Distribution device and distribution method for high-operating-flexibility liquid

A liquid distribution device and technology of operation flexibility, applied in the field of liquid distribution of packed rectification towers, can solve the problems of insufficient operation elasticity, increased tower height, small operation elasticity, etc., and achieves low installation level requirements, small liquid level fluctuation, gas Low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

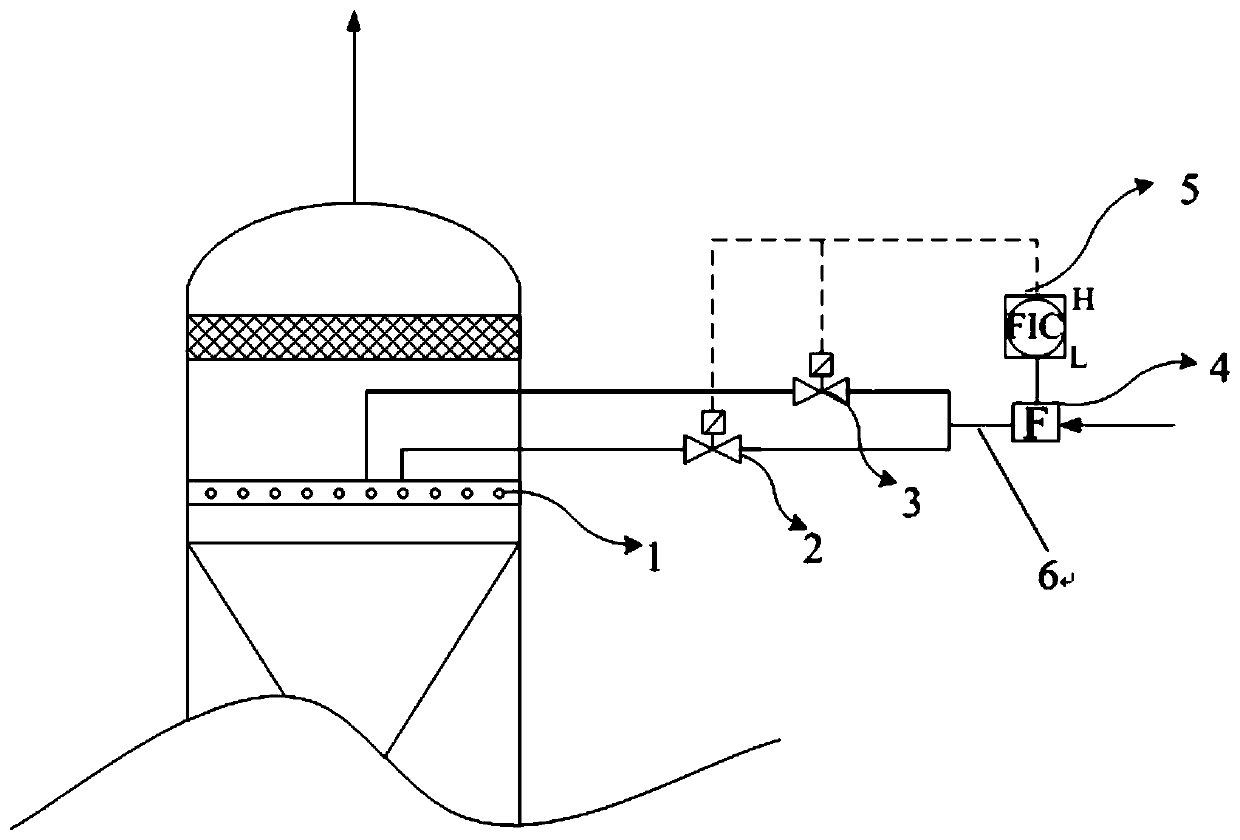

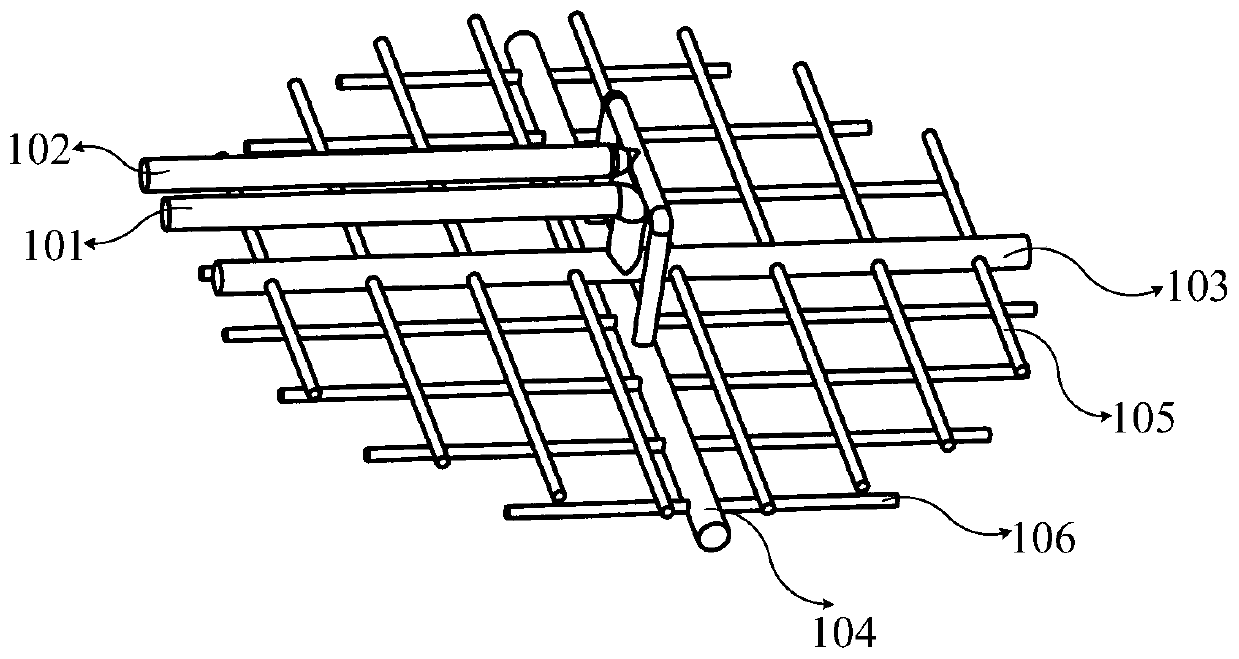

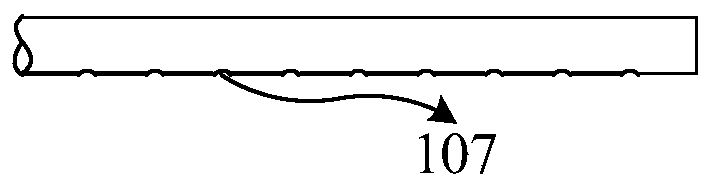

[0061] structured as figure 1 , 2 shown. Tower diameter 700mm, maximum return flow 10m 3 / h, the minimum return flow is 0.77m 3 / h, the inner diameter of the first feeding pipe is 25mm, the inner diameter of the second feeding pipe is 50mm, the inner diameter of the two branch pipes branched out from the second feeding pipe is 32mm, the inner diameter of the first liquid distribution pipe is 25mm, and the first liquid distribution pipe The inner diameter of the pipe is 15mm, the number of the first liquid distribution pipes is 2×8, arranged symmetrically, the diameter of the liquid distribution hole is 5mm, the distance between the liquid distribution holes is 82mm, arranged in a square and the distance from the tower wall is 50mm without holes, the center of the bottom of the first liquid distribution pipe There are 6 holes on the line, the diameter is 5mm, and the spacing is 82mm. There are 52 holes on the center line of the bottom of the first liquid distribution pipe, a...

Embodiment 2

