High-efficiency oil fume adsorption molecular sieve and preparation method

A molecular sieve and oil fume technology, applied in the field of molecular sieve, can solve the problems of air duct instability, total weight and specific gravity of the device, etc., and achieve the effects of well-developed pores, good adsorption effect, and small gas resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method for high-efficiency oil fume adsorption molecular sieves, comprising the steps of:

[0031] The ceramic fiber carrier is soaked in lye, washed with water and dried to make a honeycomb mesh matrix;

[0032] After mixing diatomite, attapulgite, kaolin and 13x molecular sieve raw powder, grinding, sieving and mixing with silica sol aqueous solution to obtain a slurry;

[0033] Immersing the slurry on the surface of the honeycomb mesh matrix, and obtaining the honeycomb carrier with the slurry attached after soaking;

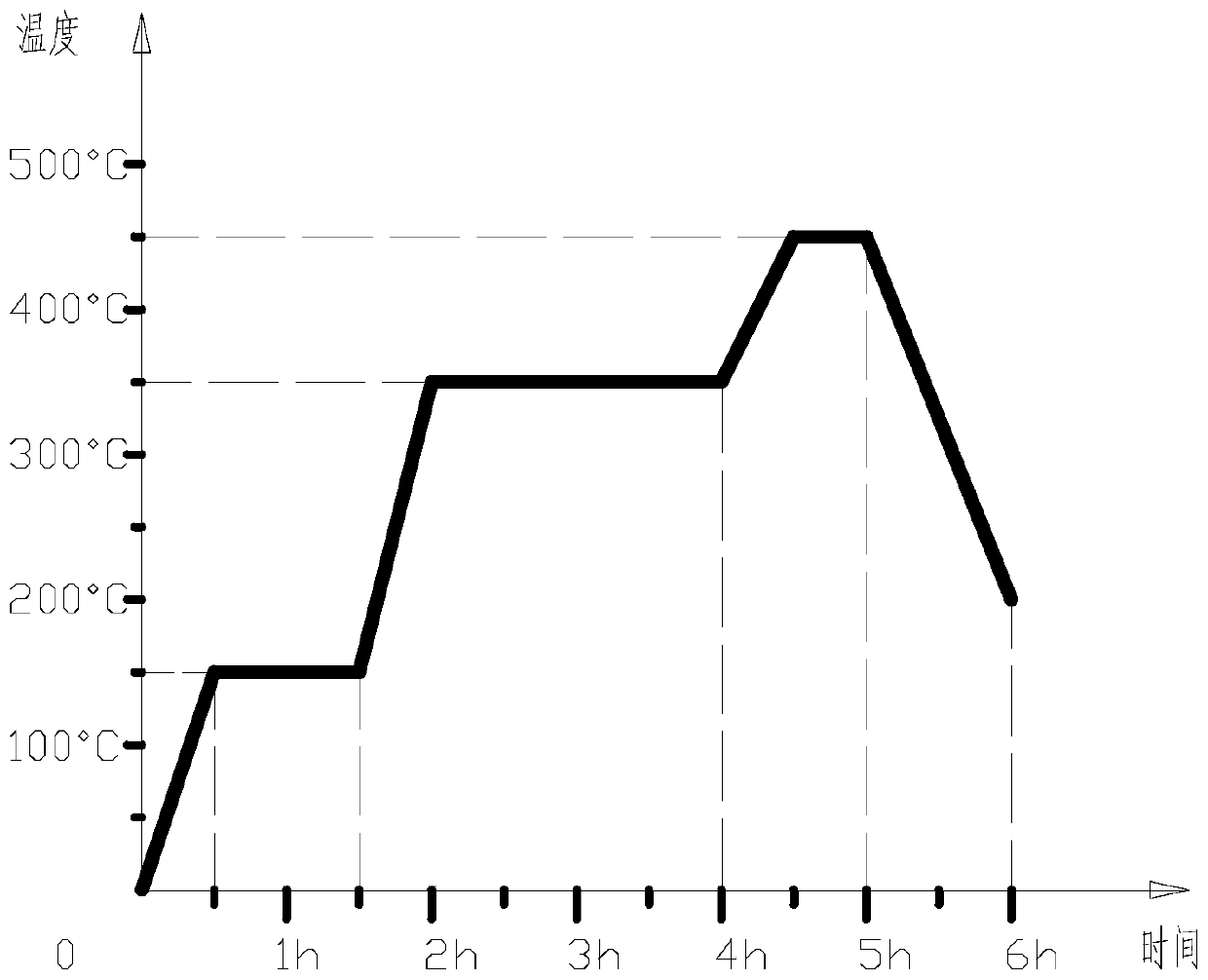

[0034] The honeycomb carrier attached with the slurry is dried and then calcined to obtain a high-efficiency oil fume adsorption molecular sieve.

[0035] Further, the lye used for soaking the ceramic fiber carrier with lye is sodium hydroxide with a mass fraction of 2%, and the immersion time is 30 minutes; after the ceramic fiber carrier is washed with water, the pH value of its surface is less than 8; The treatment method adopted in ...

Embodiment 1

[0040] A high-efficiency oil fume adsorption molecular sieve is made of a ceramic fiber carrier and a filler filled in the ceramic fiber carrier; the filler is composed of the following raw materials in parts by weight: 2 parts of diatomite; 0.5 part of attapulgite; kaolin 1.3 parts; 0.5 parts of 13x molecular sieve powder and 4.2 parts of silica sol.

Embodiment 2

[0042] A high-efficiency oil fume adsorption molecular sieve is made of a ceramic fiber carrier and a filler filled in the ceramic fiber carrier; the filler is composed of the following raw materials in parts by weight: 4 parts of diatomite; 1.2 parts of attapulgite; kaolin 1.8 parts; 1.2 parts of 13x molecular sieve powder and 6 parts of silica sol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com