Metal identification piece and manufacturing method thereof

A production method and marking technology, which is applied to metal processing equipment, marking, manufacturing tools, etc., can solve problems such as burrs, material fractures on the side of workpieces, and poor finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

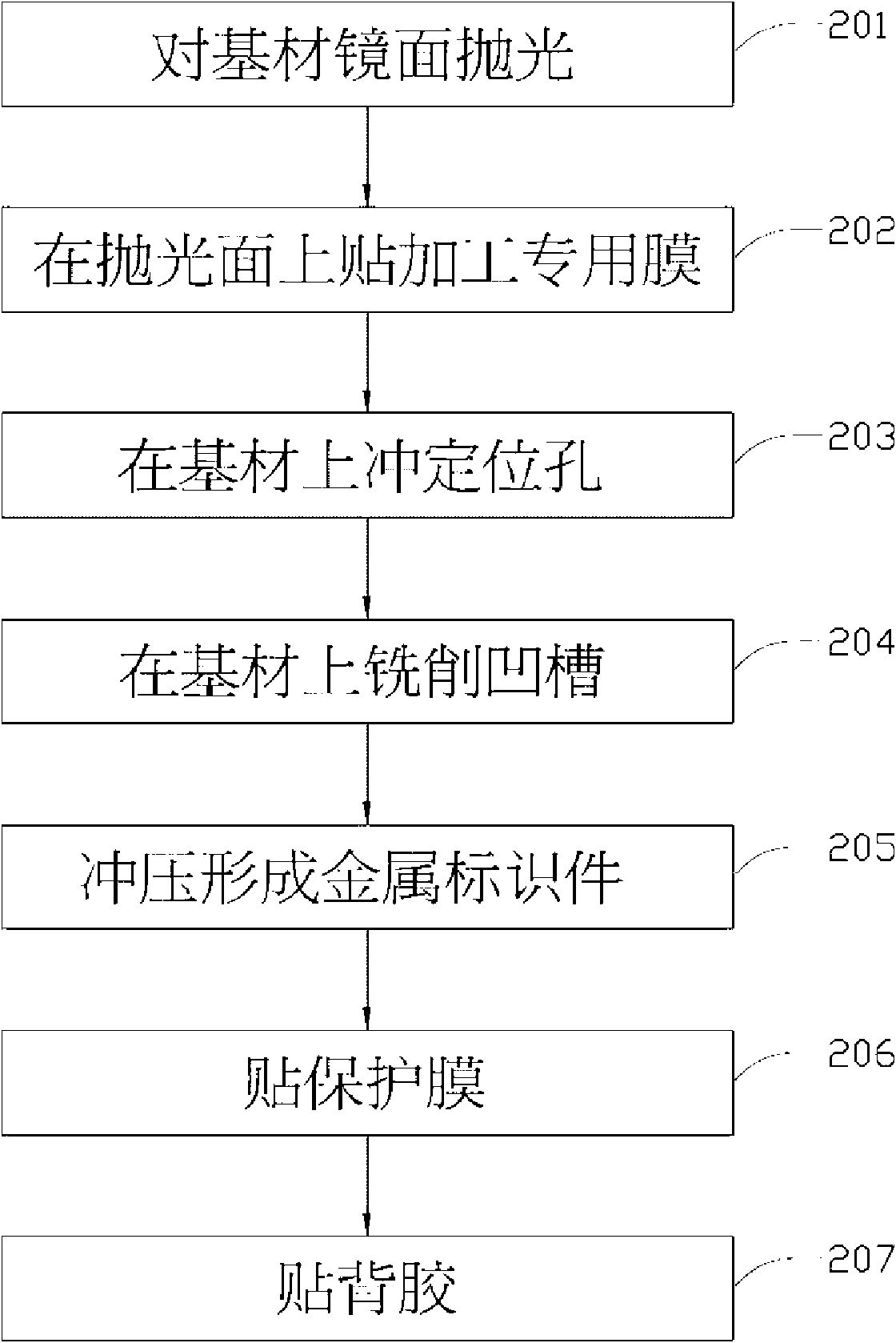

Method used

Image

Examples

Embodiment Construction

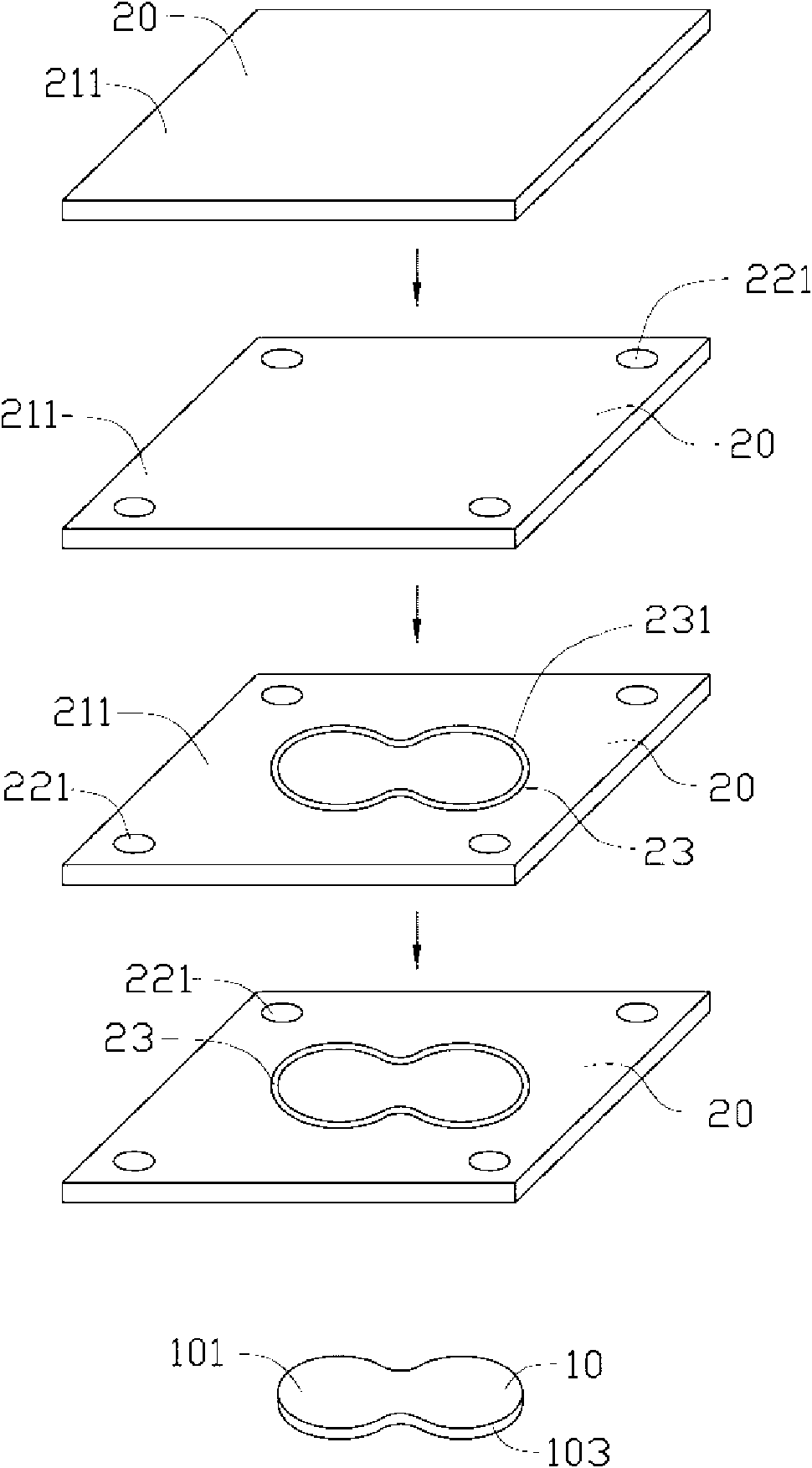

[0021] The metal marker and its manufacturing method of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

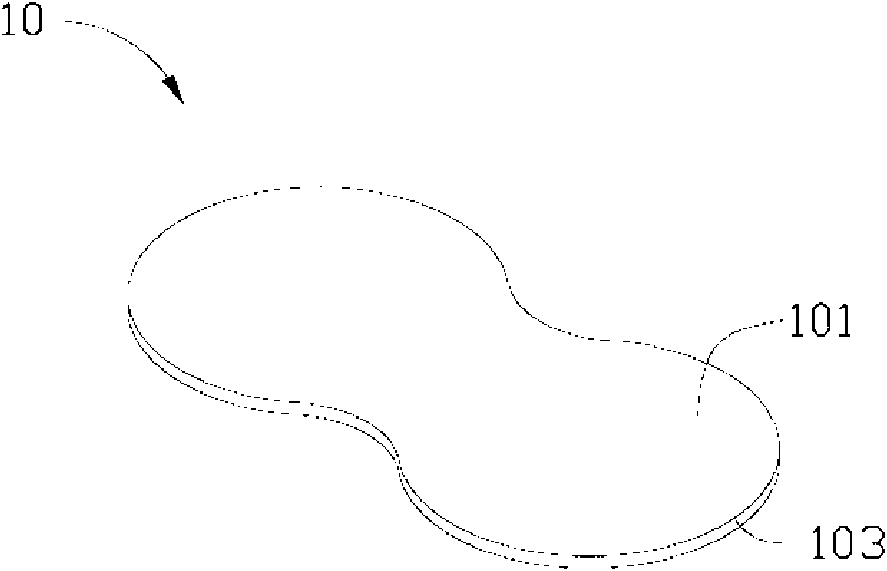

[0022] See figure 1 , the metal marker 10 of the preferred embodiment of the present invention is flat and has a symmetrical structure, and its contour line is formed by smooth connection of four arcs in sequence. The metal sign 10 includes an appearance surface 101 , a back surface (not shown) opposite to the appearance surface 101 , and a side surface 103 connecting the appearance surface 101 and the back surface. The appearance surface 101 is smooth and smooth, the side surface 103 is bright and has no burrs and has milling lines, the side surface 103 is roughly perpendicular to the appearance surface 101, and there is no slump at the connection between them. The appearance surface 101 is a high mirror surface, and its mirror effect is obtained by polishing.

[0023] The material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com