[0066] Tower diameter 1000mm, maximum return flow 20.4m 3 / h, the minimum return flow is 1.57m 3 / h, the inner diameter of the first feeding pipe is 50mm, the inner diameter of the second feeding pipe is 65mm, the inner diameter of the two branch pipes branched from the second feeding pipe is 45mm, the inner diameter of the first liquid distribution pipe is 50mm, and the first liquid distribution pipe The inner diameter of the pipe is 15mm, the number of the first liquid distribution pipes is 2×12, symmetrically arranged, the diameter of the liquid distribution hole is 4mm, and the distance between the liquid distribution holes is 72mm, arranged in a triangle and the distance from the tower wall is 72mm without holes, the center of the bottom of the first liquid distribution pipe There are 12 holes on the line, the diameter is 4mm, and the spacing is 72mm. There are 136 holes on the center line of the bottom of the first liquid distribution pipe, a total of 148 liquid distribu...

Embodiment 3

[0069] Tower diameter 1200mm, maximum return flow 17m 3 / h, minimum return flow 1.3m 3 / h, the inner diameter of the first feeding pipe is 32mm, the inner diameter of the second feeding pipe is 65mm, the inner diameter of the two branch pipes branched out from the second feeding pipe is 45mm, the inner diameter of the first liquid distribution pipe is 32mm, and the first liquid distribution pipe The inner diameter of the pipe is 15mm, the number of the first liquid distribution pipes is 2×10, arranged symmetrically, the diameter of the liquid distribution hole is 5mm, the distance between the liquid distribution holes is 100mm, arranged in a square and the distance from the tower wall is 100mm without holes, the center of the bottom of the first liquid distribution pipe There are 5 holes on the line, the diameter is 5mm, and the spacing is 100mm. There are 108 holes on the center line of the bottom of the first liquid distribution pipe, a total of 113 liquid distribution holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com