Electronic dust remover

An electrostatic precipitator and negative electrode technology, which is applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of high operating cost of bag filter, large operating resistance of bag filter, and no electrostatic effect. , to achieve the effect of low cost, good high temperature tolerance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

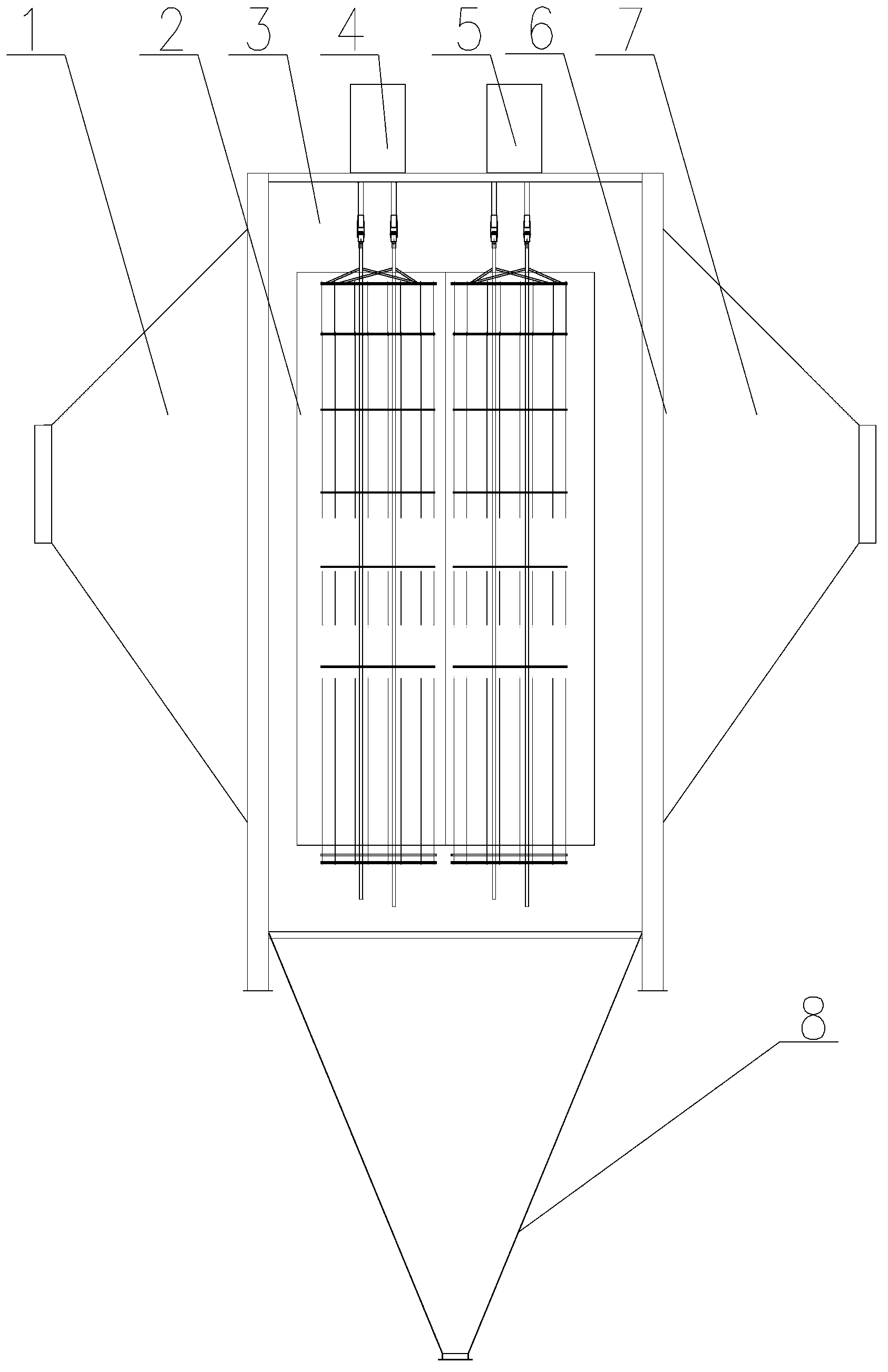

