Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Realize automatic quantification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

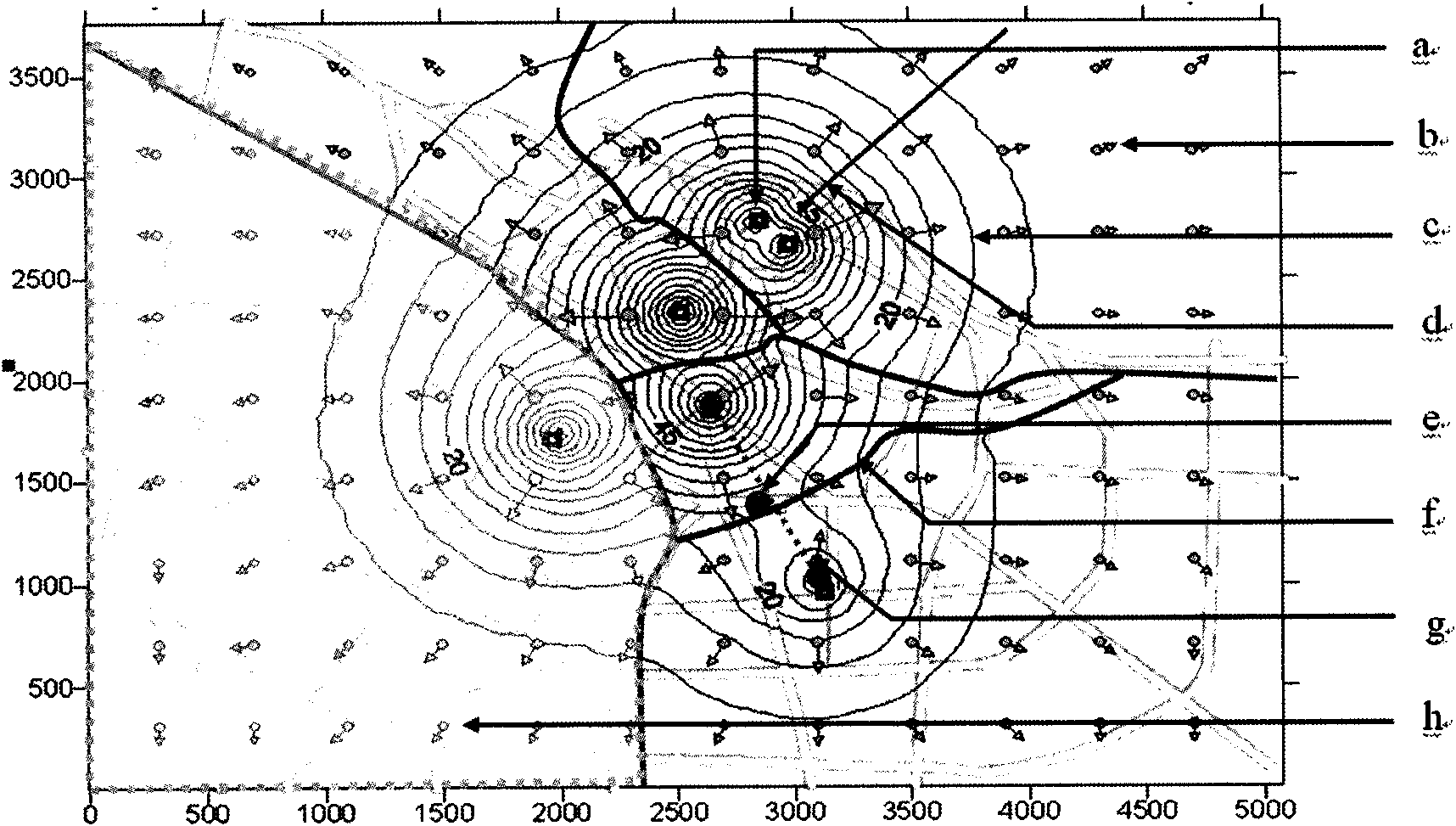

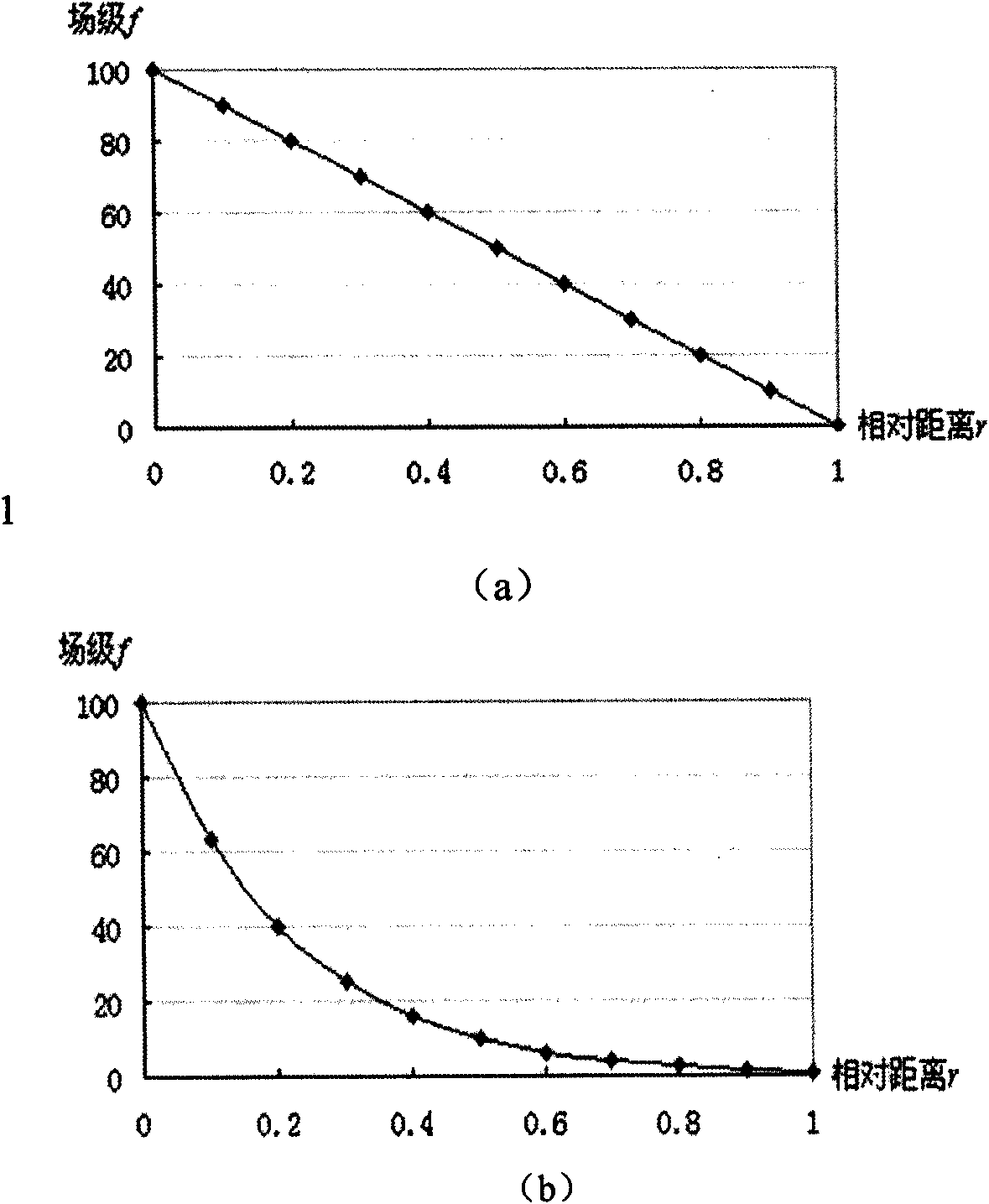

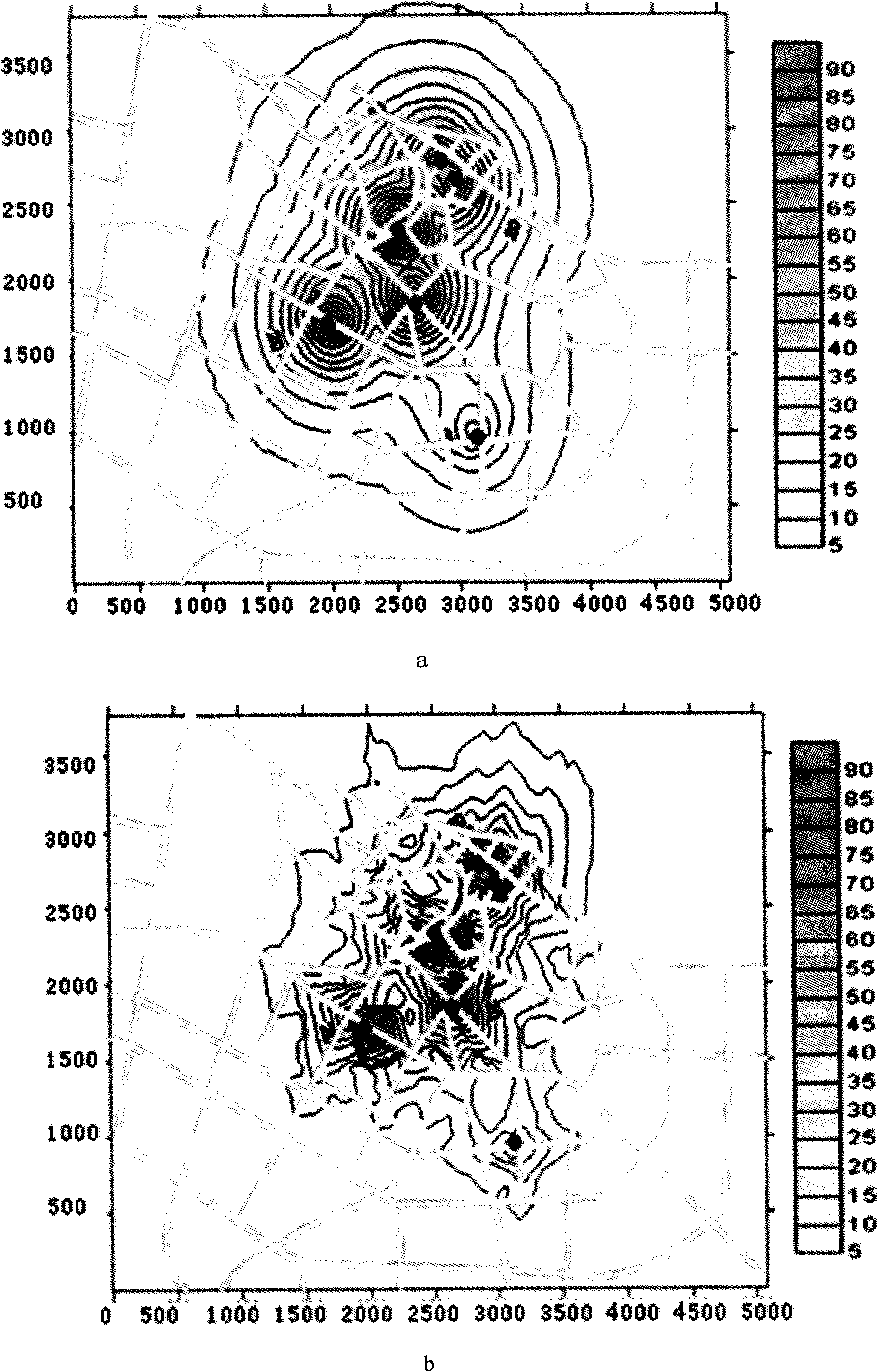

Land evaluation index classification quantitative method based on spatial data field

InactiveCN101599142ASolve the problem of lack of unified quantitative measurementRealize automatic quantificationData processing applicationsSpecial data processing applicationsData fieldIndex system

The invention discloses a land evaluation index classification quantitative method based on spatial data field, the method comprises the following steps: (1) constructing a land evaluation spatial data field; (2) classifying land evaluation spatial data field source; (3) classifying and quantizing the land evaluation index based on the land evaluation spatial data field source. The method leads factors affecting land price and the distribution of the land price to be viewed as a special geographic space data field, different types of the evaluation index are different field sources of land price data field, and according to the radiation characteristics of the data field source, the invention provides a set of land evaluation index classification quantitative method based on spatial data field, so as to provide technical support for quantitative and automatic land evaluation.

