A-directional sapphire mobile phone cover plate polishing solution and preparation method thereof

A technology for sapphire and mobile phone covers, applied in polishing compositions containing abrasives, etc., can solve the problems of low removal rate and poor surface quality, and achieve the effect of eliminating scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

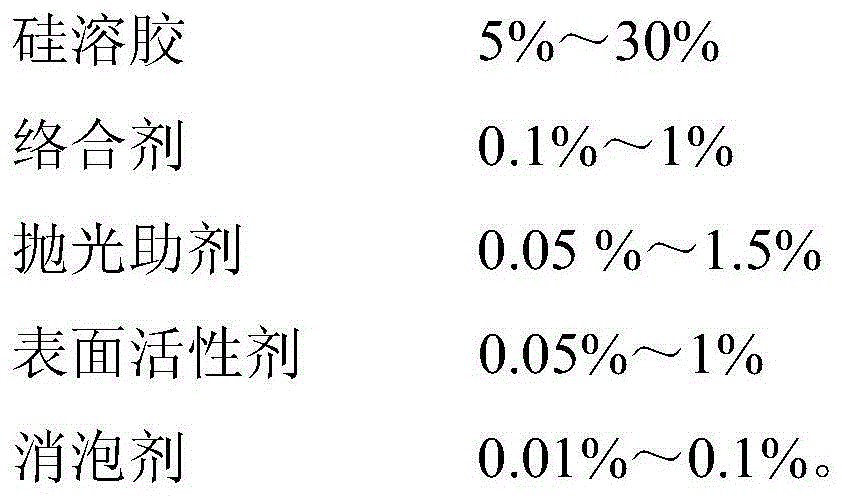

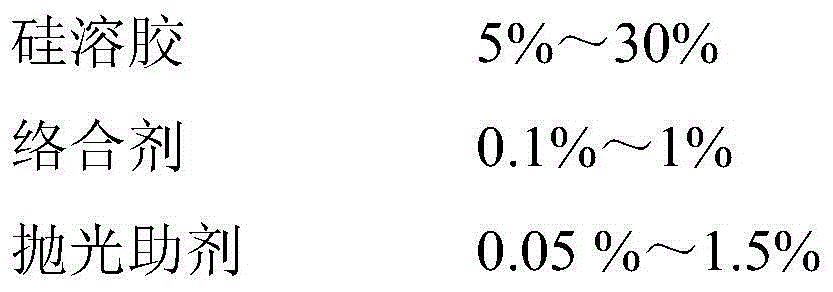

[0030] Under the action of mechanical stirring, the silica sol was added into deionized water to disperse and dilute, then sequentially added polishing aids, complexing agents, surfactants, and defoamers, and used a pH regulator to adjust the pH value of the polishing solution, specifically See Table 1 for the ratio.

[0031] Table 1. Each group distribution ratio in embodiment 1-5

[0032]

[0033] Use the above polishing solution to perform chemical mechanical polishing on the A-direction sapphire mobile phone cover. The process conditions are shown in Table 2:

[0034] Table 2. The processing conditions of embodiment and comparative example

[0035] polisher

HAMAI-16B (double-sided)

Disk Size(mm)

1160

polishing pad

SUBA 800

speed(rpm)

35

[0036] Pressure (g / cm 2 )

300

Polishing liquid flow rate (L / min)

1

Polishing time (min)

150

Workpiece to be processed

5.5 inch sapp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com