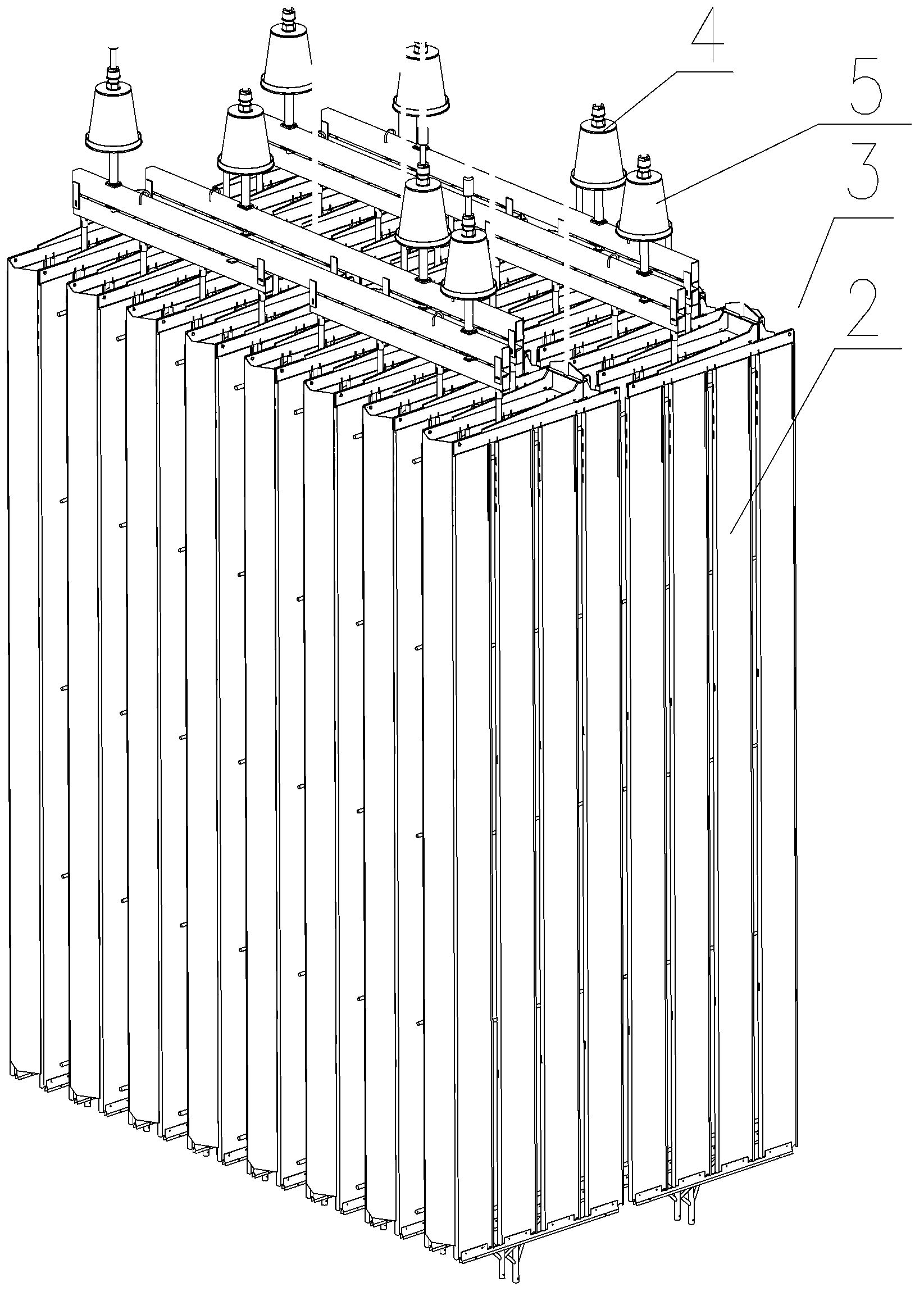

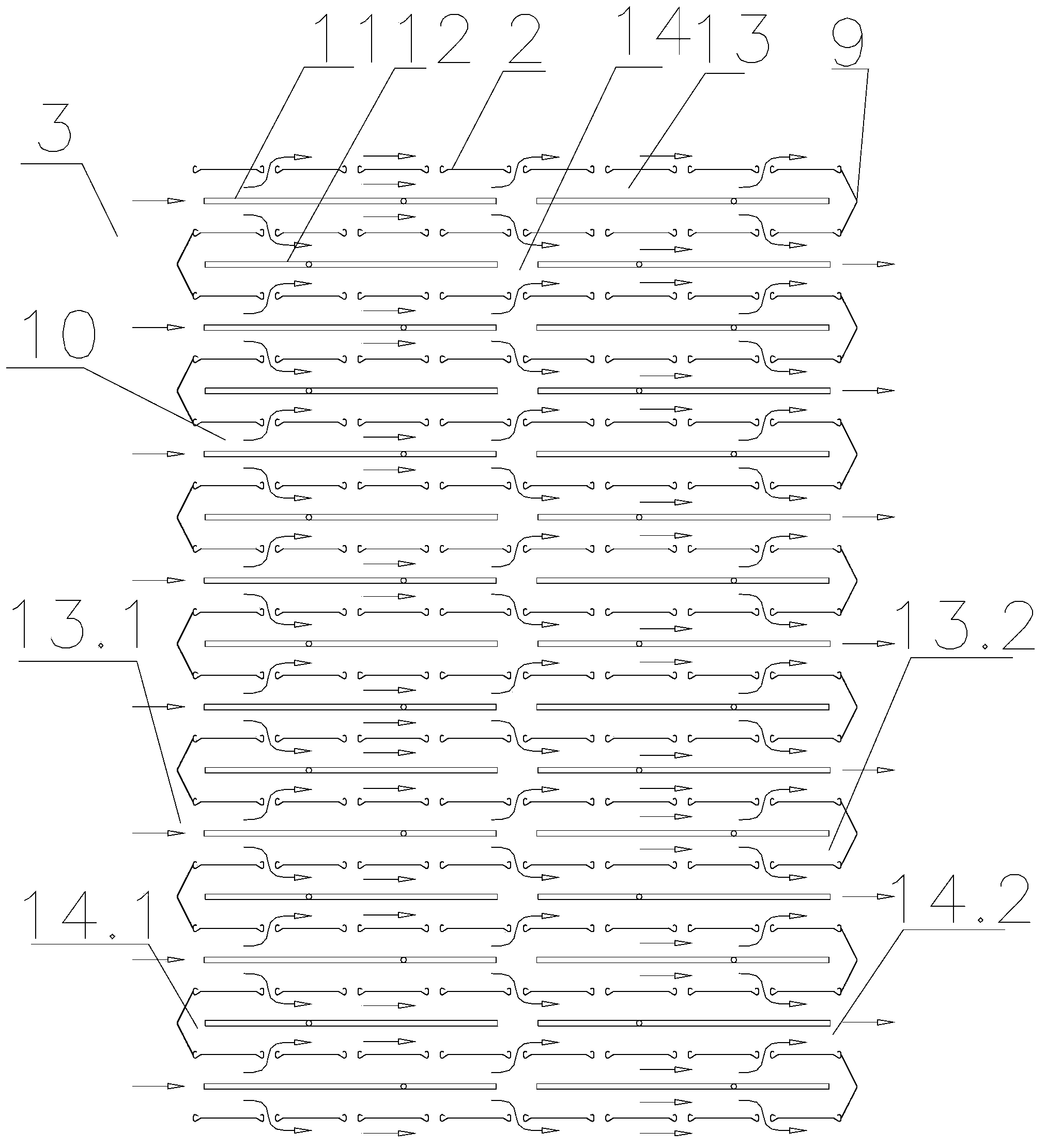

[0033] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are explained to make the present invention clearer and easier to understand.

[0034] For the convenience of description, the present invention starts with Figure 1 to Figure 6 The illustrated embodiment is taken as an example to illustrate the invention in detail:

[0035]With reference to the accompanying drawings, it can be seen that the electrostatic precipitator includes a housing 6 with a dust removal cavity 3 inside, one side of the housing 6 communicates with the air intake device 1, and the other side communicates with the exhaust device 7, and the dust removal cavity 3 is provided with a multi-layer grounded dust collection pole 2. The dust collection cavity 3 is divided into a plurality of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com