Owner:WUHAN UNIV

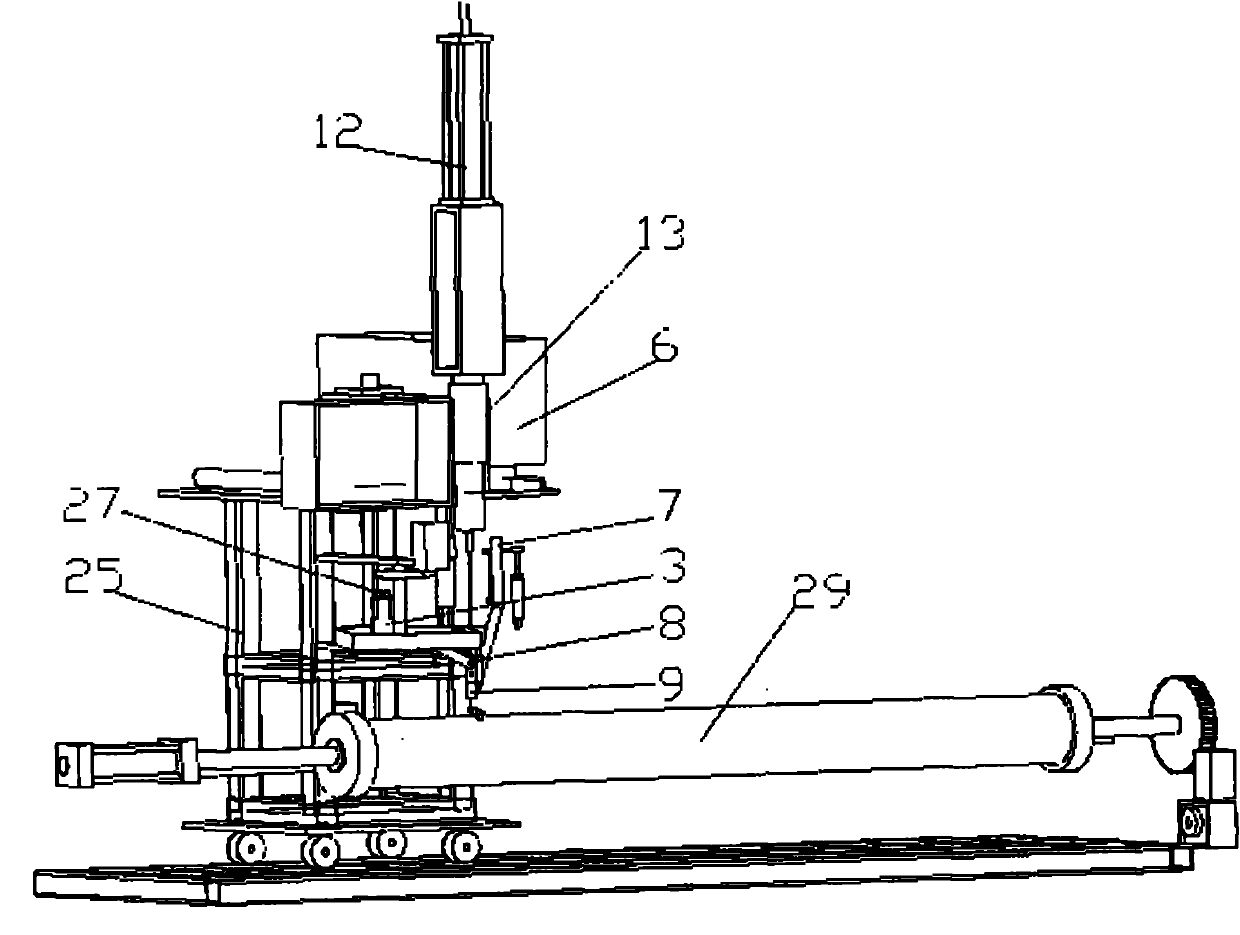

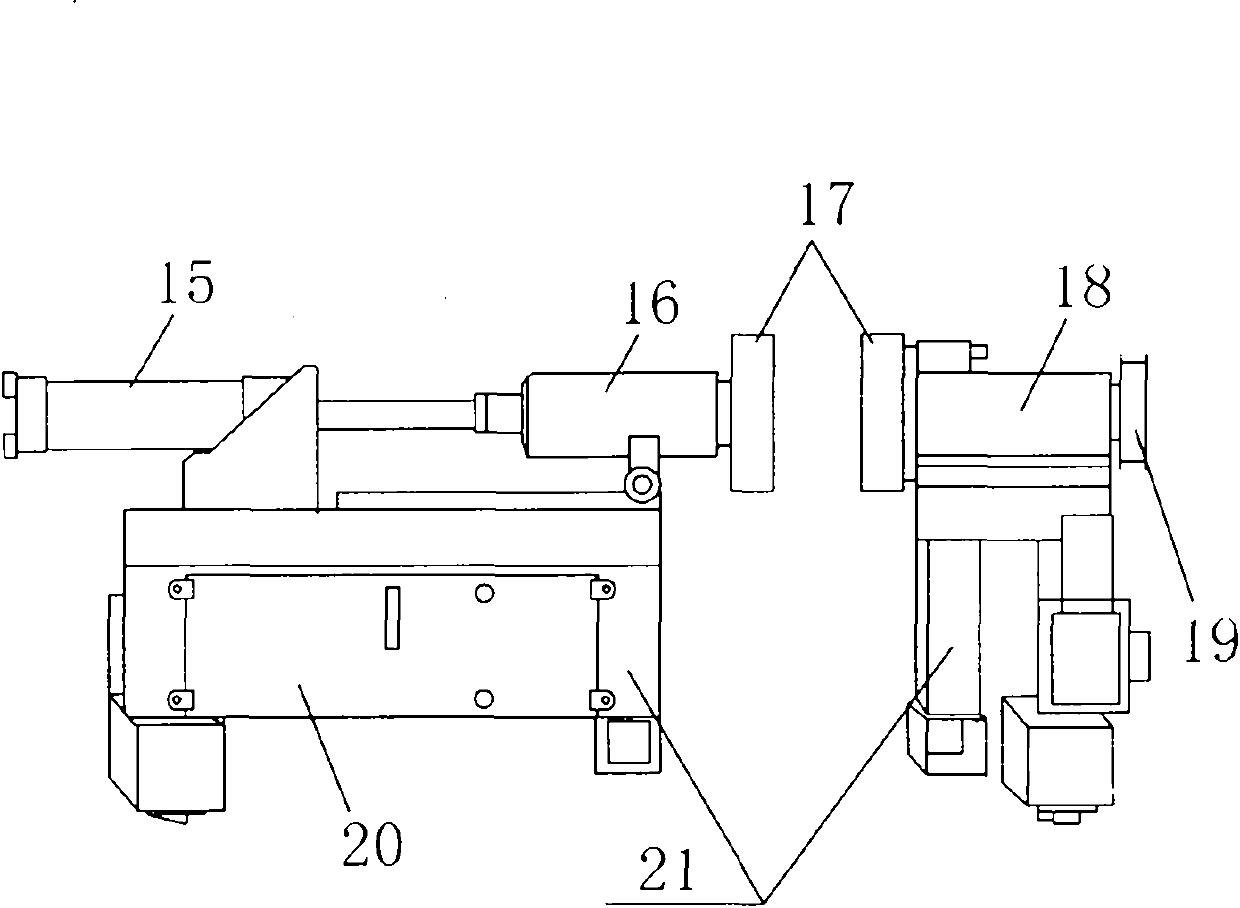

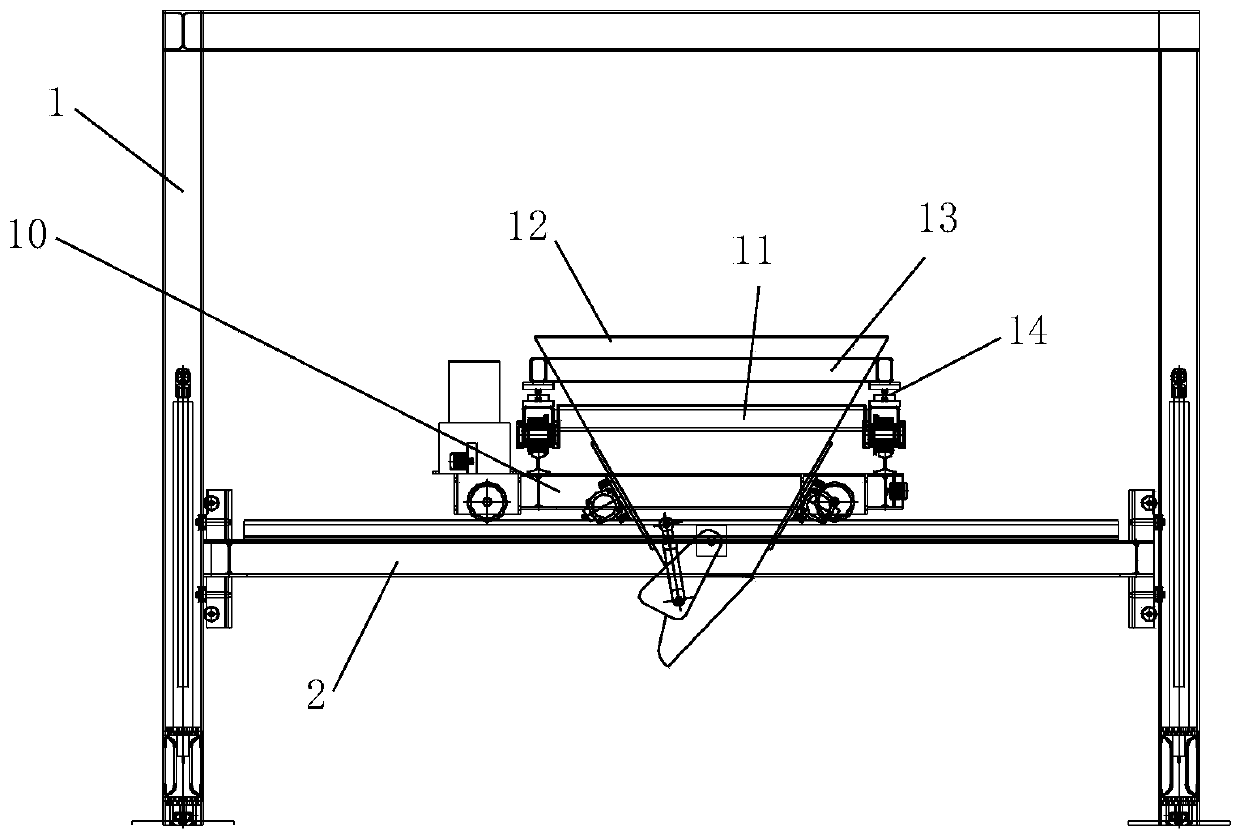

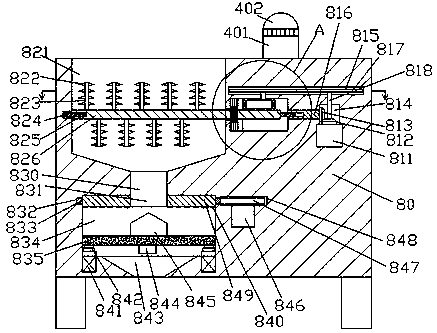

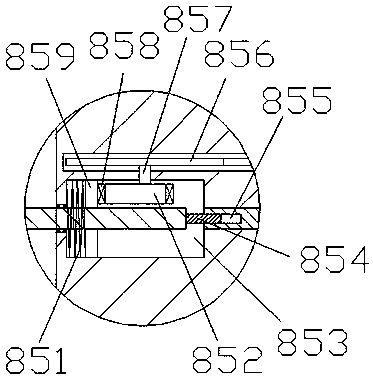

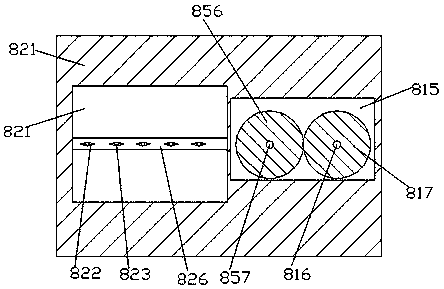

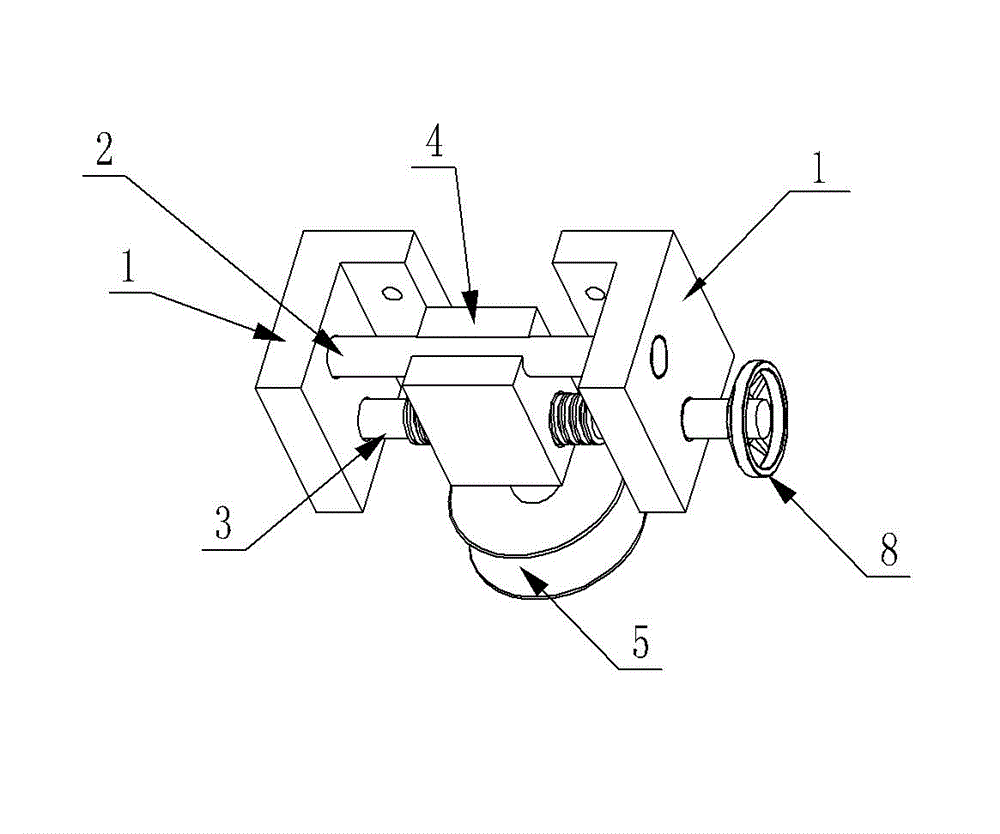

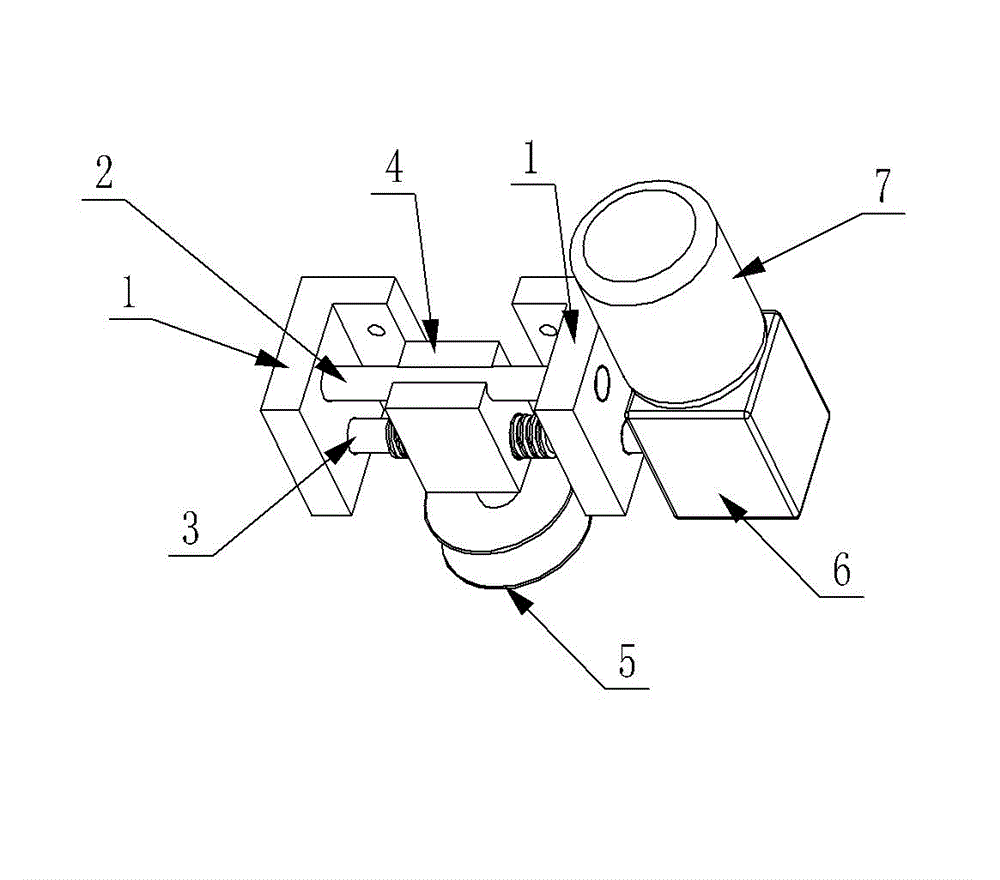

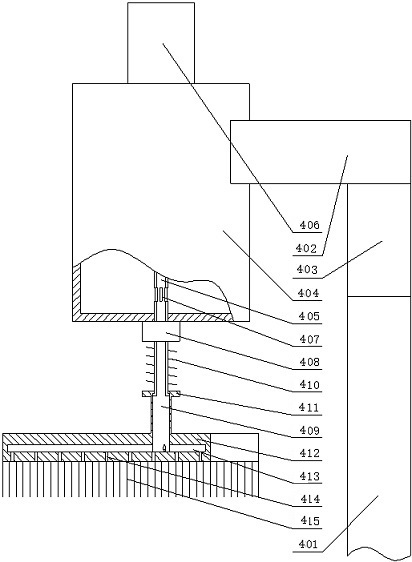

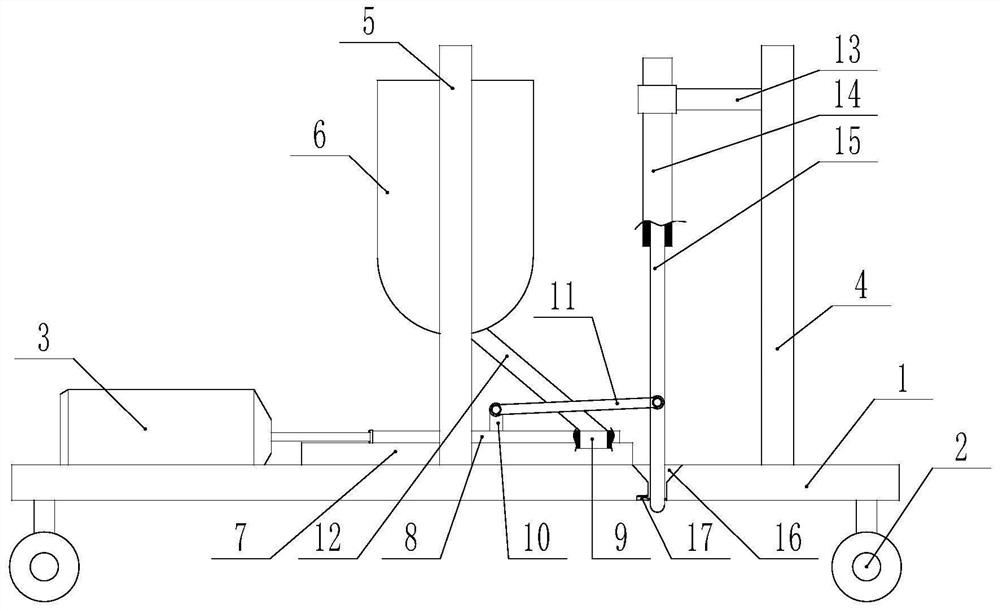

Pin tube automatic set submerged arc welding set

InactiveCN102000905ARealize automatic quantificationNovel structureProgramme control in sequence/logic controllersWelding accessoriesAutomatic controlControl system

The invention provides a pin tube automatic set submerged arc welding set which is characterized by comprising a pin automatic loading-unloading system, a welding system, an automatic pin delivering and centering mechanism and a programmable logic controller (PLC), wherein the PLC is connected with the automatic loading-unloading system, the welding system and the automatic pin delivering and centering mechanism; the functions of automatic nail feeding under air pressure, hydraulic centering, and automatic sending of fixed quantity of welding flux and the like are realized through using the welding set; in the control system, the PLC is mainly used as the main control device matched with a full-digital AC servo driver, so that the pin tube welding set can be used to realize accurate and effective full-automatic control in the welding process; and the welding set is suitable for automatic welding of large-diameter pins and large-diameter light tubes in shapes of cylinder, droplet and rhomboid, and overcomes the defects of arc pits, welding beading, bubbles and the like, the production efficiency is enhanced and the labor intensity is lowered. The invention has simple structure and is easy to manufacture.

Owner:SHENYANG POLYTECHNIC UNIV

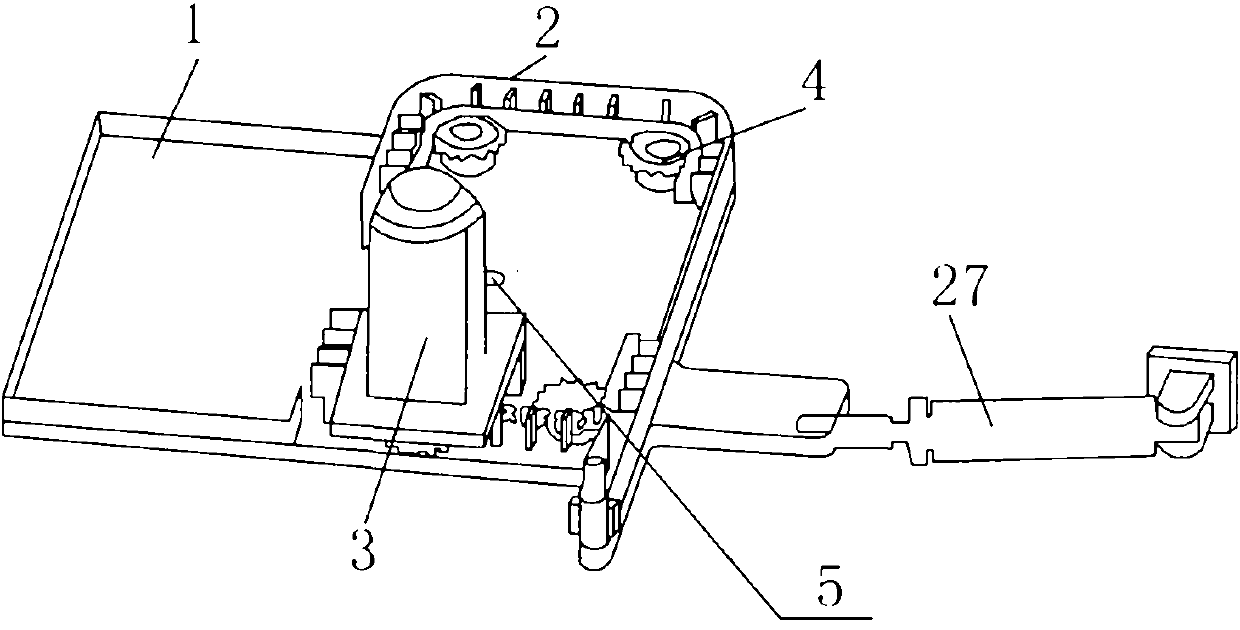

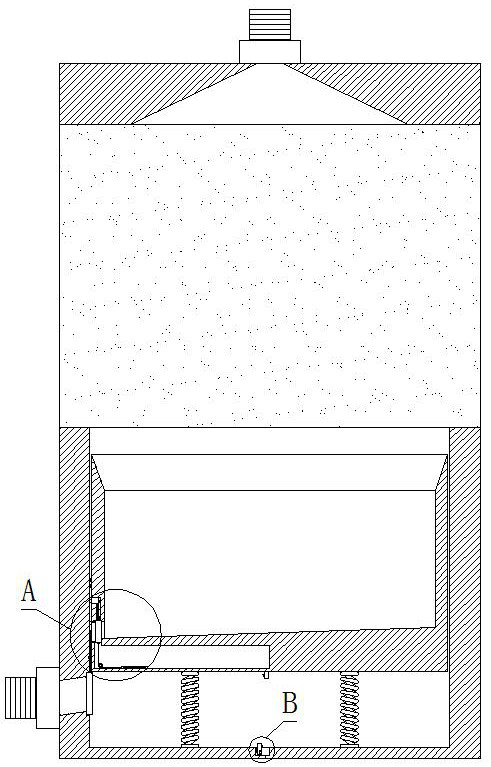

Milk maker

InactiveCN101589913ARealize the stirring functionAchieve self-heatingBeverage vesselsDrive motorEngineering

The invention discloses a milk maker, which comprises a support cylinder, a base for placing a milk making bottle, and a water barrel, wherein the inside of the support cylinder is provided with a driving motor, the support cylinder is provided with a powdered milk barrel, a rotating shaft is inserted into the bottom surface of the powdered milk barrel, and the rotating shaft is linked with an output shaft of the driving motor; the inside of the powdered milk barrel is provided with a link mechanism, the link mechanism is connected with a powder pushing block, and the powder pushing block can travel to the outer wall, which is provided with a powder falling cavity, of the powdered milk barrel; the milk making bottle is arranged below the powder falling cavity, a stirring shaft is inserted into the bottom surface of the milk making bottle and is provided with stirring blades, and the stirring blades are positioned in the milk making bottle; the inside of the base is provided with a mechanism for driving the rotation of the stirring shaft; and the inside of the water barrel is provided with a water pump, the water pump is connected with a water outlet pipe, and a tail-end water outlet of the water outlet pipe aligns with a bottle mouth of the milk making bottle. The milk maker realizes the integrated automation of automatic and quantificational powdered milk taking, water feeding and automatic stirring.

