Pipeline prefabrication system and method

A technology for pipes and pipe groups, which is applied to manufacturing tools, auxiliary devices, printing, etc., can solve the problems of low prefabrication efficiency, long time, and many operators, and achieve the effects of high construction efficiency, low cost of assembly, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a pipe prefabrication system, including a beveling machine, an automatic inkjet printer, a pipe assembly device, and a welding machine. The inlet side of the beveling machine is provided with a conveying roller table, and the outlet side is provided with an output roller. The other side of the output roller table is connected to the pipe pairing device, the automatic inkjet printer is arranged above the output roller table, and the welding machine is arranged in the direction of the exit of the pipe pairing device.

[0028] The pipeline prefabrication system provided in this embodiment realizes continuous production and manufacturing through the integration of beveling machines, automatic inkjet printers, pipeline assembly devices, and welding machines, and alleviates the contradiction between pipeline prefabrication requirements and construction period. It makes the prefabrication of the whole pipeline more convenient and fast, overcomes the dep...

Embodiment 2

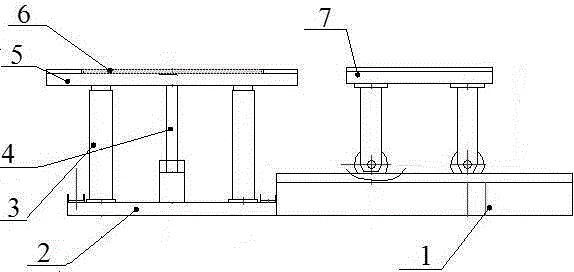

[0030] On the basis of Embodiment 1, this embodiment provides a pipeline prefabrication system, such as figure 1 As shown, the pipeline assembly device includes a connected base I1 and base II2, the base I1 is provided with a lifting platform 5, and a first hydraulic lifting cylinder 4 is provided below the lifting platform 5, and the first hydraulic lifting cylinder The telescopic rod end of 4 is connected with the middle part of the lower end surface of the lifting platform 5, and the lifting platform 5 is provided with a rotating platform 6, and the rotating platform 6 is connected with the side of the lifting platform 5 through a horizontal axis, and the rotating platform 6 is rotated around the horizontal axis. Rotate upward relative to the lifting platform 5, wherein, the side of the lifting platform 5 is perpendicular to the pipe movement direction, the rotating platform 6 is connected to a motor, and the motor is connected to a motor control cabinet, and a track is prov...

Embodiment 3

[0039] On the basis of Embodiment 2, this embodiment provides a pipeline prefabrication method, using a pipeline prefabrication system, including the following steps:

[0040] Step 1) The beveling machine cuts and bevels the pipe to be processed;

[0041] Step 2) The automatic inkjet printer performs inkjet marking on the pipes that have completed the groove processing;

[0042] Step 3) The pipes that have been coded and marked enter the mobile platform of the pipe assembly device through the output roller table, and the pipes are fixed with pipe clamps, and the pipe fittings corresponding to the size and identification code of the pipe are placed on the lifting platform 5 of the pipe assembly device And fix it with a pipe fitting clamp. When the axis of the pipe fittings (such as elbows, tees, etc.) is parallel to the pipe axis, adjust the height of the lifting platform 5 so that the pipe fittings and pipes are at the same height, and the movable platform 7 moves to make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com