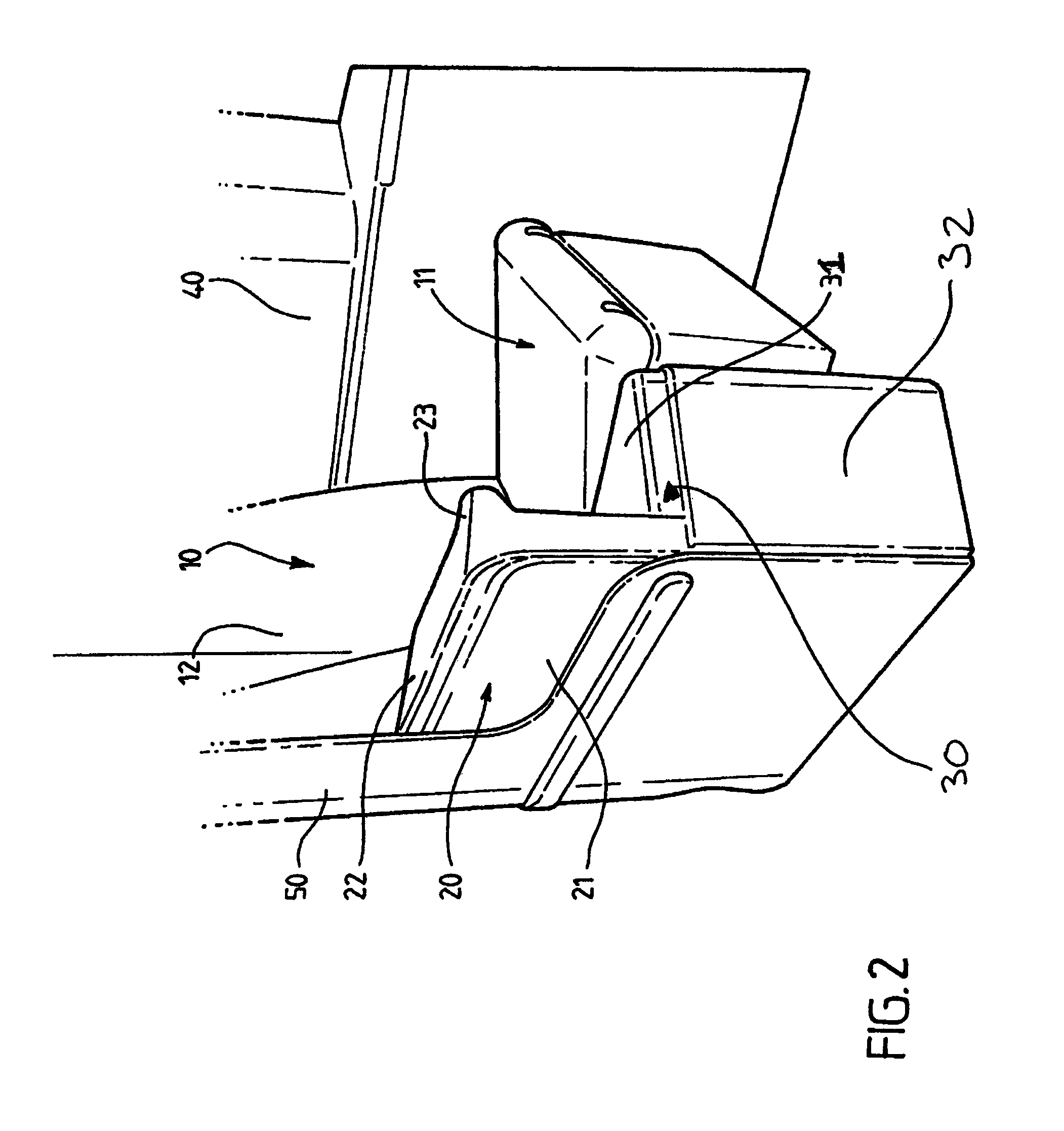

In herringbone seats of the prior art, armrests on the closed angle side form an obstacle for the passengers in the seat in case of a shock, since the latter are generally projected along the axis of the vehicle and thus towards the armrest thus creating a high risk of injury for the passenger in case of a shock. The present invention provides a secure herringbone arrangement for the armrest of a seat i.e. making it possible to reduce the risk of injuries caused by the armrest, in case of a shock. Therefore, the present invention provides to leave a space between the seating part structure and the armrest to enable the passenger on the seat to be projected along the axis of the airplane in case of a shock without hitting the armrest. More precisely, the aim of the invention is a herringbone arrangement for the armrest of a seat wherein the armrest is angularly shifted with respect to the seat, so as to form a free space (33) between the seat and the armrest. The present invention also relates to a seat and a seat assembly provided with such an arrangement.

Owner:SAFRAN SEATS

Secure herringbone arrangement for the armrest of a seat, seat and two seat assembly provided with such an arrangement

ActiveUS8690254B2Reduce riskRestraint torsionSeating arrangementsAir-treatment apparatus arrangementsAirplaneClosed angle

In herringbone seats of the prior art, armrests on the closed angle side form an obstacle for the passengers in the seat in case of a shock, since the latter are generally projected along the axis of the vehicle and thus towards the armrest thus creating a high risk of injury for the passenger in case of a shock. The present invention provides a secure herringbone arrangement for the armrest of a seat i.e. making it possible to reduce the risk of injuries caused by the armrest, in case of a shock. Therefore, the present invention provides to leave a space between the seating part structure and the armrest to enable the passenger on the seat to be projected along the axis of the airplane in case of a shock without hitting the armrest. More precisely, the aim of the invention is a herringbone arrangement for the armrest of a seat wherein the armrest is angularly shifted with respect to the seat, so as to form a free space (33) between the seat and the armrest. The present invention also relates to a seat and a seat assembly provided with such an arrangement.

Owner:SAFRAN SEATS

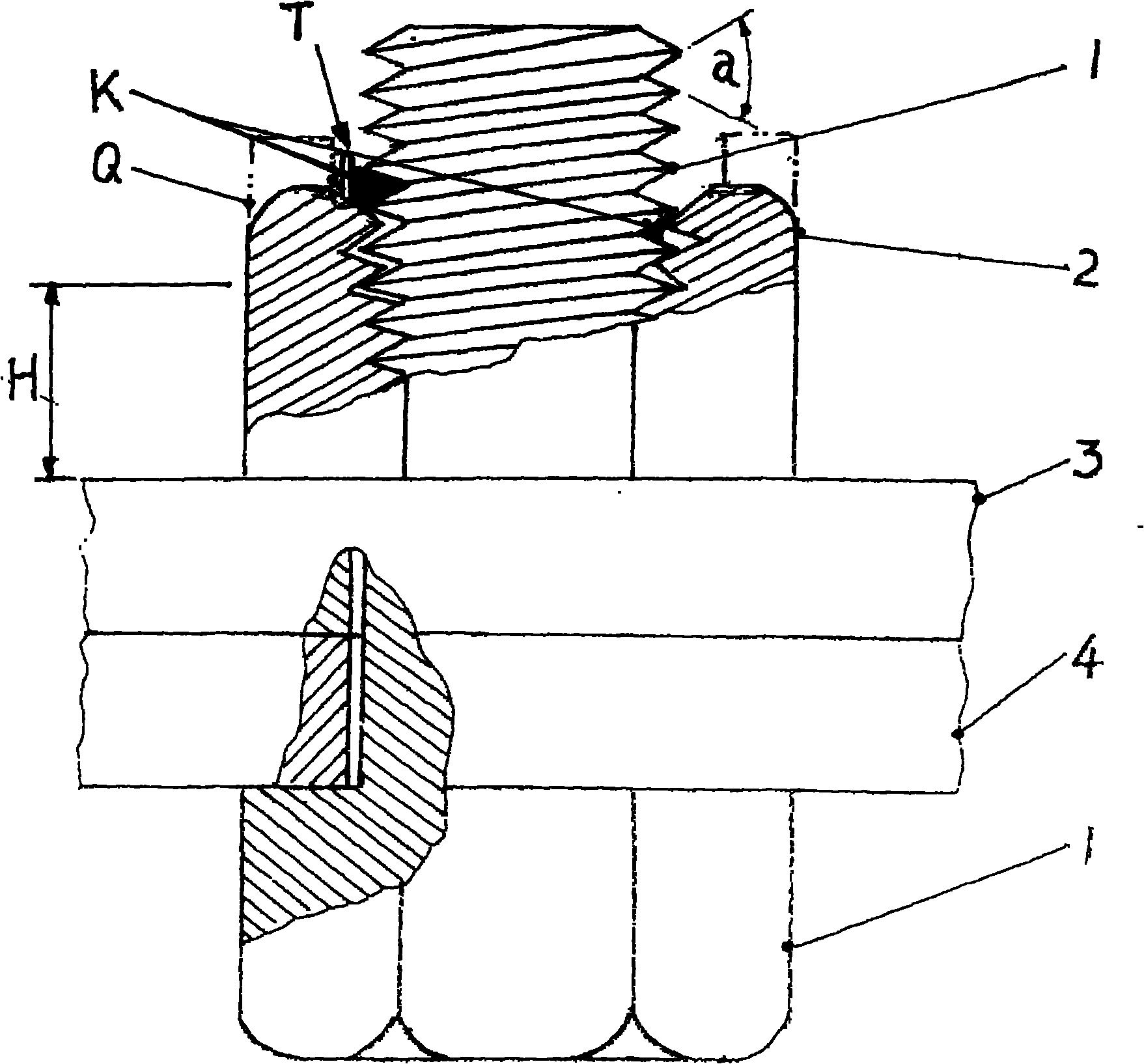

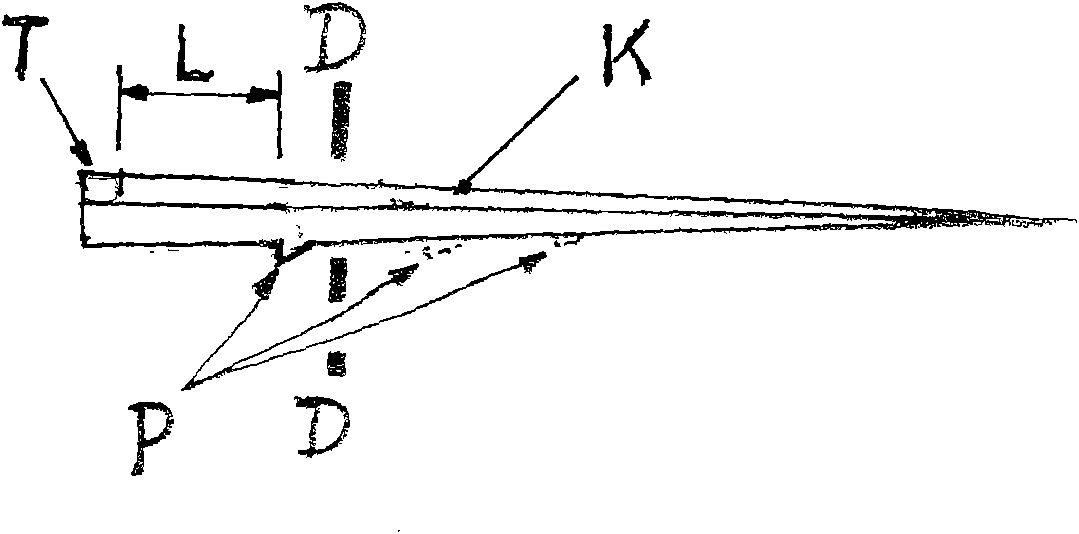

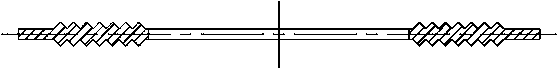

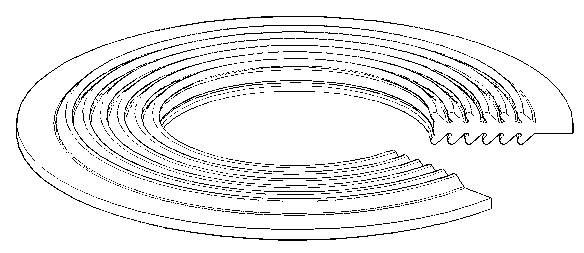

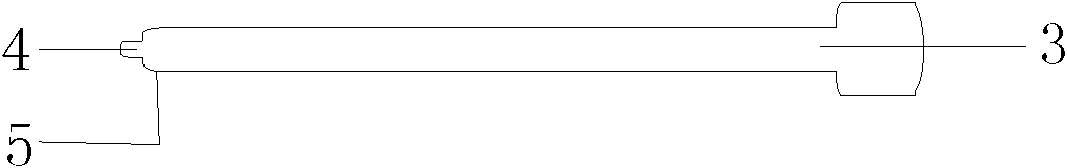

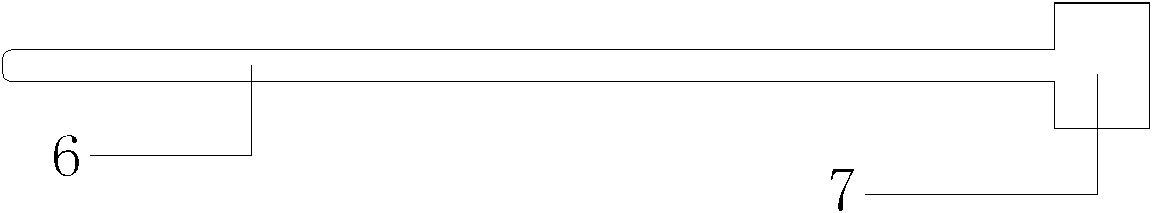

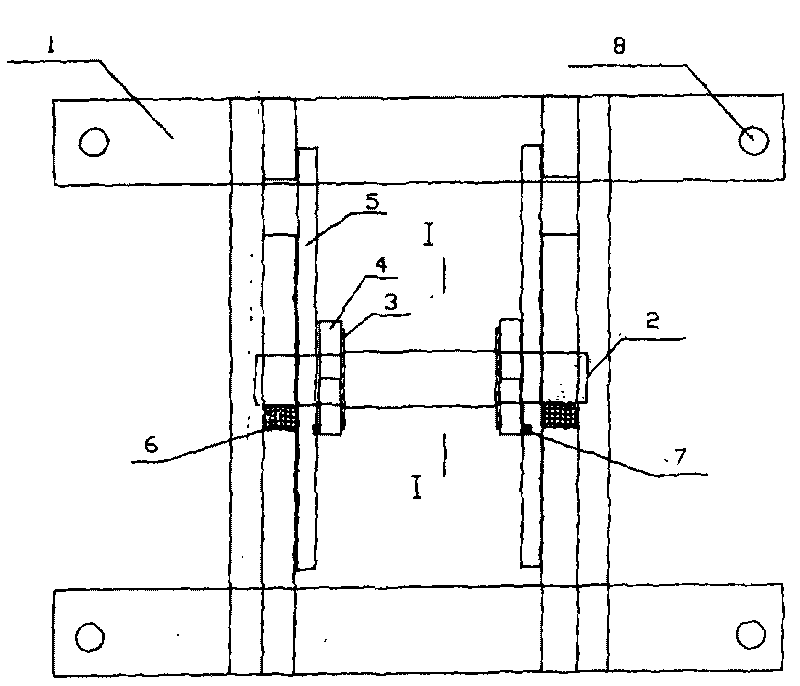

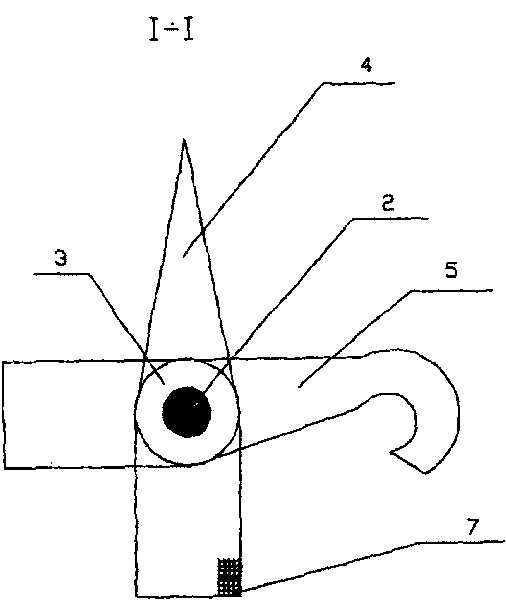

Double-raised-head slope-shaped loosening-proof clamp spring with rivet function screw component and using method thereof

The invention relates to a double-raised-head slope-shaped loosening-proof clamp spring with a rivet function screw component, which is based on the technology of CN100398848C. The double-raised-head slope-shaped loosening-proof clamp spring with a rivet function screw component is characterized in that a single-raised-head slope-shaped loosening-proof clamp spring (K) is lengthened from the rear part, a second raised head which is used for assisting to exit the slope-shaped loosening-proof clamp spring (K) is also arranged at a distance (L) from an anti-skidding closed angle (P) serving as the first raised head of the aftermost part so as to form the double-raised-head slope-shaped loosening-proof clamp spring; and the protruding direction of the second raised head (T) on the clamp spring is different from that of the anti-skidding closed angle (P). A magnetic propelling and screwing special tool absorbs the double-raised-head slope-shaped loosening-proof clamp spring and embeds and positions the double-raised-head slope-shaped loosening-proof clamp spring in the screw component; and a magnetic dismantling special tool screws out the double-raised-head slope-shaped loosening-proof clamp spring and absorbs and sticks out. If the reverse out-screwing force of a nut (2) is used after the double-raised-head slope-shaped loosening-proof clamp spring (K) is propelled and screwed so that the anti-skidding closed angle (P) acts to form a permanently dismountable normal rivet, the dismounting special tool is useless.

Owner:梁嘉麟

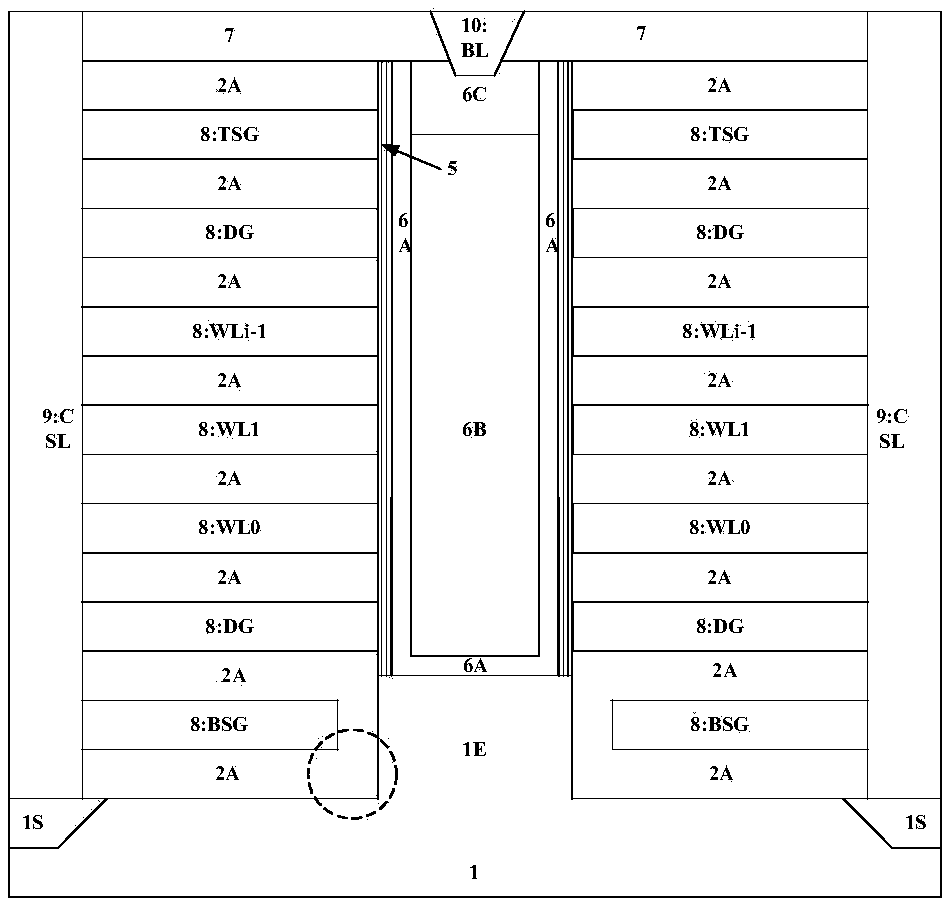

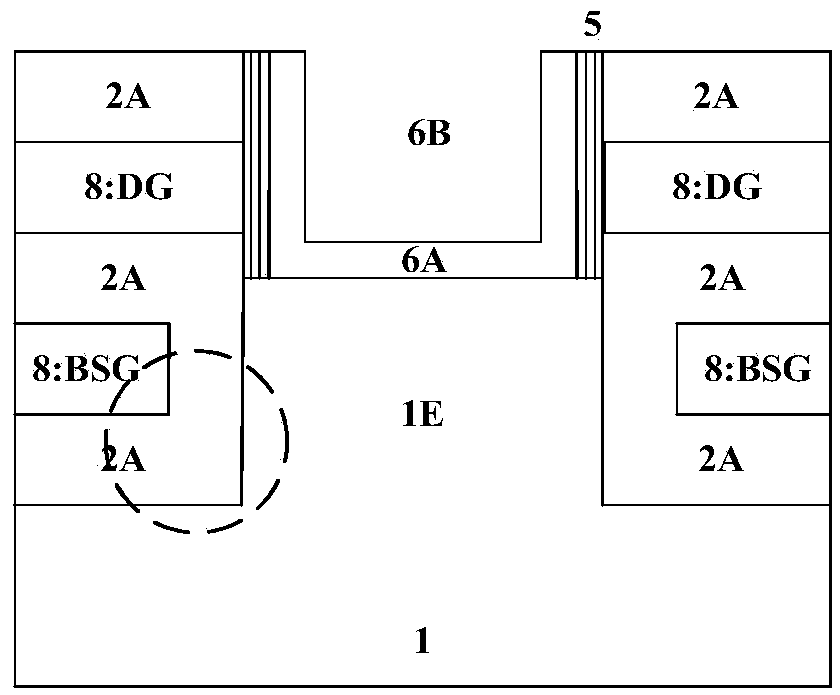

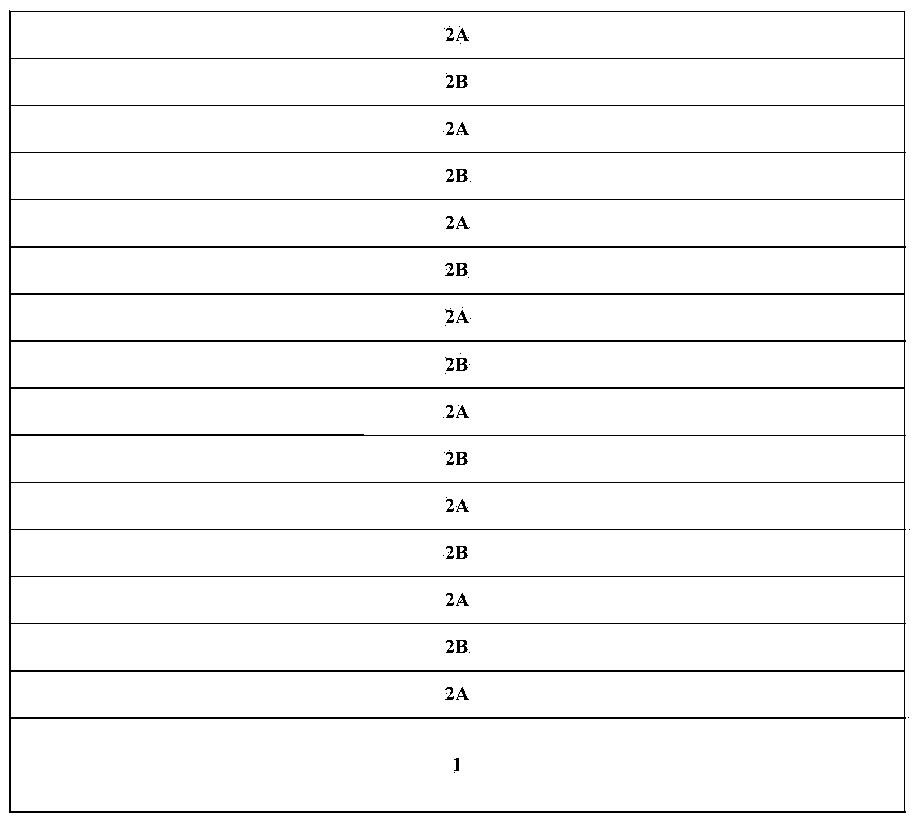

Three-dimensional semiconductor device and manufacture method thereof

ActiveCN105374826AEvenly distributedSuppression of local electric field enhancement effectsSolid-state devicesSemiconductor devicesGate dielectricEngineering

