Pipeline outer opening aligning device and pipeline grouping welding method

A technology of external pairing and device pairing, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low construction efficiency and poor welding quality, and achieve the effect of simple operation, guaranteed welding quality and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the invention will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

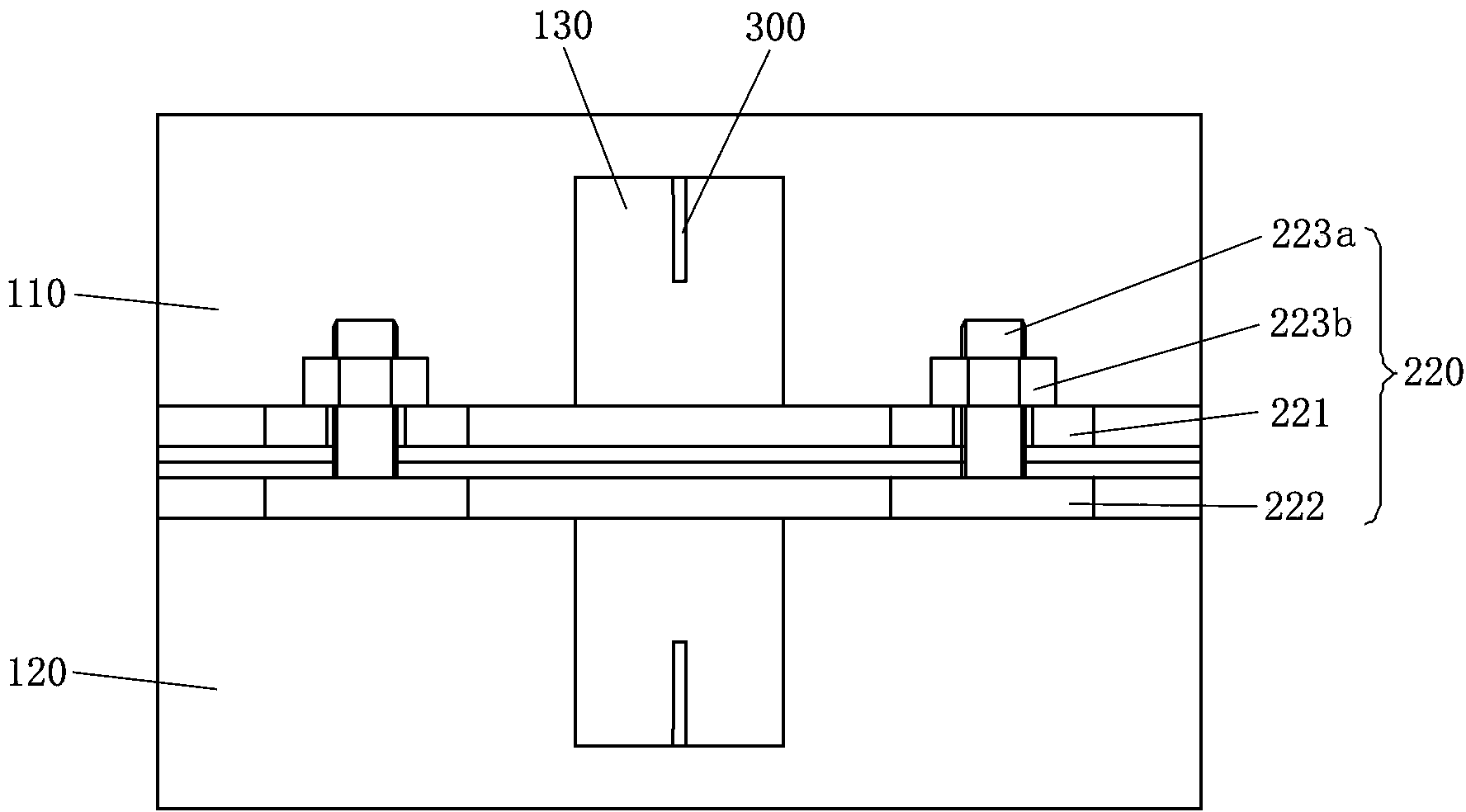

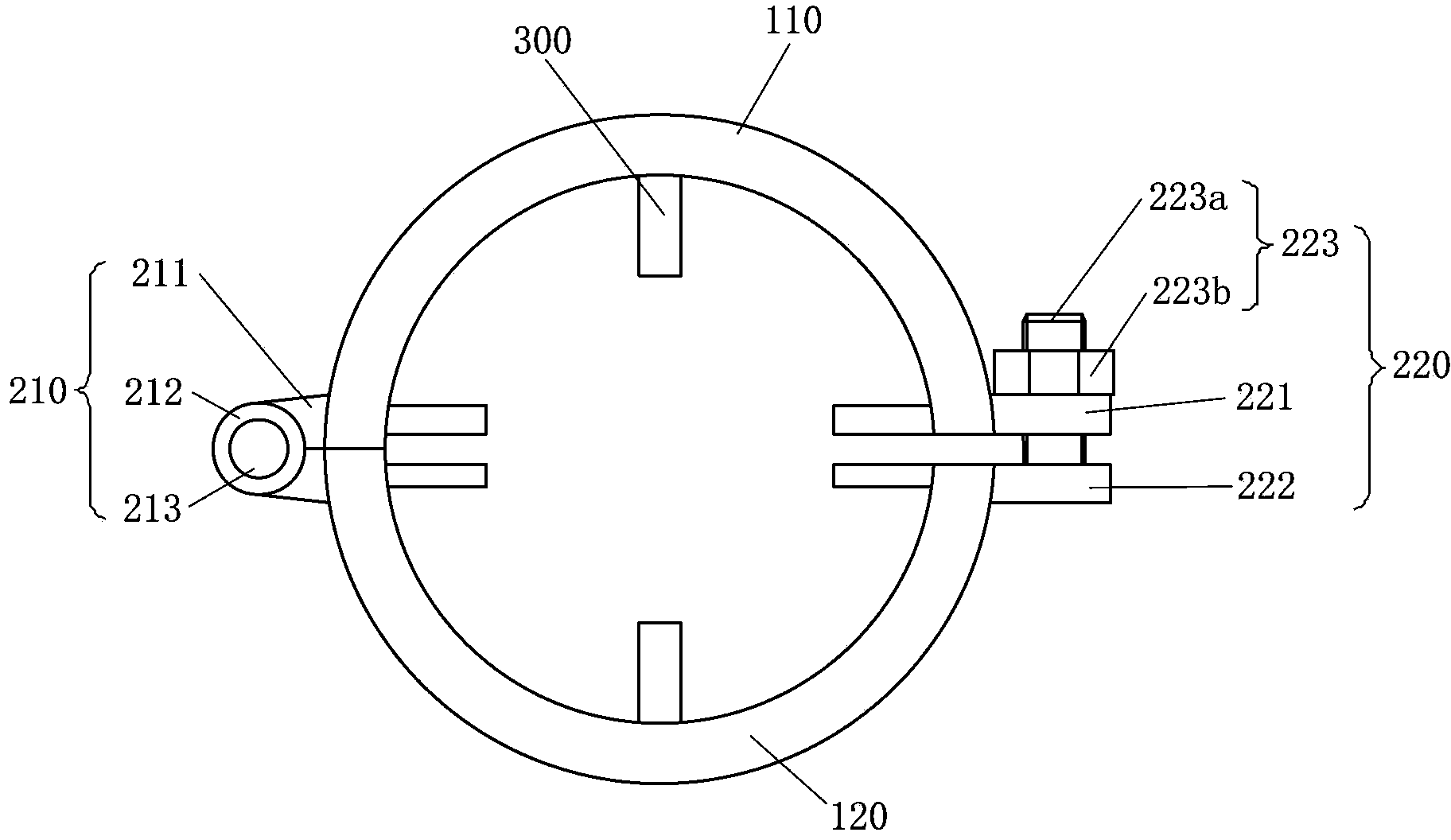

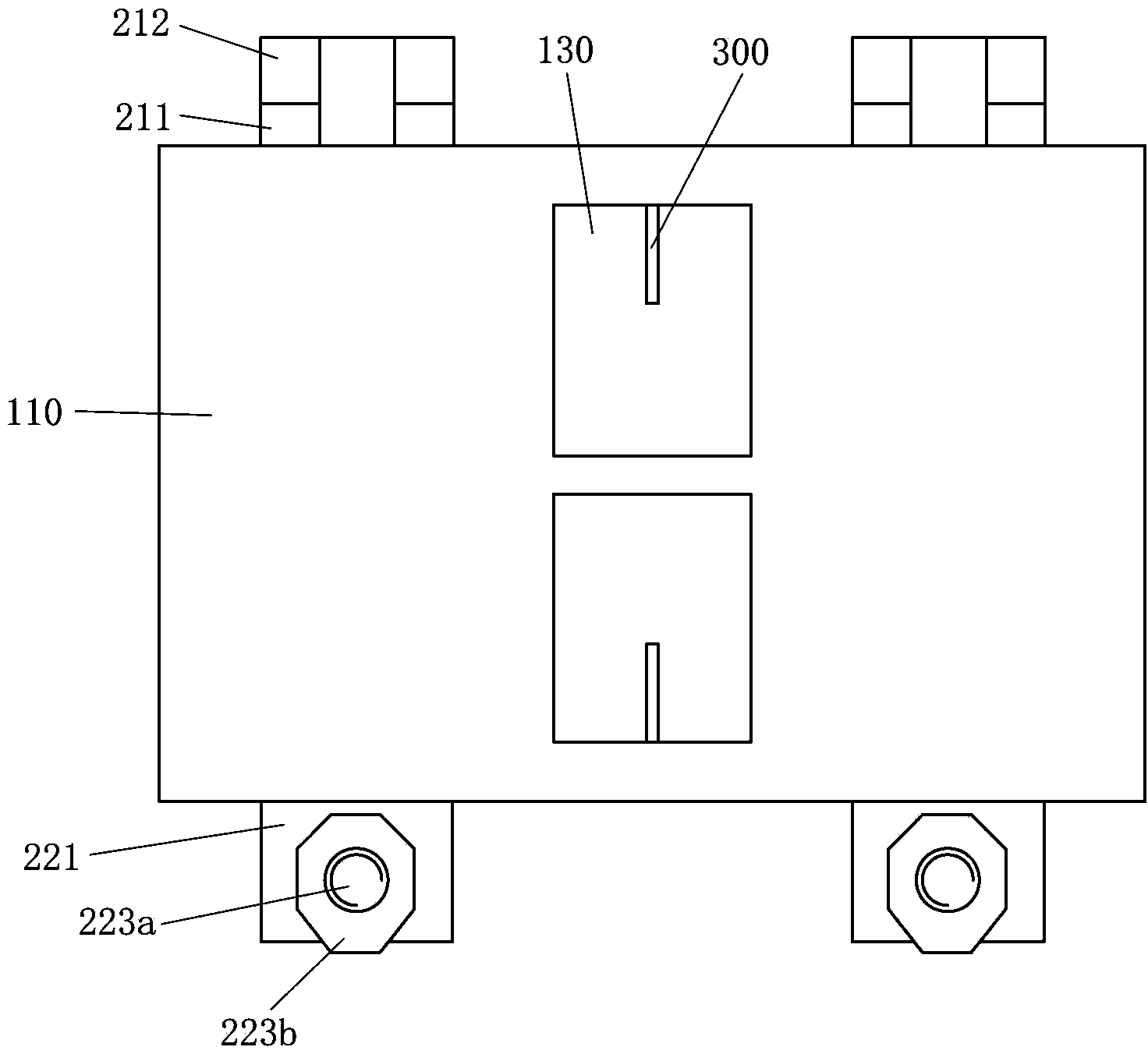

[0027] figure 1 It shows the front view of the pipe external mouthpiece device according to the embodiment of the present invention; figure 2 A side view of a pipe external mouthpiece device according to an embodiment of the present invention is shown; image 3 Shows a top view of the pipe external mouthpiece device according to an embodiment of the present invention; Figure 4 It shows a side view of the pipe outer counterpart device in an open state according to an embodiment of the present invention.

[0028] refer to Figure 1 to Figure 4 , according to the embodiment of the present invention, the pipe external mouth device includes: a main body 100, which is cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com