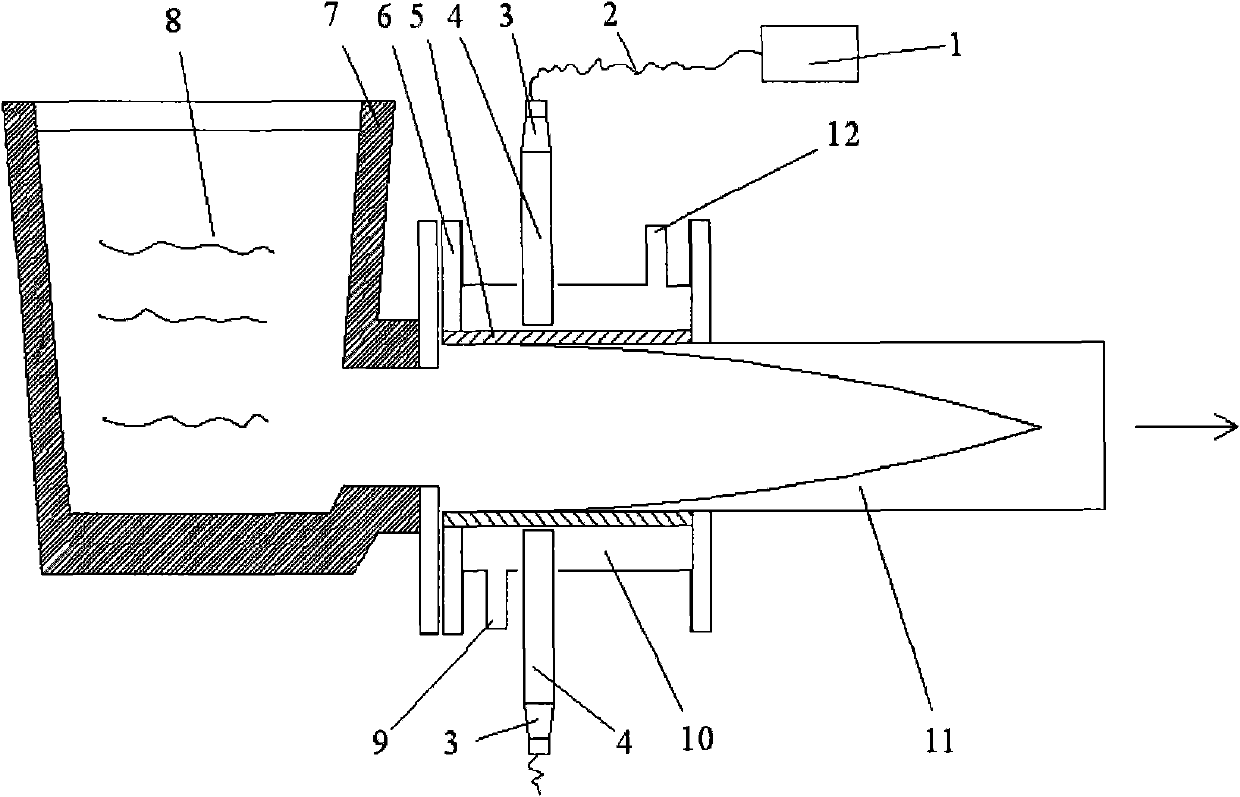

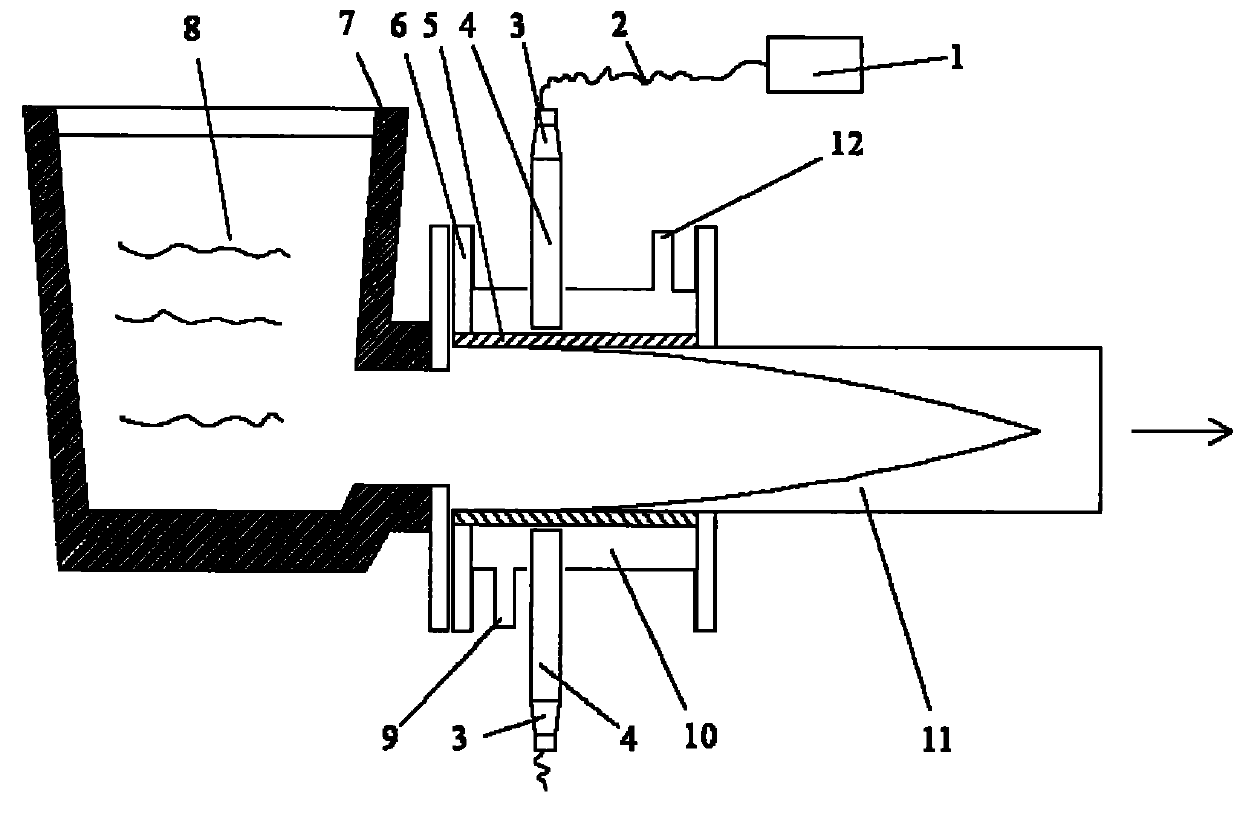

Continuous casting crystallizer device using ultrasonic vibration

A technology of continuous casting crystallizer and ultrasonic wave, which is applied in the field of metallurgical continuous casting, can solve problems such as vibration defects of slabs that cannot be solved, and achieve the effects of reducing height, saving investment, and eliminating bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: In this embodiment, aluminum ingots are cast continuously. The size of the crystallizer used is 50×50mm in section and 500mm in length. It is a rectangle made of copper plate. The ultrasonic vibration crystallizer is made according to the method described in the patent of the present invention. The power of the ultrasonic wave is 100W and the frequency is 15KHz. The ratio of copper plate area is 1000W / M 2 . One end of the ultrasonic vibration crystallizer is connected to the tundish, and the other end is plugged with a dummy head in the copper plate of the mold before pouring. The dummy head is pulled by a steel wire rope, and the other end of the wire rope is connected to the winch driven by a motor and a gearbox. During the test, first put 100 kg of aluminum ingot into a 100 kg medium frequency induction furnace to melt, after it is completely melted, turn on the ultrasonic power supply, let the ultrasonic crystallizer start to work; then pour the melte...

Embodiment 2

[0021] Embodiment 2: This embodiment continuously casts copper ingots. The size of the crystallizer used is 50 × 50mm in cross section and 500mm in length. It is a rectangle made of copper plate. The ultrasonic vibration crystallizer is made according to the method described in the