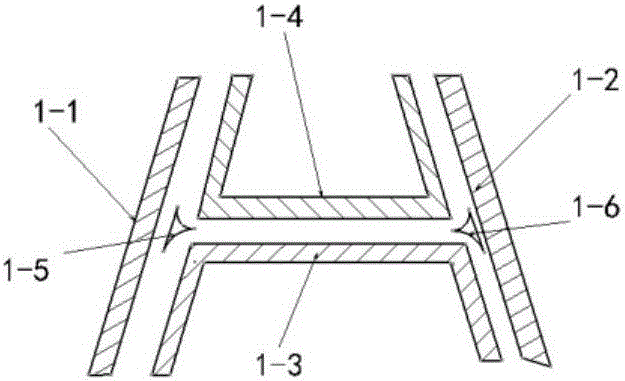

Provided is a three-dimensional semiconductor device which comprises multiple storage units. Each storage unit comprises a channel layer stack, multiple insulated layers, multiple gate conductive layers, a gate dielectric layer, a drain, and a source. The channel layer stack is distributed along the direction vertical to the surface of a substrate. The multiple insulated layers and the multiple gate conductive layers are stacked alternately along the sidewall of the channel layer stack. The gate dielectric layer is arranged between the multiple gate conductive layers and the sidewall of the channel layer stack. The drain is arranged on the top of the channel layer stack. The source is arranged in the substrate between two adjacent storage units of the multiple storage units. The lowest insulated layer is provided with an obtuse or rounded corner portion. According to the three-dimensional semiconductor device and a manufacture method thereof, the closed angle of a transistor on the bottom is made obtuse or rounded in order to suppress a local electric field enhancement effect so that a gate dielectric electric field of the transistor on the bottom is uniformly distributed and reliability is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

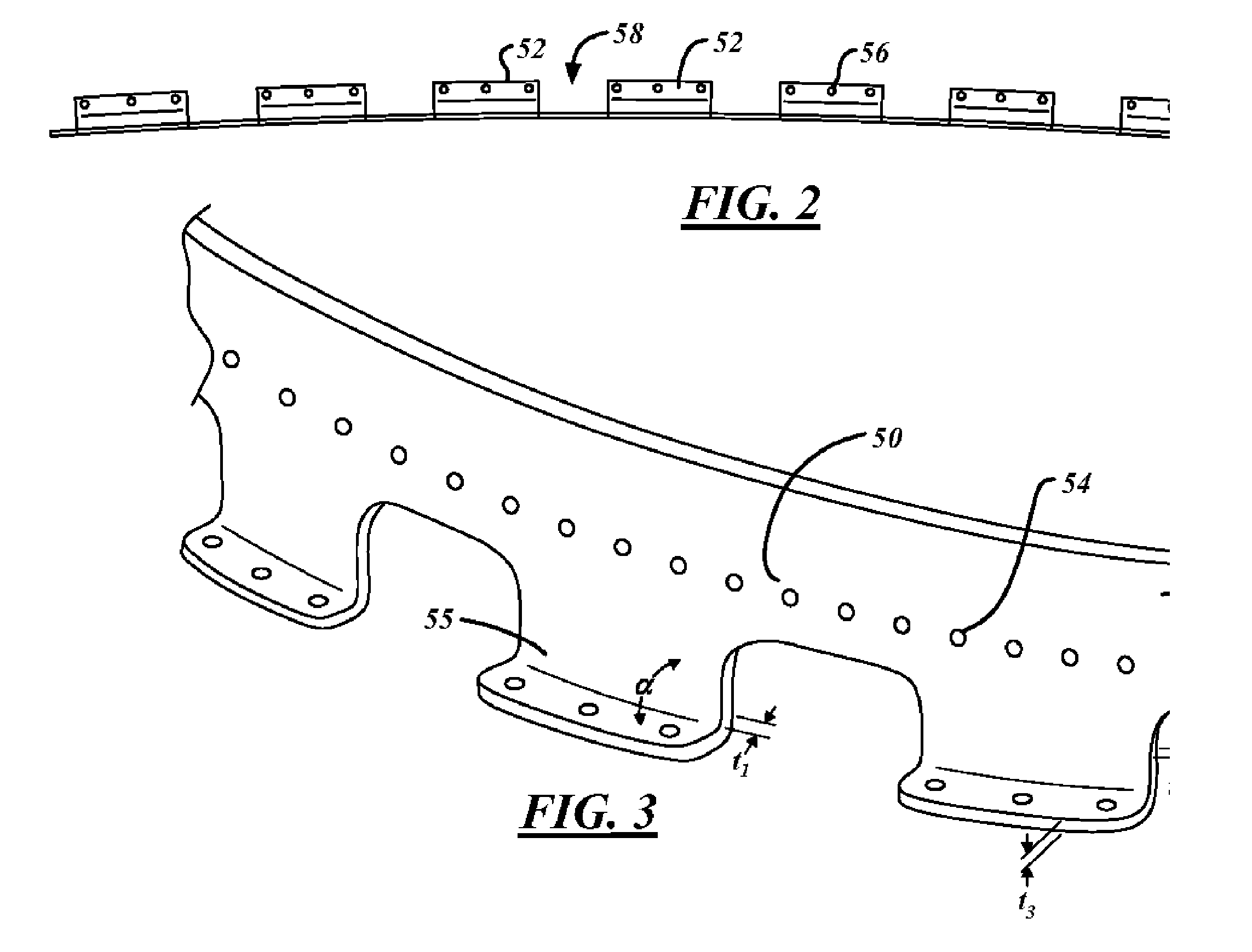

Method to control thickness in composite parts cured on closed angle tool

ActiveUS20070102839A1Improve uniformityUniform thicknessHollow wall articlesBeltsJet aeroplaneAviation

The present invention provides a method for controlling the thickness of composite laminates cured on closed angel tools. The invention utilizes a peel ply rather than a breather during the preparation for cure of laminate parts having a substantially uniform initial thickness. This method allows composite parts to be formed with greater uniformity and without the need for extra hardware. The composite part formed by the above method may find use in a wide variety of applications, including, for example, automotive and aerospace applications. Thus, for example, a composite part formed in accordance with the present invention is ideally suited for use as a shear tie in a commercial aircraft, which are used to secure the inner framework of the aircraft to the airplane skin.

