Metal gasket with fishbone-shaped section and inclined teeth

A metal gasket and tooth-shaped technology, which is applied in the sealing of engines, flange connections, pipes/pipe joints/fittings, etc., can solve the problem of small metal resilience, easy damage to the flange surface, and the inability to use fluid pressure to seal the compensation force and other issues to achieve high resilience and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the drawings and embodiments.

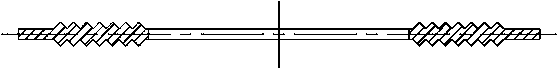

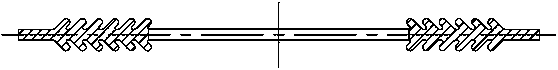

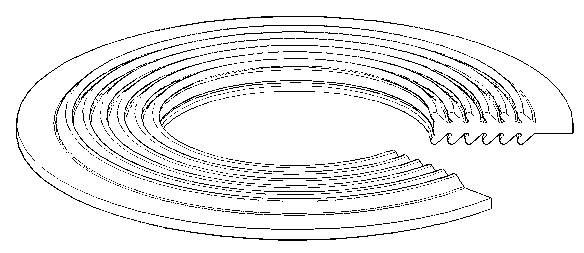

[0019] versus figure 1 The existing sharp-angled gaskets are different. The tooth tip angles of the gaskets of the present invention are non-sharp angles, and some or all of the teeth are arranged obliquely toward the pressure source. When the pressure source is inside the gasket, the gear ring Internal tilt, see figure 2 , image 3 with Figure 4 As shown, the tops of the teeth are rounded or flat, and are evenly arranged. The cross-section of the entire gasket is like a "fish bone" shape. Figure 5 It is the non-uniform arrangement and distribution of the spur gear rings, and there can be vacant toothless areas between the gear rings, forming a double-sealed or multi-sealed gasket structure.

[0020] In addition to the above-mentioned single round tooth or flat tooth structure, the gasket can also adopt a combination of these two structures, such as Image 6 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com