Continuous production soft pancake machine

A pancake machine and pancake technology, applied in the fields of baking pancakes, food coating, food science, etc., can solve the problems of slow speed of soft pancakes, limited number of soft pancakes, and high labor intensity of operators, so as to achieve uniform spreading, The effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

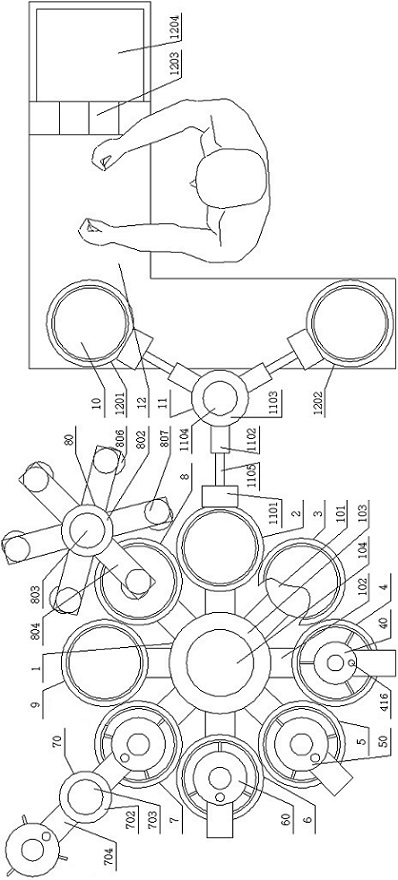

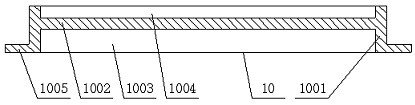

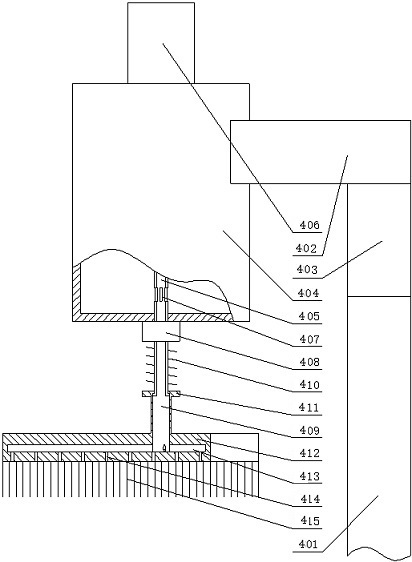

[0058] combine Figure 1~Figure 7 It can be seen that the continuous production soft pancake machine of the present invention includes a frying pan turret 1, and a plurality of electromagnetically heated frying pan brackets 101 are arranged around the frying pan turret 1, and the frying pan bracket 101 uses a frying pan The center of the turret 1 is evenly distributed, and the frying pan brackets 101 rotate around the center of the frying pan turret 1 respectively. Frying pans 10 are respectively placed on the frying pan brackets 101, and the frying pan turret 1 Frying pan turnover station 2, preheating station 3, oil brushing station 4, cake spreading station 5, egg spreading station 6, sauce brushing station 7 and material spreading station 8 are arranged in sequence around the Oil brushing station 4, cake spreading station 5, egg spreading station 6, sauce brushing station 7 and material spreading station 8 are respectively equipped with oil brushing device 40, cake spreadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com