Owner:THE BOEING CO

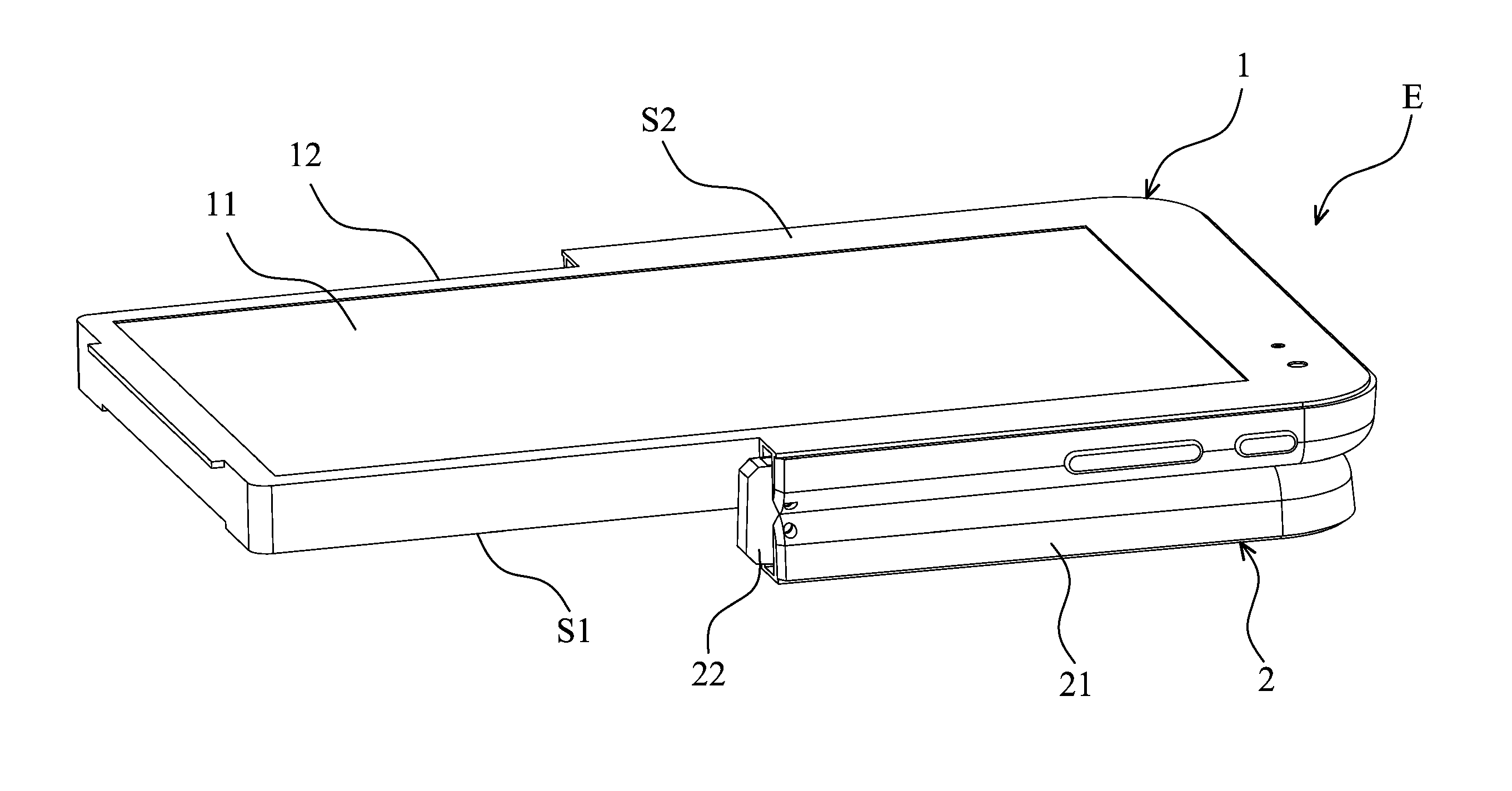

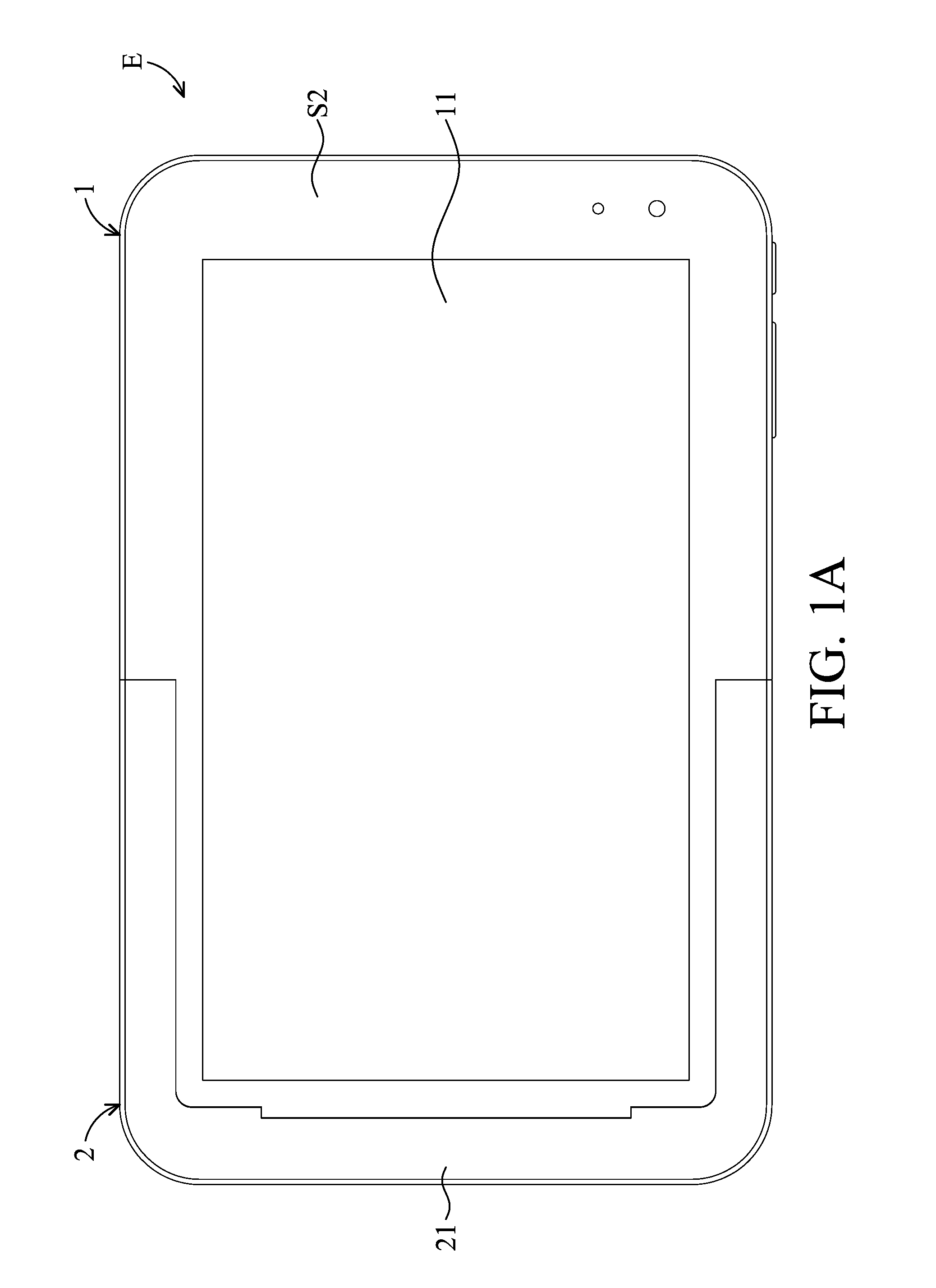

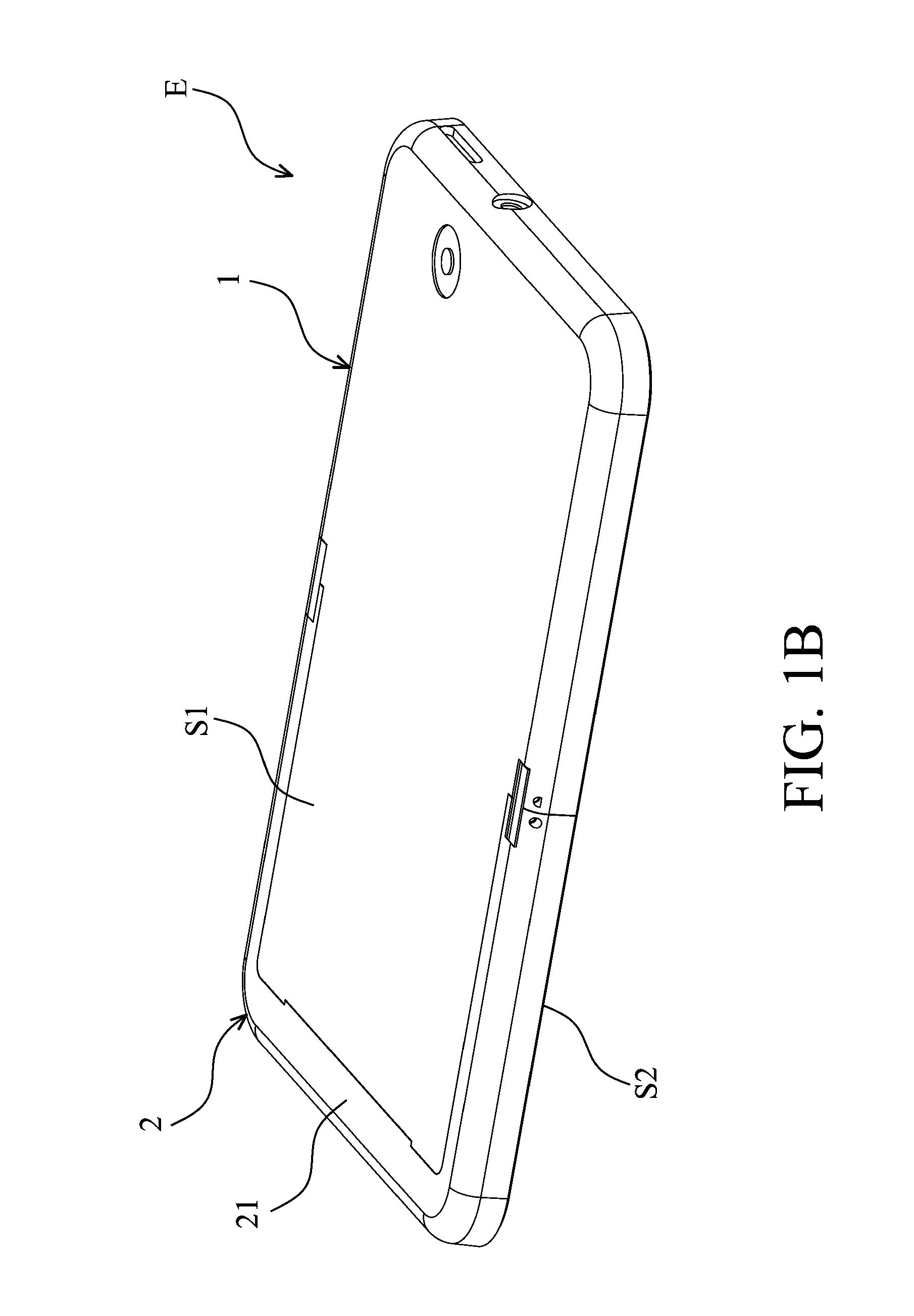

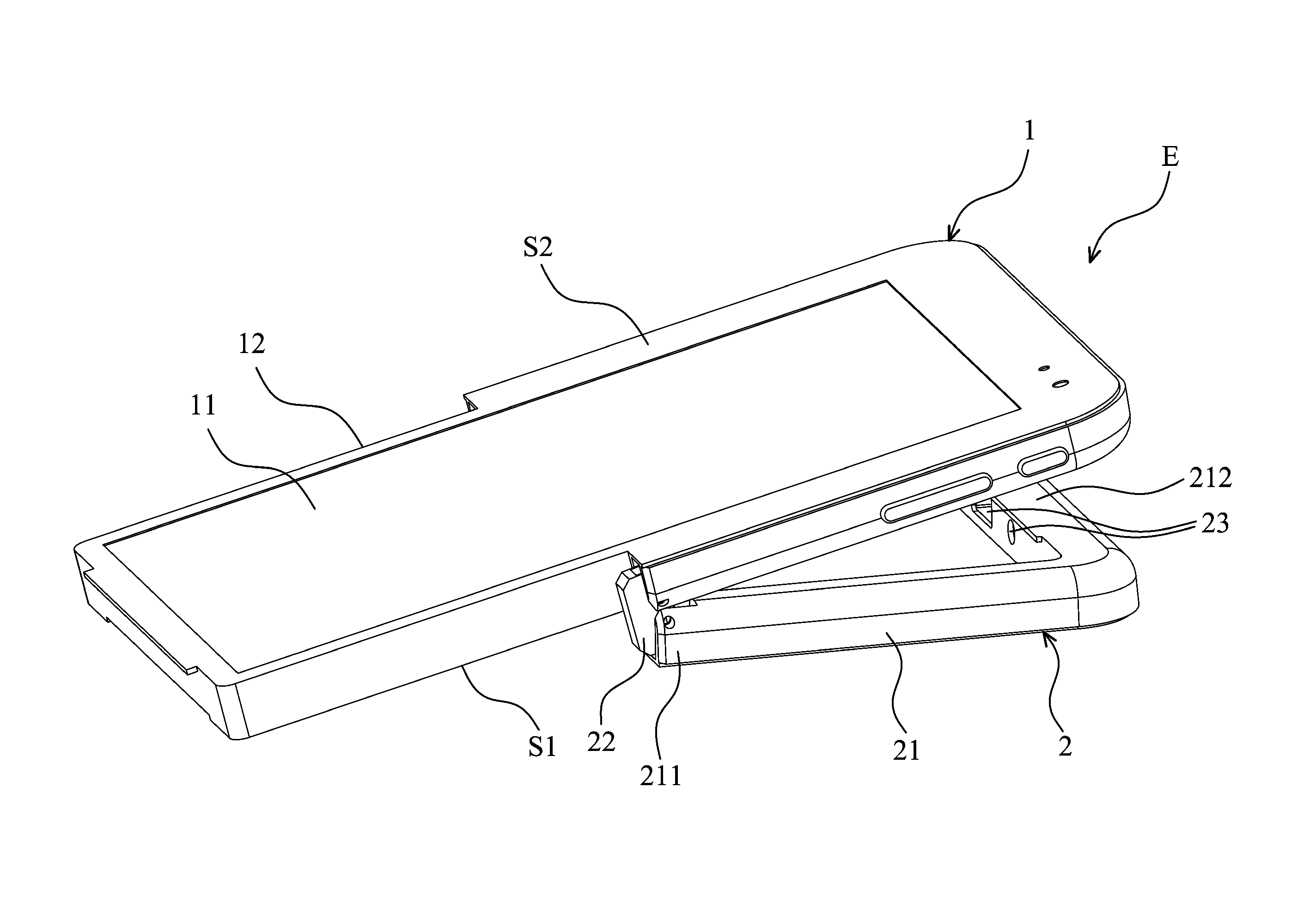

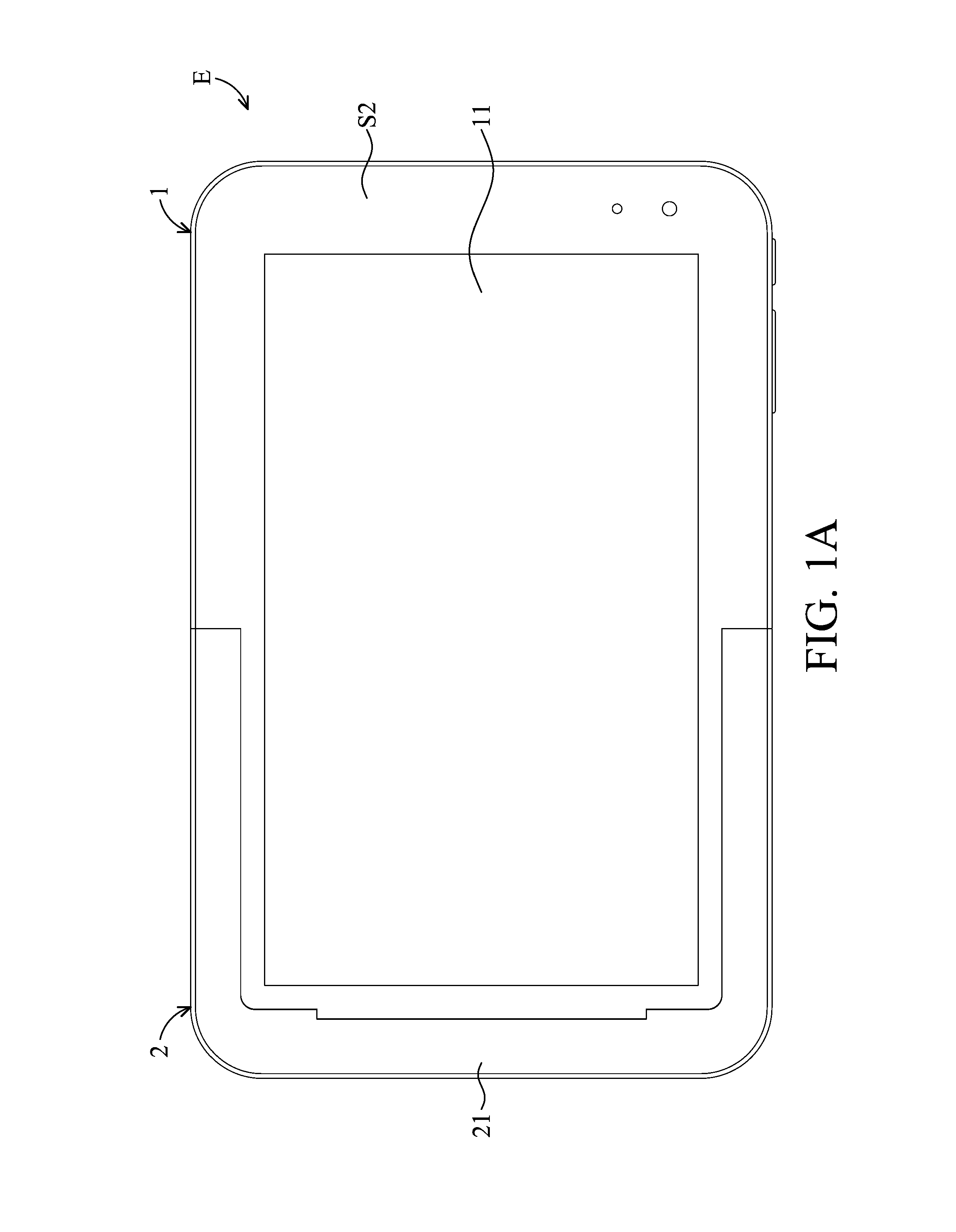

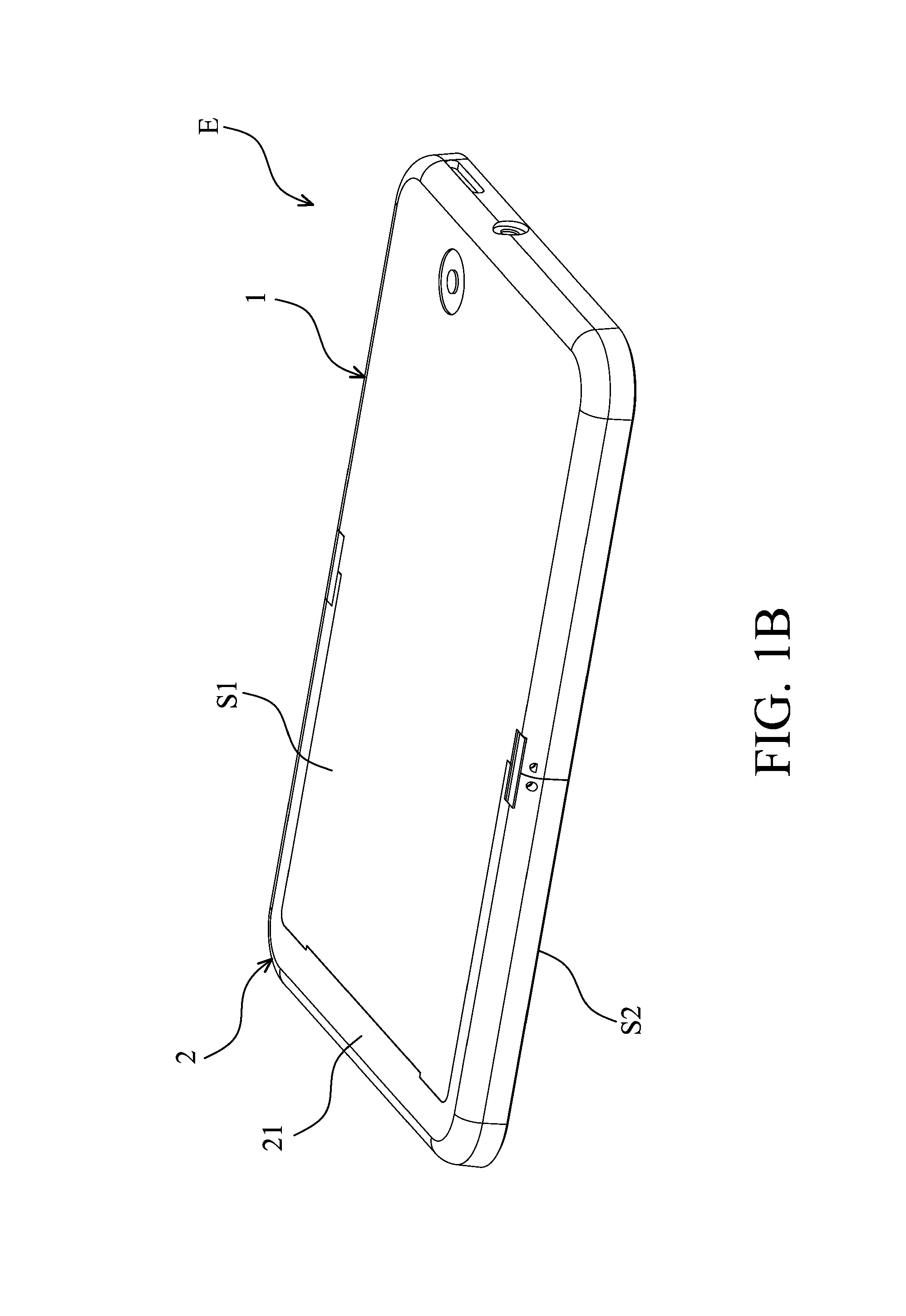

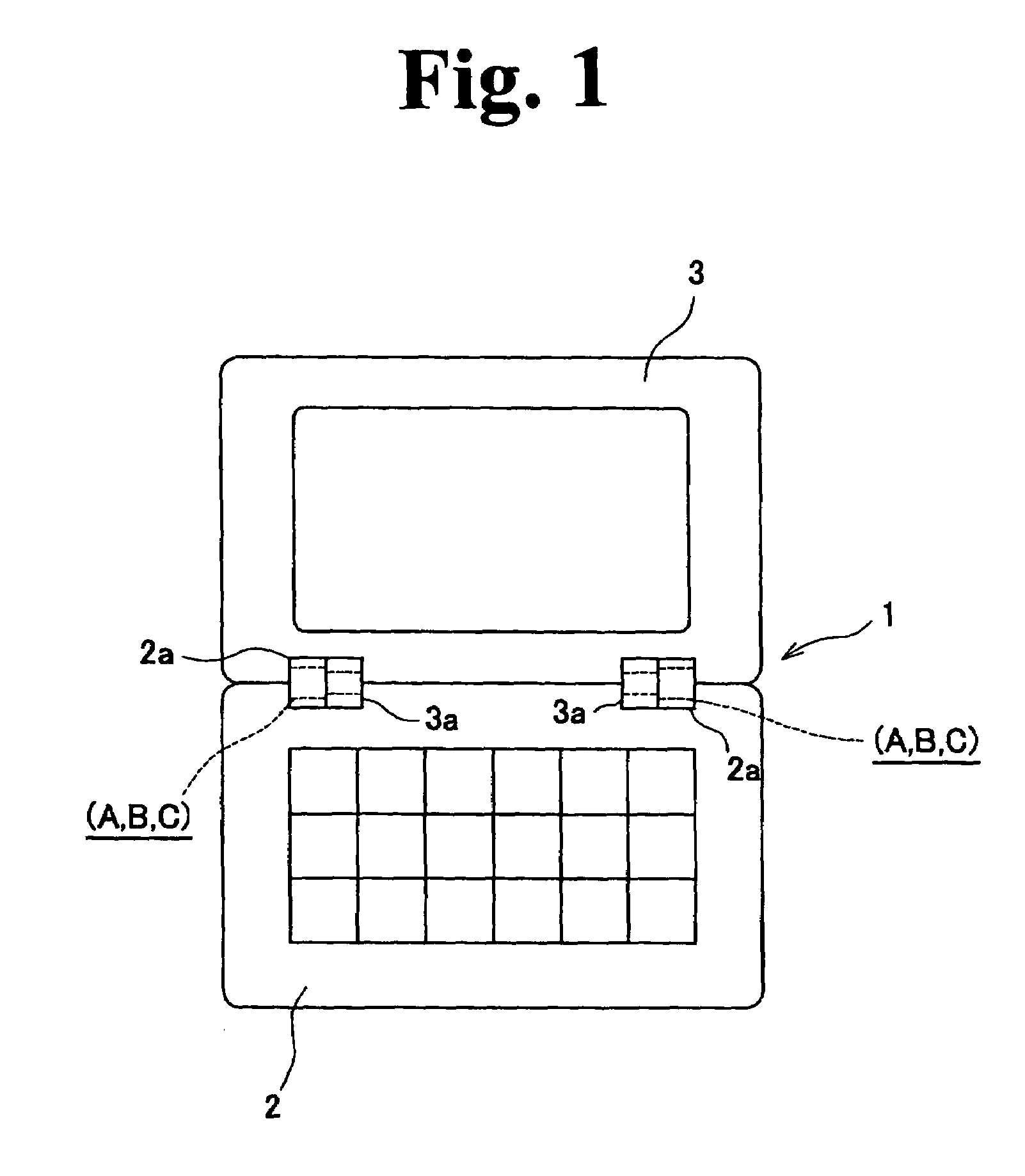

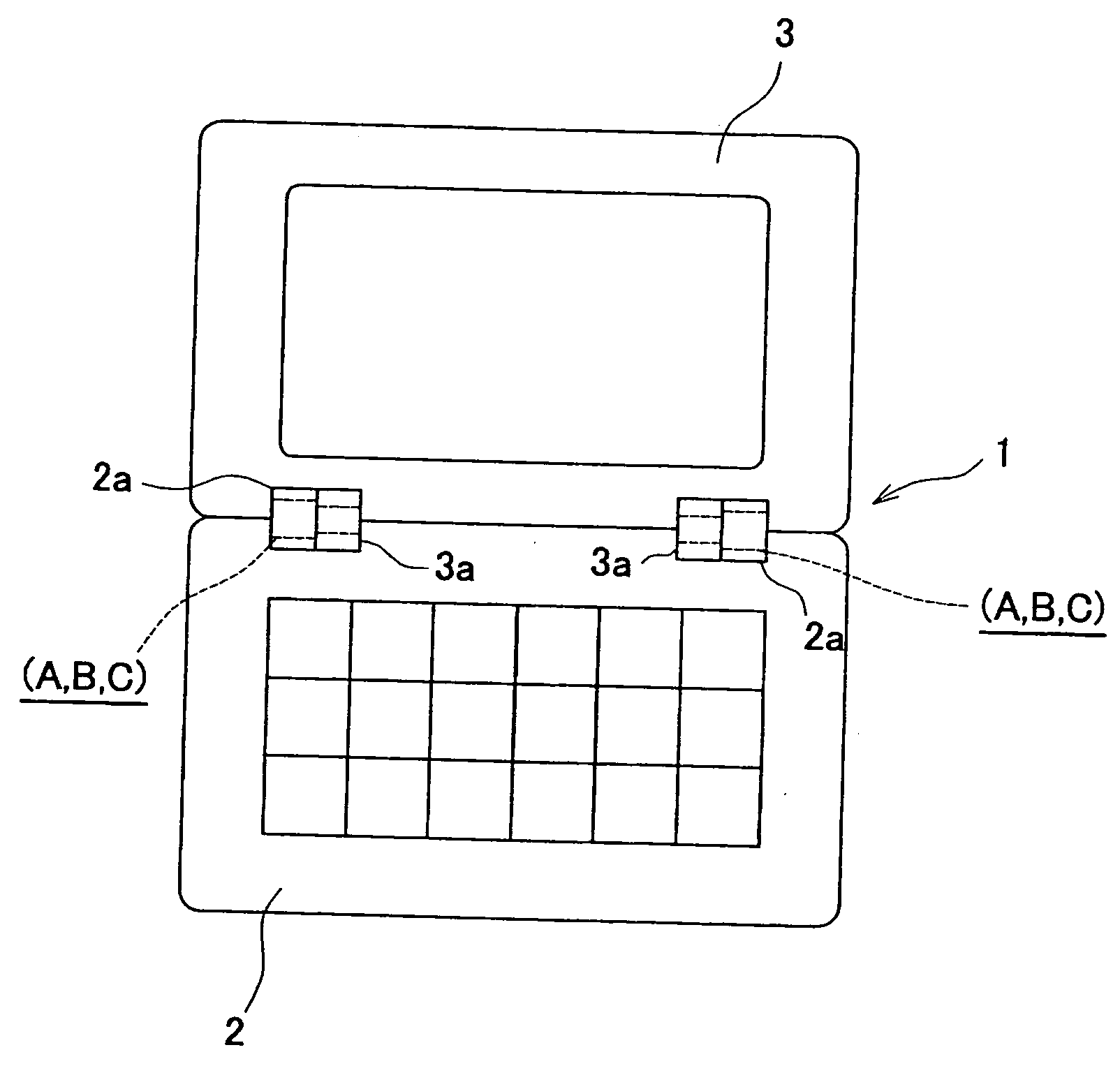

Electronic device and support mechanism thereof

ActiveUS20130335891A1Casings/cabinets/drawers detailsDetails for portable computersElectricityElectrical connection

An electronic device is provided, including a main body and a support mechanism. The main body forms a U-shaped recess. The support mechanism includes a U-shaped support, two pivot members and an electrical connection port. The support forms two ends, and the pivot members rotatably connect the two ends to the main body. The electrical connection port is disposed on the support. When the support is in a closed angle position that is relative to the main body, the support is received in the recess and parallel to the main body, and the electrical connection port is covered by the main body. When the support is rotated relative to the main body and is released from the recess, the electronic device can stand on a surface by the support, and the electrical connection port is exposed to a surface of the support.

Owner:WISTRON CORP

Electronic device and support mechanism thereof

An electronic device is provided, including a main body and a support mechanism. The main body forms a U-shaped recess. The support mechanism includes a U-shaped support, two pivot members and an electrical connection port. The support forms two ends, and the pivot members rotatably connect the two ends to the main body. The electrical connection port is disposed on the support. When the support is in a closed angle position that is relative to the main body, the support is received in the recess and parallel to the main body, and the electrical connection port is covered by the main body. When the support is rotated relative to the main body and is released from the recess, the electronic device can stand on a surface by the support, and the electrical connection port is exposed to a surface of the support.

Owner:WISTRON CORP

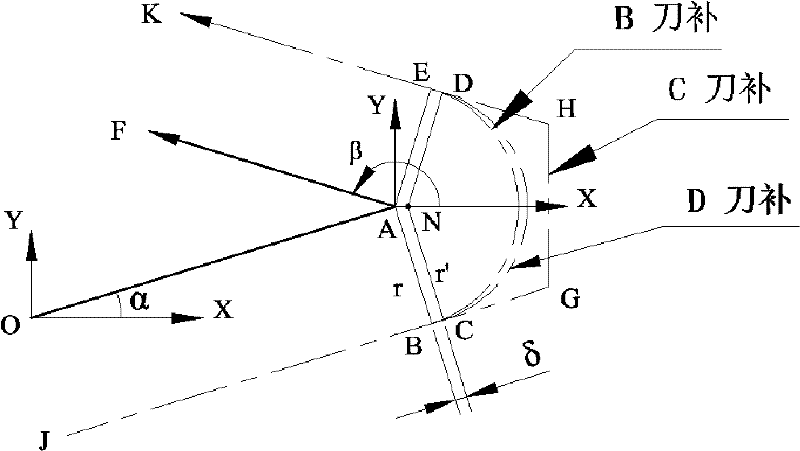

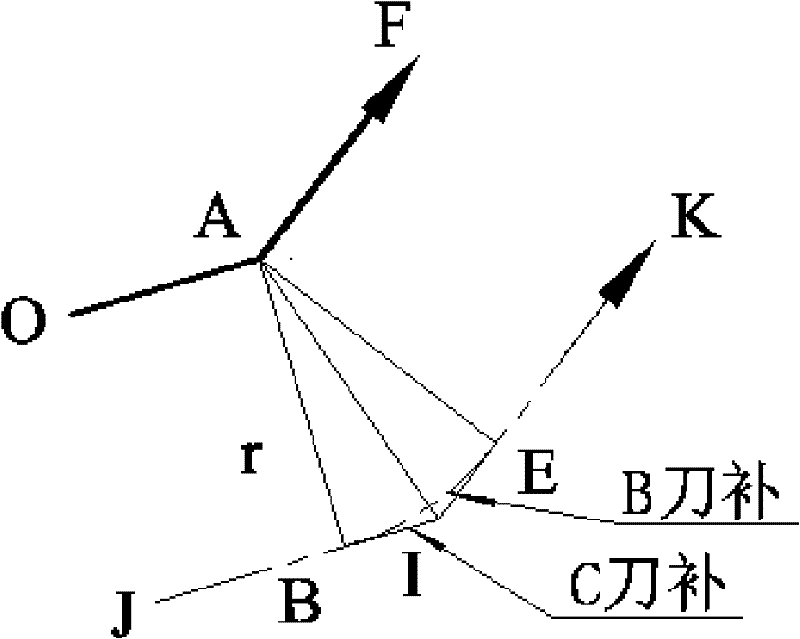

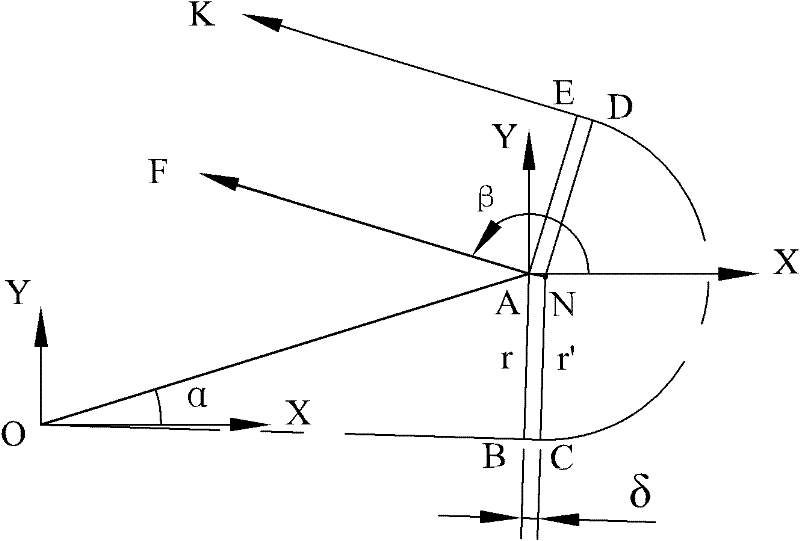

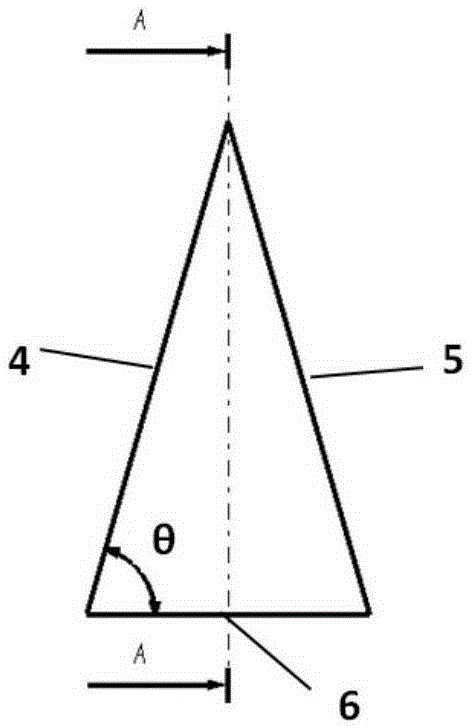

Radius compensation algorithm for convex contour closed-angle linear and circular arc composite transitional cutting tool

InactiveCN102354157AAvoid burnsSolve the problem that frequent acceleration and deceleration is required and it is difficult to increase the processing speedProgramme controlComputer controlEngineeringIncenter

The invention discloses a radius compensation algorithm for a convex contour closed-angle linear and circular arc composite transitional cutting tool, namely D-type cutting tool radius compensation. The radius compensation algorithm comprises the following steps of: taking a ling segment BC, a circular arc CD and a line segment DE as a cutting tool central track of the radius compensation algorithm for the linear and circular arc composite transitional cutting tool; calculating the coordinate of a switching point; and establishing or canceling cutting tool radius compensation. Because the cutting tool central track is extended at a convex contour closed-angle transitional part, the cutting tool cannot always contact an A point any more, and the problem of closed-angle burn caused by B-type cutting tool radius compensation which stays at a closed-angle part for an overlong time is effectively solved. Due to the adoption of circular arc transition at the convex contour closed-angle transitional part, the cutting tool central track is smooth and continuous, and the problem that frequently acceleration and deceleration are required and the processing speed is difficult to improve because of broken line transition of C-type cutting tool radius compensation. The length of the cutting tool central track of the D-type cutting tool radius compensation is longer than that of the cuttingtool central track of the B-type cutting tool radius compensation, and is shorter than that of the cutting tool central track of the C-type cutting tool radius compensation.

Owner:DALIAN JIAOTONG UNIVERSITY

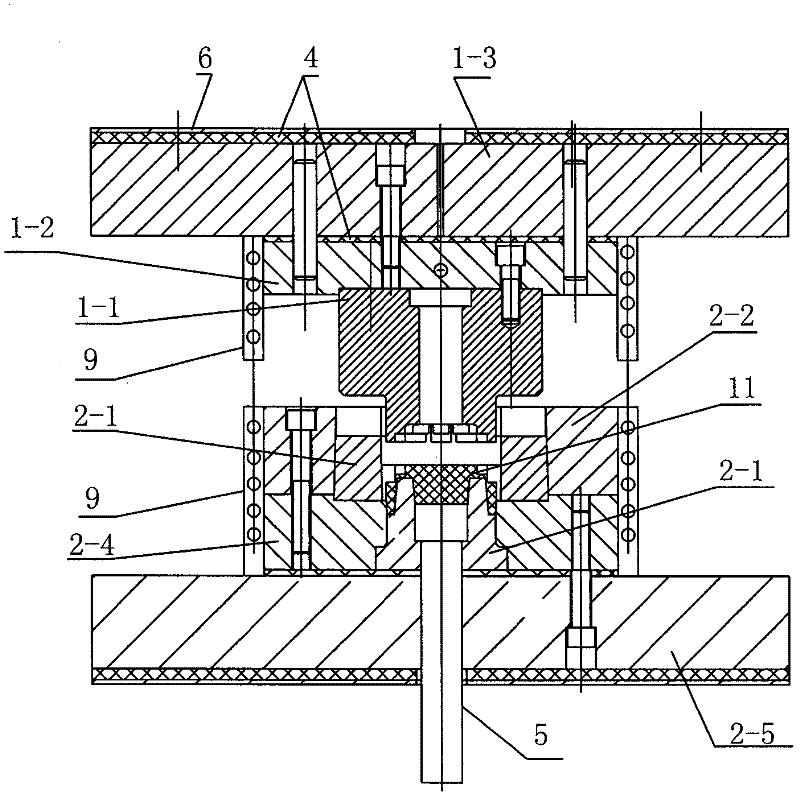

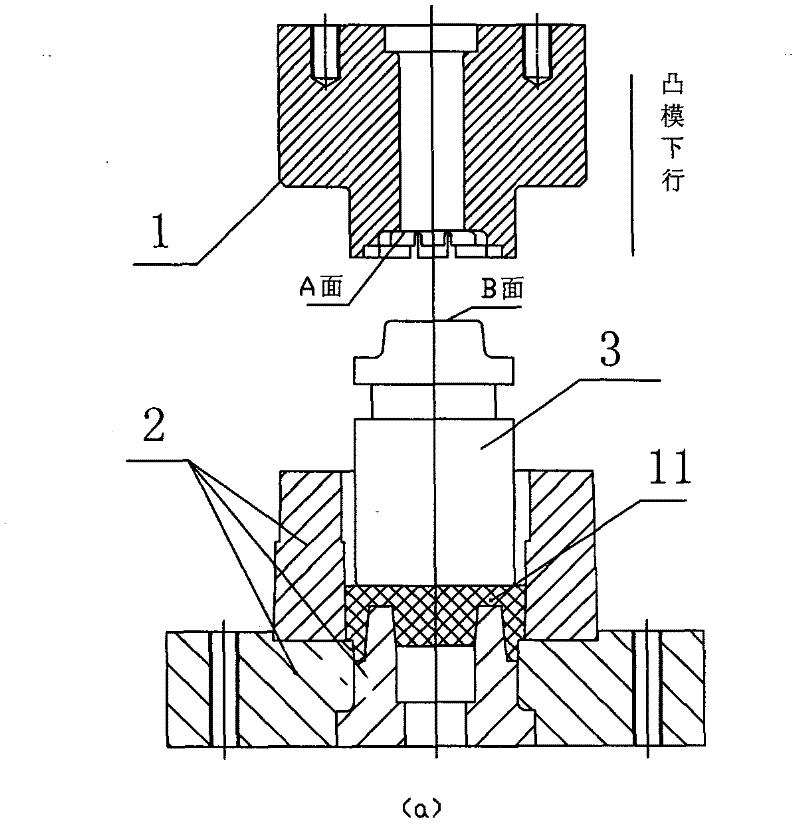

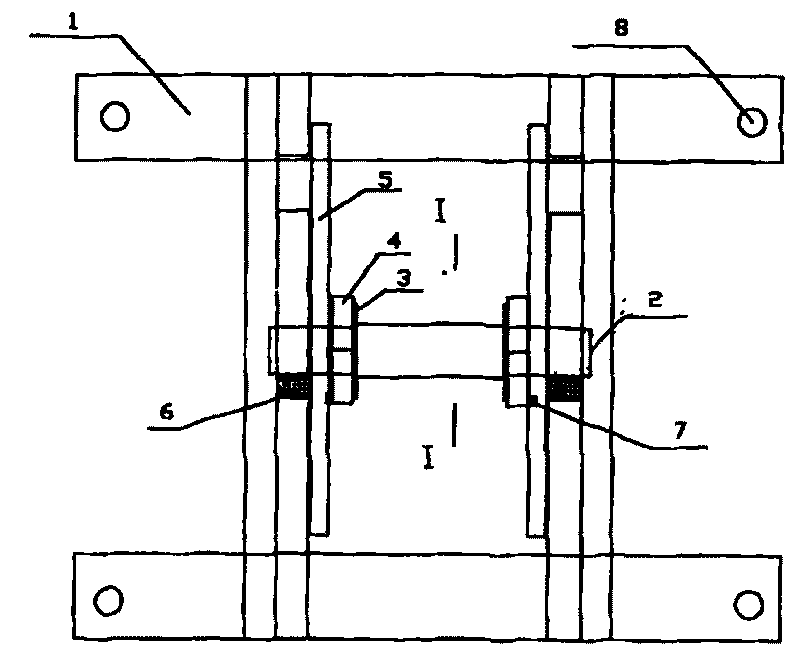

Accurate extrusion mould and method of light alloy stepped workpiece

The invention relates to an accurate extrusion mould and method of a light alloy stepped workpiece. The accurate extrusion method of the light alloy stepped workpiece is characterized by comprising the following steps of: processing a convex crossed guide on a convex mould part and a crossed guide groove on a concave mould part, wherein the convex crossed guide is matched with the crossed guide groove; retaining the thickness of a step shape on a preformed planar blank; and filling metal into a cavity part, which is arranged on the side wall of the cuspidal edge and closed angle stepped surface of a convex mould or a concave mould and is provided with a groove used for metal flow in a vertical direction, by adopting a flow direction sequence control method so as to achieve the purpose of the formation of a cuspidal edge and closed angle step of the workpiece; and placing isopyknic blanks into the concave mould by adopting primary heating: a. prepressing by using a prepressing mandril, and b. finally forming by using the convex mould. The accurate extrusion module and method provided by the invention have the advantages of high utility ratio of materials, short manufacturing process, high accuracy and efficiency, low cost, and the like.

