Flexible substrate, manufacturing method thereof and display device

A flexible substrate and flexible substrate technology, which is used in the identification of devices, climate sustainability, and final product manufacturing, etc., can solve the problems of metal wire disconnection, large bending stress, etc. The effect of line risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the flexible substrate, the manufacturing method thereof, and the display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

[0026] When a back film is provided on a flexible substrate, in order to facilitate production, the back film is usually covered on the entire back of the flexible substrate, and the back film is generally made of polyethylene terephthalate (PET) material. The back film is relatively hard, and the flexibility of the back film is relatively poor, resulting in that the back film is prone to generate a large bending stress when it is bent, causing damage to the metal wires inside the flexible substrate, resulting in disconnection of the metal wires.

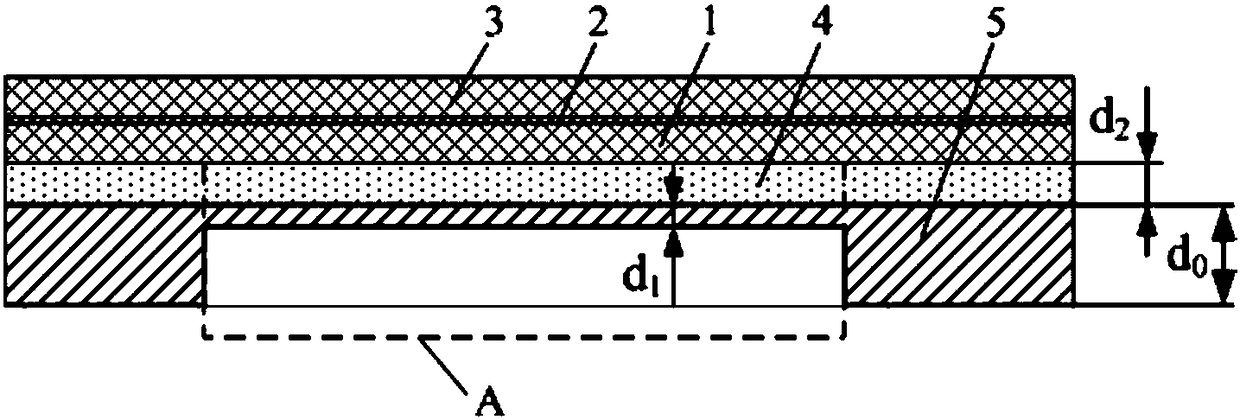

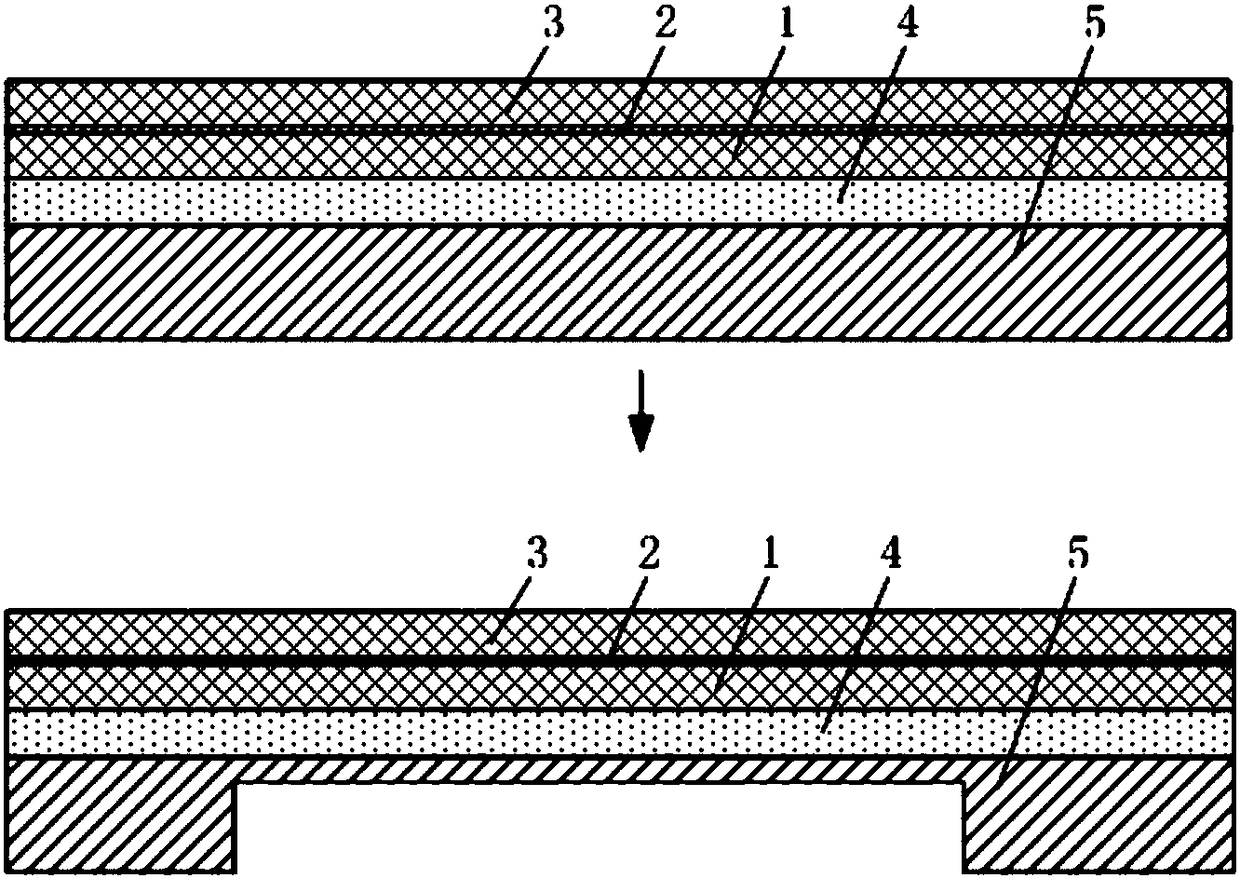

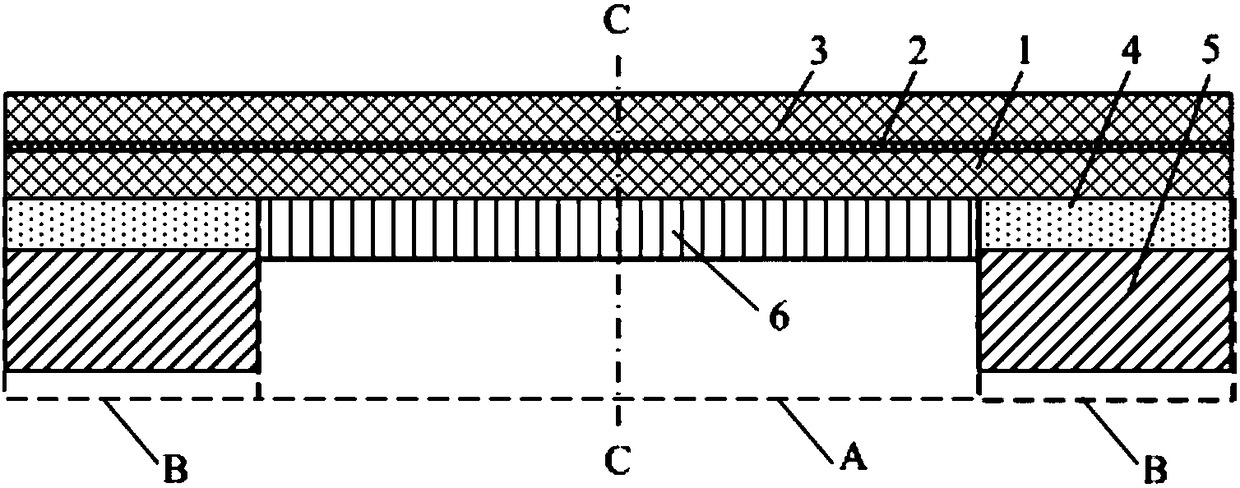

[0027] Currently, in order to reduce the tensile stress required to withstand the metal lines inside the flexible substrate, see figure 1 and figure 2 , the bending stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com