Owner:王光力

Rice dumpling and preparation process thereof

The invention discloses a rice dumpling which, from inside to outside, sequentially comprises a dumpling body, an inner plastic film, a dumpling leaf and an outer plastic film. The invention also discloses a preparation process of the rice dumpling, which comprises the following steps of hermetically wrapping the dumpling leaf between the inner plastic film and the outer plastic film, taking the cooked dumpling body, attaching the inner plastic film of the dumpling leaf to the dumpling body, folding, and sealing so as to obtain the rice dumpling. According to the invention, through pre-wrapping the dumpling leaf between food-grade plastic films with an easily-torn tape, the dumpling leaf is kept in a clean state; no poaching process is required to be performed, so that the delicate fragrance of the dumpling leaf is kept more completely, and before the rice dumpling is eaten, through a short-term reheating process, the delicate fragrance of the dumpling leaf is emitted; and when the rice dumpling is eaten, an operation of removing the easily-torn tapes is only required to be performed, thereby not only realizing the easy stripping of the dumpling leaf, but also keeping the delicate fragrance of the dumpling leaf well, so that the dumpling leaf is kept in a clean state, and the rice dumpling is eaten more conveniently; and the whole technological process can achieve automated production.

Owner:ZHEJIANG WUFANGZHAI INDAL

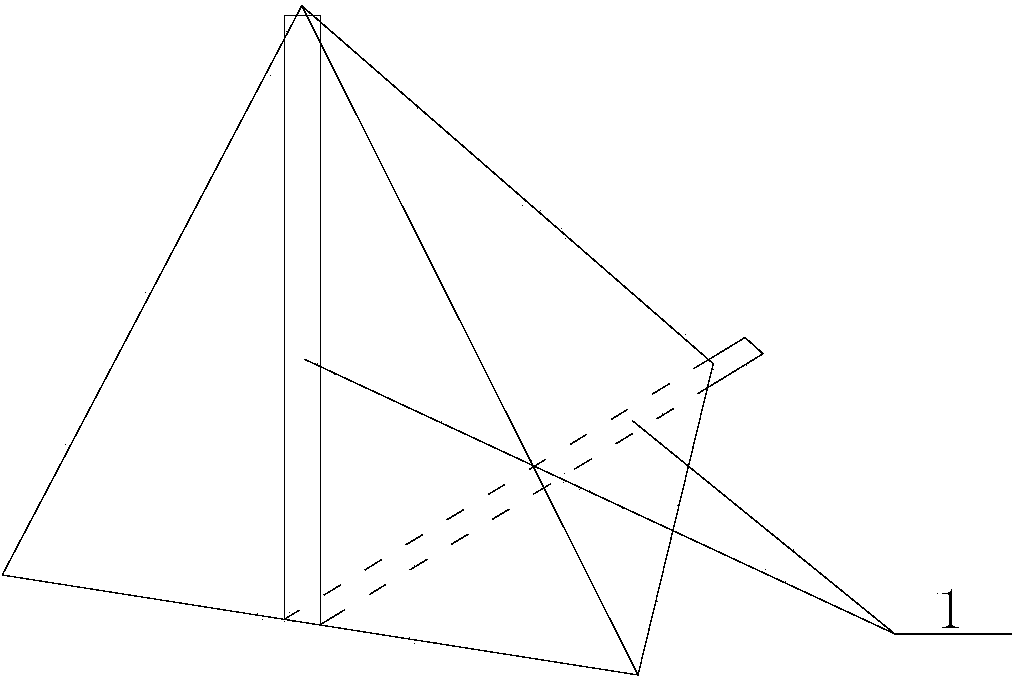

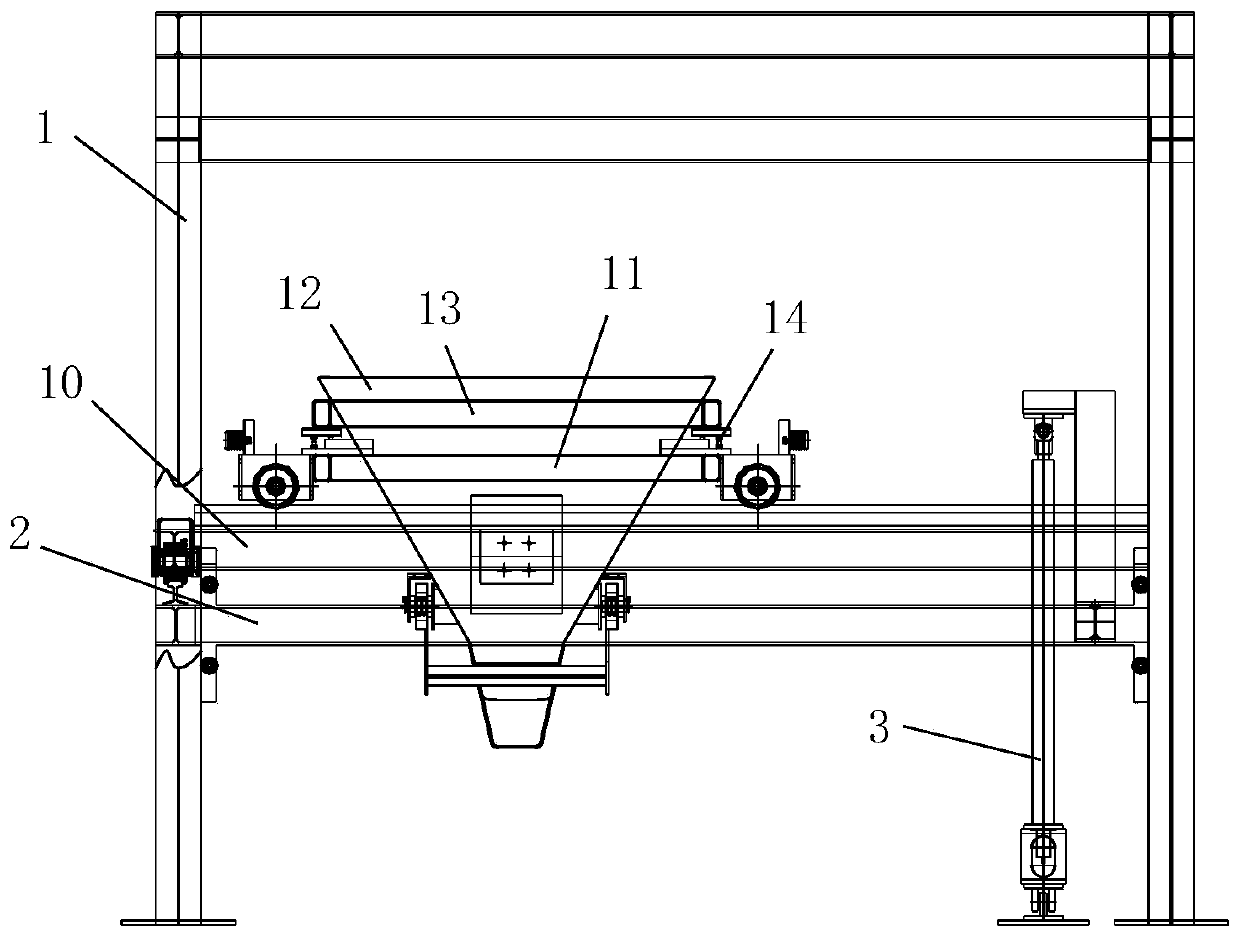

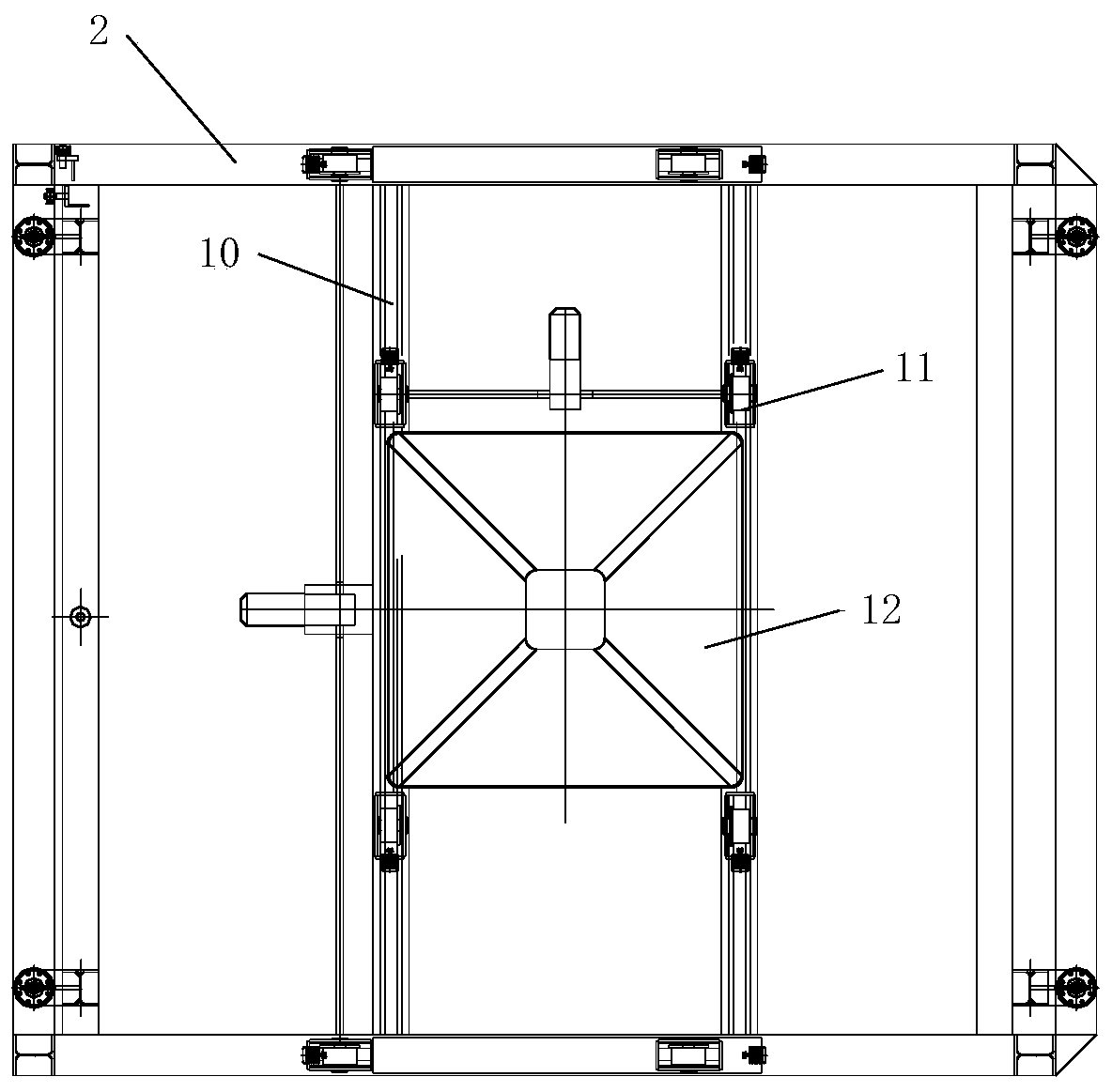

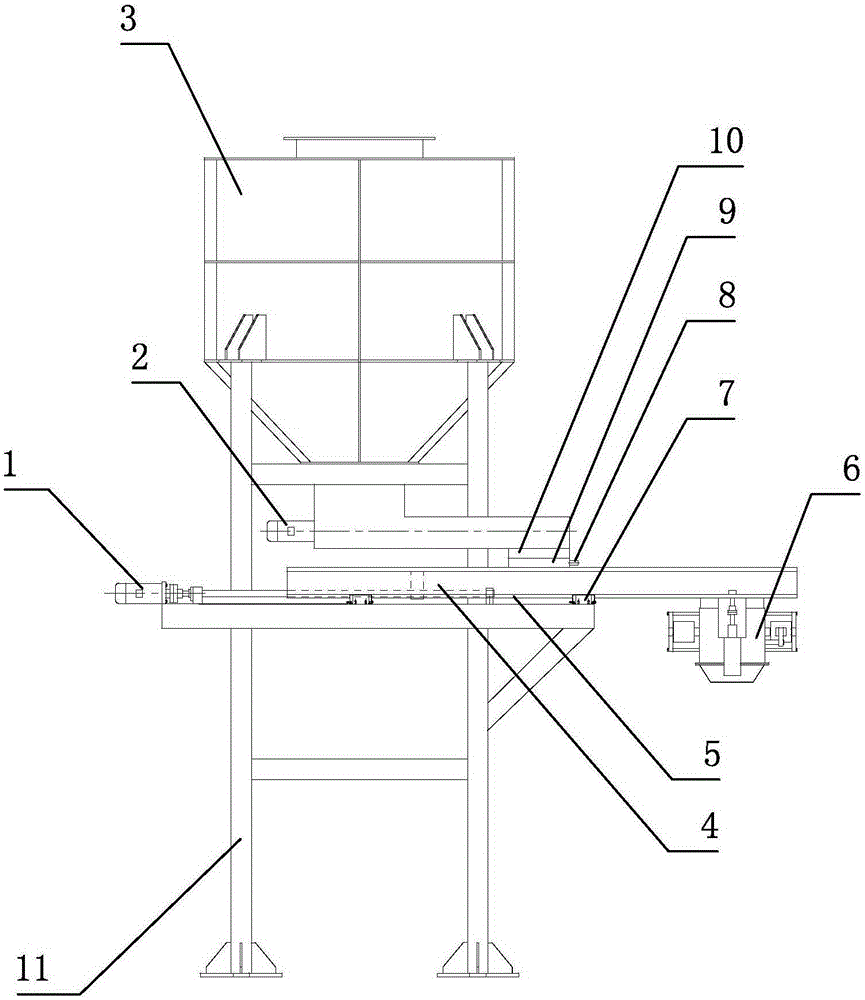

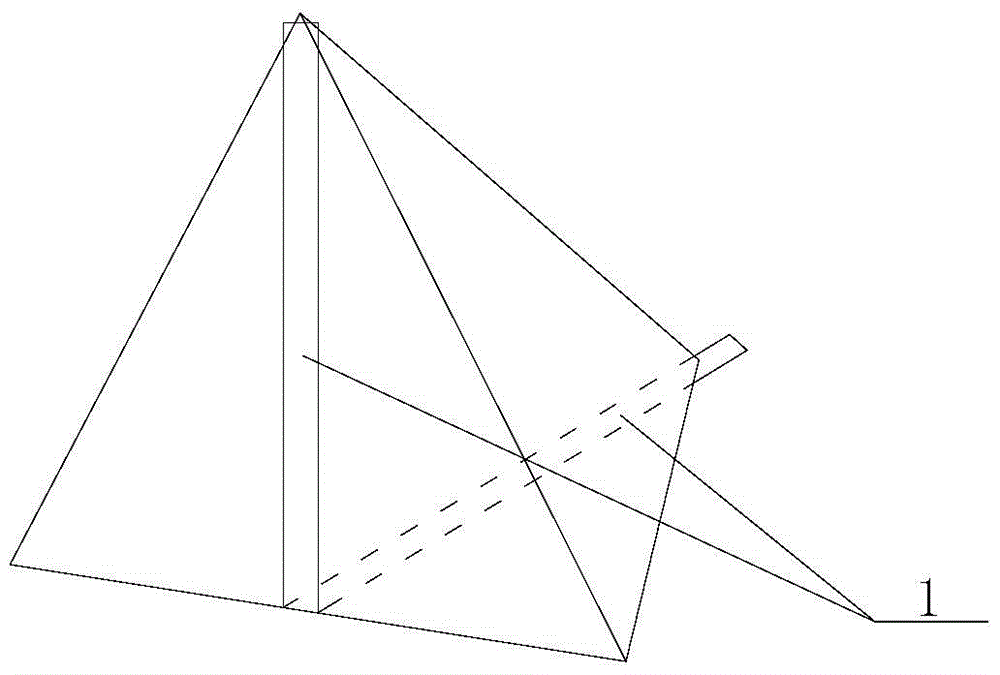

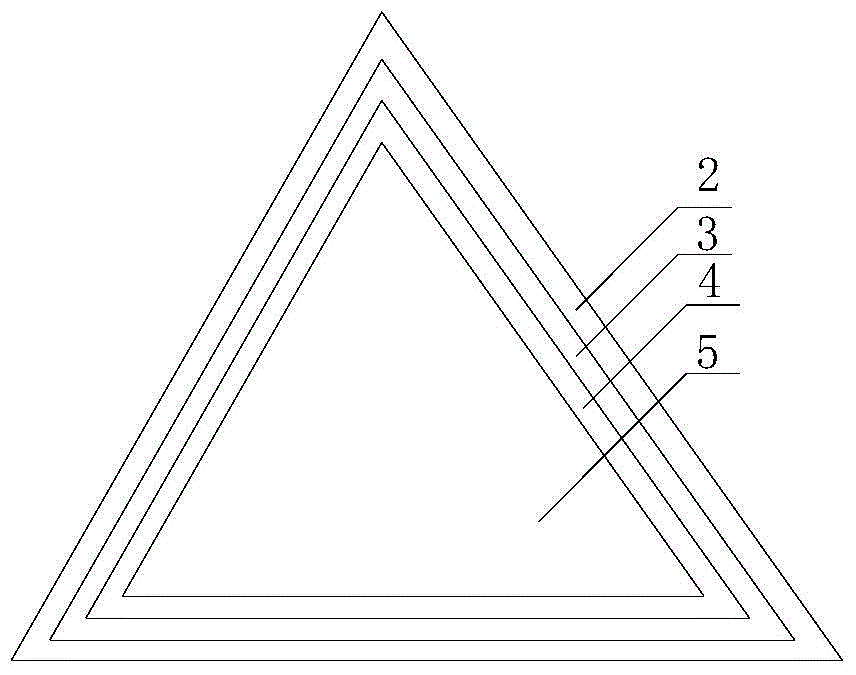

Three-dimensional full-automatic distribution machine

InactiveCN109910154AMeet the fabric requirementsSmall footprintFeeding arrangmentsAuxillary shaping apparatusHydraulic cylinderFixed frame

The invention discloses a three-dimensional full-automatic distribution machine. The three-dimensional full-automatic distribution machine comprises an outer frame, wherein a lifting frame is connected to the outer frame in a sliding mode, four hydraulic cylinder assemblies are connected to the lifting frame, and the lifting frame is pushed to slide up and down on the outer frame by the four hydraulic cylinder assemblies; a traverse moving frame is connected to the lifting frame in the sliding mode, the traverse moving frame can slide from left to right on the lifting frame, a longitudinal moving frame is connected to the traverse moving frame in the sliding mode, and the longitudinal moving frame can slide from front to back on the traverse moving frame; and a hopper assembly is arrangedon the longitudinal moving frame, the hopper assembly comprises a hopper main body, a fixed frame is arranged on the upper part of the hopper main body, a plurality of weighing sensors are arranged onthe lower end of the fixed frame, and the lower ends of the weighing sensors are connected with the longitudinal moving frame. According to the three-dimensional full-automatic distribution machine,a three-dimensional movement driving mode is adopted, the distribution machine can be reliably operated in the directions of an X axis, a Y axis and a Z axis, products are identified, and proper procedures are selected to distribute by a controller, so that automatic distribution is realized, and the distribution requirements of users on different member products are met.