Owner:ZHONGBEI UNIV

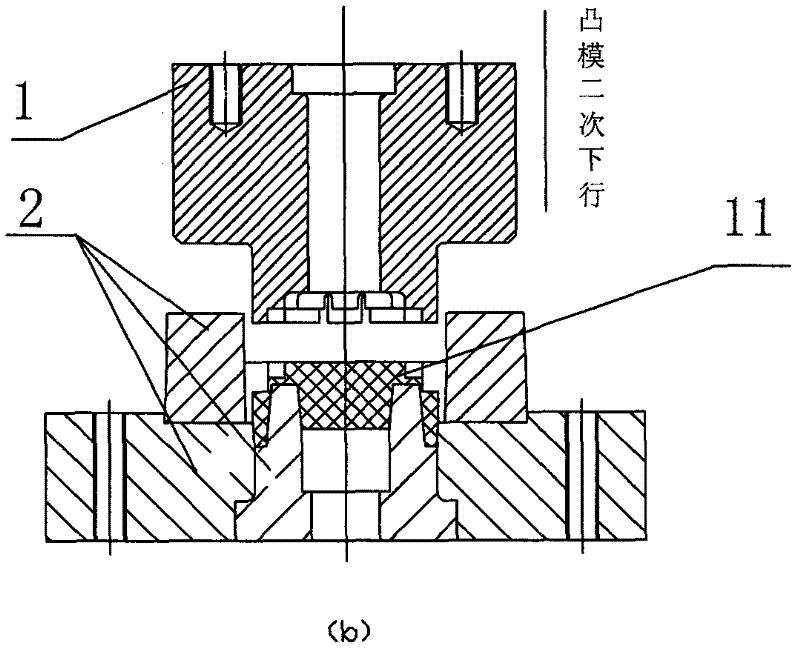

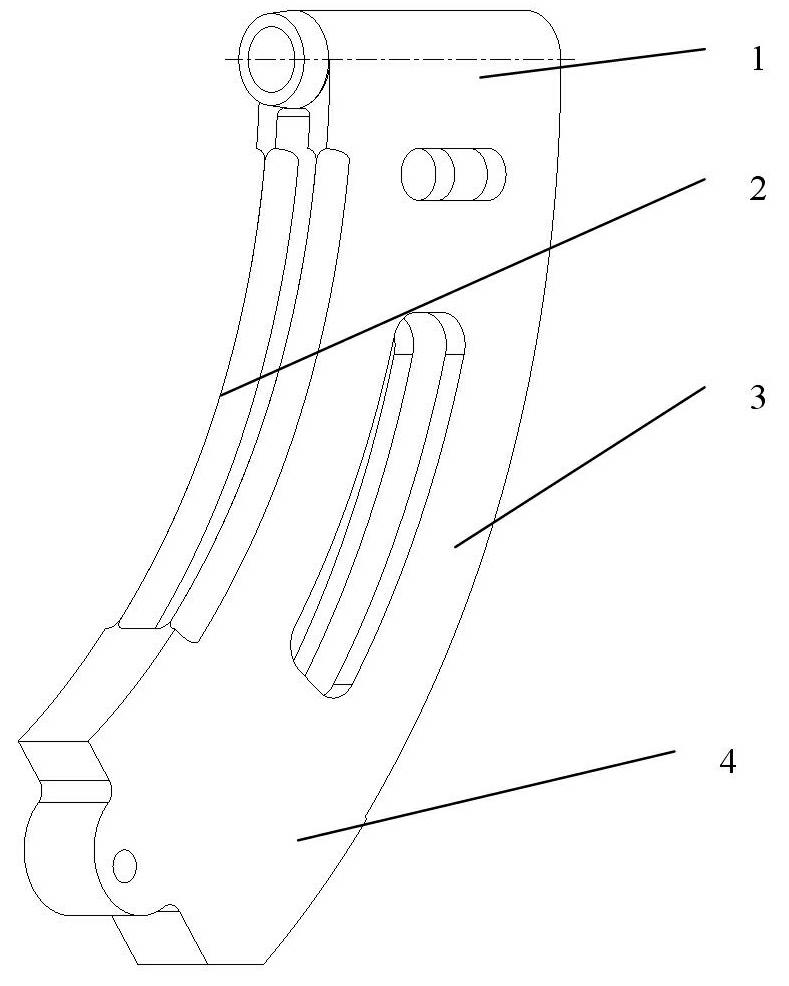

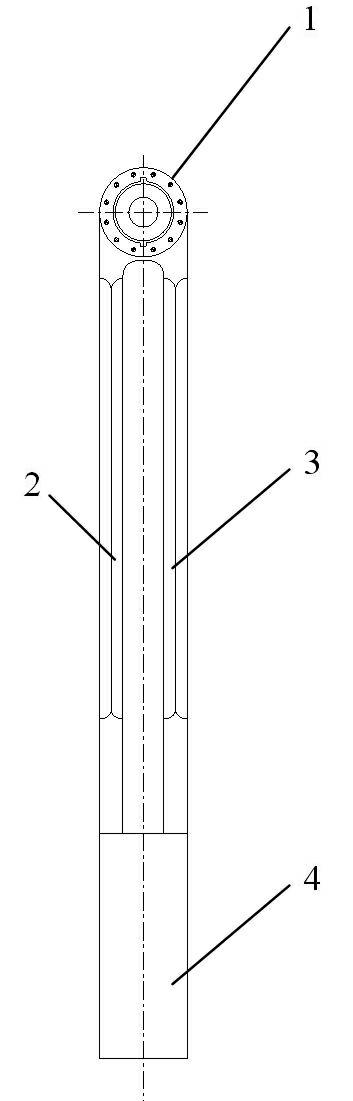

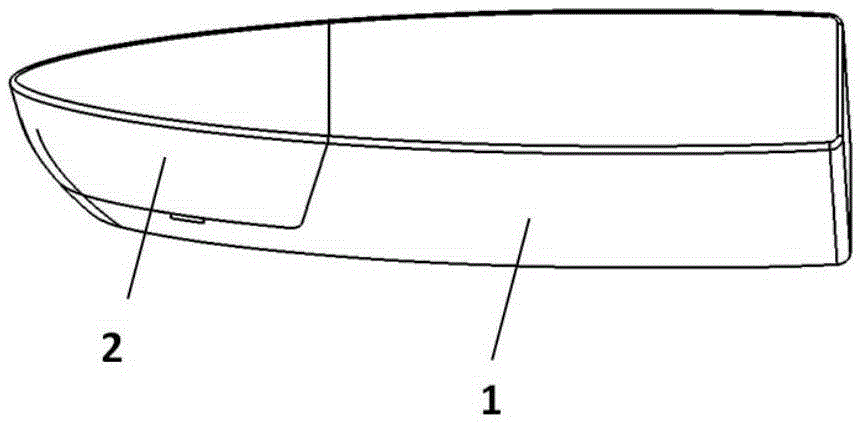

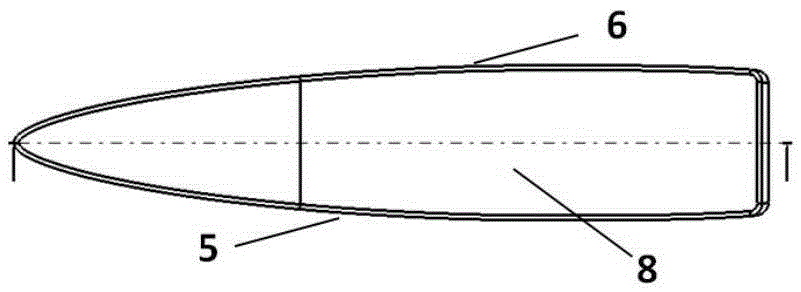

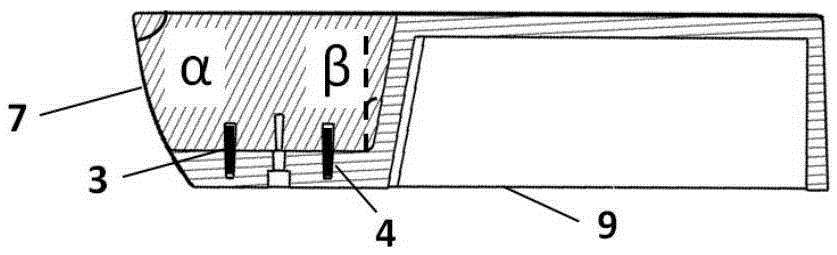

Framework-type support component for wind tunnel test model

InactiveCN102494866AImprove carrying capacityImprove support stiffnessAerodynamic testingEngineeringModel test

The invention belongs to the technical field of aerodynamic wind tunnel test, and provides a framework-type support component for a wind tunnel test model. The support component is of a sector framework-type support structure comprising a middle support, a left support plate, a right support plate and a lower connecting seat, a discharge channel is arranged in the middle of the support component, discharge holes are arranged on the left and the right of the support component, and a windward side is provided with a windward airflow closed angle. When in a wind tunnel test, airflow can pass through a framework, so that airflow blockage due to a support device is decreased. The support component is capable of solving the problem that a test model support component greatly blocks airflow and is insufficient in rigidity under the action of high-speed aerodynamic force when a wind tunnel is in a lateral-directional model test.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

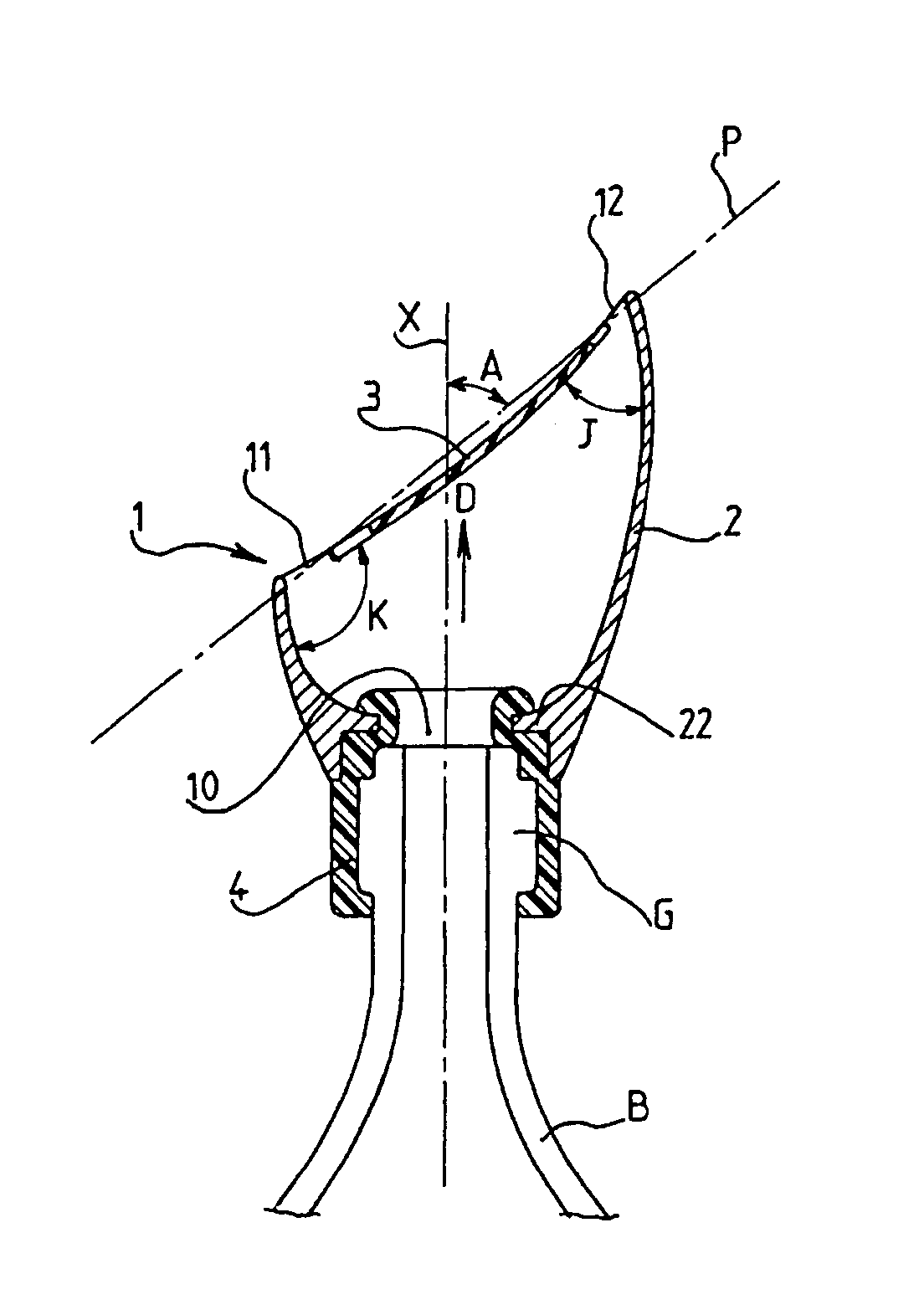

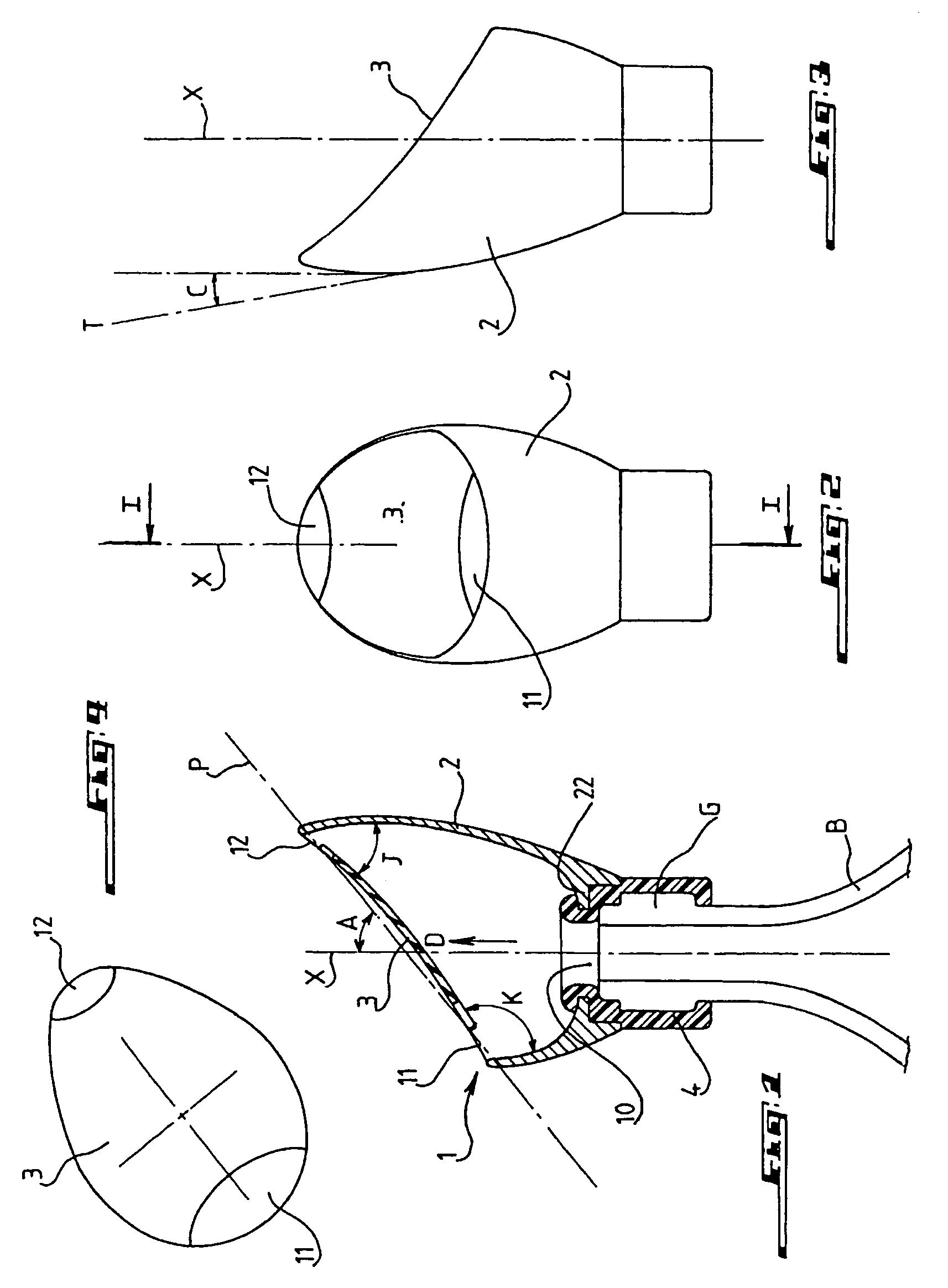

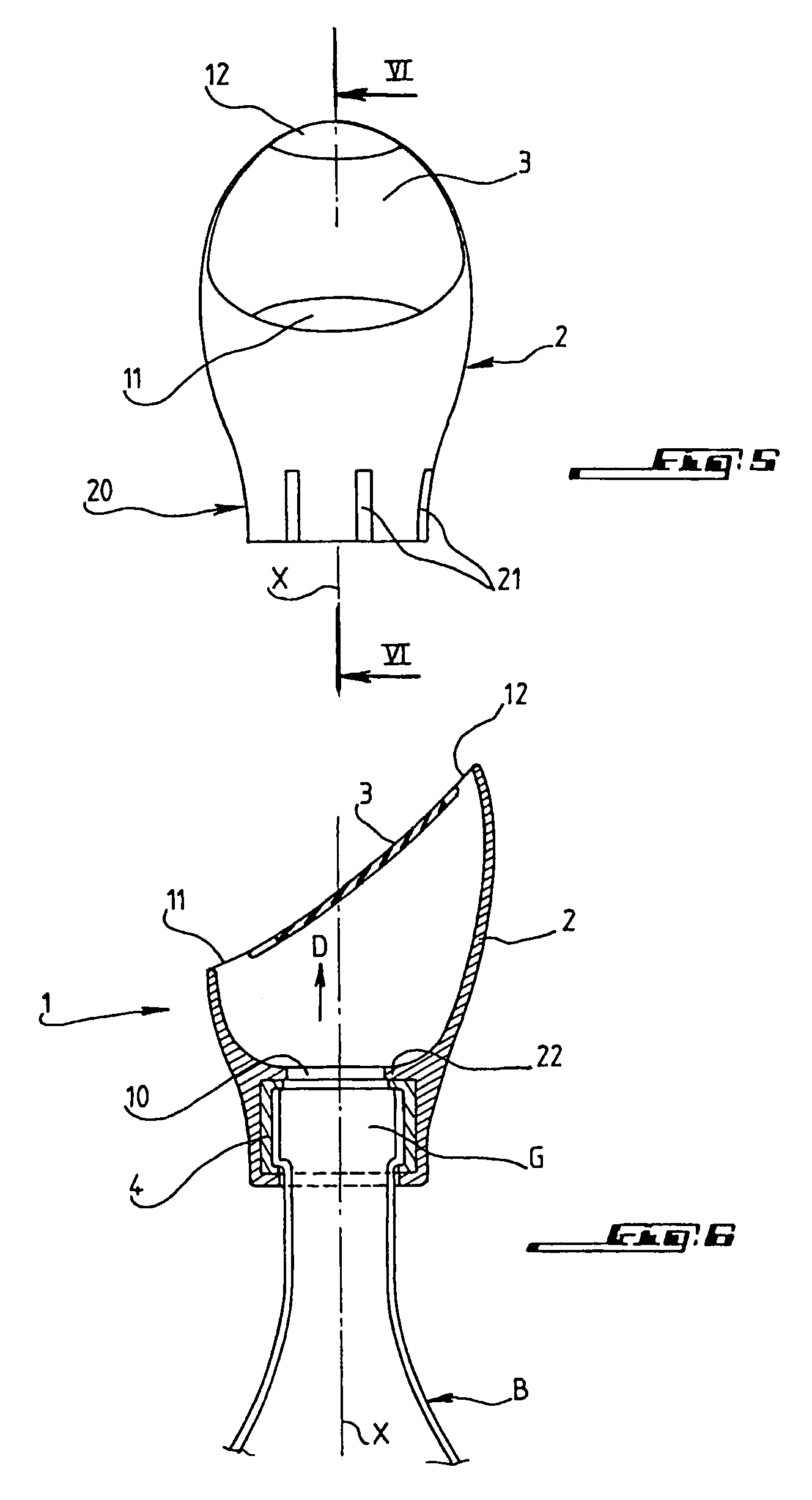

Drinking-cup for beverage consumption, and use for tasting champagne

A drinking-cup placed on a bottle containing a beverage to be consumed. The drinking-cup has a hollow body pierced by a beverage intake, an air intake, and a mouth, and defined by a wall with an annular cross-section enclosing an axis. A closure wall is arranged obliquely relative to the axis. The air intake and the mouth are in respective connecting zones and form an open angle and a closed angle between the wall having an annular cross-section and the closure wall. The wall with an annular cross-section is a surface of rotation and flares out at some distance from the beverage intake. A mid-plane connecting the air intake to the mouth forms, with the axis, an angle not less than 30 degrees. The cup is particularly applicable to champagne tasting.

