Treatment Process for Bars

a technology of rolled bars and treatment process, which is applied in the direction of quenching devices, furnace types, furnaces, etc., can solve the problems of reducing mechanical resistance and impact resistance, affecting the quality of rolled bars, so as to achieve high quality, free of scoring and surface defects, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

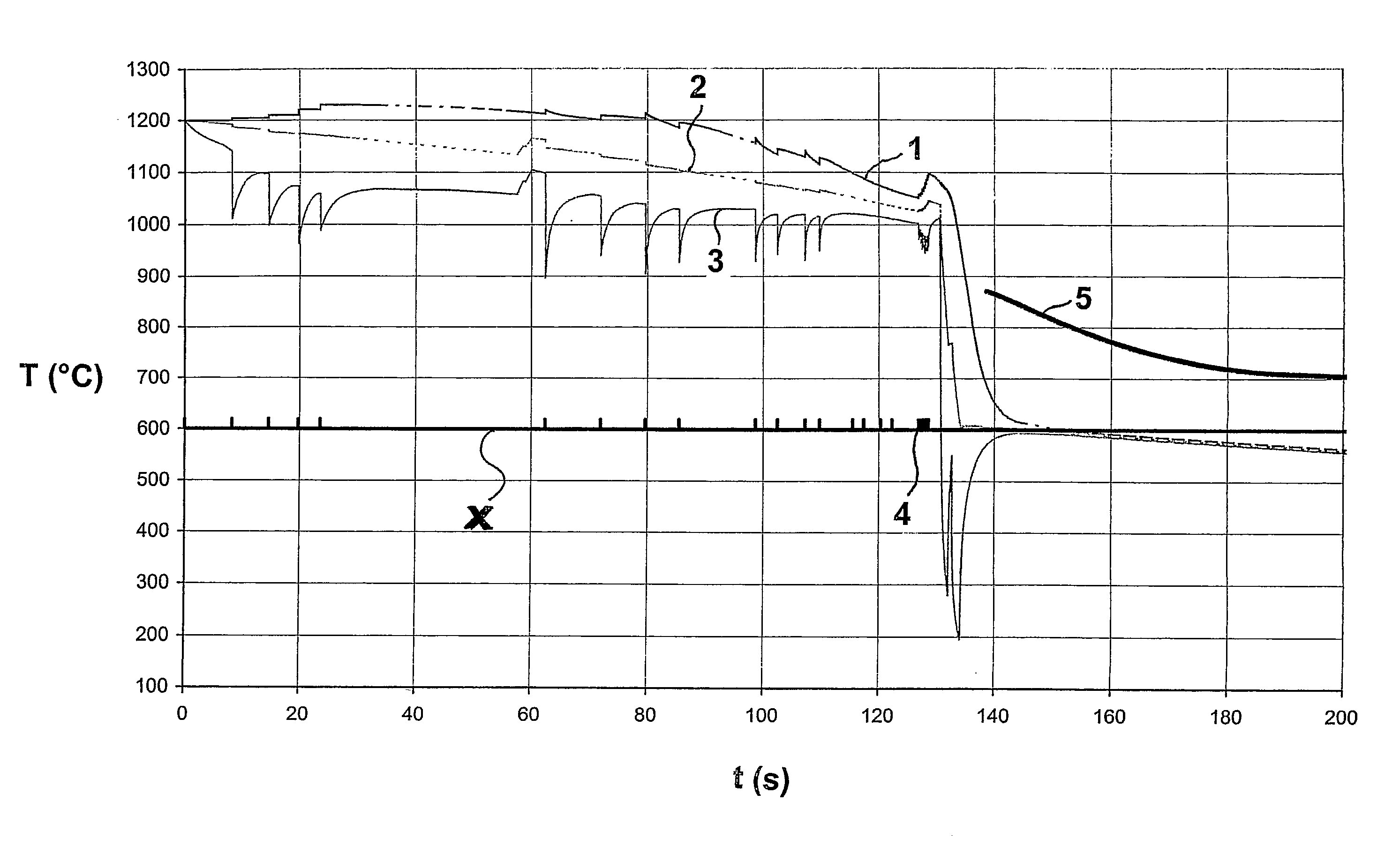

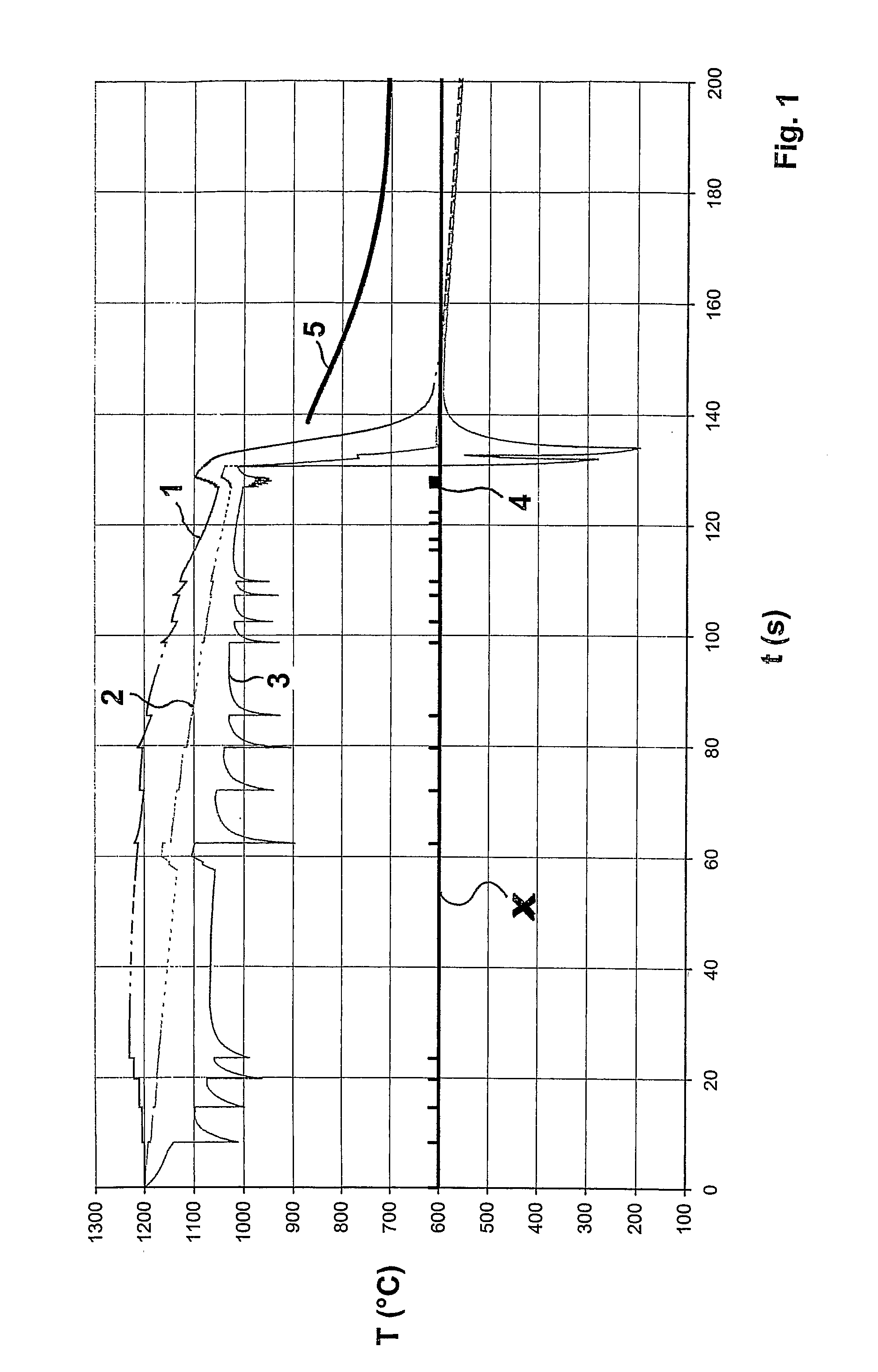

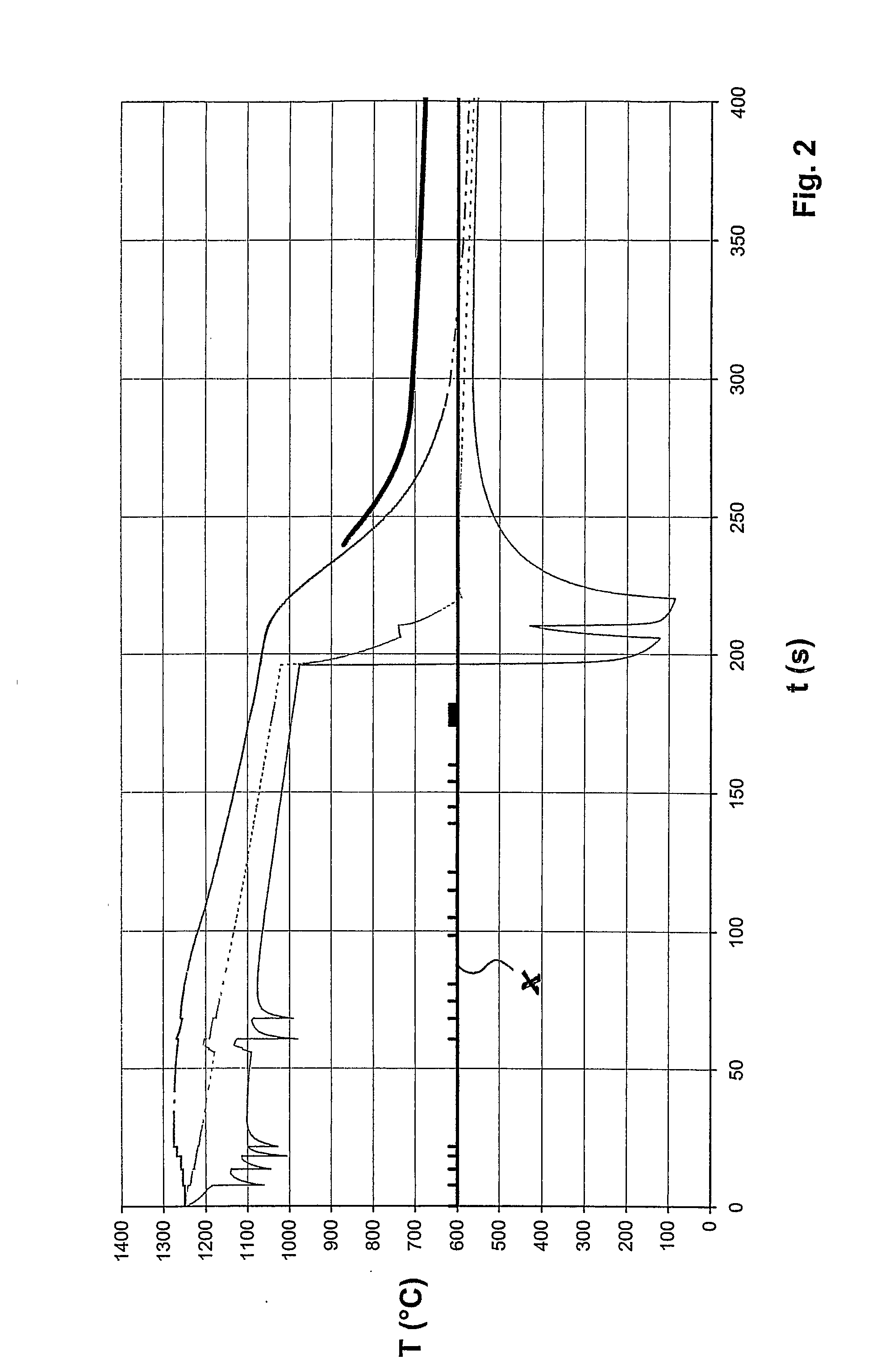

[0039]To determine the treatment process of the invention, which makes it possible to obtain, directly after rolling, a material devoid of intergranular corrosion and with microstructural characteristics suitable for subsequent uses, it was fundamental to identify the following parameters:[0040]the position of the devices adapted to guarantee the correct treatment;[0041]the initial treatment temperature interval to obtain a structure totally devoid of carbides and with a homogeneous microstructure;[0042]the end of treatment temperatures, that is, those for which passing through the critical range of carbide precipitation can be considered to have terminated, and for which distortion due to residual heat is avoided.

[0043]The duration of the treatment according to this invention is a parameter which depends on the dimensions of the bar and on the rolling speed.

[0044]Other important parameters to perform the solution quenching treatment in line, directly downstream of the rolling mill,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com