Owner:青岛环球重工科技有限公司

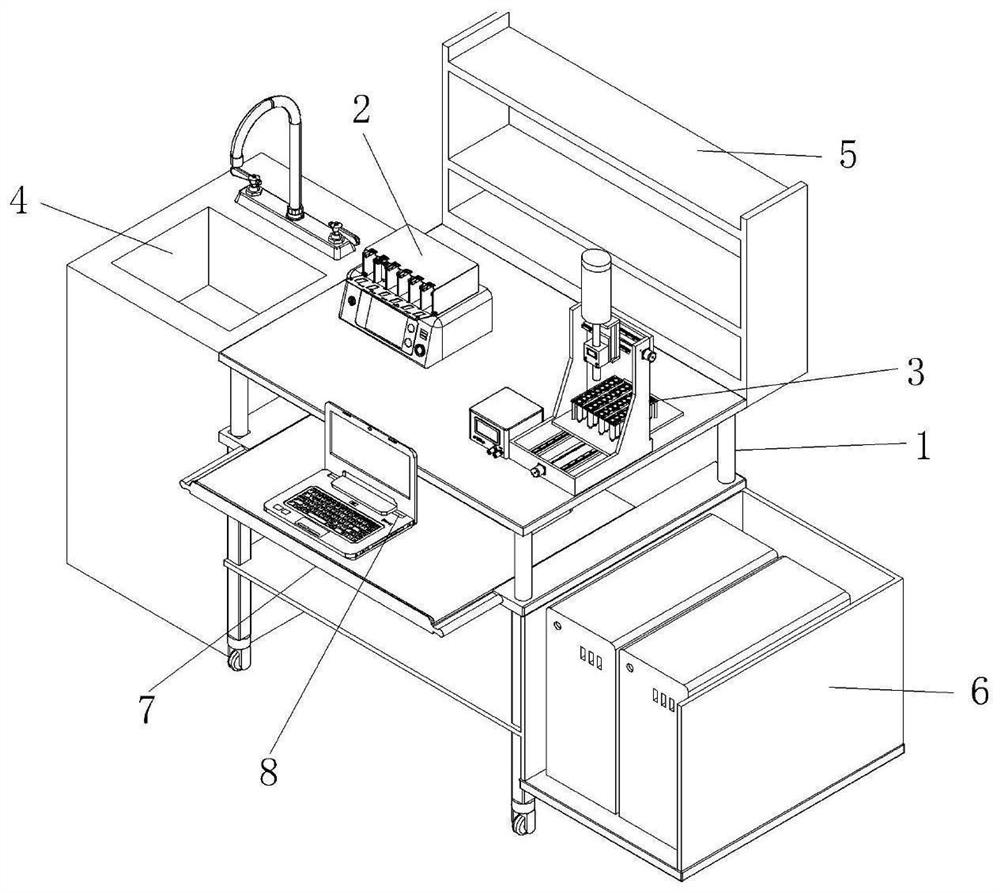

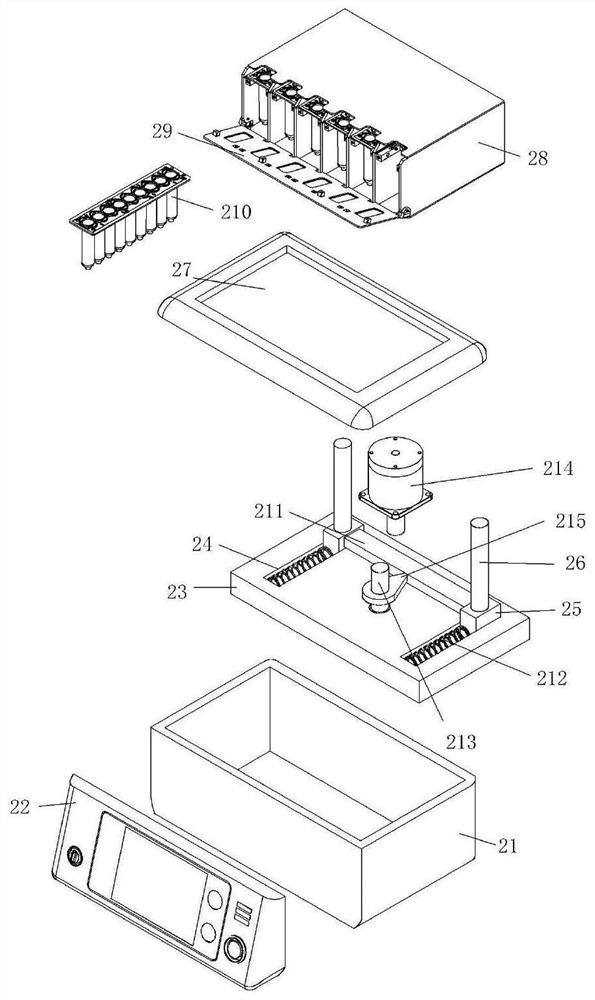

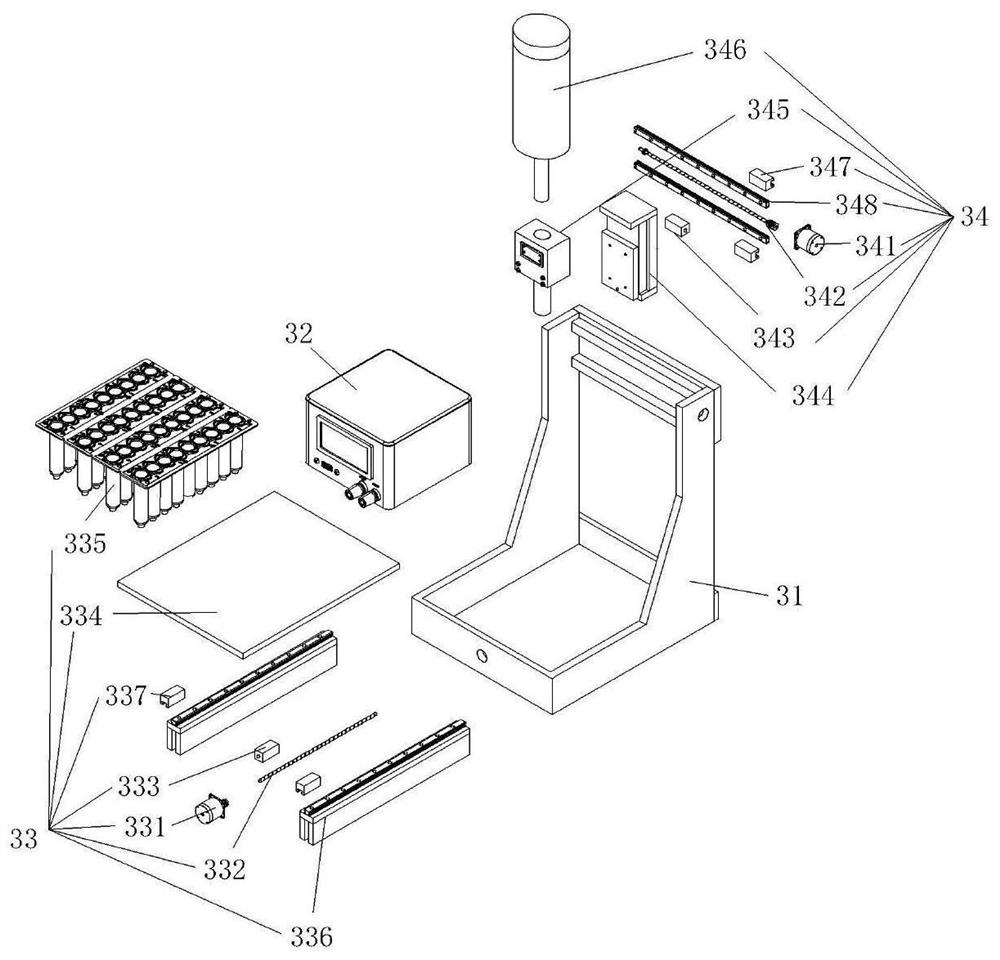

Rapid detection platform equipment for food detection

InactiveCN111889060AReduce food inspection cyclePracticalFeed devicesChemical/physical/physico-chemical moving reactorsTest tubeEngineering

The invention discloses rapid detection platform equipment for food detection. The rapid detection platform equipment comprises a main operation table body, a mixing mechanism, an injection mechanism,a water tank, a container storage rack, an equipment storage rack, a pull plate and a computer for food detection, wherein the mixing mechanism is arranged on the left side of the top end of the mainoperation table body; the injection mechanism is arranged on the right side of the top end of the main operation table body; the water tank is installed on the left side of the main operation table body in a vertical direction; the container storage rack is installed at the top end of the rear side of the main operation table body in a left-right direction; and the equipment storage rack is installed at the bottom end of the right side of the main operation table body. According to the rapid detection platform equipment for food detection, a detection solvent can be automatically, quantitatively and sequentially injected into a detection test tube, manual injection of detection personnel is not needed, manual operation items of the detection personnel are reduced, and a reaction solutionin the test tube can be automatically oscillated and mixed with a food sample, so time and labor are saved, a food detection period is shortened, and practicability is high.