Owner:VEUVE CLICQUOT PONSARDIN MAISON FONDEE & 1772

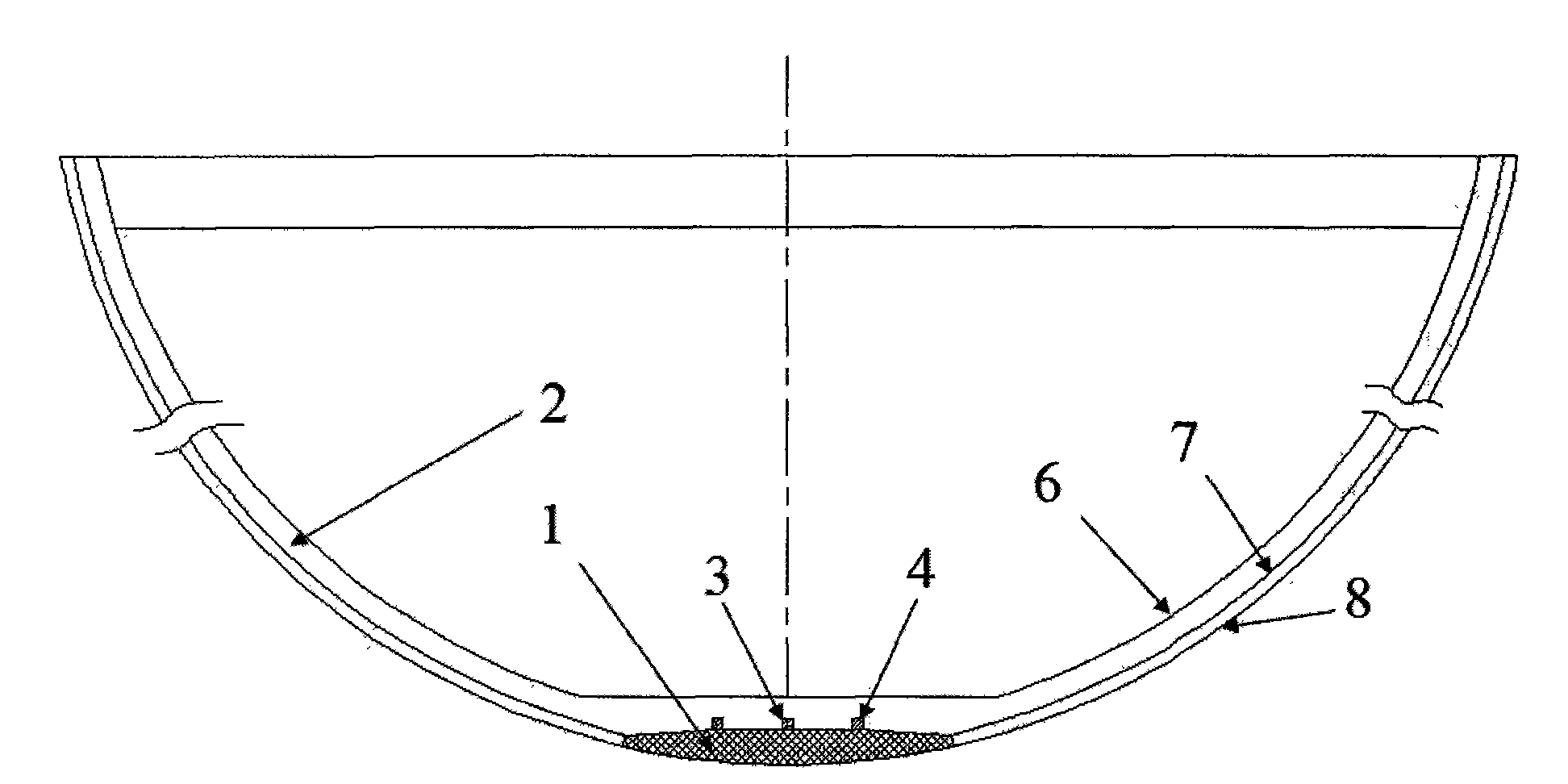

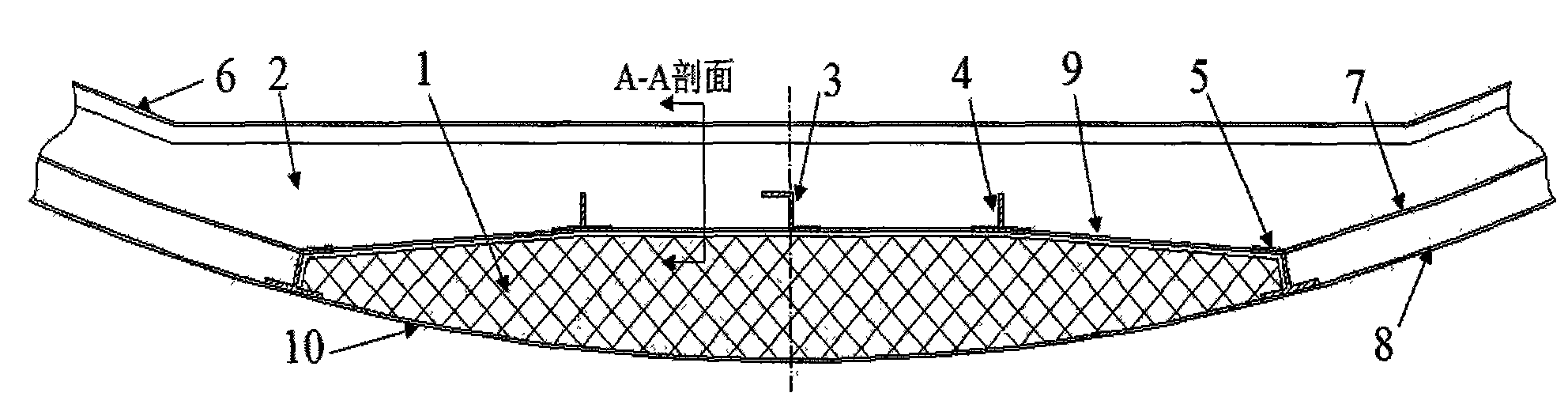

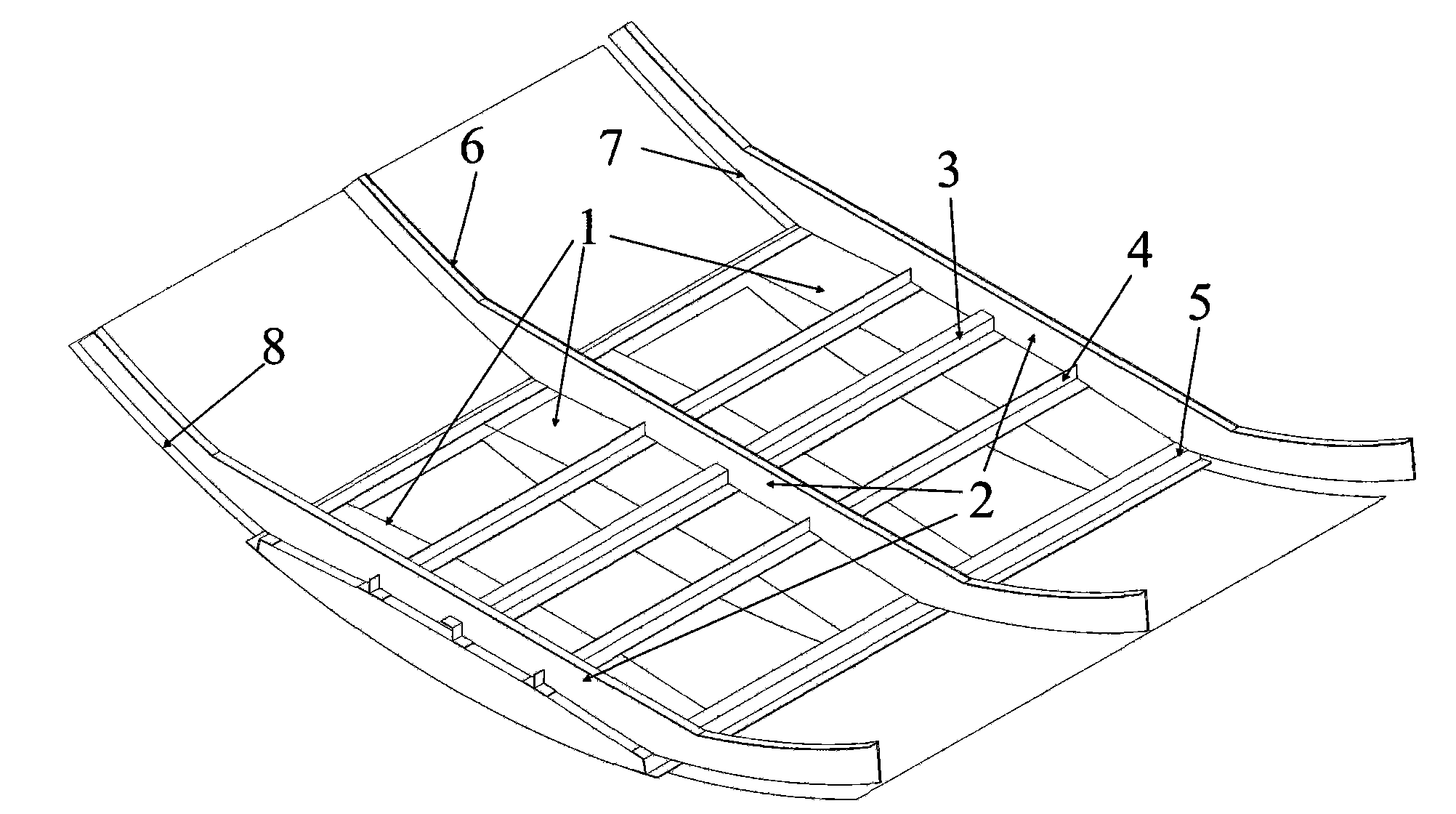

Civil aircraft fuselage bottom structure based on impact strength tests

The invention discloses a civil aircraft fuselage bottom structure considering impact strength, comprising bulkheads, outer panel skin, long purlins and foam; on the foundation of arc-shaped fuselage bulkheads, the contour of the fuselage remains unchanged, upper architraves and lower architraves of the bulkheads are hoisted upwards, the arc shape of the bulkhead bottom is changed to the flatbottom shape, the lower part of each bulkhead is symmetrically provided with a piece of foam, the ends at the two sides of the foam are provided with non-closed-angle-shaped structures in certain height, the lower part of the foam is supported by ventral outer panel skin, the top and sides of the foam adopt the outer panel skin for supporting, the two sides and the top of the foam are provided with long purlin structures which have the function of longitudinal reinforcement. The fuselage bottom foam structure of the invention can greatly improve the crash resistance of the fuselage structure, the new structure consisting of the outer panel skin and the foam contributes to bearing distributed load, as a result, the fuselage bottom structure of the invention not only has good crash resistance against ground crash but also has good crash resistance against water surface impact accidents.

Owner:BEIHANG UNIV

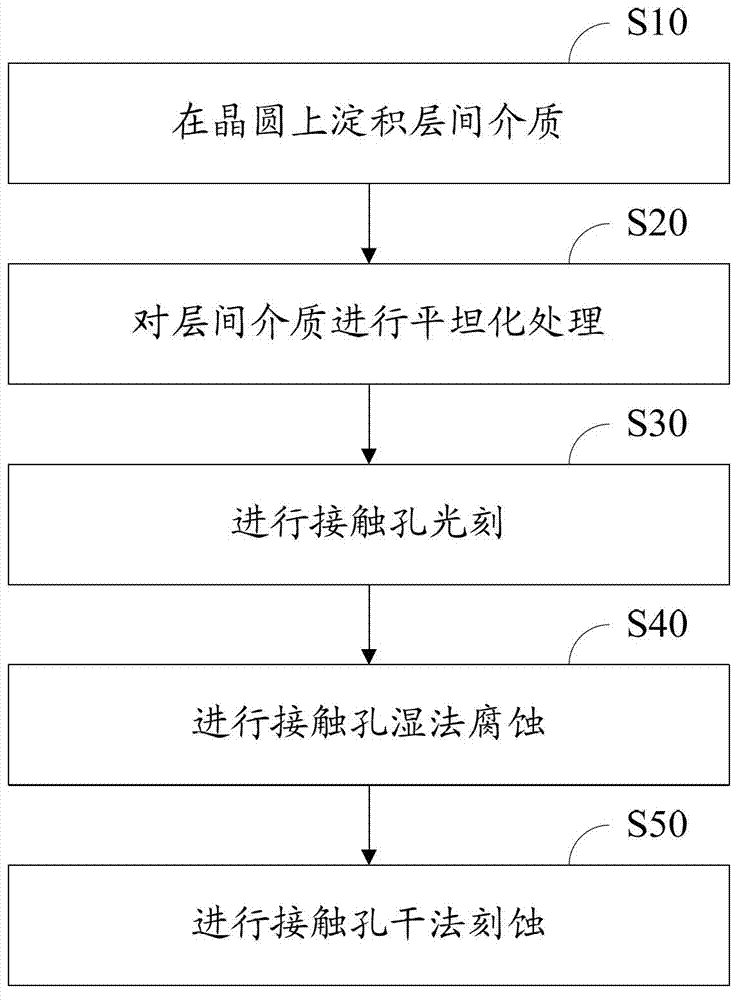

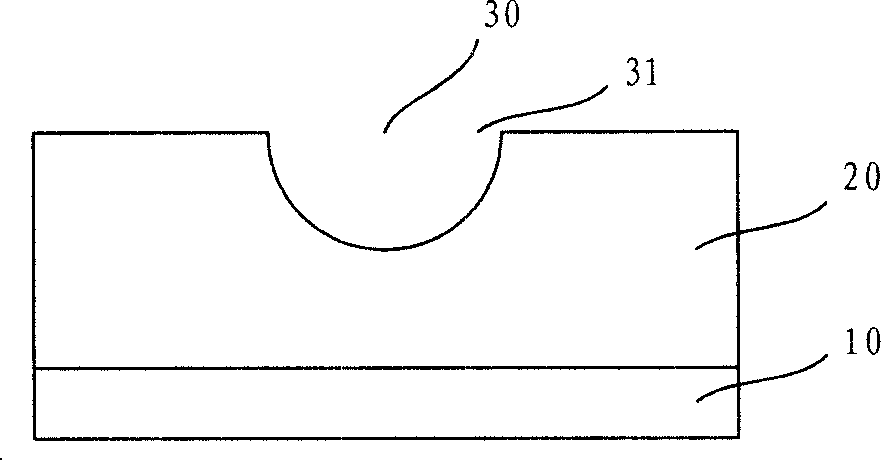

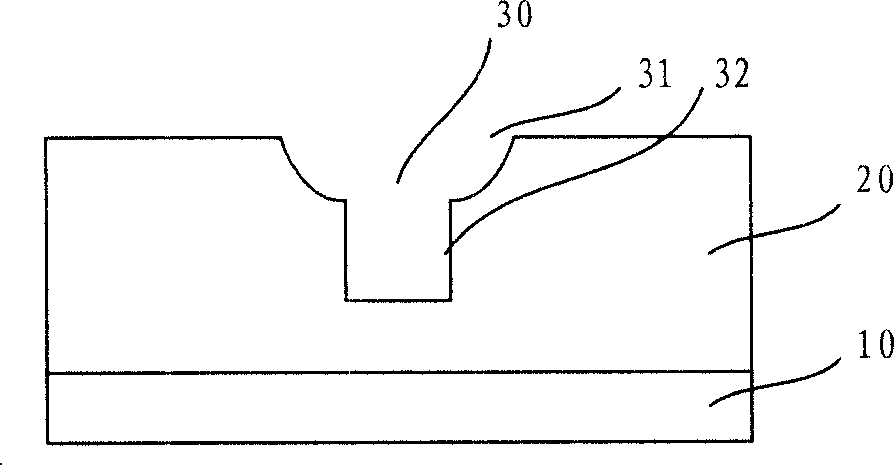

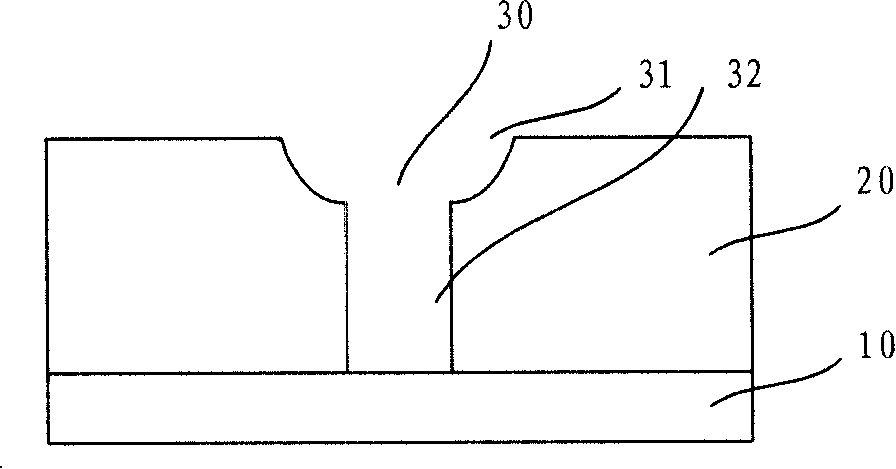

Etching method of contact hole

ActiveCN103050438AEnough thicknessAvoid it happening againSemiconductor/solid-state device manufacturingDielectricTwo step

The invention relates to an etching method of a contact hole. The method comprises the following steps of: depositing an interlayer dielectric on a wafer; flattening the interlayer dielectric; etching the contact hole; performing contact hole wet etching, and etching 30%-70% thickness of the interlayer dielectric; and performing contact hole dry etching. Through two steps of etching technologies, the wet etching uses the isotropic characteristics of the etching, so that the interlayer dielectric is in bowl-like appearance at the steps of the contact hole; and the dry etching uses the anisotropic of the dry etching, so that the appearance of the steps is approximate to a right angle. Through the combination of the wet etching and the drying etching, the steps at the contact hole are smooth without large closed angle; a metal layer can be avoided from generating cavities at the closed angle at the edge of the contact hole; the interlayer dielectric can be ensured to have enough thickness at the steps of polysilicon gates; and enough BVDSS (drain-source breakdown voltage) can be guaranteed.

Owner:深圳深爱半导体股份有限公司

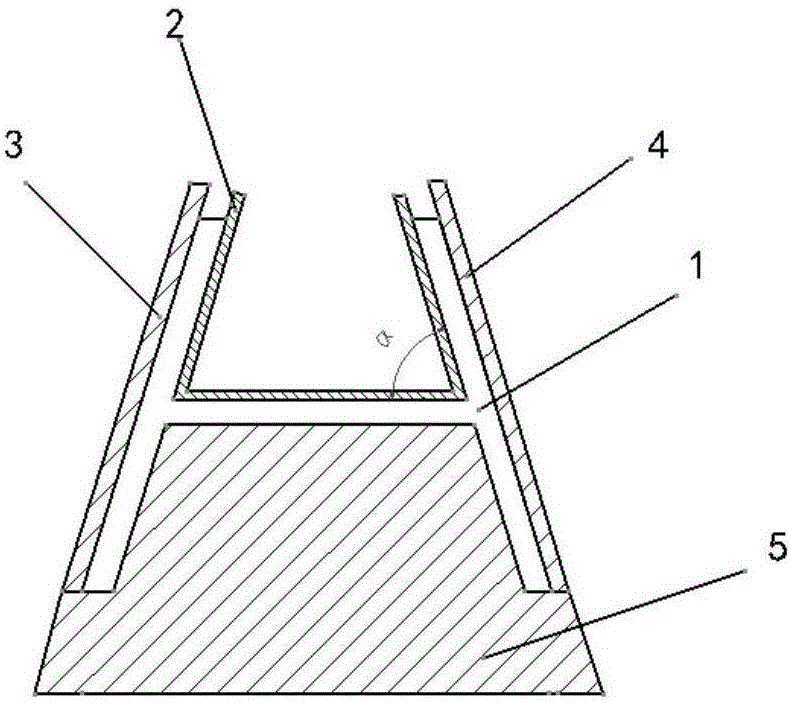

Molding tool for composite of closed angle structure

ActiveCN106313586AImprove surface qualityReduce manufacturing difficultyMaterials scienceDimensional precision

The invention belongs to the technical field of composite manufacturing, and relates to a molding tool for a composite of a closed angle structure. By means of locating combination of a lower hard mold, a left edge strip profile cover plate, a right edge strip profile cover plate and a semi-rigid pressurization pad, the relative position and profile precision of a mold can be guaranteed, and therefore the boundary dimensional precision of a part is guaranteed; and meanwhile, in the demolding process after the part is molded, the semi-rigid pressurization pad can be firstly demounted from a closed angle web area, then the left edge strip profile cover plate and the right edge strip profile cover plate are demounted, the part is finally taken down from the lower hard mold, and part demolding is completed. Compared with a traditional rigid split mold of a closed angle structure, according to the molding tool for the composite, the parting surface jump of the split mold and part deviation caused by mold deformation after long-time use are eliminated, traces, caused by mold jointing, on the surface of the part are eliminated, and the surface quality of the part is improved; and meanwhile, the mold manufacturing difficulty is greatly reduced, the cost is greatly reduced, and the problem of complex demolding generated after the part is molded is solved.

