Efficient benzene VOCs gas adsorption molecular sieve and preparation method thereof

A gas adsorption and molecular sieve technology, applied in the field of molecular sieves, can solve the problems of unsatisfactory gas adsorption effect of benzene series VOCs, failure, easy blockage of internal pores by dust and water vapor, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

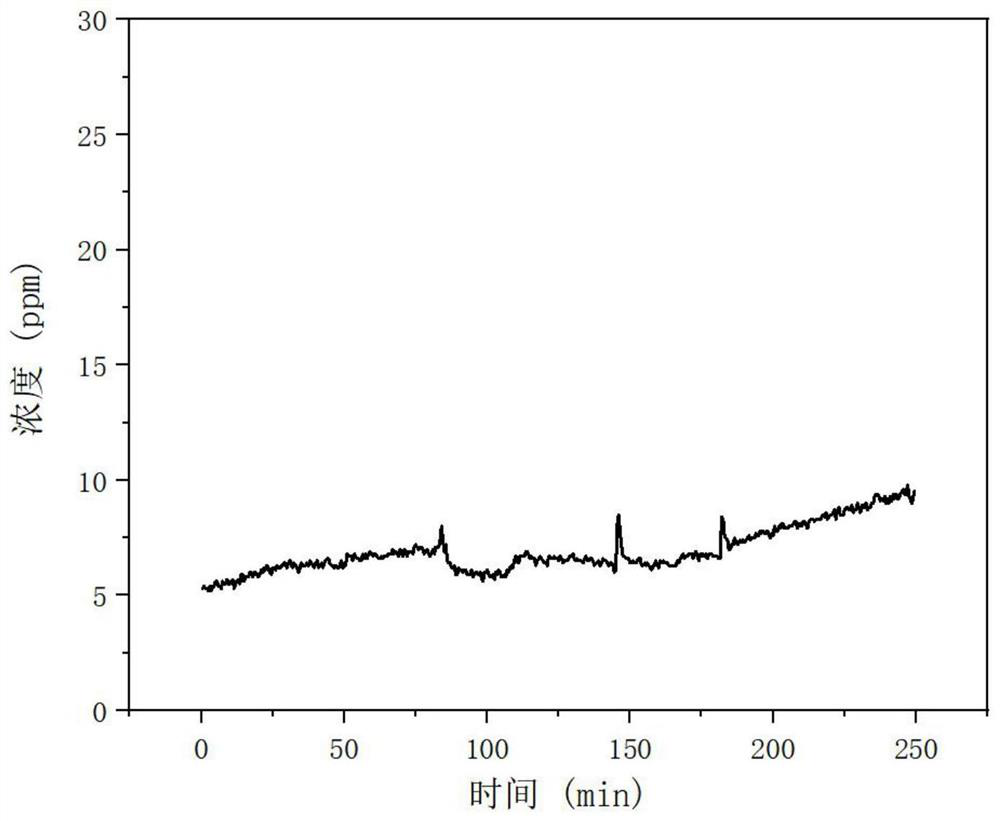

Examples

preparation example Construction

[0025] A preparation method for highly efficient benzene-based VOCs gas adsorption molecular sieves, comprising the steps of:

[0026] After the powder is soaked in lye, washed with water and dried, the honeycomb mesh matrix is made;

[0027] Mix diatomite, attapulgite, kaolin, carbon powder and ZSM-5 molecular sieve raw powder, grind, sieve and mix with silica sol aqueous solution to obtain slurry;

[0028] Immersing the slurry on the surface of the honeycomb mesh matrix, and obtaining the honeycomb carrier with the slurry attached after soaking;

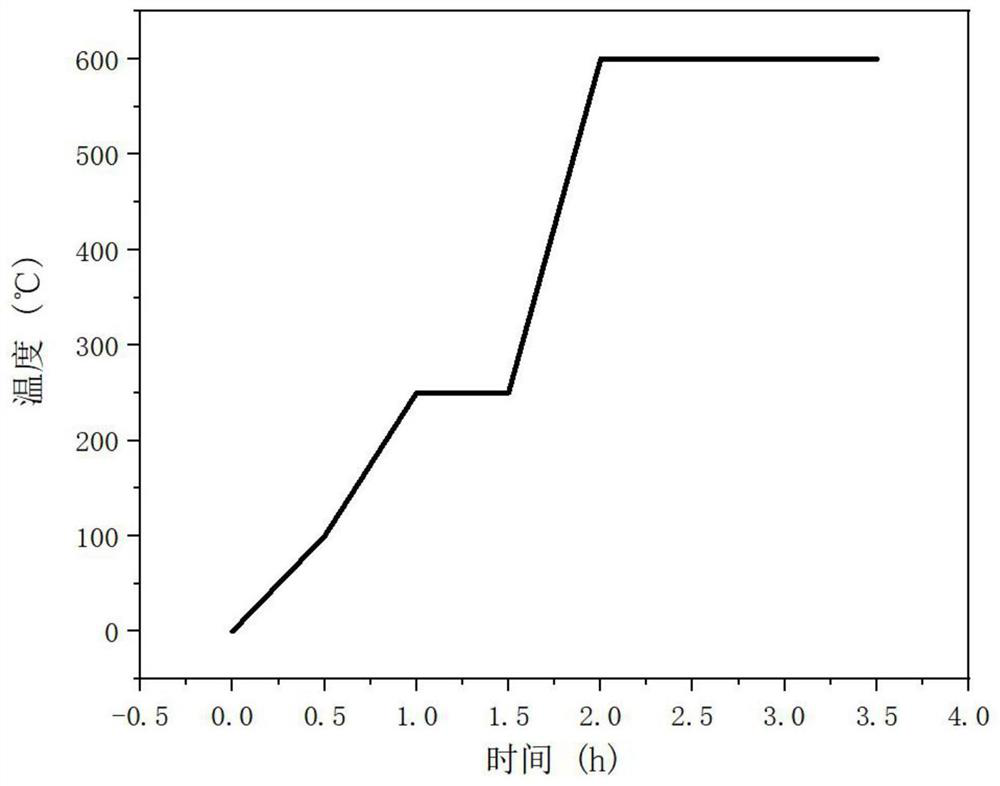

[0029] The honeycomb carrier with the slurry attached is dried and then calcined to obtain a high-efficiency benzene-based VOCs gas adsorption molecular sieve.

[0030] Further, the lye used for soaking the carrier with lye is sodium hydroxide with a mass fraction of 2%, and the immersion time is 30 minutes; after the carrier is washed with water, the pH value of its surface is less than 8; the carrier drying treatment uses The...

Embodiment 1

[0035] A high-efficiency benzene-based VOCs gas adsorption molecular sieve, which is composed of the following raw materials in parts by weight: 2 parts of diatomite; 0.5 parts of attapulgite; 1.3 parts of kaolin; 1.3 parts of carbon powder; 0.5 parts of ZSM-5 molecular sieve raw powder And 4.2 parts of silica sol.

Embodiment 2

[0037] A high-efficiency benzene-based VOCs gas adsorption molecular sieve, which is composed of the following raw materials in parts by weight: 4 parts of diatomite; 1.2 parts of attapulgite; 1.8 parts of kaolin; 1.8 parts of carbon powder; 1.2 parts of ZSM-5 molecular sieve raw powder And 6 parts of silica sol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com