Owner:赵丰

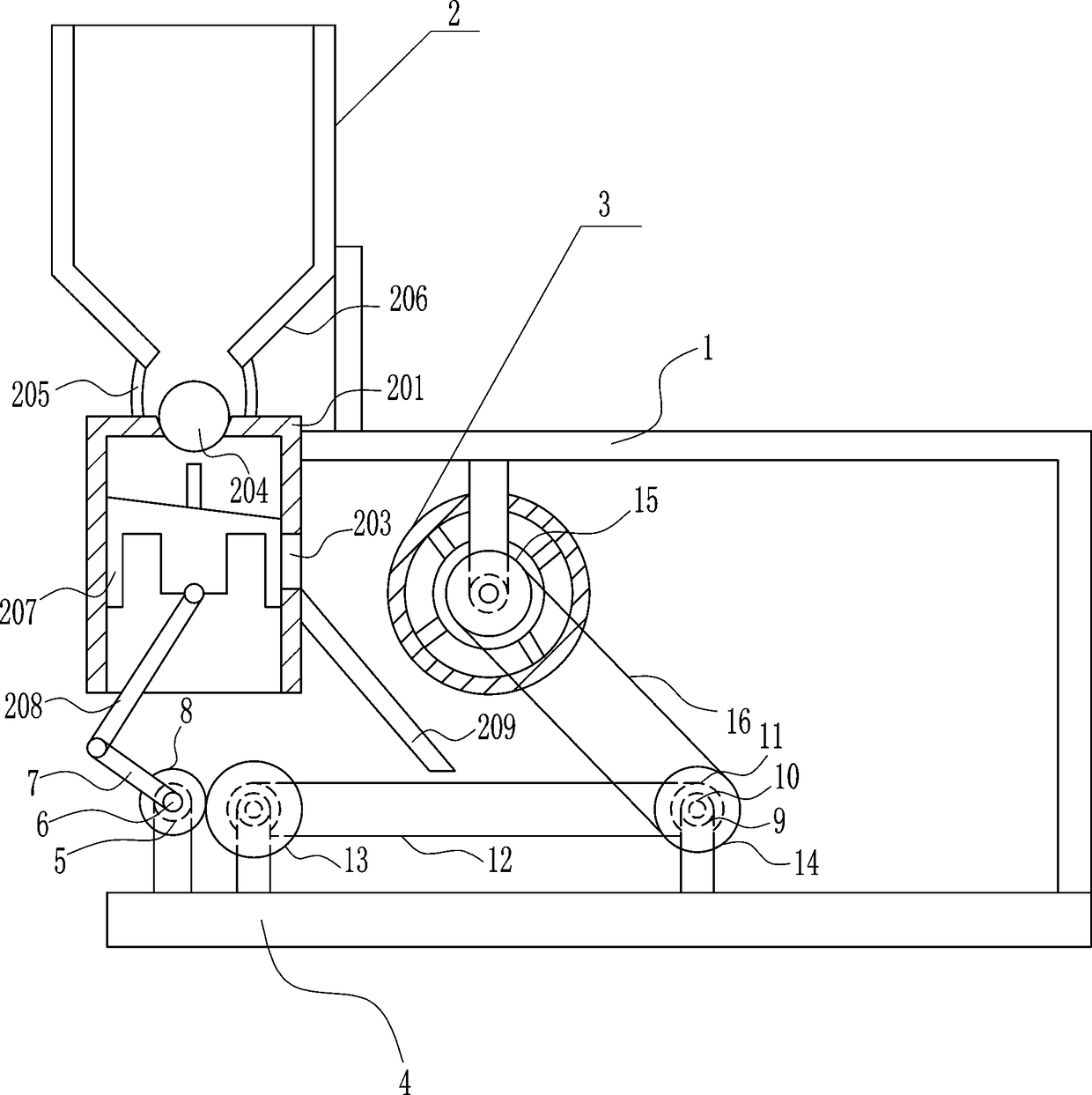

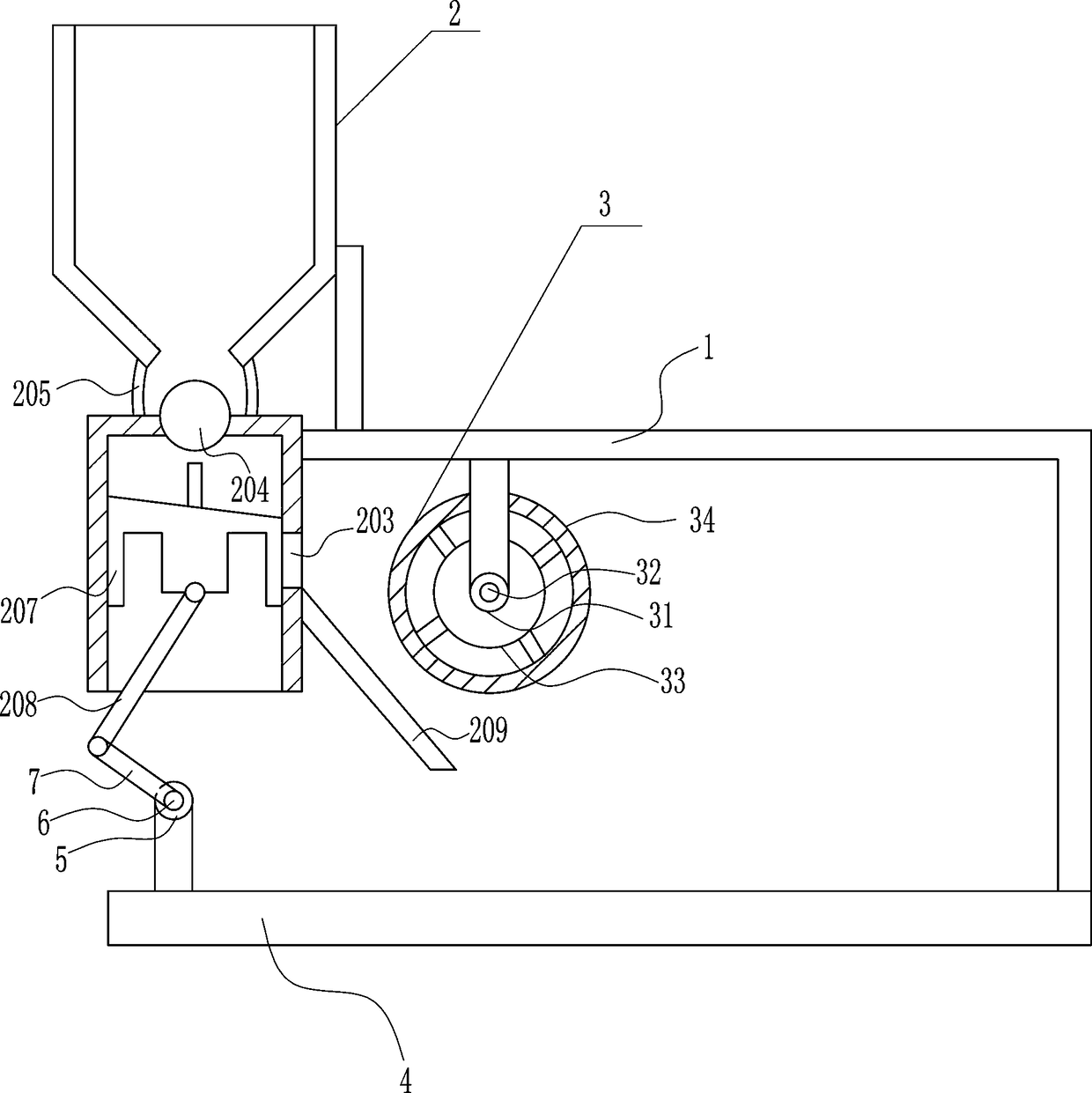

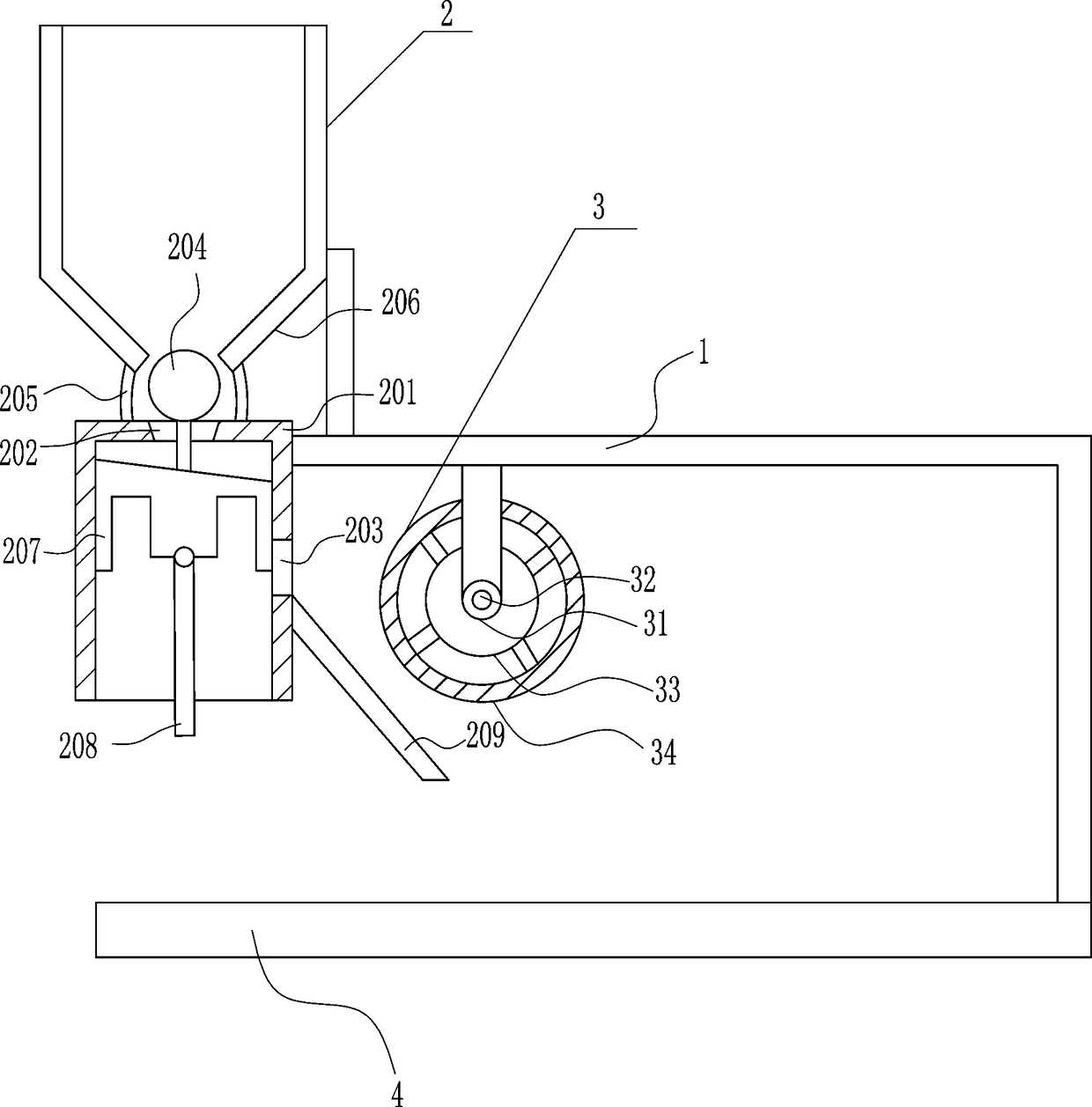

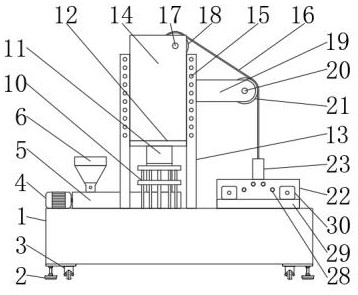

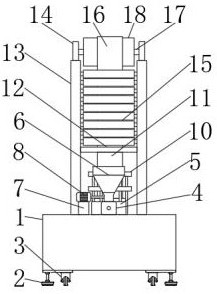

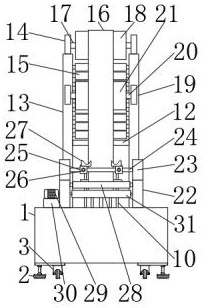

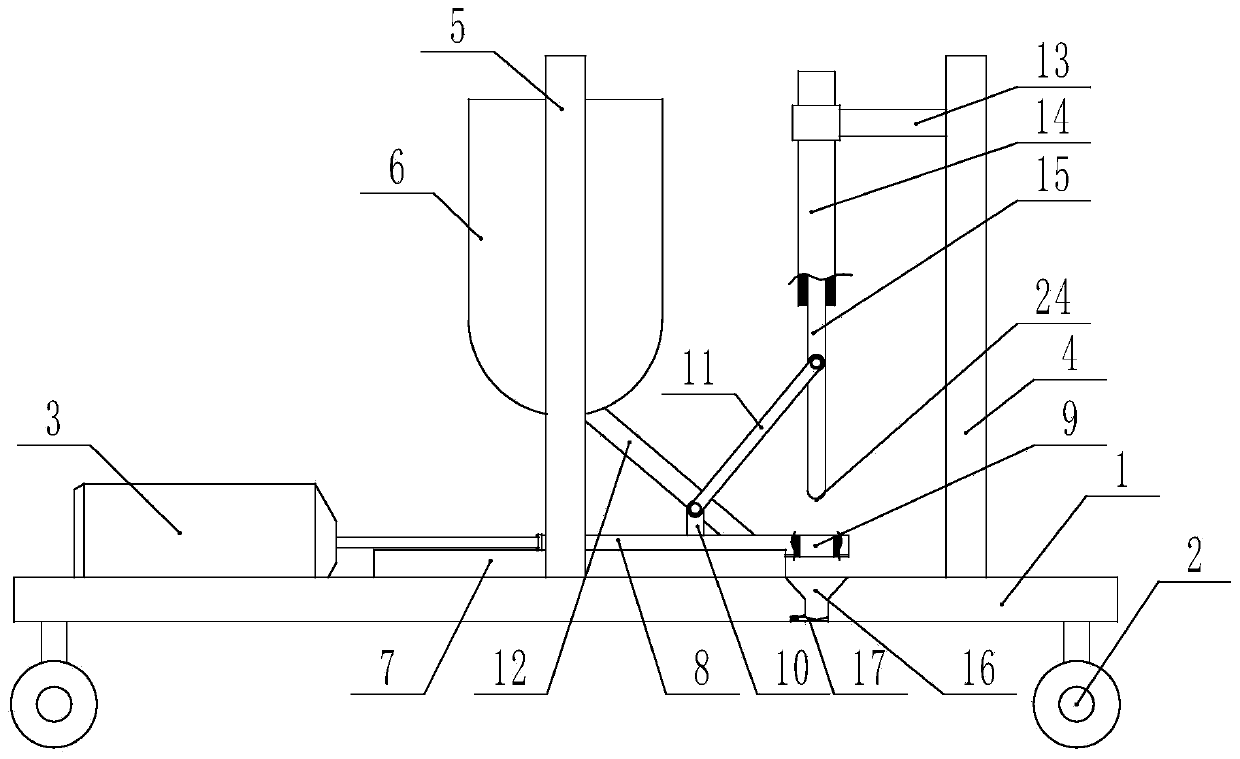

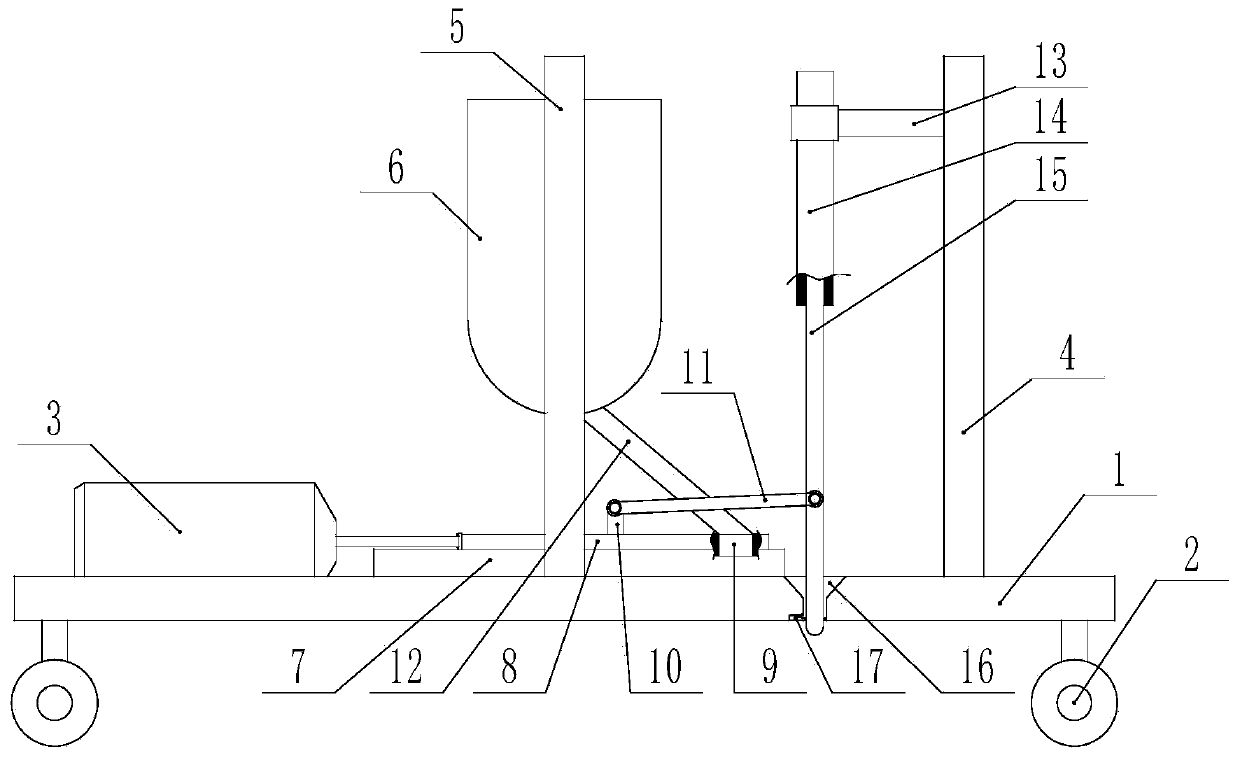

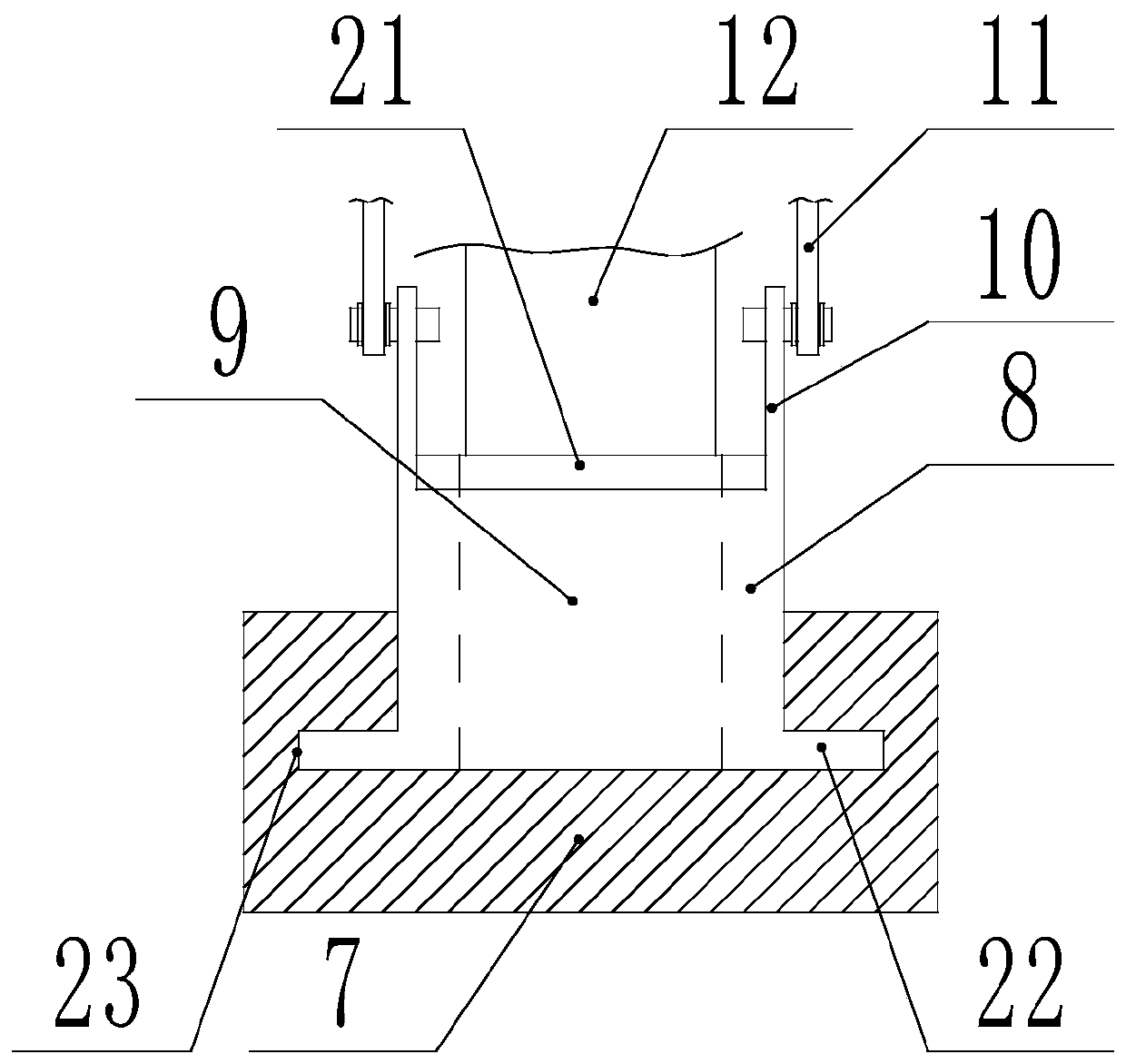

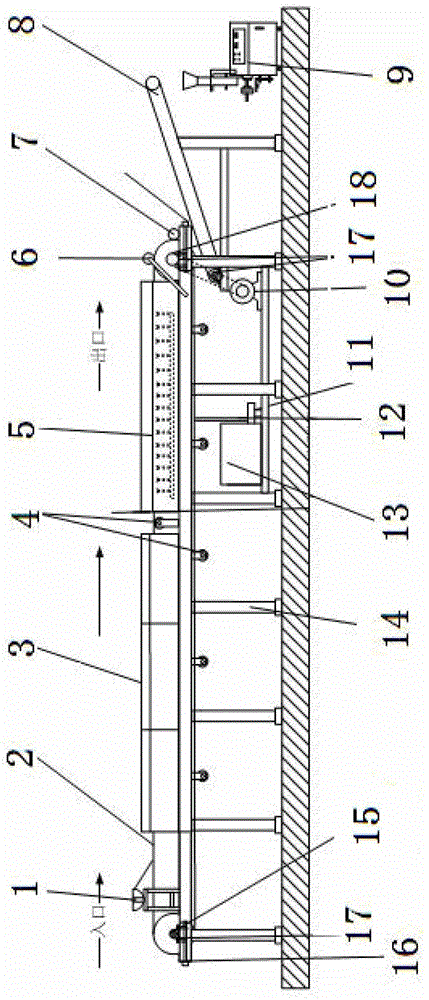

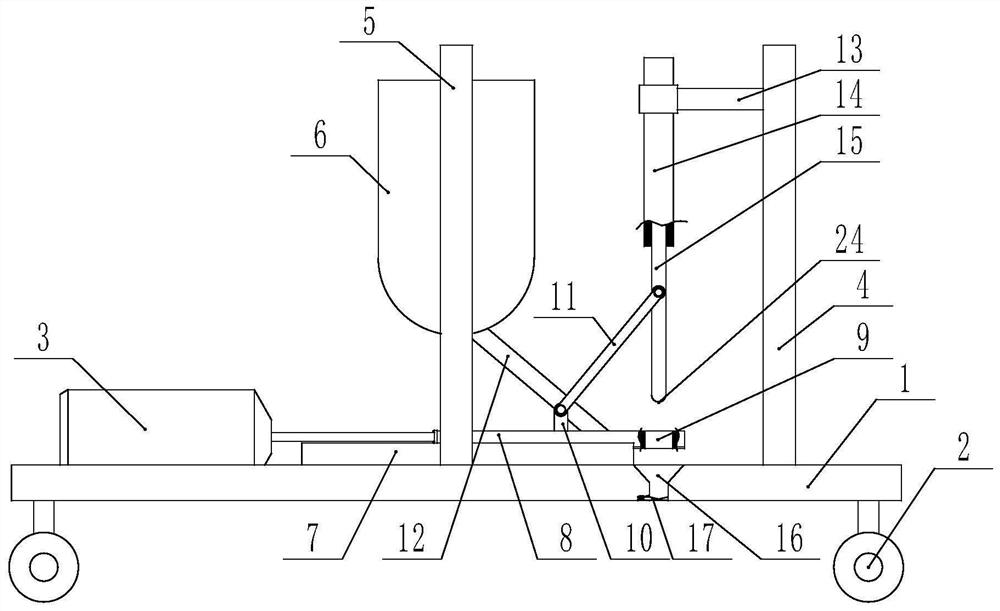

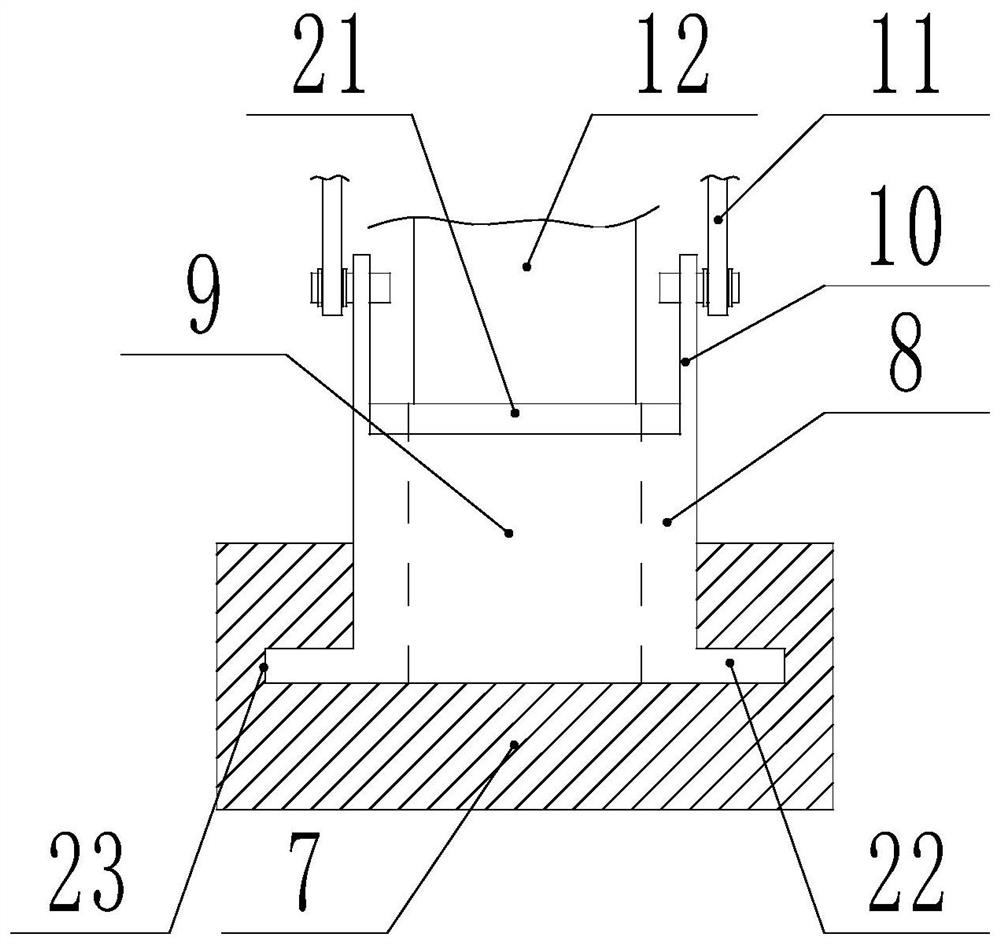

Automatic feeding machine