Owner:AVIC BASIC TECH RES INST

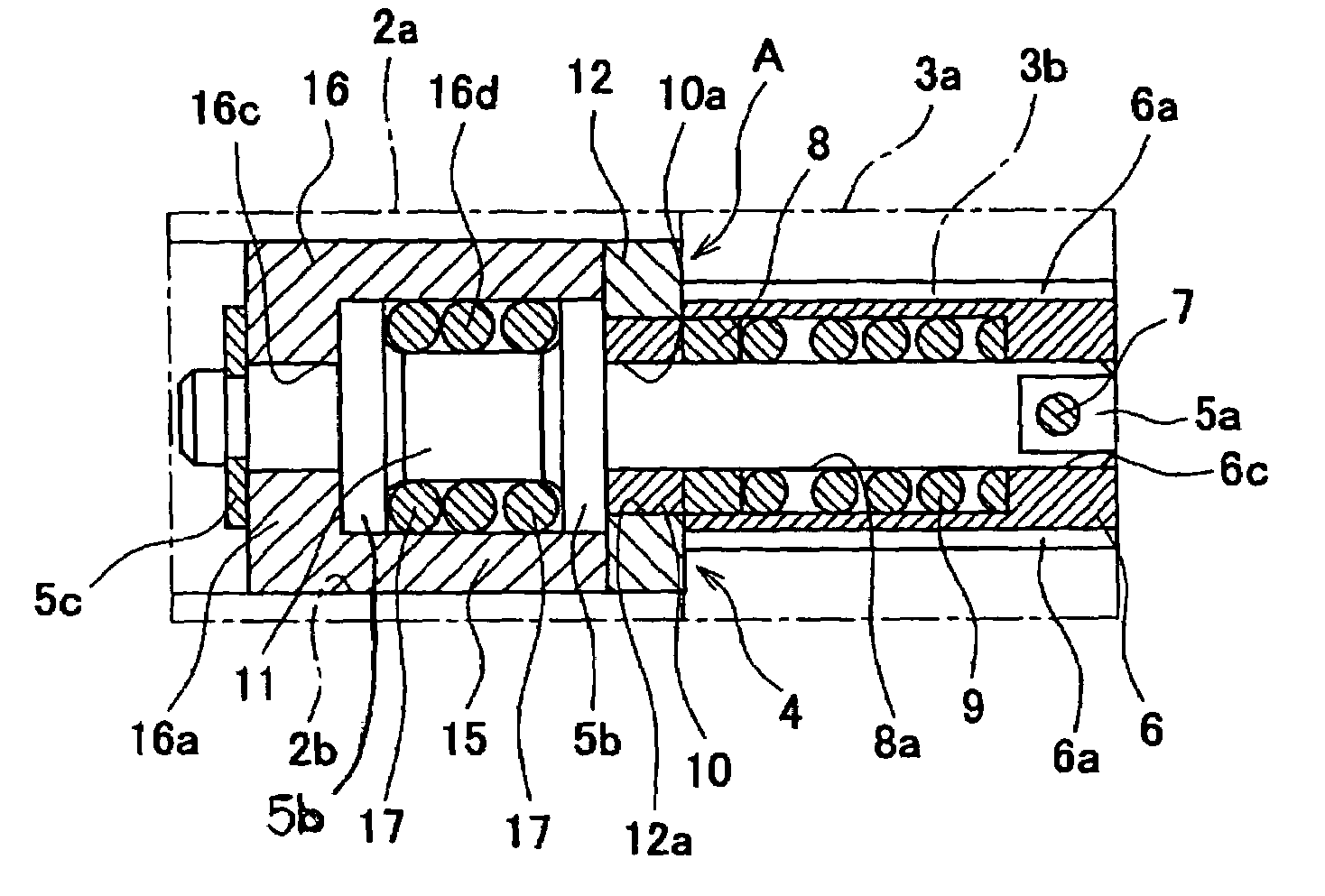

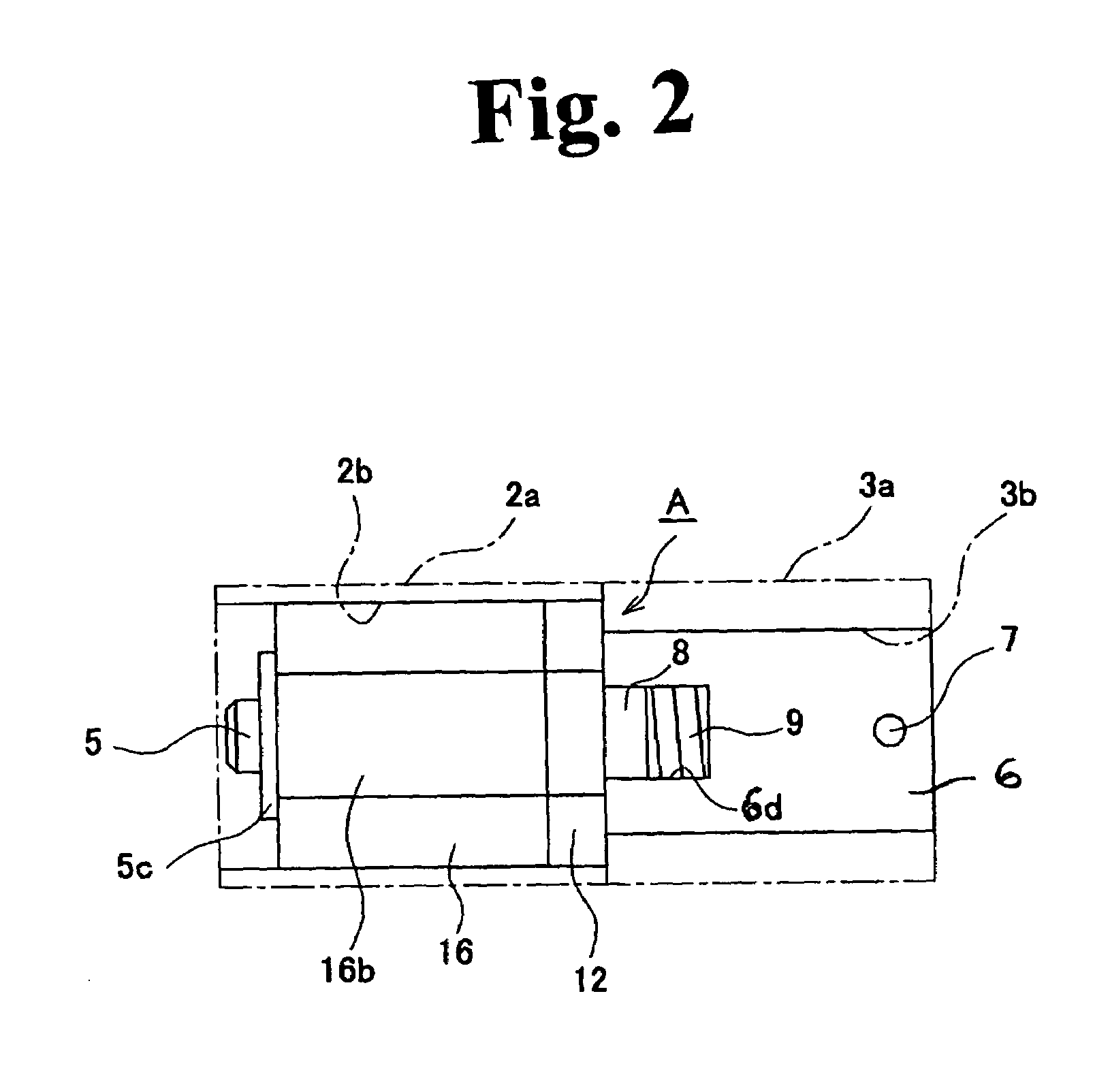

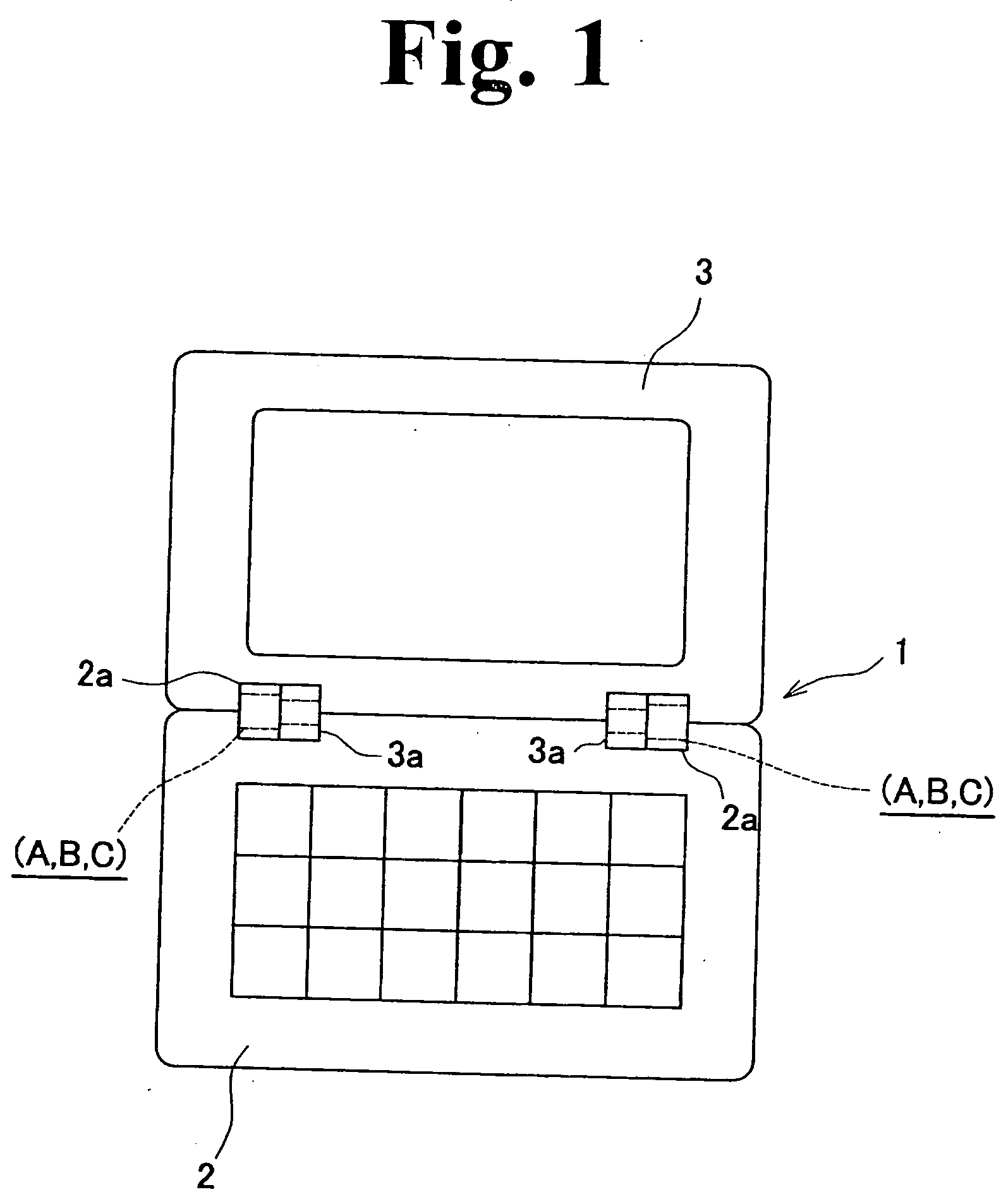

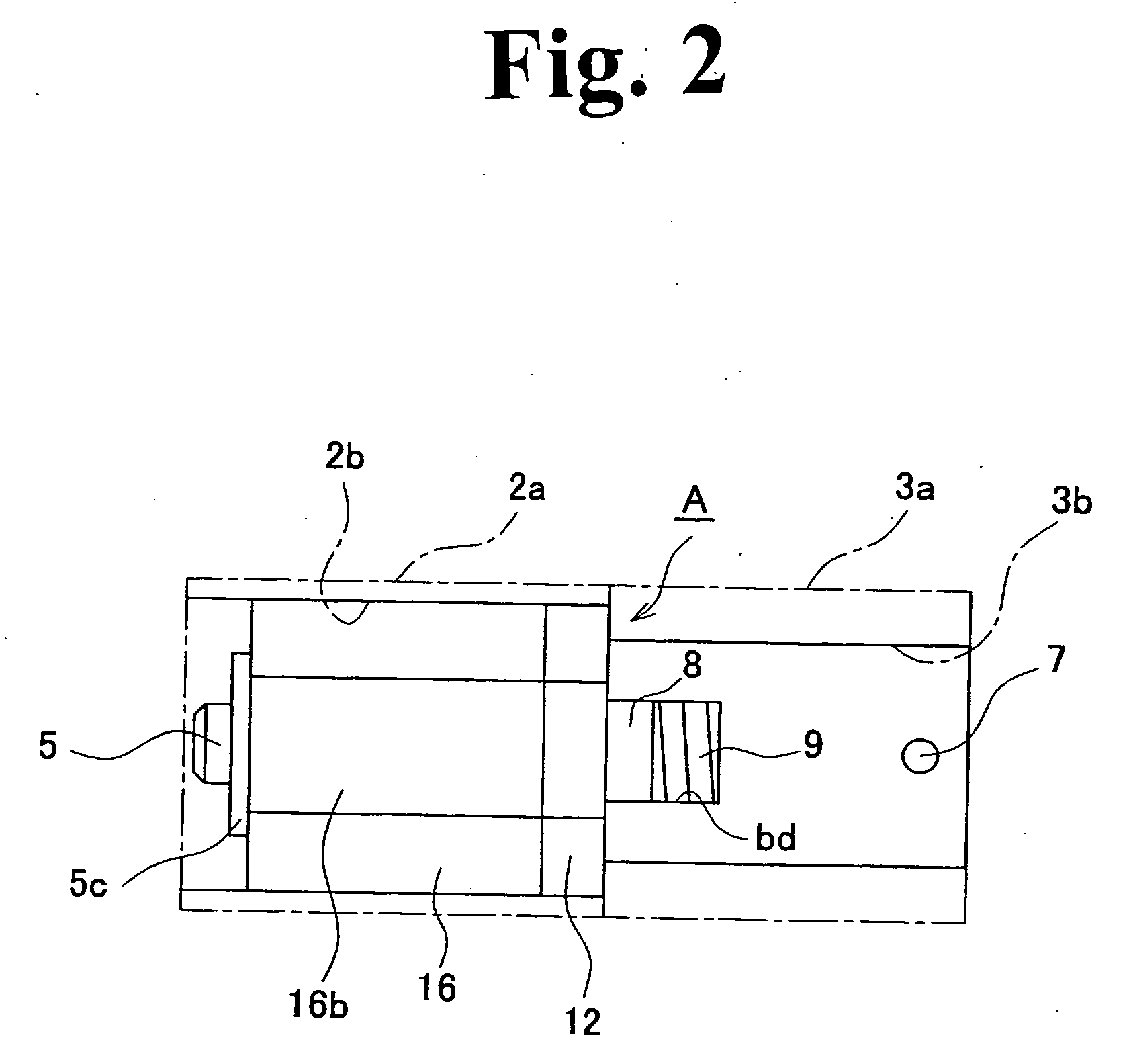

Hinge device

A hinge device of a portable intelligence terminal, which connects a first member having a keyboard and a second member composed of a comparatively massive display device in an openable and closable manner as well as possible includes a cam mechanism and a friction mechanism coaxially on a shaft. The cam mechanism is structured with a fixing cam provided by allowing a shaft to insert through axially at each central portion into a cam case having a rotation arresting means fixed on the shaft, a slider cam provided slidably in a manner to confront to the fixing cam, being restrained its rotation by the cam case, and an elastic means to press the slider cam toward the fixing cam side, and the friction mechanism is structured with a friction ring attached to the shaft and fitted into the friction case with pressure having a rotation arresting means attached to the shaft in a manner to be rotatable, so that both of automatic closed lock function from a predetermined closed angle between the first and second members and a free stop function when opening and closing operation of the first and second members can be realized together without strain.

Owner:KATOH ELECTRIC MACHINERY

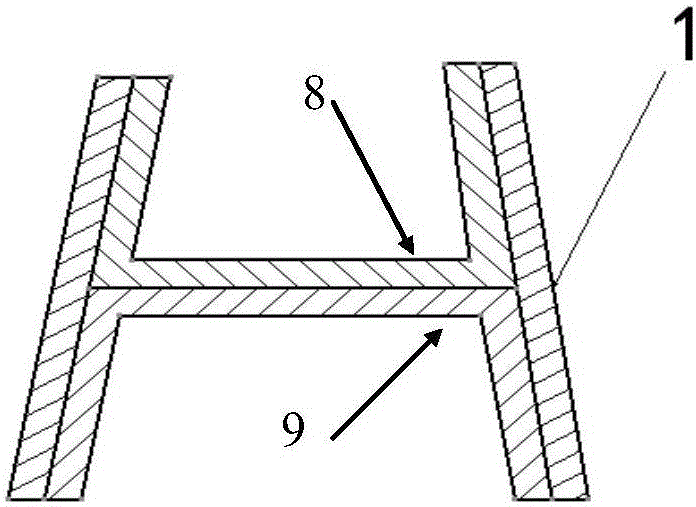

Forming mould for composite material part of box type closed-angle structure

The invention belongs to the technical field of aeronautical manufacturing and particularly relates to a forming mould for a composite material part of a box type closed-angle structure. In the present, composite material forming moulds include metal moulds, composite material moulds, rubber moulds, foam moulds, plaster moulds and soluble polymer moulds. Traditional composite material parts of irregular-shaped structures can be manufactured and formed by rubber shrinkage moulds, foam and plaster, and then the moulds are broken to obtain the parts. However, the moulds can only be used for once or several time and is not suitable for batch production, and the surface accuracy and the quality of the composite material parts manufactured by the moulds are not as good as the surface accuracy and the quality of the composite material parts manufactured by metal moulds totally. The forming mould for the composite material part of the box type closed-angle structure is reasonable in design and simple to manufacture and also solves the problem of demoulding of the composite material part of the box type closed-angle structure.

Owner:AVIC BASIC TECH RES INST

Method for etching throughhole

InactiveCN101207036AImprove etch selectivitySemiconductor/solid-state device detailsSolid-state devicesAnisotropic etchingSemiconductor

The invention relates to a method of etching through holes. The method comprises the following steps: a through hole etching substrate is formed on a semiconductor substrate; an anisotropic etching manufacturing procedure is performed, a through hole is etched on the through hole etching substrate; a sacrificial layer is deposited, and is filled into the through hole; the sacrificial layer is etched, so as to expose the opening of the though hole; an istropic etching manufacturing procedure is performed, so as to ensure the opening of the through hole to have a round angle structure; the sacrificial layer is removed. The invention adopts an anisotropic method to etch the through hole firstly, and then adopts an isotropic method to expand the opening of the through hole, and therefore a through hole structure with a round angle opening can be formed, and compared with the through structure with a closed angle opening, as for the through hole with the identical aspect ratio, the piling of the deposition materials is not easy to occur at the opening.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

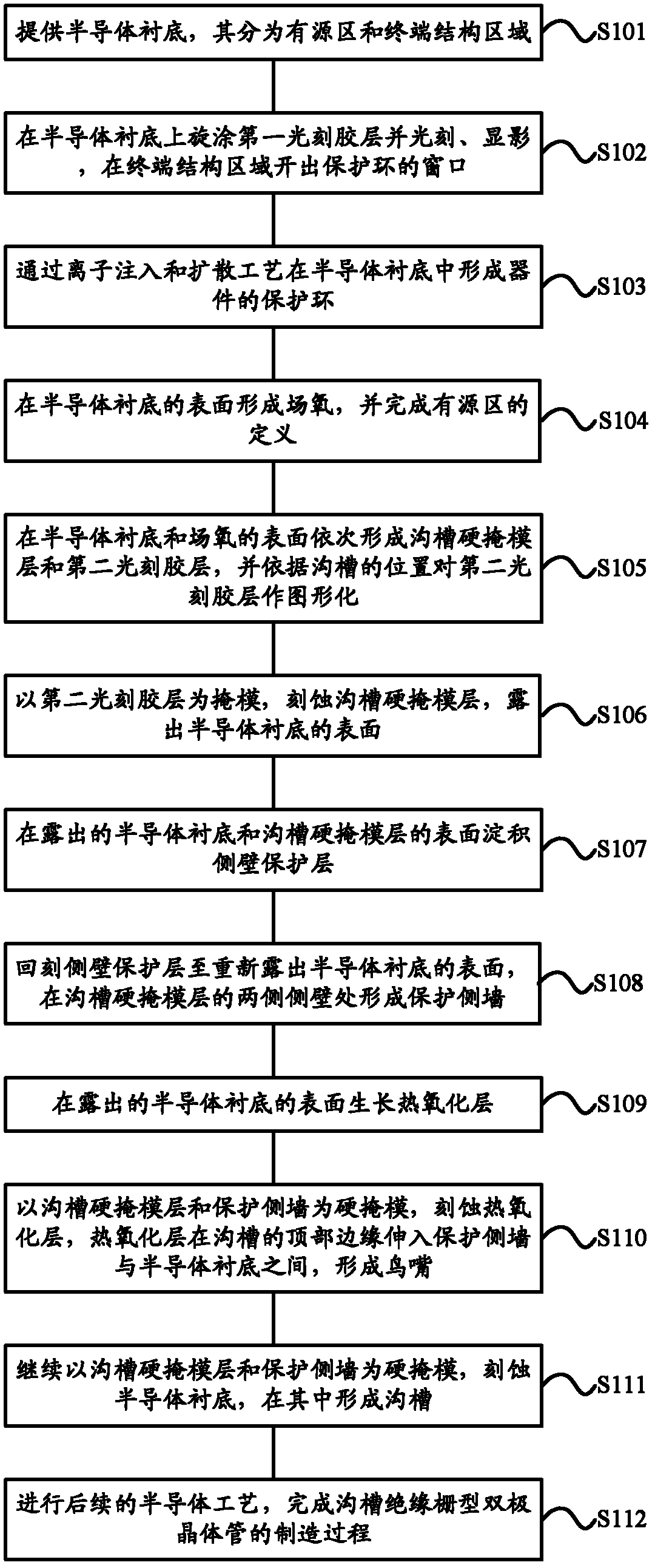

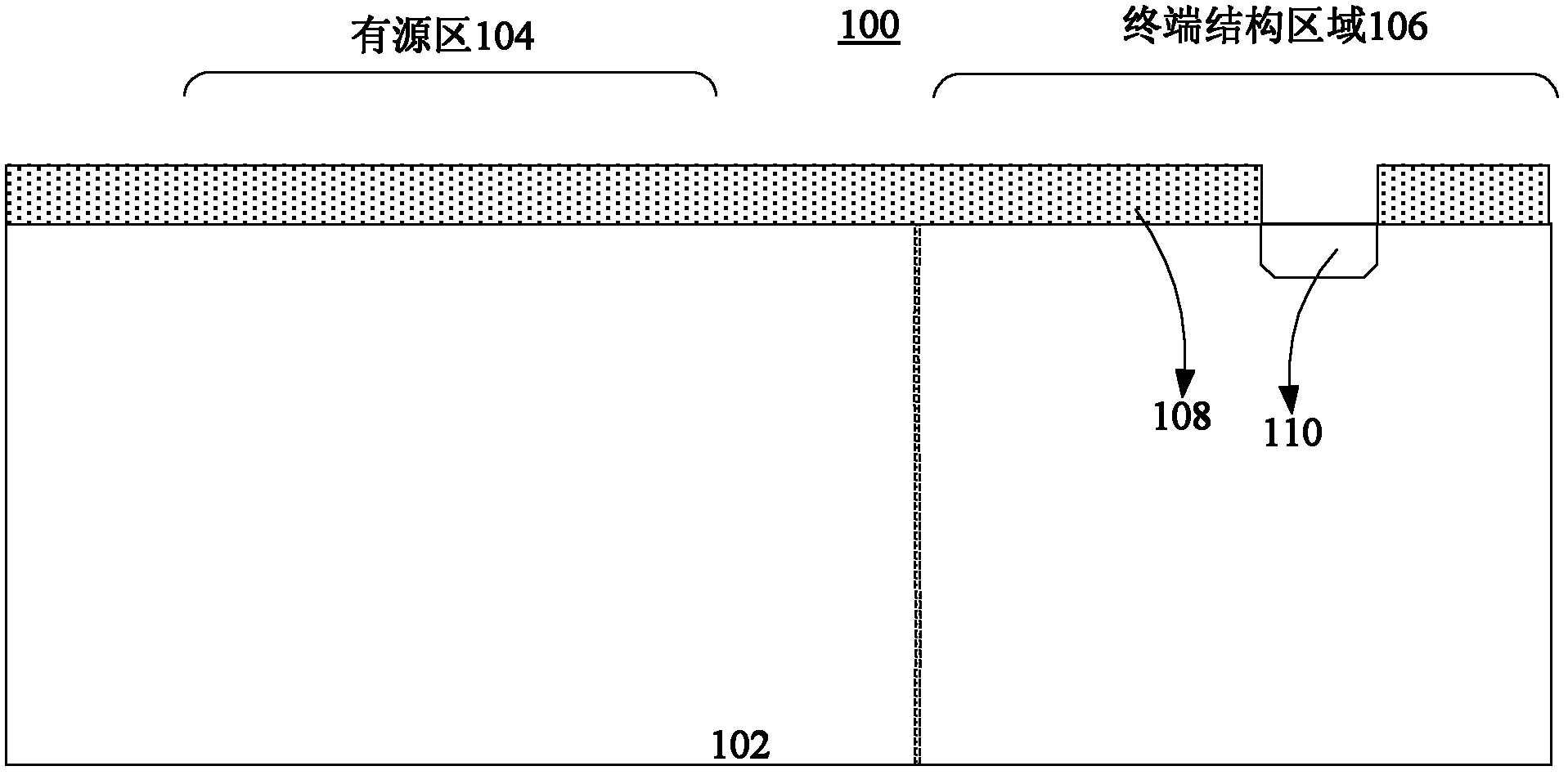

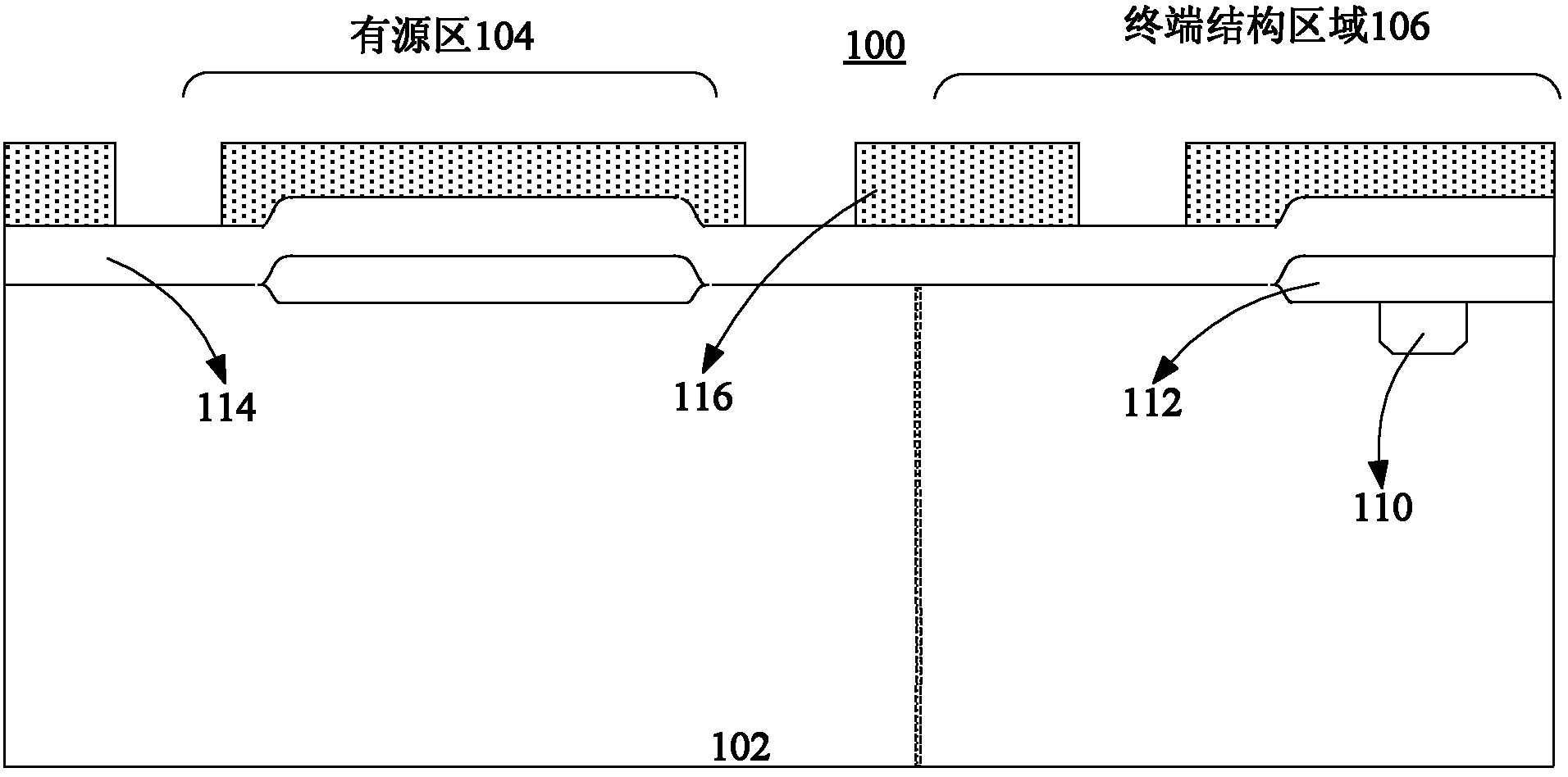

Manufacturing method of trench IGBT

ActiveCN102496573AAvoid leakage failureAvoid reliabilitySemiconductor/solid-state device manufacturingTrench igbtEngineering

The invention provides a manufacturing method of a trench IGBT. The method comprises the following steps: providing a substrate and dividing into an active region and a terminal structure region; opening a window of a protection ring in the terminal structure region; through an ion implantation and diffusion technology, forming the device protection ring in the substrate; forming field oxide on a surface of the substrate and completing an active region definition; forming a groove hard mask layer and a photoresist layer on the surfaces of the substrate and the field oxide, and imaging the photoresist layer; etching the groove hard mask layer and exposing the substrate; depositing a sidewall protection layer on the surface of the substrate and performing etchback, forming protection side walls on sidewalls of two sides of the groove hard mask layer and growing a thermal oxide layer on the surface of the substrate; taking the groove hard mask layer and the protection side walls as the hard mask so as to successively etch the thermal oxide layer and the substrate and forming a groove in the substrate, wherein the thermal oxide layer which is on a top of the groove extends between the protection side walls and the substrate so as to form a beak. According to the invention, generation of a closed angle of the groove top can be avoided. Grid leakage failure and a reliability problem caused by the closed angle can be prevented.

Owner:ADVANCED SEMICON MFG CO LTD

Hinge device

A hinge device of a portable terminal connects a keyboard member to a comparatively massive display member and has cam and friction mechanisms. The cam mechanism has a fixing cam for axially receiving a shaft which extends into a cam case having a rotation arresting mechanism fixed on the shaft, a slider cam provided slidably in a manner to confront the fixing cam restrained in its rotation by the cam case, and an elastic mechanism for pressing the slider cam toward the fixing cam. The friction mechanism has a friction ring attached to the shaft and fitted into the friction case under pressure with a rotatable rotation arresting mechanism, so that both of automatic close lock function from a predetermined closed angle between the first and second members and a free stop function when opening and closing operation of the first and second members can be realized together without strain.

