Low-liquid-level boiling pot

A low-level, pot-covered technology applied to low-level boiling pots. It can solve the problems of short service life, slow heating speed and high nutrient loss, etc., and achieve the effect of beautiful appearance, uniform heating and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

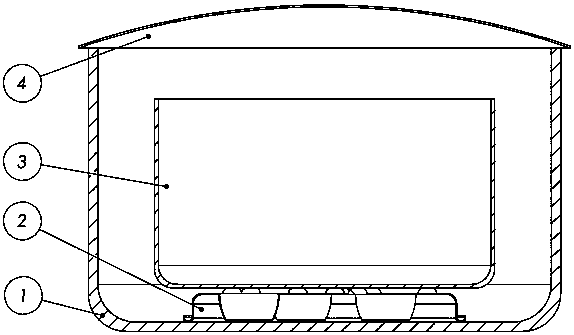

[0024] Such as figure 1 As shown, a low-level boiling pot includes an inner tank (1), a tray (2), a rice bowl (3), and a pot cover (4); the inner tank (1) of the pot is placed on the inner bottom of the tray (2 ), the rice bowl (3) is placed on the tray (2), and the upper edge of the inner container (1) is covered with a pot cover (4); the general technical parts other than the inventive technology of the present invention will not be repeated, and the tray (2 ) is smaller than the inner diameter of the inner pot (1), the rice bowl (3) is smaller than the inner pot (1), and there is a gap between the rice bowl (3) and the pot cover (4).

[0025] figure 2 It is the front view of the tray (2). The main body of the tray (101) is an upside-down basin. There are multiple egg holes (102) on the tray. The hole is similar in shape to an oval egg, and the lower edge of the egg hole (102) is flush with the lower edge of the outer ring of the tray main body (101) or slightly higher by...

Embodiment 2

[0031] Such as Figure 4 As shown, a soybean milk machine with low liquid level boiling includes a heating plate II (11), a steam pot (12), a tray (13), a soybean milk cup (14), a beating head (15), and a heating plate Put the steam pot (12) on the top of Ⅱ (11), place the tray (13) on the inner bottom of the steam pot (12), place the soybean milk cup (14) on the groove of the tray (13), and place the bean milk cup (14) on the top of the steam pot (12). Paddle head (15); the general technical part other than the inventive technology of the present invention will not be repeated. The diameter of the tray (13) is equal to the inner diameter of the bottom of the steam pot (12), that is to say, the tray (13) is stuck in the constriction at the bottom of the steam pot (12), and the soybean milk cup (14) is smaller than the tray (13) just in line with the tray ( 13), the soybean milk cup (14) is stuck in the groove to prevent the soybean milk cup (14) from moving when the beating h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com