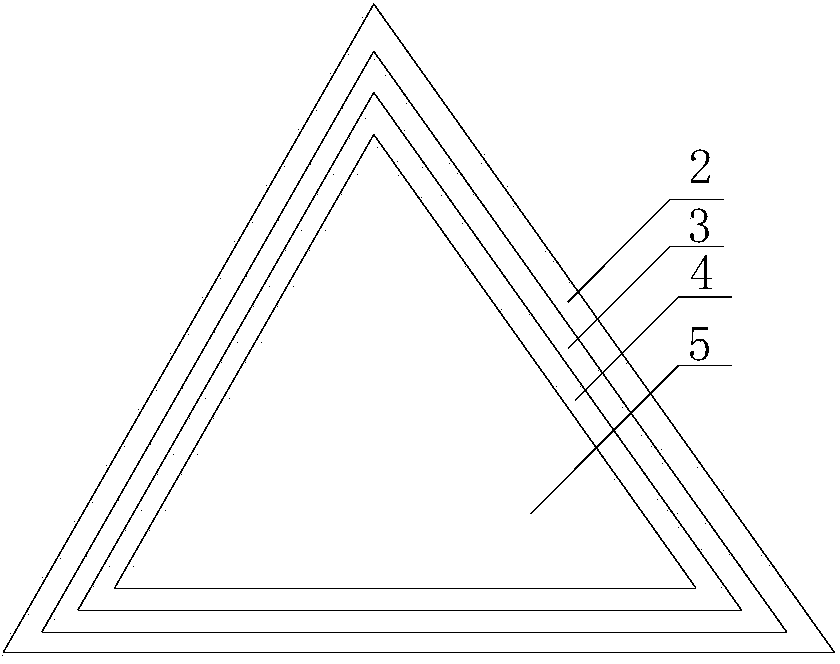

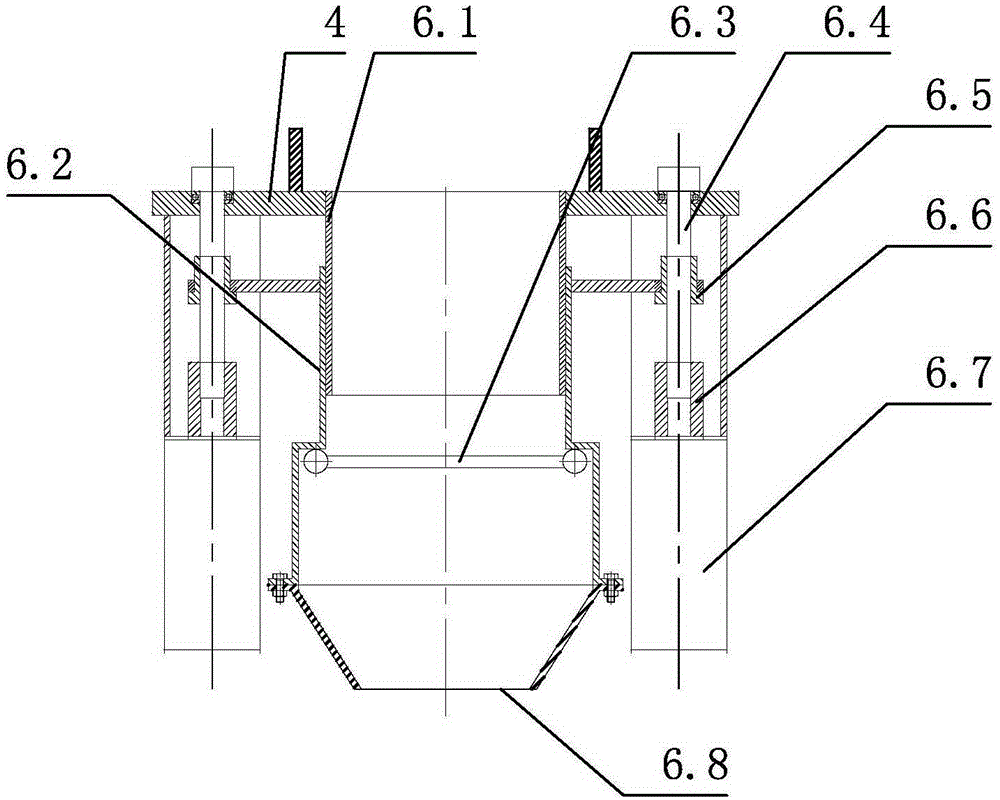

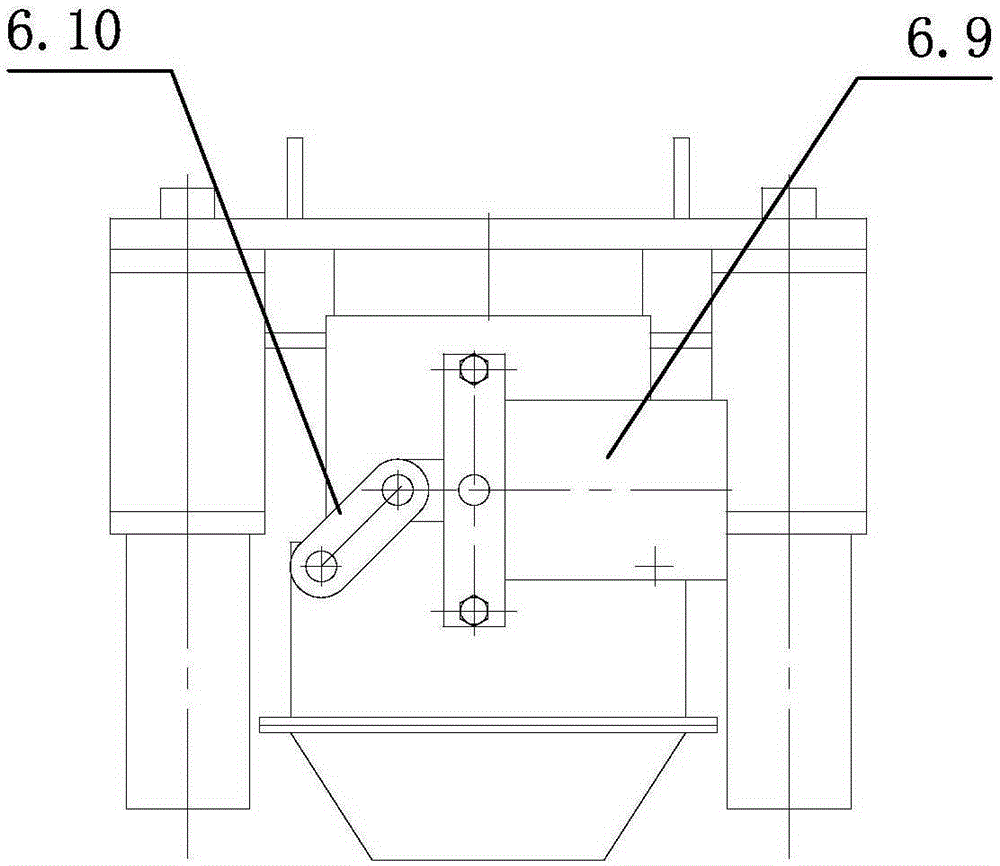

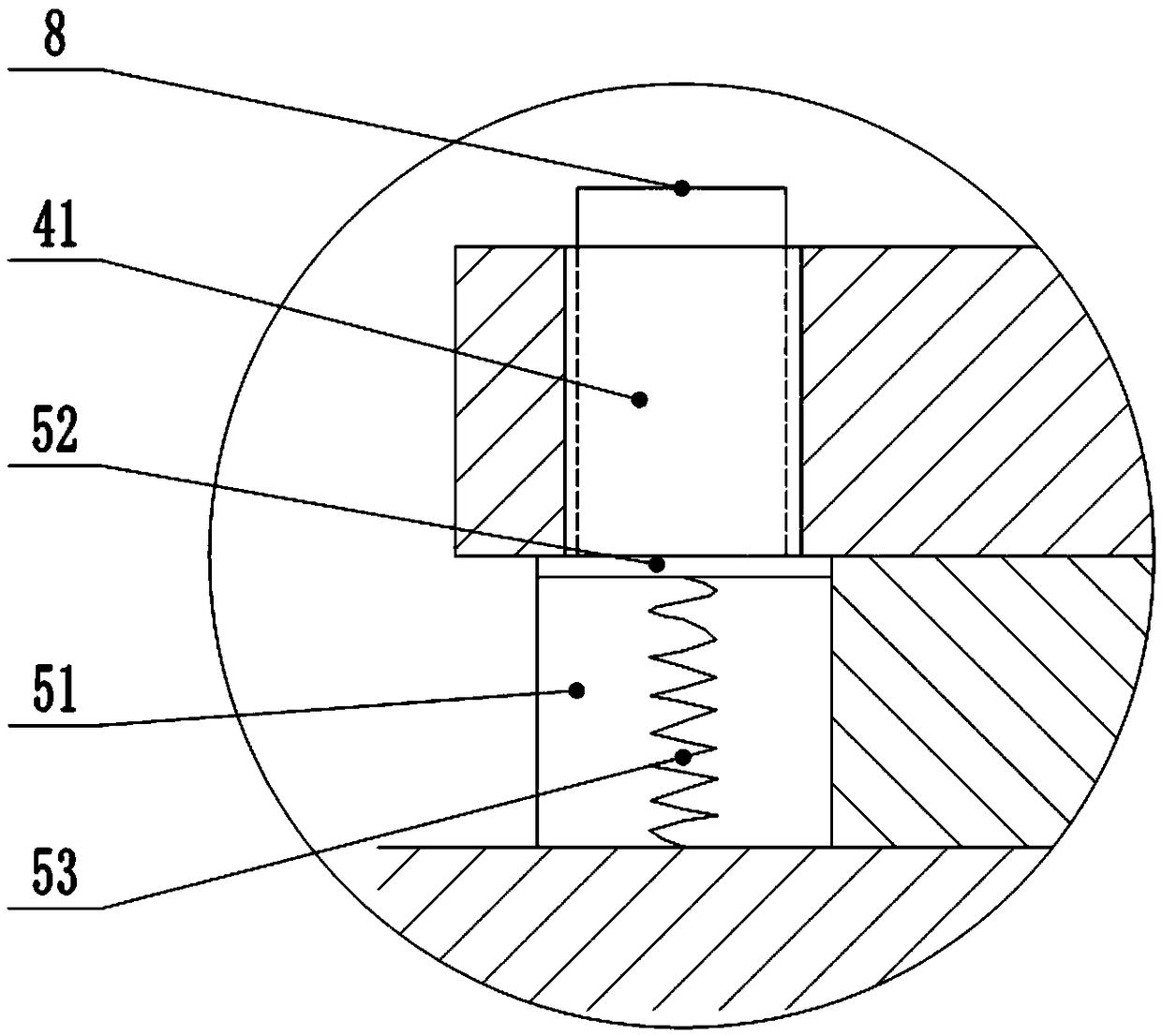

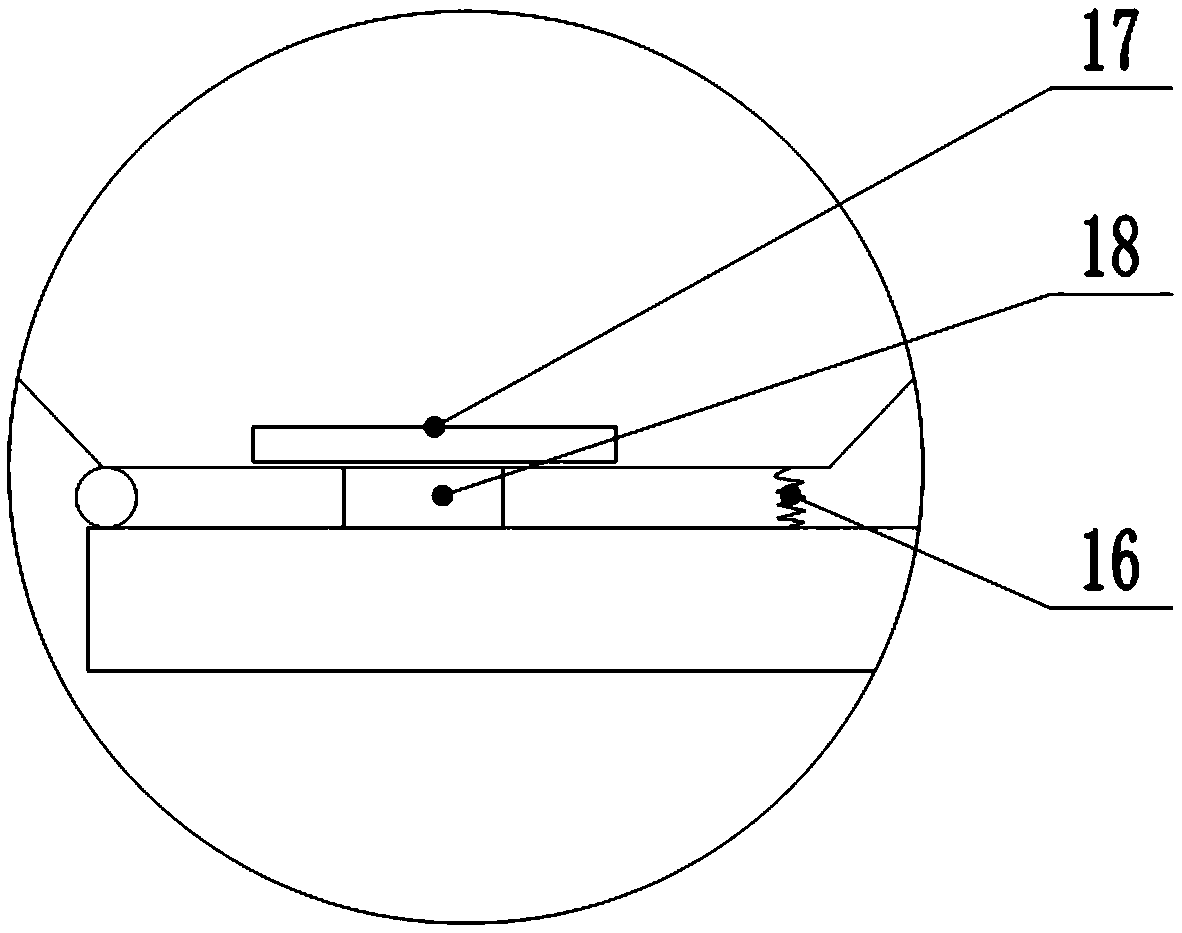

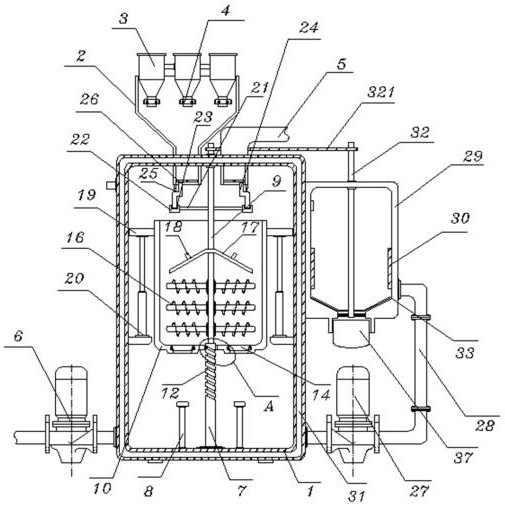

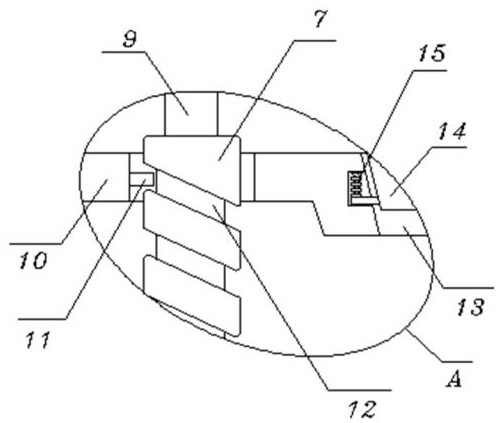

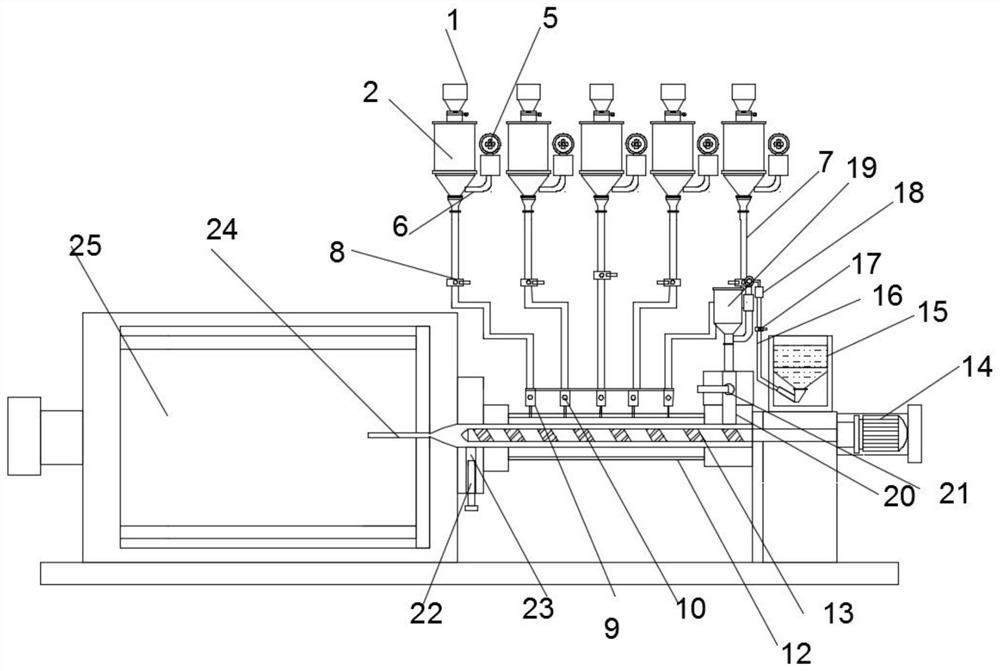

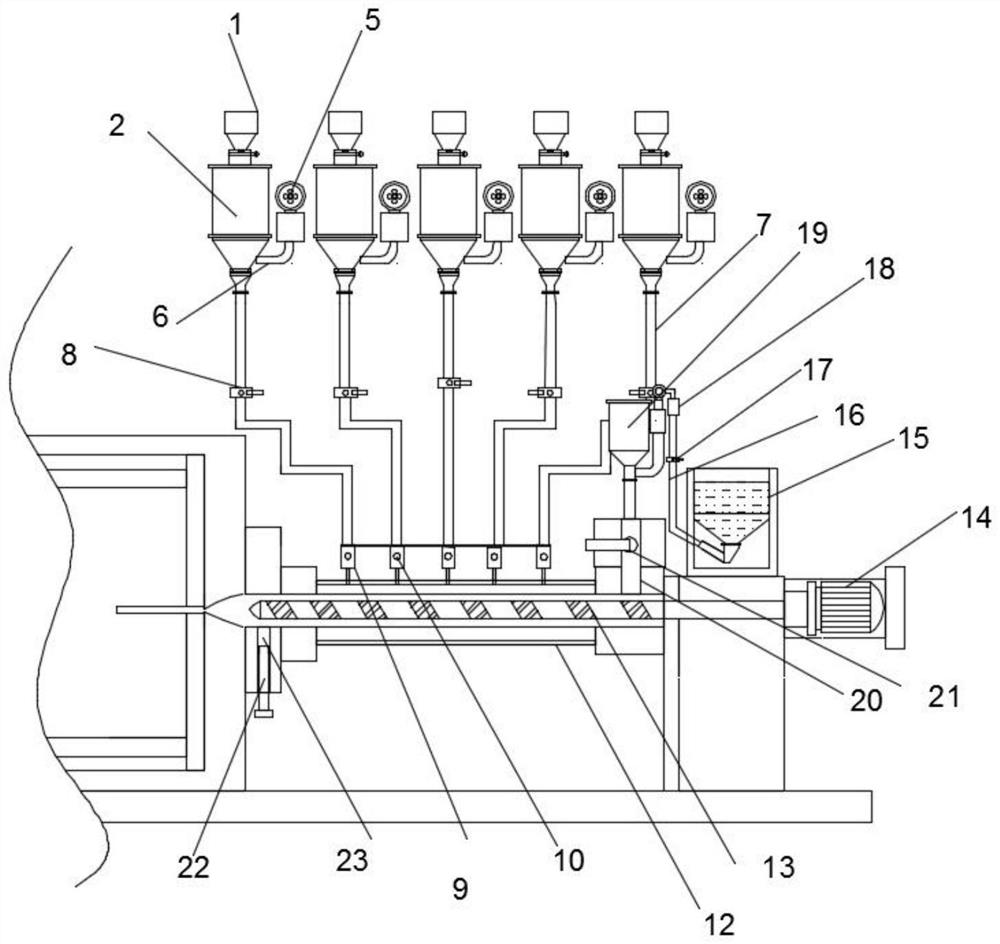

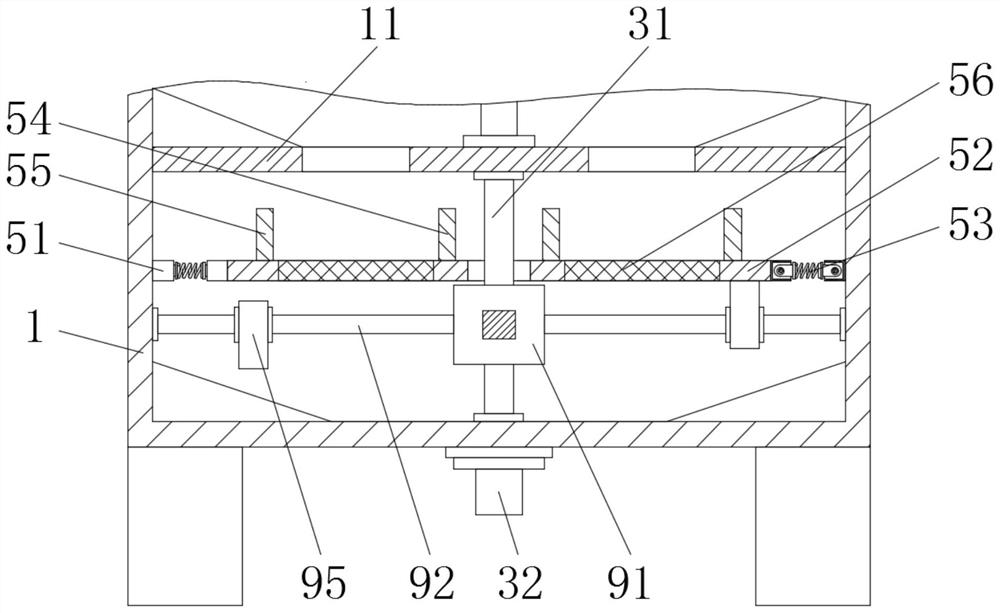

InactiveCN105235060AGuaranteed accuracyRealize automatic quantificationFeeding arrangmentsFixed frameWorking environment