Owner:KATOH ELECTRIC MACHINERY

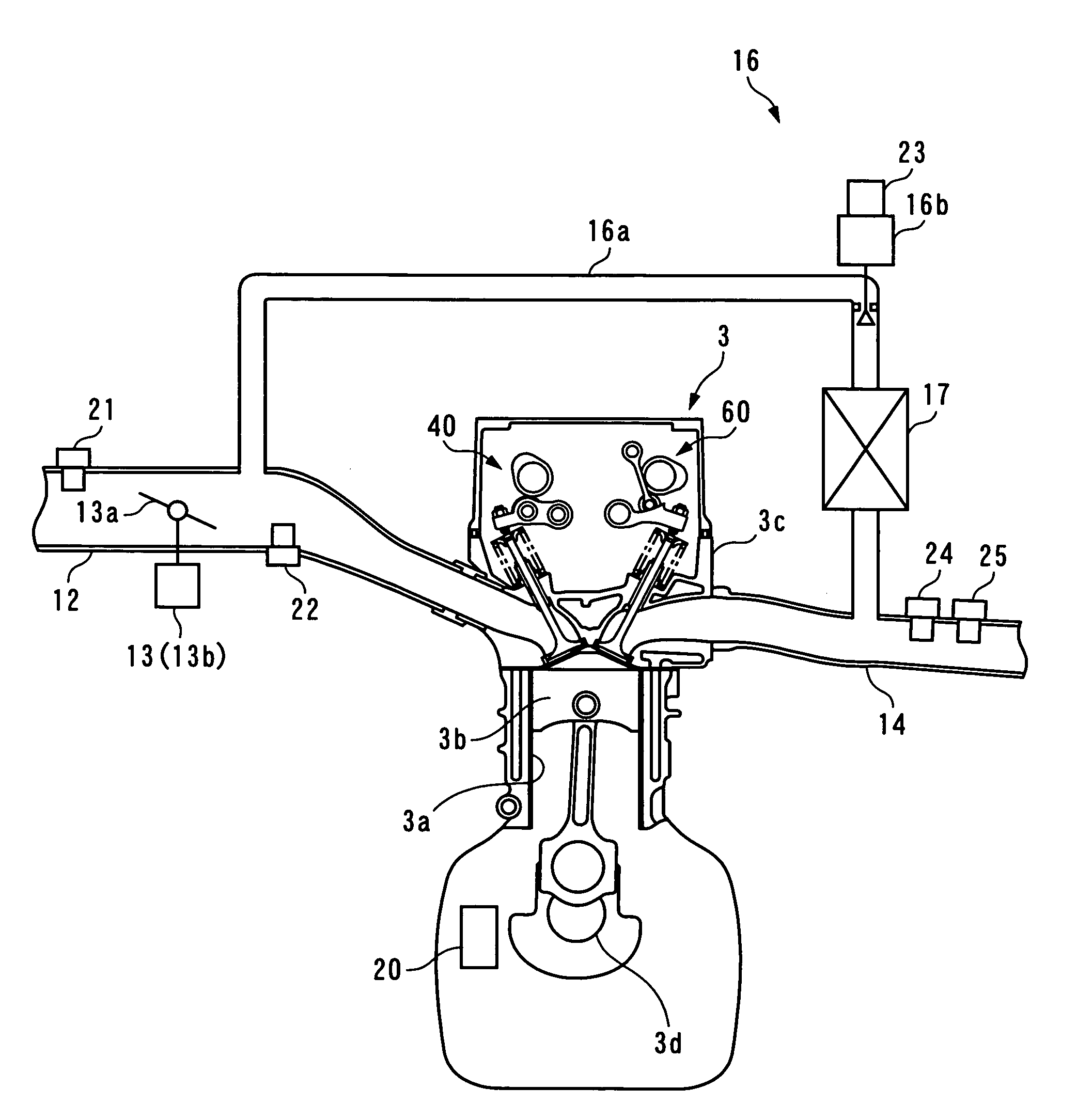

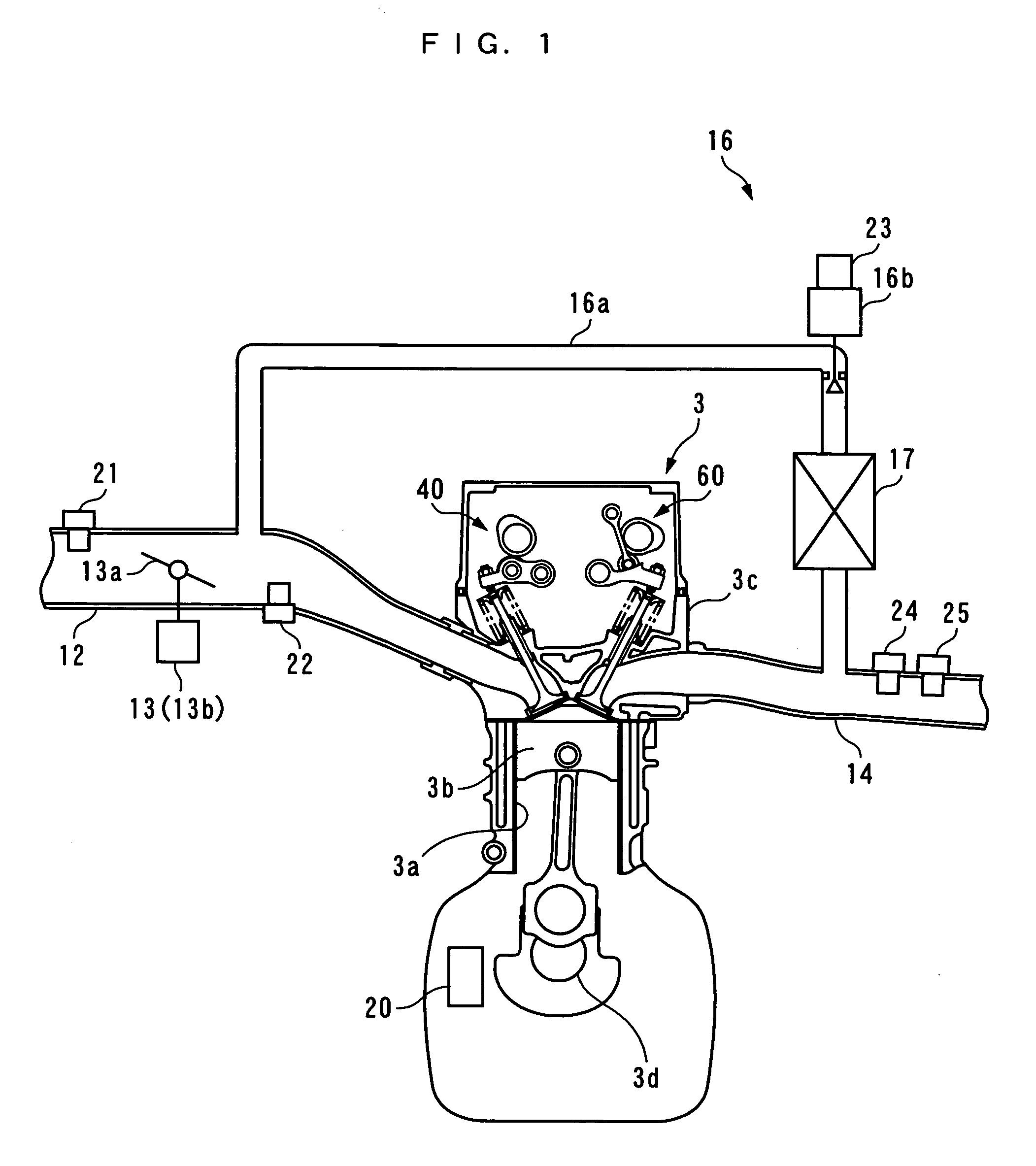

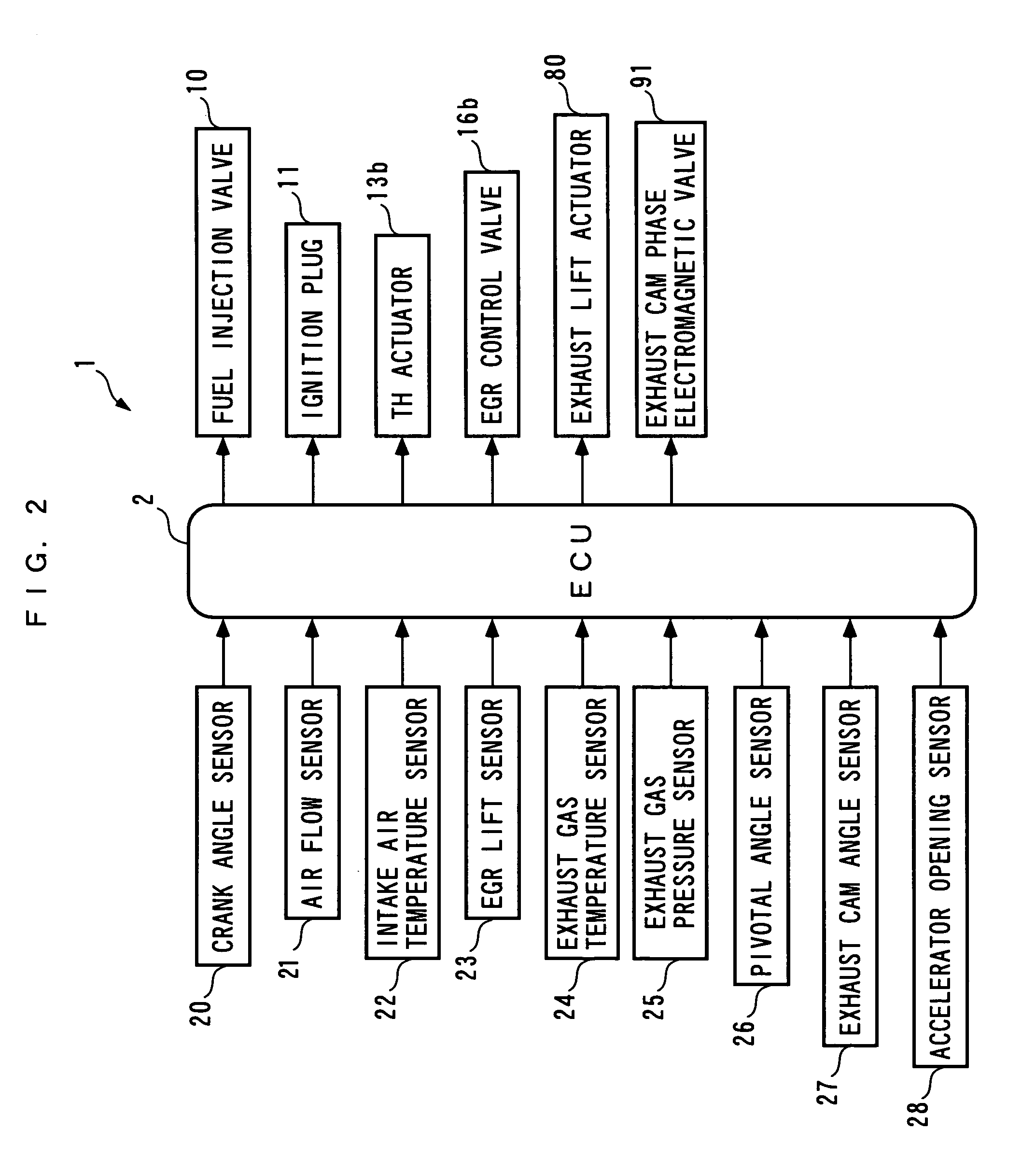

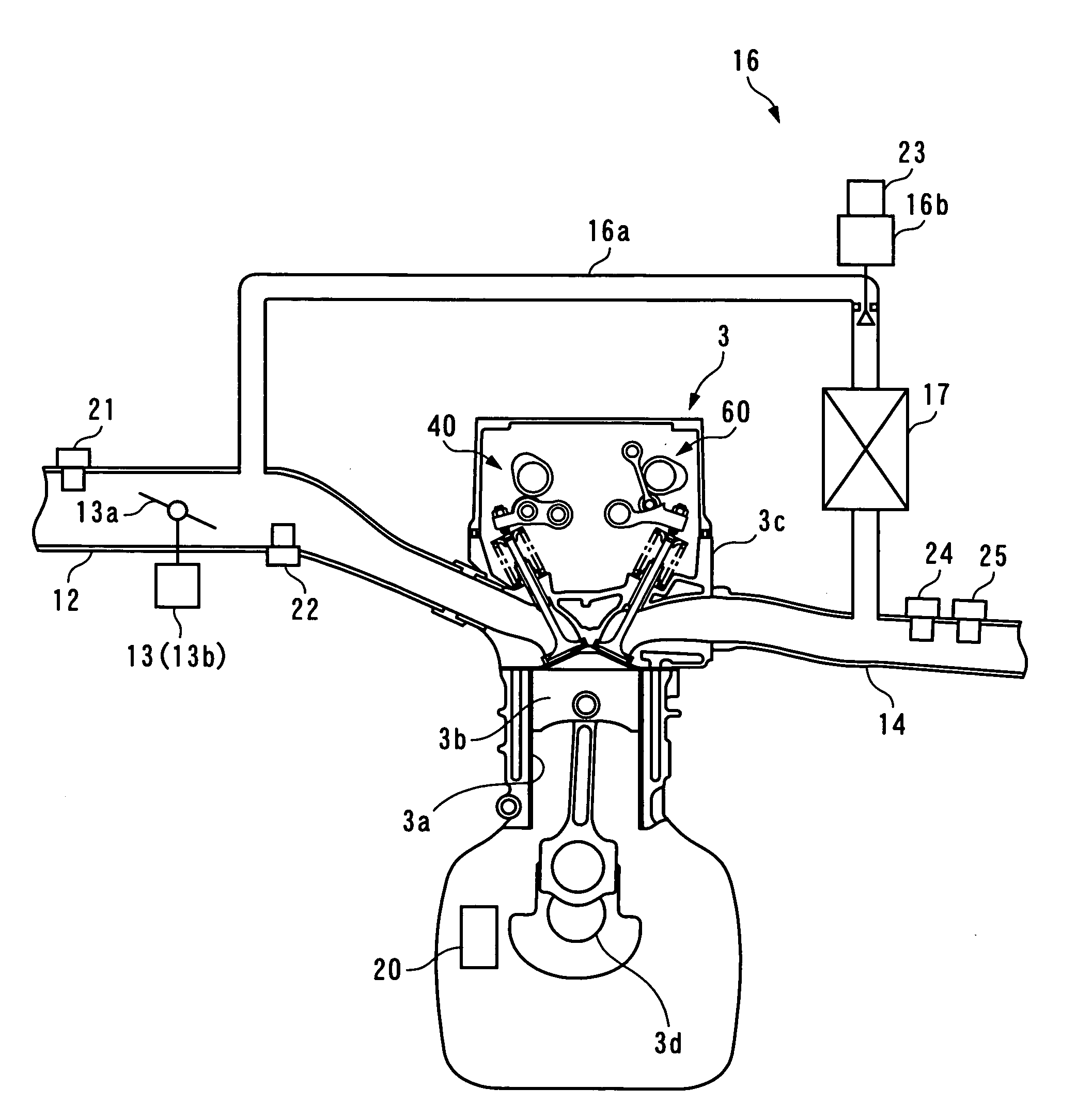

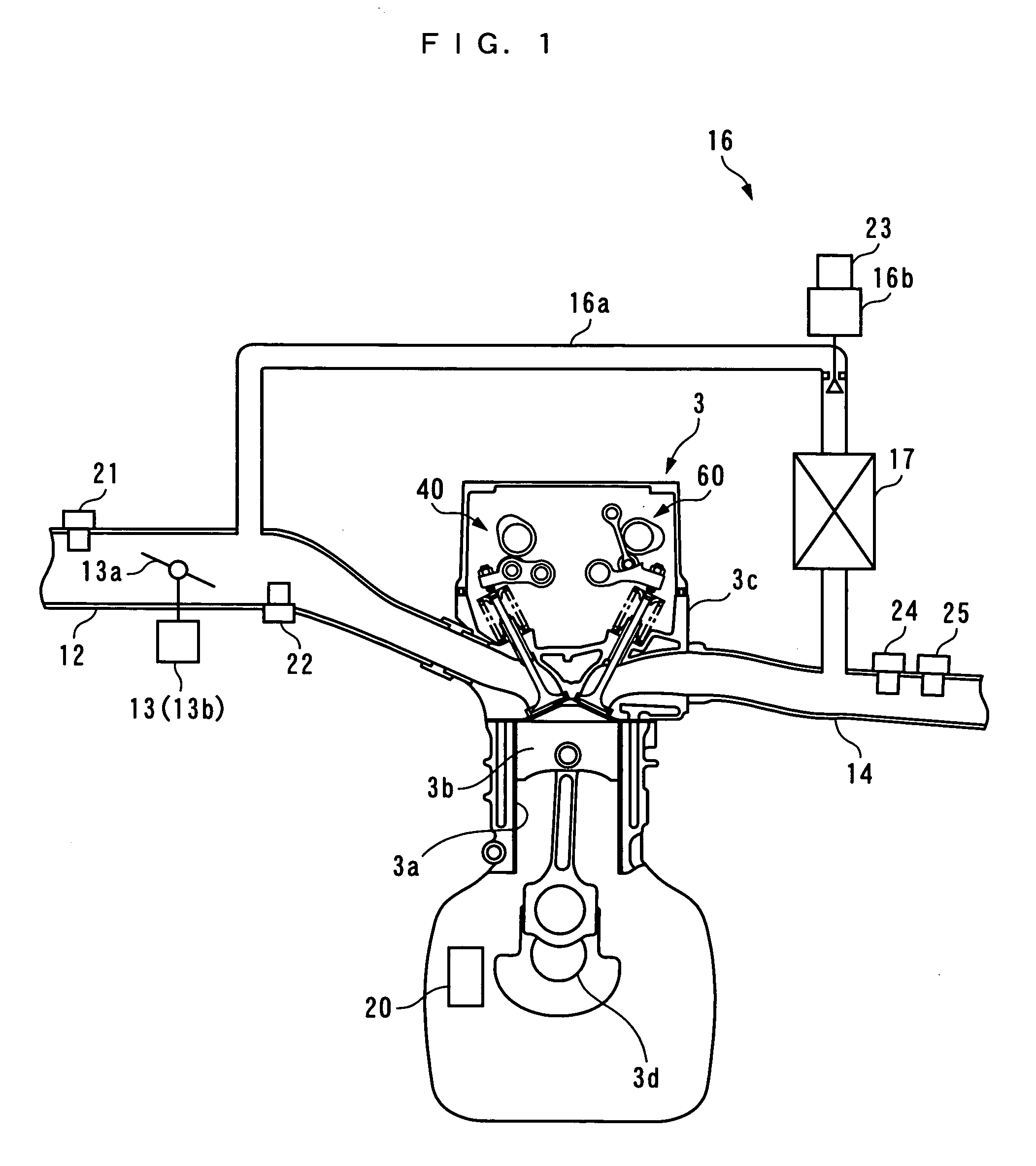

Control apparatus and method for internal combustion engine

InactiveUS7725244B2Increase heatVehicle testingElectrical controlExternal combustion engineFuel efficiency

A control apparatus and method for an internal combustion engine are provided for ensuring a stable combustion state and improving the fuel efficiency when an air-fuel mixture is burnt with self ignition while auxiliarily using a spark ignition. The control apparatus for an internal combustion engine which is operated in a plurality of modes including a torch self ignition combustion mode comprises an ECU. In the torch self ignition combustion mode, the ECU controls an internal EGR amount, calculates an actual exhaust closing angle, calculates a target exhaust closing angle, calculates a closing angle deviation, calculates a fuel injection amount for forming a homogeneous air-fuel mixture, calculates a correction coefficient in accordance with the closing angle deviation, and corrects a basic value by the correction coefficient to calculate a fuel injection amount for forming a stratified air-fuel mixture.

Owner:HONDA MOTOR CO LTD

Metal gasket with fishbone-shaped section and inclined teeth

The invention discloses a metal gasket with fishbone-shaped section and inclined teeth. The peripheral direction of the upper end face and the lower end face of the gasket distributes annular tooth-shaped grooves. Teeth of the tooth-shaped grooves are integrated with the metal gasket and are arranged slantingly to a direction of pressure source. The section of the gasket is in the shape of a fishbone. The angle of inclination is more than 0 degree and less than 90 degrees. The contact surface of the top of teeth and the flange is of no closed angle. The top points of teeth are designed into rounded shape, flat angle or wave arc angle and the contact surfaces with the flange are round or flat so that damaging to the surface of the flange by the traditional closed-angle teeth is avoided. The design of the inclined tooth improves the rebound resilience of the metal gasket. The tooth-shaped grooves arranged slantingly on the ring surface form a plurality of sealed compress-resisted chambers to release the pressure from a pressure source gradually. The seal chambers utilize the fluid pressure to generate sealed balancing force effectively so as to improve the sealed reliability.

Owner:ENVIRONMENTAL GASKET COMPANY

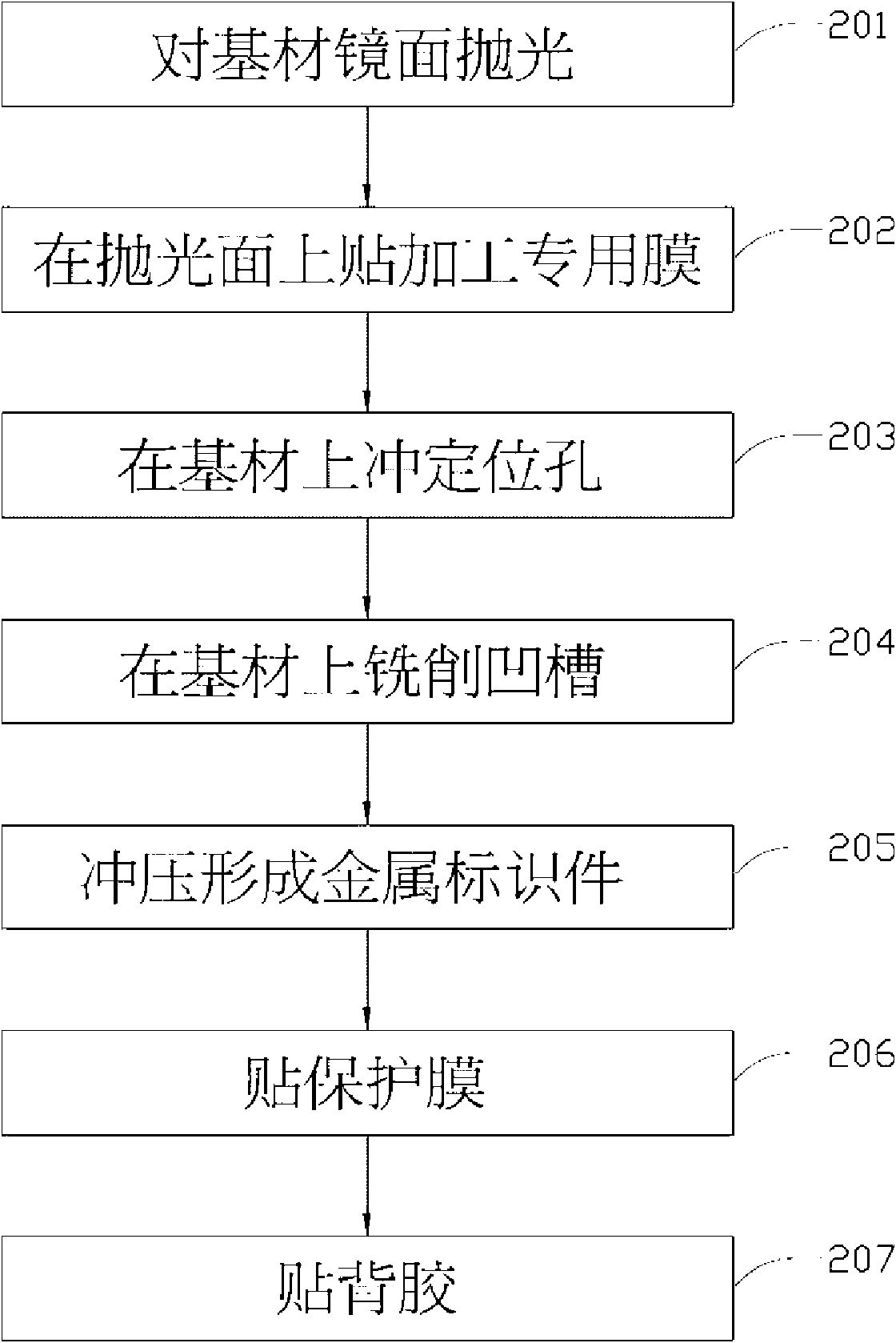

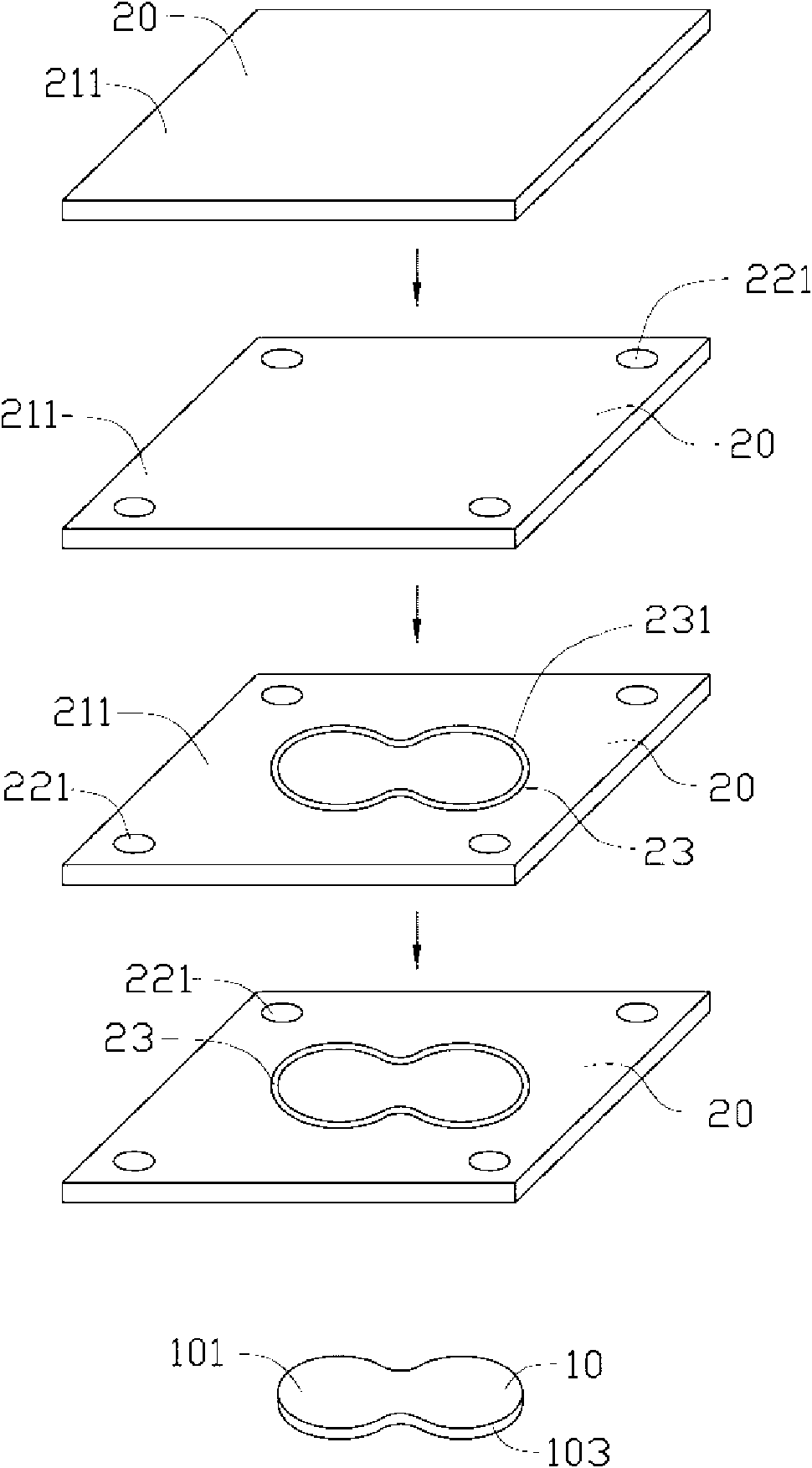

Metal identification piece and manufacturing method thereof

InactiveCN101635117AReduce tensile stressWith milled textureOrnamental structuresSpecial ornamental structuresMaterial RuptureMetallic substrate

