High-performance composite adsorbing material and preparing method and application thereof

A composite adsorption material, high-performance technology, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of poor adsorption of small molecular substances, the adsorption effect is not as good as activated carbon, zeolite specific surface area, etc. Tunable channels, fast adsorption/desorption rates, and fast diffusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

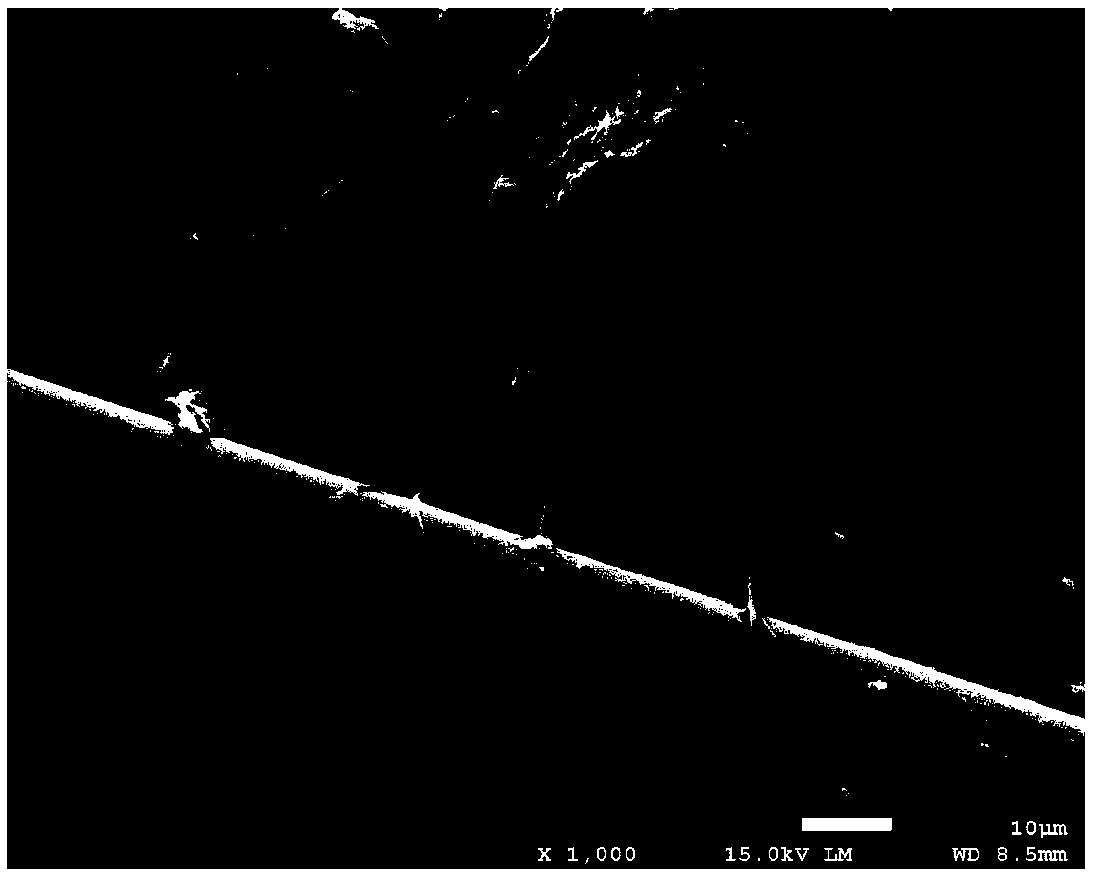

[0025] Weigh 2.2g beating degree of 62 ° SR wood pulp fiber, 0.8g special fiber (diameter 5μm, length 6mm), 1.0g polyvinyl alcohol, 5g powdered zeolite, 5g powdered activated carbon, 1.1g water-insoluble flame retardant, 20kg Water, after mixing the components, disperse with a mixer for 30 minutes. Put the uniformly dispersed mixed material into the water filter machine to form and dry it, and use scanning electron microscope to characterize it, as shown in figure 1 shown by figure 1 It can be seen that the wood pulp fiber has a dense continuous structure, and the special fibers are intertwined in a disorderly manner to form a skeleton, and the zeolite and activated carbon are fixed in the large gaps of the skeleton. Facilitate the diffusion and mass transfer of adsorbate.

[0026] The same formula and process as above were used to prepare comparative products. In comparison 1, polyester fiber was used to replace special fiber, and in comparison 2, glass fiber was used to re...

Embodiment 2

[0033] Take by weighing 1.8g degree of beating and be 40 ° SR wood pulp fiber, 0.6g special fiber (diameter 5 μ m, length 6mm), 2.25g chitosan, 6.75g powdered zeolite, 3g powdered active carbon, 0.6g aluminum hydroxide, 33.3kg water , After mixing the components, disperse with a stirrer for 30 minutes. Put the uniformly dispersed mixed material into a water filter machine to form and dry.

Embodiment 3

[0035] Take by weighing 2.25g degree of beating and be 50 ° SR wood pulp fiber, 0.75g special fiber (diameter 10 μm, length 10mm), 0.9g starch, 4.95g powdered zeolite, 4.95g powdered active carbon, 0.6g aluminum phosphate, 0.6g magnesium phosphate, 3.34kg of water, after mixing the components, disperse with a stirrer for 15 minutes. Put the uniformly dispersed mixed material into a water filter machine to form and dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com