The invention relates to an automatic feeding machine, in particular to an automatic feeding machine for automatically and quantitatively feeding refractory materials in the pressure forming process of the refractory materials. The automatic feeding machine comprises a machine frame and a fixed material bin arranged on the machine frame; a feeding car is arranged below a discharging outlet of the fixed material bin and connected with a conveying assembly; the feeding car is provided with a proportioner; the proportioner comprises a fixed frame; the fixed frame is fixed to the feeding car; the fixed frame is sleeved with a movable frame capable of vertically lifting; a falling port is arranged at the lower end of the movable frame; the movable frame is connected with a lifting assembly controlling the movable frame to ascend or descend; a movable door is arranged inside the movable frame; when the movable door is closed, the movable frame is divided into an upper area and a lower area, and the outer side of the movable door is connected with an overturning drive device. As the proportioner is arranged, volumetric-method quantification is achieved and not affected by the work environment, the quantification accuracy is ensured, automatic quantification and feeding process is achieved, the production efficiency is high, and quality of products is stable.

Owner:郭小红

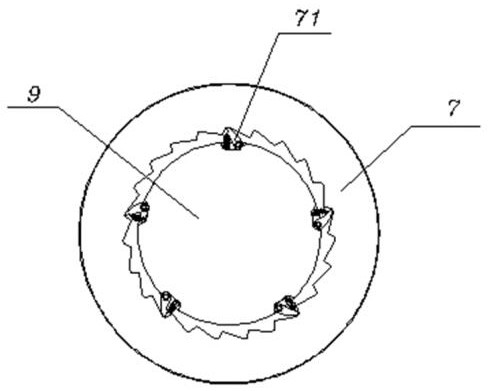

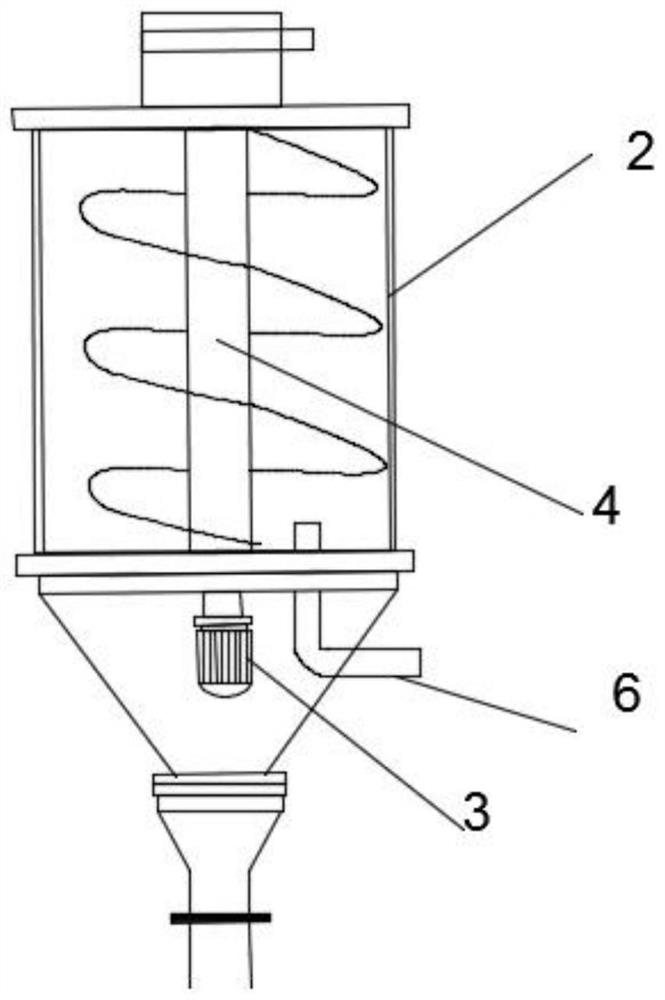

Rotary magnetic separation equipment for quartz sand utilized as building material

ActiveCN108405174AConvenient for magnetic separationUniform magnetic separationMagnetic separationConveyor partsBuilding materialEngineering

The invention relates to a feeding device, in particular to rotary magnetic separation equipment for quartz sand utilized as a building material, and aims to solve technical problems in the prior art.In order to solve the above technical problems, the rotary magnetic separation equipment which is applicable to the quartz sand utilized as the building material, has the intermittent adding function, and is good in magnetic separation effect is provided. The rotary magnetic separation equipment for the quartz sand utilized as the building material comprises ab racket and the like, wherein the bracket is connected with the right side of the top of a base; a discharging mechanism is connected with the left end of the bracket; and a magnetic separation mechanism is connected with the left sideof the inner top of the bracket and positioned on the right side of the discharging mechanism. By adoption of the designed rotary magnetic separation equipment for the quartz sand utilized as the building material, the quartz sand can be quantitatively and intermittently added; the manual adding operation is not needed; more convenience is brought; and through the arrangement of a motor, a secondrotating rod and a third rotating rod, the automatic, quantitative and intermittent adding operation can be achieved without manually moving a connecting rod.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