Owner:广东金雅实业有限公司

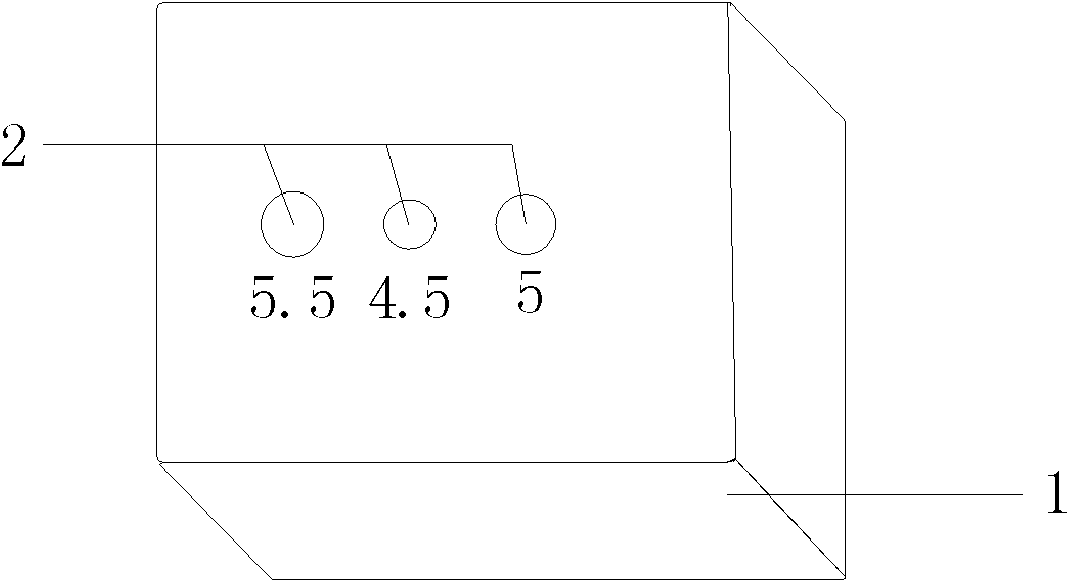

Fuel-economizing maintenance tool of carburetor

ActiveCN101585130ASolve the problem of high fuel consumptionImprove atomization combustion performanceEngineeringCarburetor

A fuel-economizing maintenance tool of a carburetor includes a sizing block, a main nozzle shrinkage void stick, a transition nozzle shrinkage void stick, a main nozzle reamer, and a transition nozzle reamer. The tool is characterized in that the height of the sizing block is more than 10mm, the length and the width are all more than 5mm, the middle of the sizing block is provided with a 5mm of a through hole, a 4mm of a through hole and a 5.5mm of a through hole; the length of the main nozzle shrinkage void stick is 70mm, the top of the main nozzle shrinkage void stick is provided with a locating needle, the stick head and the locating needle form a 15 DEG inclined angle, the stick diameter is 4mm, the diameter of the locating needle is 1.5mm; the total length of the transition nozzle shrinkage void stick is 100mm, the stick diameter is 2mm, the head has a R angle, and the R angle is equal to 1 DEG; the total length of the main nozzle reamer is 40mm, the diameter of the reamer is 2.5mm, the tool edge top of the reamer is formed a closed angle; the total length of the transition nozzle reamer is 100mm, the length of the reamer edge is 2mm, the diameter is 0.8mm, and the top of the reamer is formed a closed angle. By the invention, it is capable of preventing a large oil consumption of the carburetor caused by parts abrasion or a low manufacturing accuracy.

Owner:YANCHENG HUAYUE GASOLINEEUM MACHINERY MFGCO

Axle hung retarder

The invention discloses a run-away tramcar protecting device, in particular an axle hung kick-up block suitable for traveling crane protecting devices of mine inclined shafts (drifts) construction. The axle hung kick-up block consists of a hook stop chassis, a hook stop main axle, a hook stop check ring, a hook stop collision bar, a hook stop hook plate, an axle stop plate, a collision bar joint and a chassis fixing hole, wherein the hook stop collision bar of the axle hung kick-up block is in a long triangle; the middle of the collision bar is provided with a circular hole, and the collision bar joint is arranged below the collision bar near one side of the hook stop collision bar; and the closed angle end of the hook stop collision bar is always in an upward posture to be collided. The hook strop plate of the axle hung kick-up block is oblong, and the middle of the hook stop plate is provided with a circular hole, one end of the hook stop plate is provided with a hook, the diameter of the inner side of the hook is equal to that of the axle of a tramcar and the hook horizontally clings on the channel steel of the hook stop chassis. The axle hung kick-up block has simple manufacture, simple structure and convenient overhauling; the mounting quantity is not limited and the space limitation is small; and the kick-up block is installed in the middle of a rail, thereby not influencing the traveling of any tramcar.

Owner:中煤第一建设有限公司第三十一工程处

Composite material forming mould

InactiveCN105252790AGuaranteed positioning accuracyGuaranteed Surface AccuracyAerospace manufacturingSoluble polymer

The invention belongs to the technical field of aerospace manufacturing and particularly relates to a composite material forming mould used for forming of composite material parts of a unilateral closed angle and closed edge strip structure. Existing composite material forming moulds comprise metal moulds, composite material moulds, rubber moulds, foam moulds, gypsum moulds, soluble polymer moulds and the like. Traditional composite material parts of a special-shaped structure can be manufactured in the mode that parts are formed through rubber contraction moulds, foam moulds, gypsum moulds and other moulds and then moulds are destroyed, but the moulds are only suitable for one-time or several-time forming, batch production is not facilitated, and the surface precision, quality and the like of the composite material parts manufactured through the moulds are inferior to those of the metal mould on the whole. The composite material forming mould used for forming of the composite material parts of the unilateral closed angle and closed edge strip structure is reasonable in design and easy to manufacture, and forming and mould releasing of the composite material parts of the unilateral closed angle structure are achieved.

Owner:AVIC BASIC TECH RES INST

Microgel aqueous acrylic acid shell-core resin emulsion and preparation method thereof

The invention belongs to the field of aqueous coatings, and relates to a microgel aqueous acrylic acid shell-core resin emulsion. The resin emulsion is prepared through a reaction of 13-16 parts of an acrylic acid resin water dispersion (with the solid content of 28-34%), 18-21 parts of a vinyl monomer, 20.5-27.6 parts of an acrylic acid and acrylate monomer, 0.3-0.6 parts of an initiator, 5-6 parts of an organic solvent and 49-53 parts of water. The microgel resin emulsion is added to an aqueous coating, so the sagging property of a paint film is obviously improved, a good anti-sagging effect is reached, the thickness of the paint film in closed angles or edges and other difficult coating positions of a coated member is obviously increased, and the corrosion resistance of the surface of the coated member is improved. The nanometer-level aqueous acrylic acid emulsion with the particle size being smaller than 150nm is produced through the method, can be added to the aqueous coating without thickening the coating, and facilitates maintenance of high construction solid content.

Owner:LANGFANG JINHUILI INDAL PAINT

Control apparatus and method for internal combustion engine

InactiveUS20080162021A1Increase heatVehicle testingElectrical controlExternal combustion engineFuel efficiency

A control apparatus and method for an internal combustion engine are provided for ensuring a stable combustion state and improving the fuel efficiency when an air-fuel mixture is burnt with self ignition while auxiliarily using a spark ignition. The control apparatus for an internal combustion engine which is operated in a plurality of modes including a torch self ignition combustion mode comprises an ECU. In the torch self ignition combustion mode, the ECU controls an internal EGR amount, calculates an actual exhaust closing angle, calculates a target exhaust closing angle, calculates a closing angle deviation, calculates a fuel injection amount for forming a homogeneous air-fuel mixture, calculates a correction coefficient in accordance with the closing angle deviation, and corrects a basic value by the correction coefficient to calculate a fuel injection amount for forming a stratified air-fuel mixture.

Owner:HONDA MOTOR CO LTD

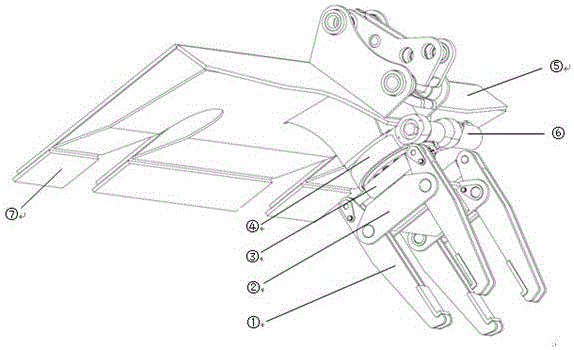

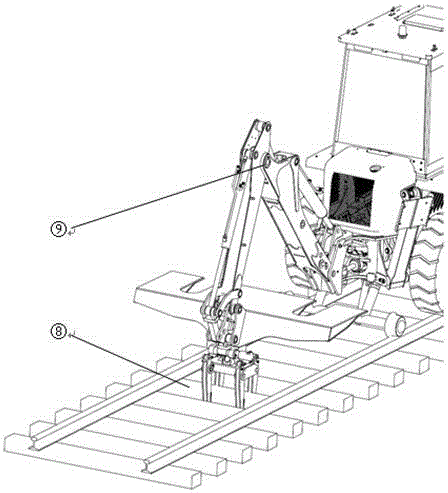

Sleeper replacing implement

InactiveCN106065550AInhibit sheddingHigh precisionRailway track constructionCrushed stoneEngineering

The invention relates to a sleeper replacing implement which comprises two pairs of clamps used for holding a sleeper, a swing mechanism, and a scraper blade for pushing crushed stone aside, wherein a connection part to be connected with an operating mechanism of an engineering vehicle is arranged on the scraper blade; the swing mechanism is connected with the lower side of the scraper blade; a support rack is connected to the lower side of the swing mechanism; a motor is mounted on the swing mechanism, and used for driving the swing mechanism to rotate; the clamps are mounted on the support rack, and connected to two ends of an oil cylinder; the oil cylinder is used for controlling the opening / closing angles of the clamps. The sleeper replacing implement can be connected to engineering vehicles, such as excavators, backhoe loaders and loaders, is high in universality, and can be operated by one person; a sleeper can be replaced fast; not only is the work efficiency improved, but also labor cost is reduced; the whole process is simple to operate, safe, reliable, and easy to implement.

Owner:XUZHOU XUGONG SPECIAL CONSTR MASCH CO LTD

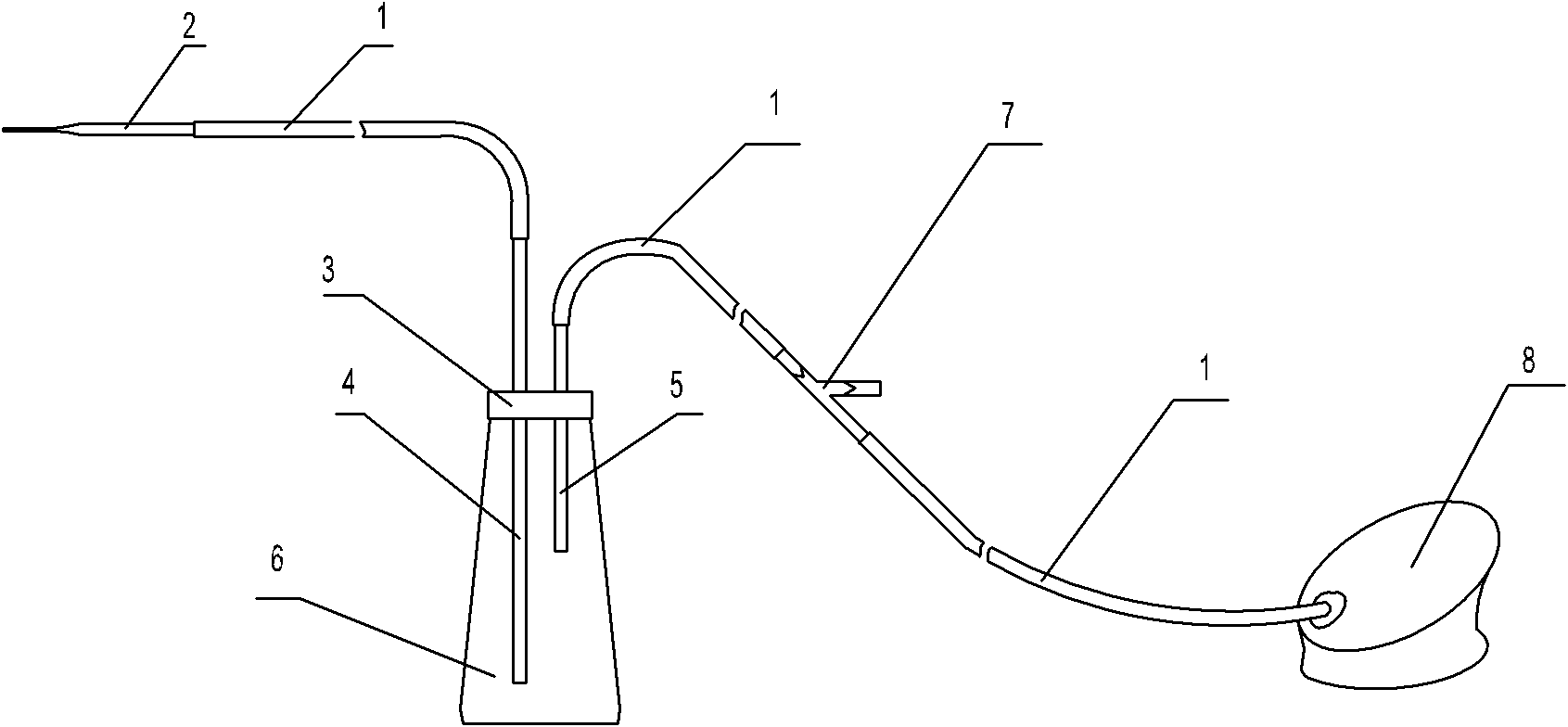

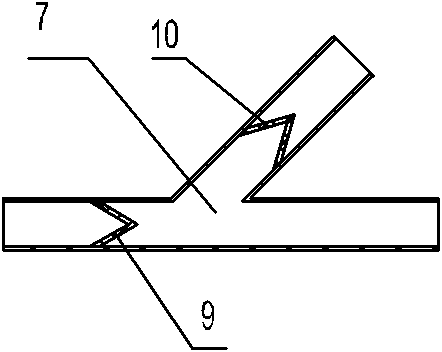

Aseptic simple liquor relief device of cell culture liquid

InactiveCN102061252APrecise suctionEfficient absorptionBioreactor/fermenter combinationsBiological substance pretreatmentsCulture fluidEngineering

The invention relates to an aseptic simple liquor relief device of a cell culture liquid, which is characterized in that a rubber hose is connected with a spearhead connector first, then respectively connected with upper pipe orifices of two intubation tubes inserted into a waste liquid collecting bottle from a plug, and then connected with a gas divider and a gas pump. The front end of the spearhead connector is contracted and thinned so as to insert the tenuous spearhead. The gas divider is a three-way pipe in a y-shaped structure. Closable elastic membranes with V-shaped sections and upward closed angles are respectively in the middle lower portion of the long dash and in the middle portion of short dash of the y-shaped structure. The included angle between the long dash and the short dash of the y-shaped structure is ordinarily 30-60 degrees, preferably 45 degrees. The aseptic simple liquor relief device of the cell culture liquid makes the liquid absorption process more accurate and efficient and is simpler and faster for operation; and the liquid is absorbed cleanly and thoroughly, thereby eliminating the corrupt practices of artificial pollution and the like.

Owner:DALIAN UNIV

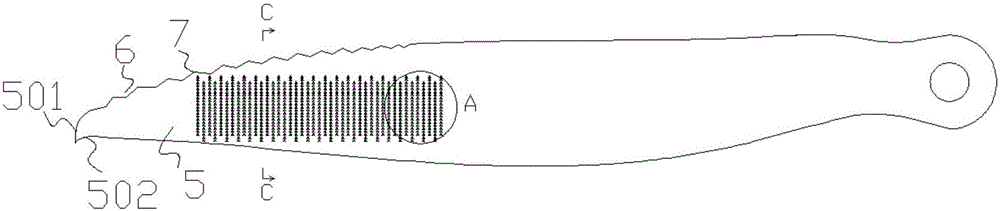

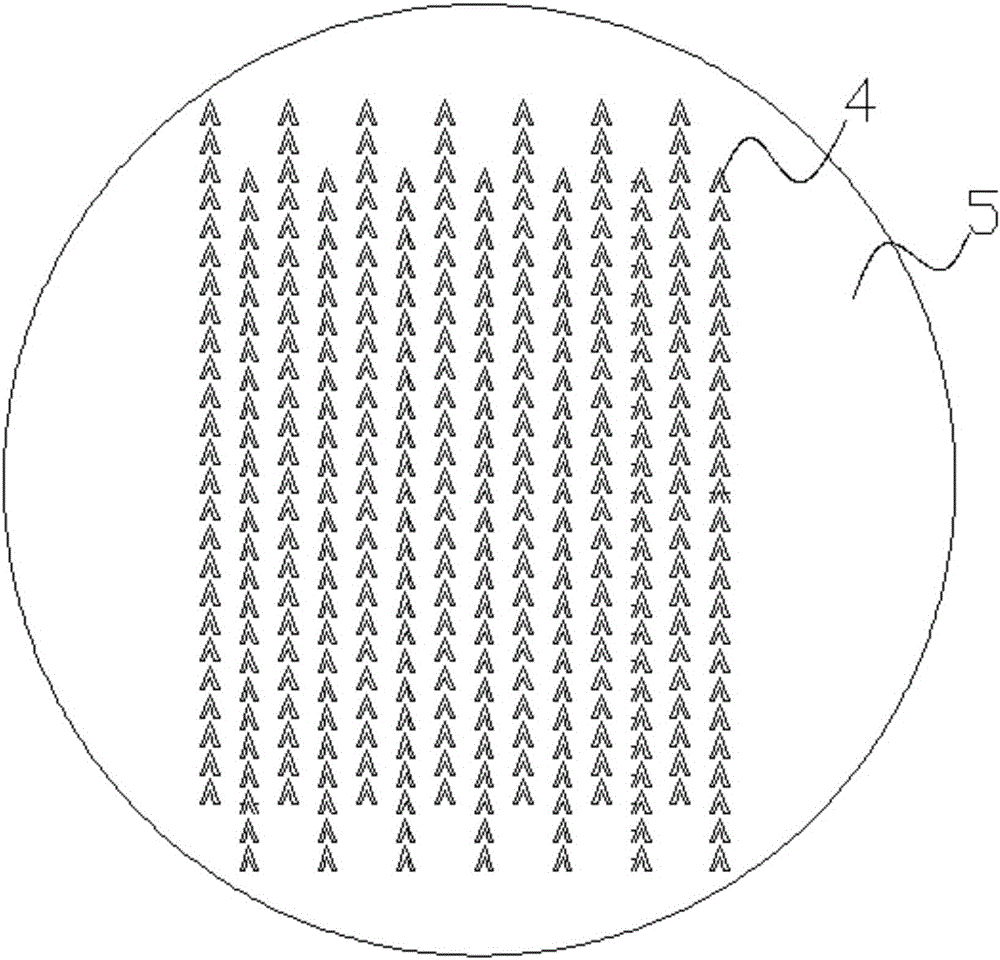

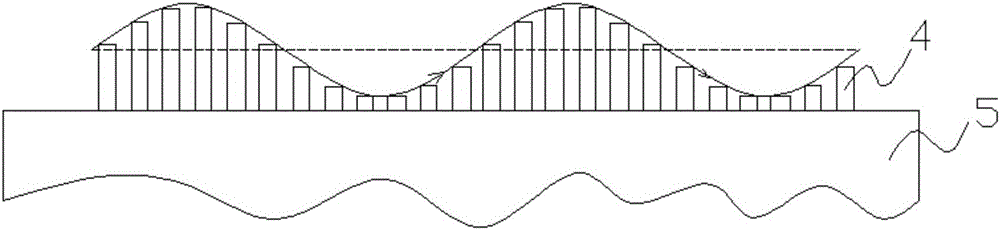

Mute propeller blade and rotor unmanned aerial vehicle with same

The invention relates to a mute propeller blade. The mute propeller blade comprises a propeller blade body, wherein a plurality of unequal sawtooth grooves are formed in the tail edge of the propeller blade body; a plurality of unequidistant saw teeth are formed between the unequal sawtooth grooves and the propeller blade body; a micro array diaphragm structure is bonded to a force suction surface of the propeller blade body; the micro array diaphragm structure consists of a plurality of protrusions with different lengths; the protrusions with the different lengths are distributed in a sinusoidal waveform manner in the width direction of the propeller blade body; and each of the protrusions adopts a sawtooth-like structure, and a closed angle part of the sawtooth-like structure faces to the tail edge of the propeller blade body, and each of the protrusions of the sawtooth-like structure comprises a first sidewall and a second sidewall, wherein a certain inclined angle is at the jointed position of the first sidewall and the corresponding second sidewall. The invention also discloses a rotor unmanned aerial vehicle, and the rotor unmanned aerial vehicle comprises the mute propeller blade. The mute propeller blade disclosed by the invention has the beneficial effects that the noise reduction effect is good, the application range is extended, the efficiency of the unmanned aerial vehicle is improved, and the flying speed of the unmanned aerial vehicle is increased.

Owner:湖北大秀智控科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com