patent of the present invention. The power of the ultrasonic wave is 500W and the frequency is 30KHz. The ratio of copper plate area is 5000W / M 2 . One end of the ultrasonic vibration crystallizer is connected to the tundish, and the other end is plugged with a dummy head in the copper plate of the mold before pouring. The dummy head is pulled by a steel wire rope, and the other end of the wire rope is connected to the winch driven by a motor and a gearbox. During the test, first add 100 kg of copper ingots to a 100 kg medium frequency induction furnace and melt them. After they are completely melted, turn on the ultrasonic power supply and let the ultrasonic crystallizer start to work; then pour t...

Embodiment 3

[0022] Embodiment 3: In this embodiment, steel ingots are cast continuously. The size of the crystallizer used is 50×50mm in cross section and 500mm in length. It is a rectangle made of copper plate. The ultrasonic vibration crystallizer is made according to the method described in the patent of the present invention. The power of the ultrasonic wave is 1000W and the frequency is 60KHz. The ratio of copper plate area is 10000W / M 2 . One end of the ultrasonic vibration crystallizer is connected to the tundish, and the other end is plugged with a dummy head in the copper plate of the mold before pouring. The dummy head is pulled by a steel wire rope, and the other end of the wire rope is connected to the winch driven by a motor and a gearbox. During the test, first put a 100 kg steel ingot into a 100 kg medium frequency induction furnace and melt it. After it is completely melted, turn on the ultrasonic power supply and let the ultrasonic crystallizer start to work; then pour t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com