High-performance adsorption film used for removing VOC exhaust gas

An adsorption film and functional technology, applied in the fields of membrane technology, inorganic chemistry, gas treatment, etc., can solve the problem of reduced adsorption performance of the honeycomb adsorption film forming body, and achieve the avoidance of device heat storage, large thermal conductivity, high adsorption and desorption The effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

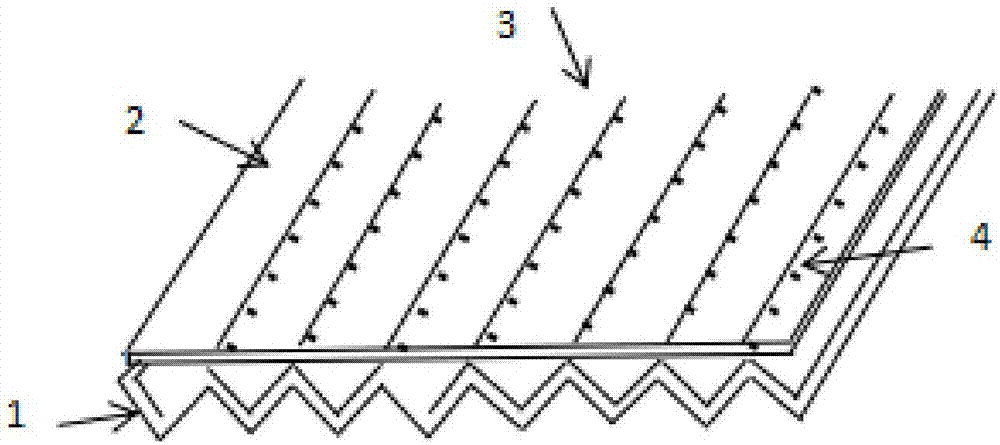

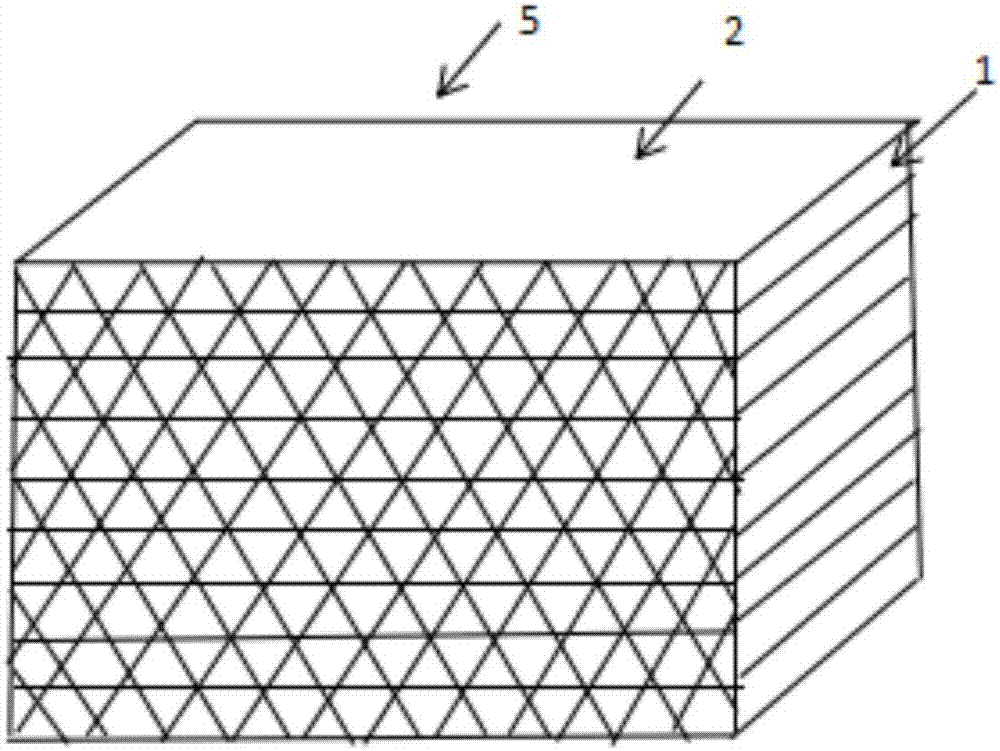

[0038] see figure 1 and figure 2 , the embodiment of the present invention also provides a method for preparing the above-mentioned high-performance adsorption membrane 5, comprising the following steps:

[0039] Utilize the method of spotting at intervals to fix adsorbent particles (not shown) with a particle size of 200-500 μm on the activated carbon fiber type non-woven fabric film through adhesive particles 4 to make two kinds of flat type 2 and corrugated type 1 Membrane products; wherein, the particle size of the binder is 1 / 4-1 / 3 of the particle size of the adsorbent particles;

[0040] The flat type 2 and corrugated type 1 membrane products are made into a semi-honeycomb membrane product 3, and then the semi-honeycomb membrane products are laminated to obtain the high-performance adsorption membrane 5.

[0041] In order to realize the purpose of the present invention, the inventors have repeatedly studied and found that the activated carbon fiber non-woven fabric me...

Embodiment 1

[0067] The adsorbent uses 350 μm zeolite particles, and the thermoplastic adhesive uses a two-component hardening adhesive made of 100 μm methacrylic resin and polyisocyanate. Liquid hardening adhesive / zeolite = 28.6%, to make a VOCs-containing exhaust gas adsorption film (that is, the high-performance adsorption film).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com