A lithium battery production process and equipment

A production process and production equipment technology, applied in the field of lithium battery production and processing, can solve the problems of high internal resistance of cells and low process production efficiency, and achieve the effects of reducing labor intensity, improving battery production efficiency, and simple and efficient process implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

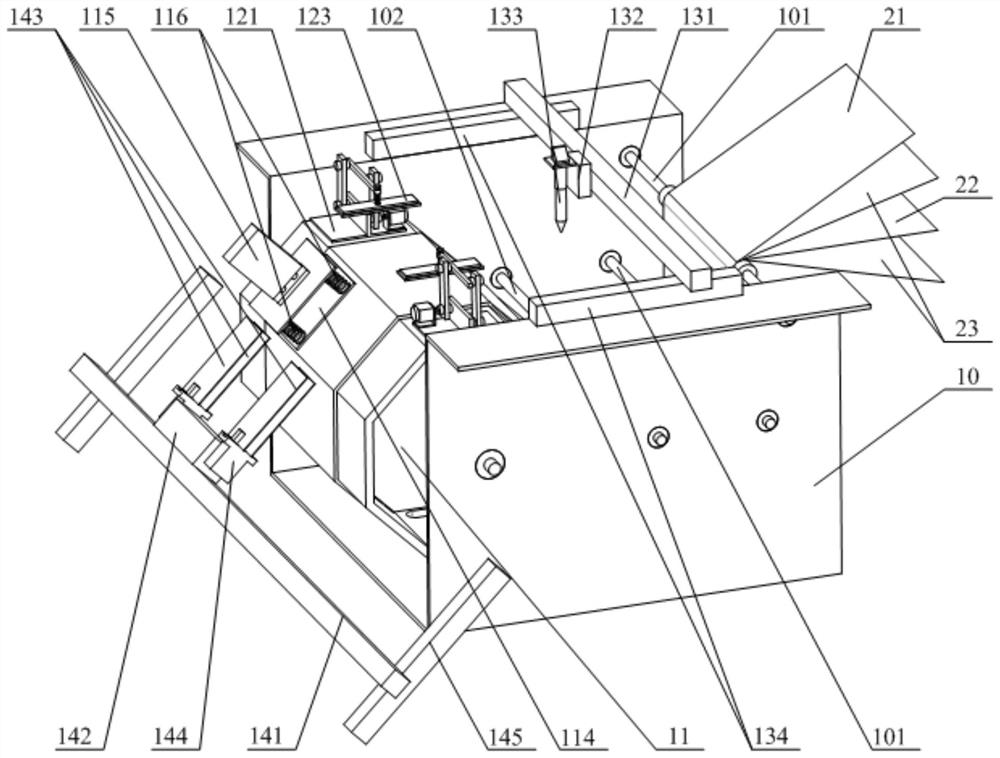

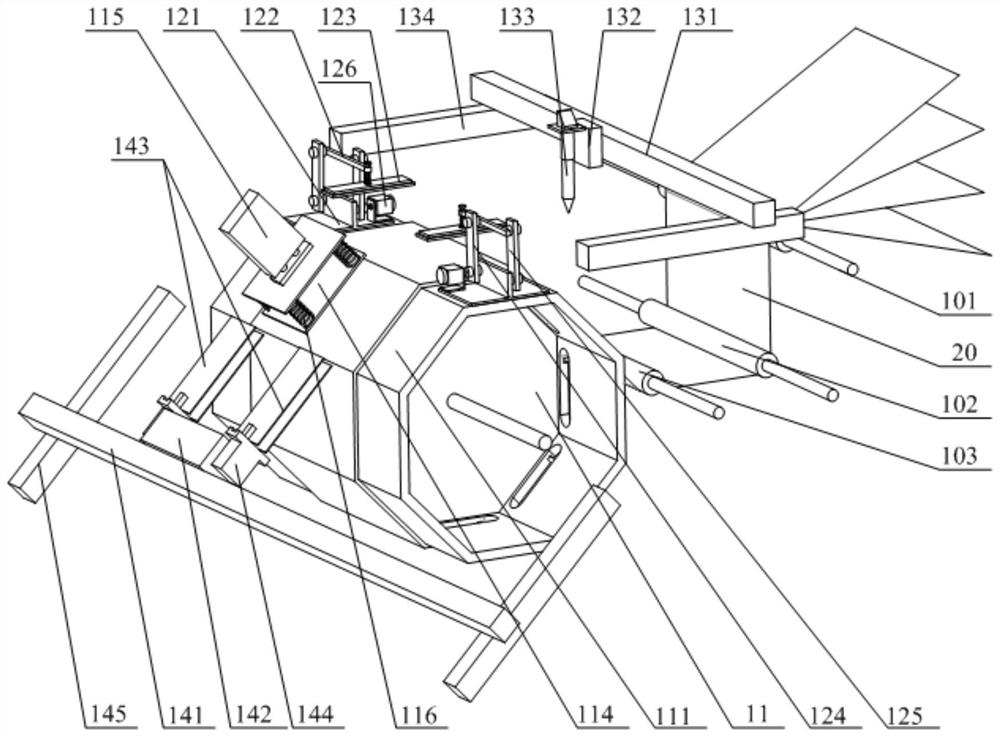

[0033] The core of the present invention is to provide a lithium battery production process, which can easily and efficiently realize the continuous production and processing of lithium batteries; in addition, it also provides a lithium battery production equipment for the above-mentioned lithium battery production process.

[0034] In order to make those skilled in the art better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

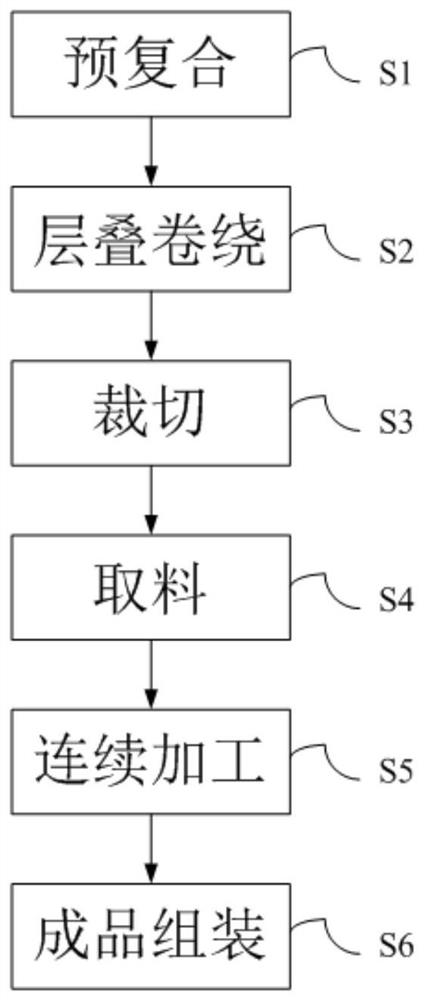

[0035] Please refer to figure 1 , figure 1 A flow chart of a lithium battery production process provided by a specific embodiment of the present invention.

[0036] In a specific embodiment, the lithium battery production process provided by the present invention includes:

[0037] Step S1: pre-compounding;

[0038] The positive electrode sheet 21 , the separator 23 , the negative electrode sheet 22 , and the separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com