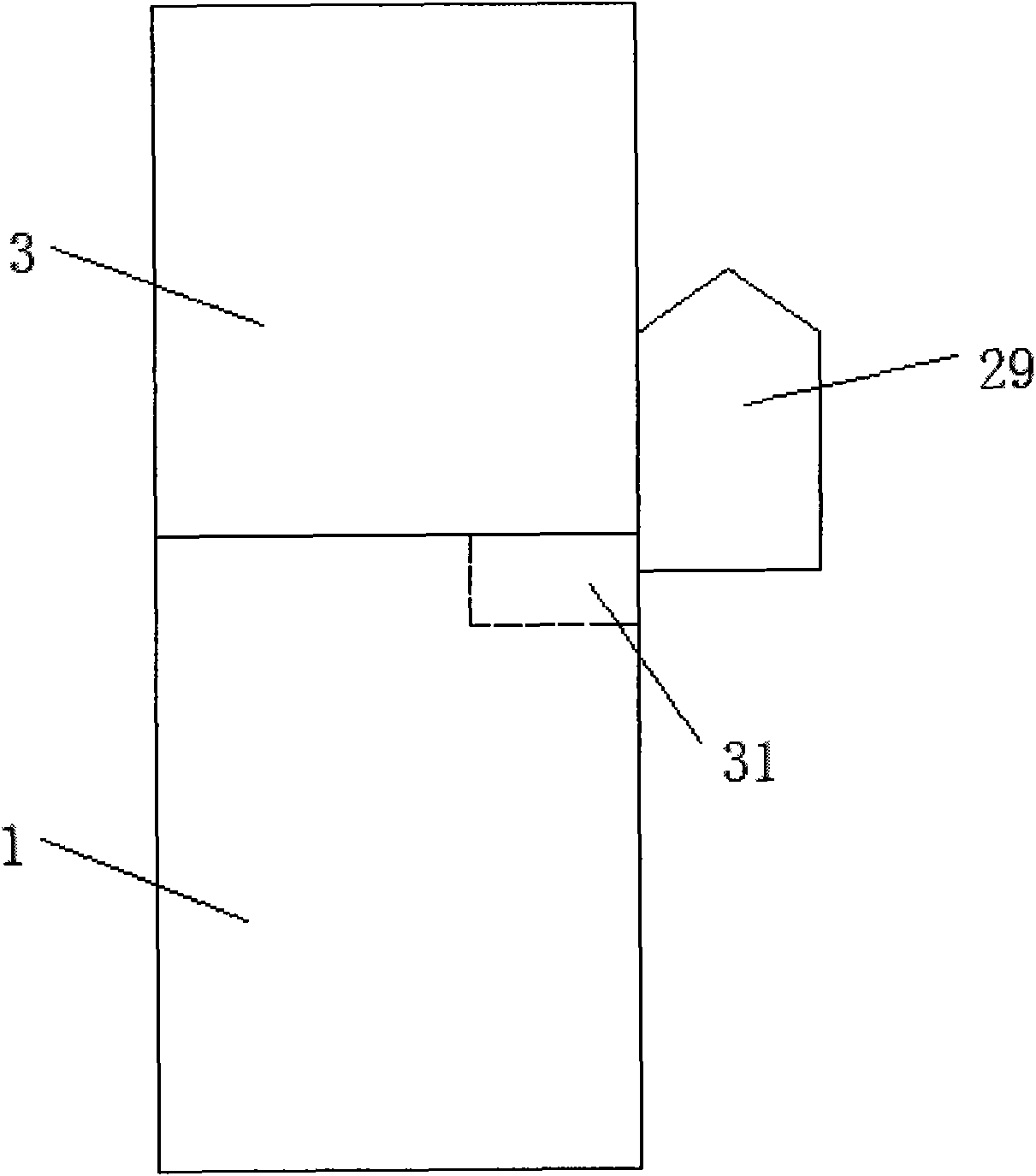

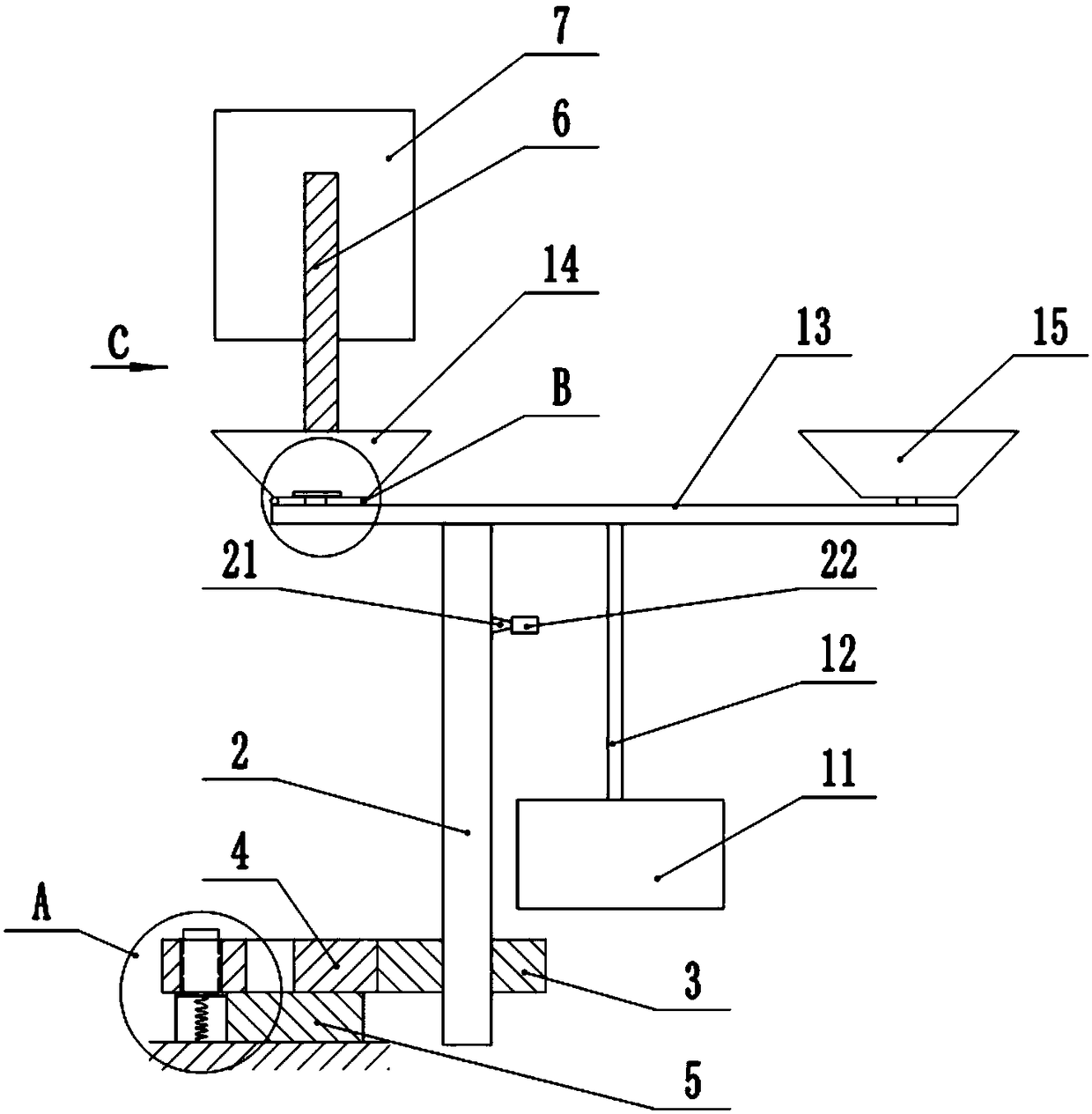

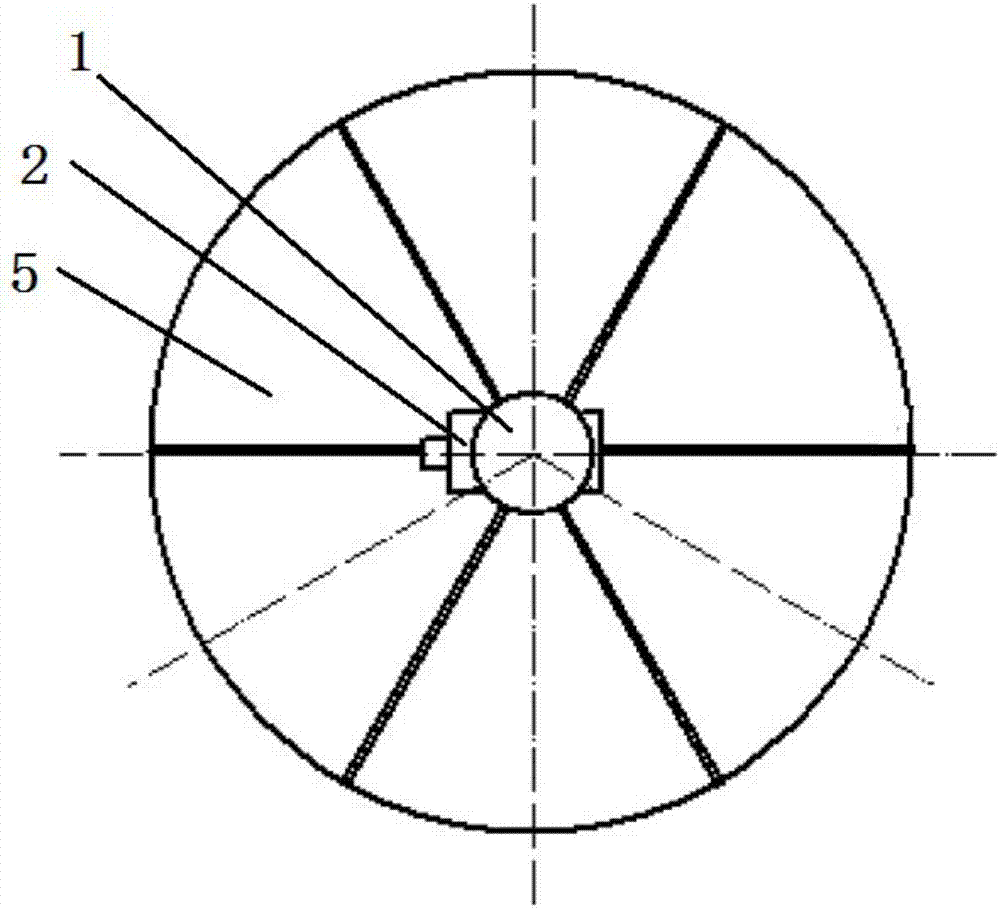

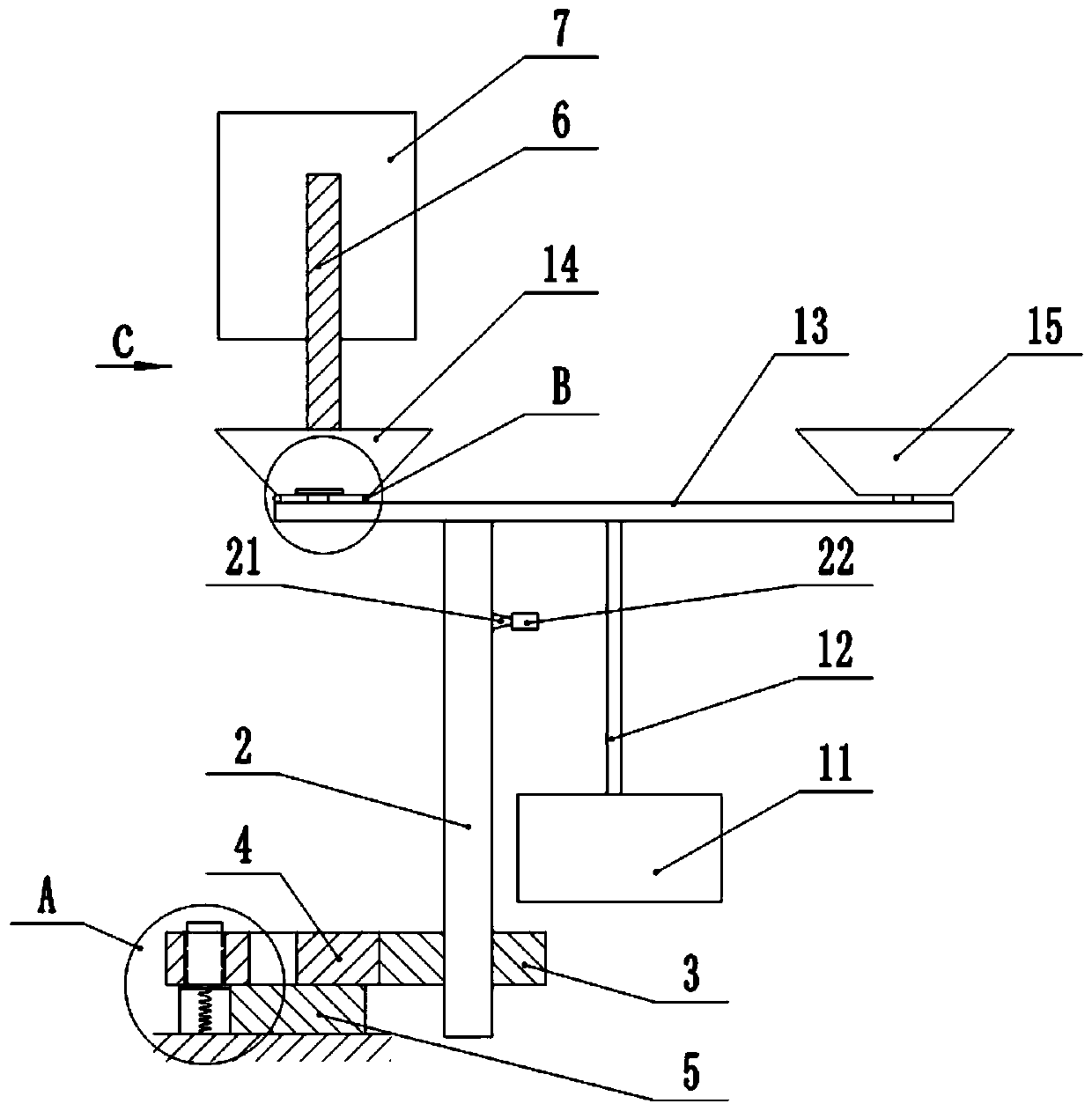

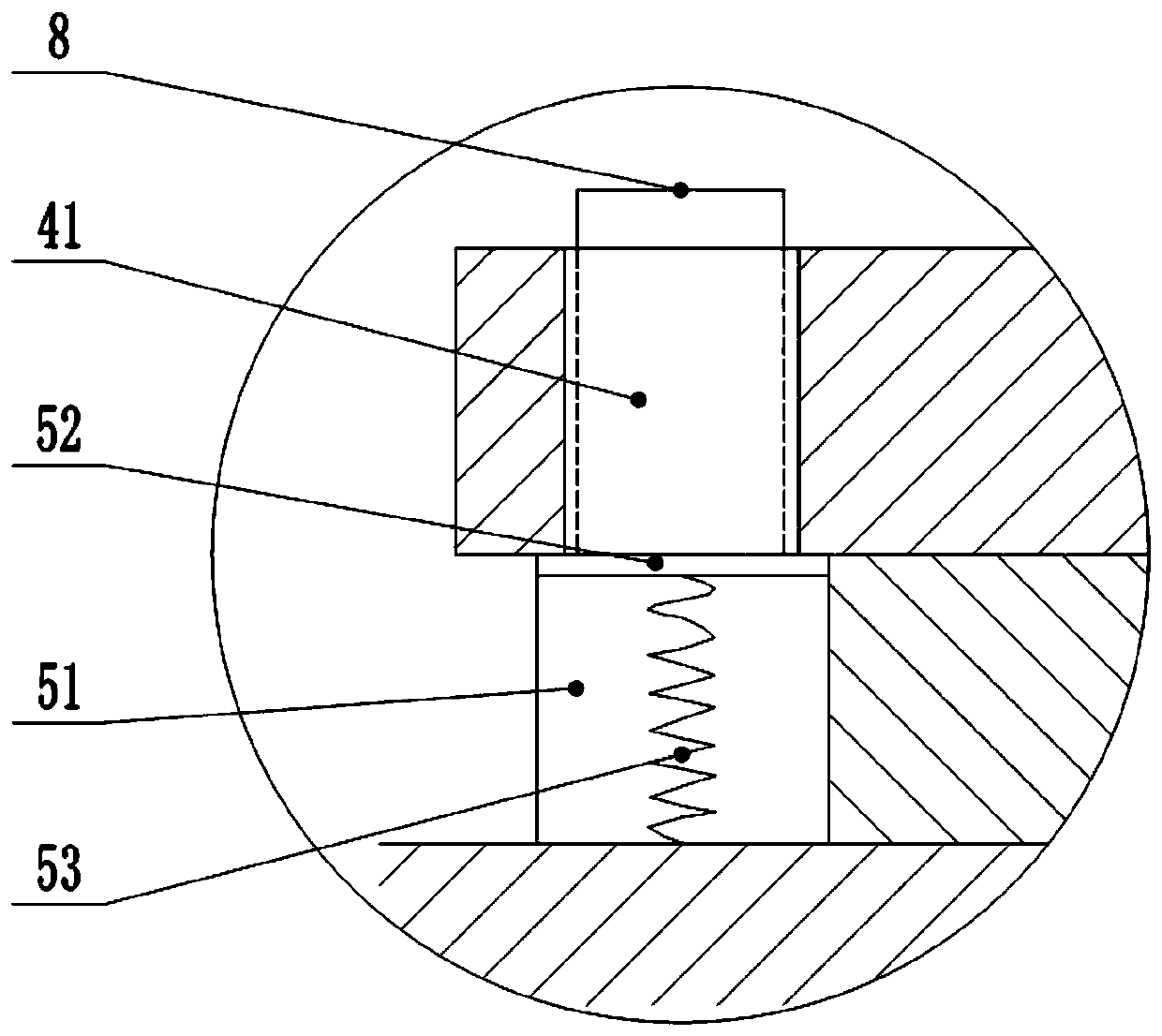

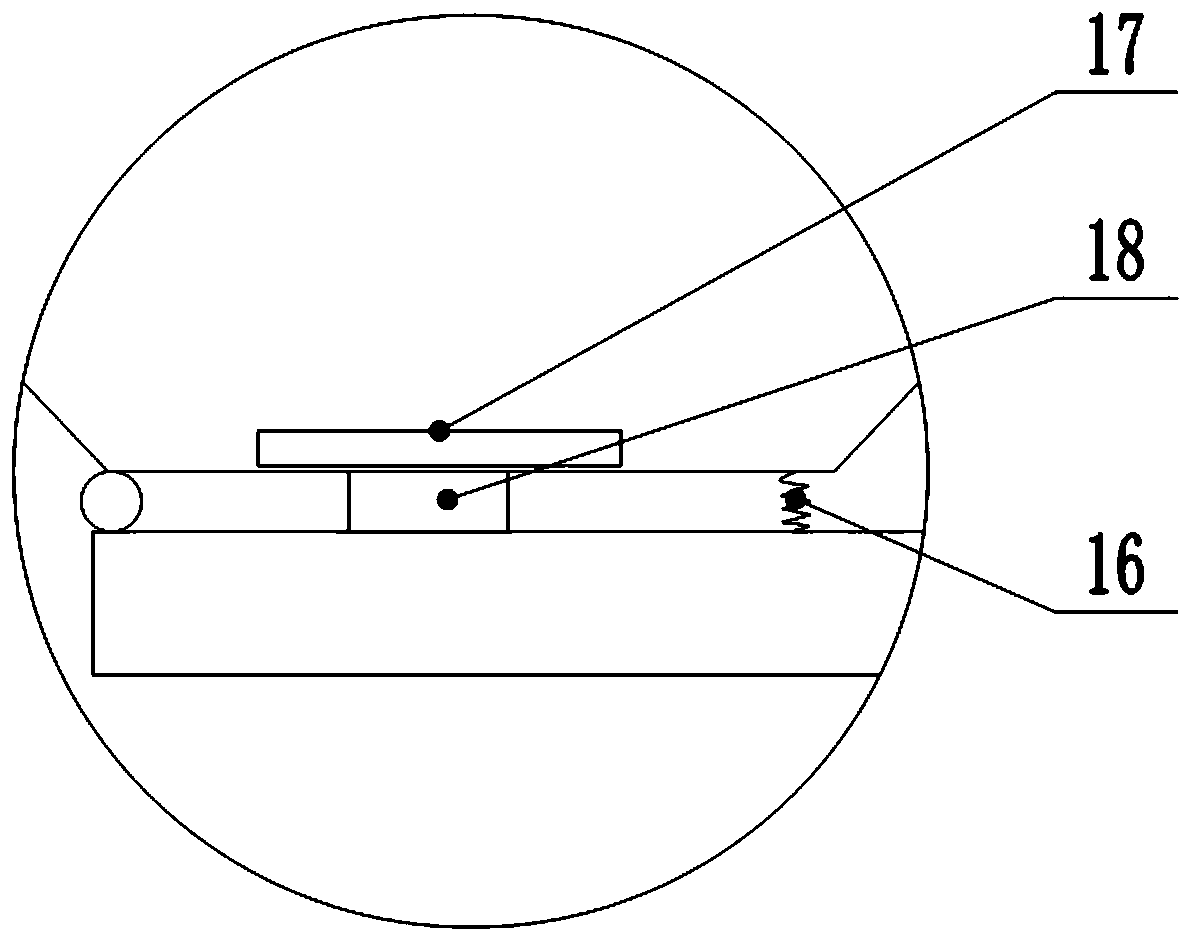

Rice packaging device

ActiveCN108688838ARealize automatic quantificationSimple structureSolid materialEngineeringElectromagnet

The invention specifically discloses a rice packaging device. The rice packaging device comprises a machine frame, a balance, a feeding box and a packaging box, wherein the balance comprises a base, atray frame and a cross beam; the tray frame is fixed on the base, and a first tray and a second tray are arranged at the two ends of the cross beam; one side of the bottom end of the first tray is rotatably matched with the cross beam, and an electromagnet is installed between the bottom of the first tray and the cross beam; a permanent magnet is arranged at the bottom of the first tray, and a screw rod is arranged on the cross beam corresponding to the first tray; a first gear and a second gear are rotatably connected to the machine frame, the first gear meshes with the second gear, and thesecond gear is located below the first tray; the screw rod penetrates through the first gear and is matched with the first gear in a threaded mode, and the second gear is provided with a first groovefor placing packing boxes; a baffle is hinged to the side wall of the first tray, the baffle is slidably connected to the side wall of the feeding box, and the baffle is provided with a through hole;and an outlet is formed in the side wall of the feeding box, and the through hole communicates with the outlet to feed the first tray. According to the rice packaging device, rice can be continuouslyand quantitatively packaged circularly, and the packaging efficiency is improved.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

Intelligent water and fertilizer all-in-one machine

ActiveCN114467463AImprove mixing efficiencyPrevent precipitationTransportation and packagingRotary stirring mixersFertilizerAgricultural engineering

The intelligent water and fertilizer all-in-one machine comprises an outer barrel, and a feeding hopper and a water inlet pipe are installed on the two sides of the top of the outer barrel in a penetrating mode respectively; the device further comprises an irrigation pump, the irrigation pump is installed on the left side of the edge of the bottom of the outer barrel, a movable column is arranged in the installation column in a penetrating mode, the top of the installation column is sleeved with an inner barrel, and a guide ring is fixed to the outer side of the movable column through a transverse rod. And the recovery pump is installed on the right side of the edge of the bottom of the outer barrel, a heater is fixed to the inner wall of the evaporation box, and a vertical rod is installed at the center of the interior of the evaporation box through a bearing. According to the intelligent water and fertilizer all-in-one machine, water and fertilizer are uniformly mixed while being used through power of the irrigation pump, the trouble that water and fertilizer sediment needs to be treated is effectively avoided, energy is effectively saved, meanwhile, internal cleaning and water and fertilizer recycling are achieved through power of the recycling pump, efficient energy conservation and environment protection are achieved, and the situation that the underground environment is affected by water and fertilizer discharge is avoided.

Owner:江苏久智环境科技服务有限公司

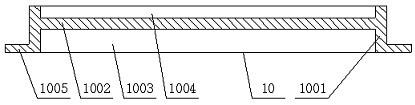

Production process of protective film

The invention discloses a production process of a protective film. A film blowing processing device comprises a first motor, a melt extruder, a feeding hopper, a second motor, a guide plate, a film blowing machine, a rack, a first limiting plate, a heat absorption pipe, a protective film, a first rotating shaft, a first rotating wheel, a supporting plate, a second rotating shaft, a second rotatingwheel, a second limiting plate, a third limiting plate, a connecting shaft, a shearing base, bolts, cutters, a guide wheel, a third motor and a receiving wheel. The production process is simple in structure and convenient to operate, through cooperation of the melting feeding hopper, the second motor and the guide plate, the structure is simple, use is convenient, and the purpose of automatic quantitative material guide is achieved; through cooperation of the rack and the heat absorption pipe, the structure is simple, and the purpose of rapid cooling forming of protective films is achieved; and through cooperation of the connecting shaft, the shearing base, the bolts, the cutters, the third motor and the receiving wheel, the structure is simple, and the purpose of automatically cutting protective films of different sizes is achieved by adjusting the distance between the cutters.

Owner:惠州市国鹏科技有限公司

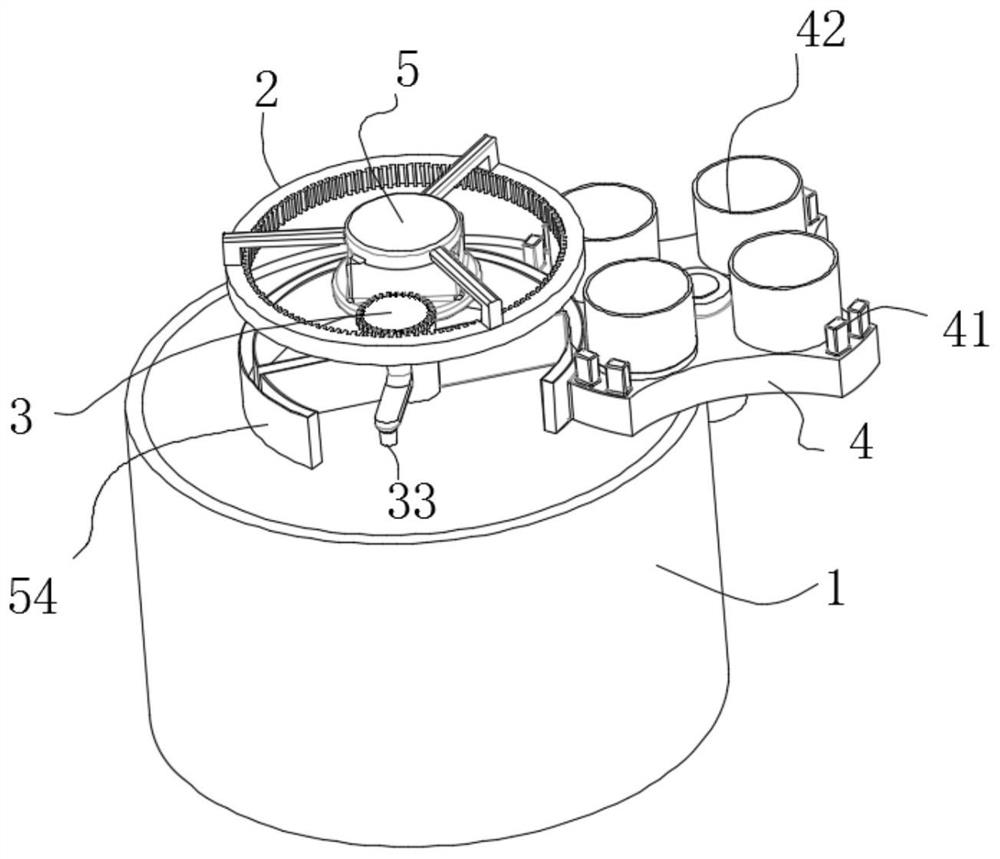

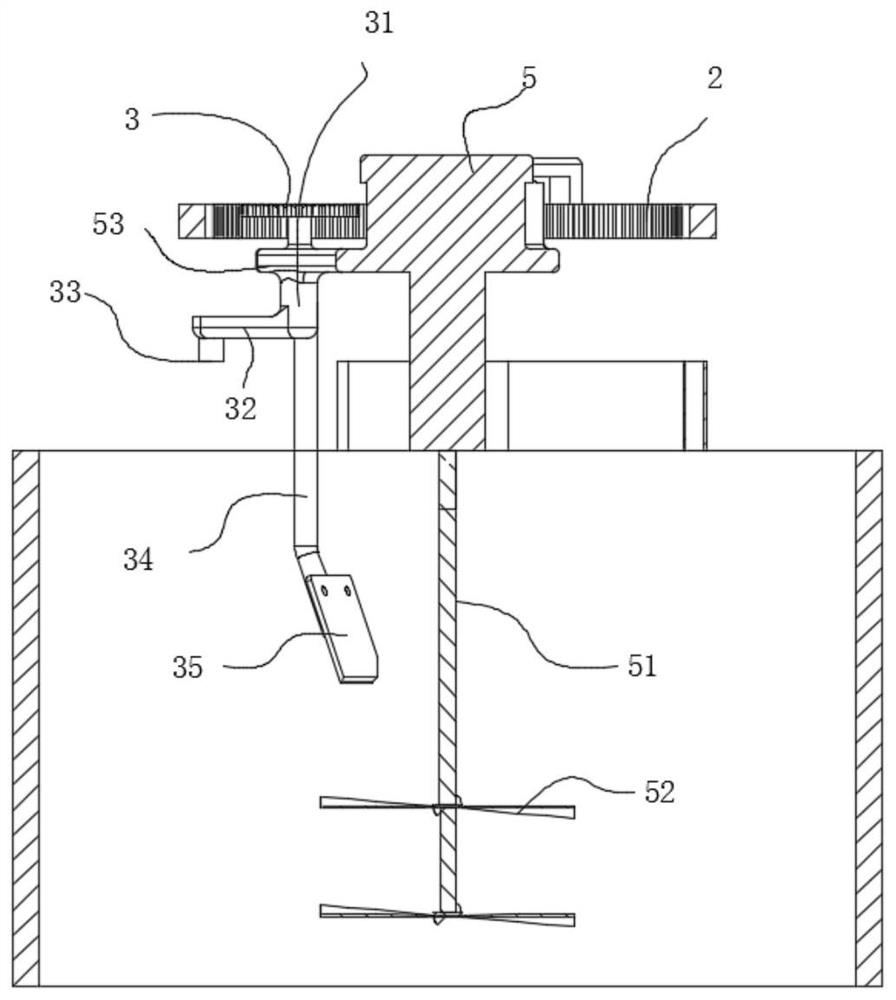

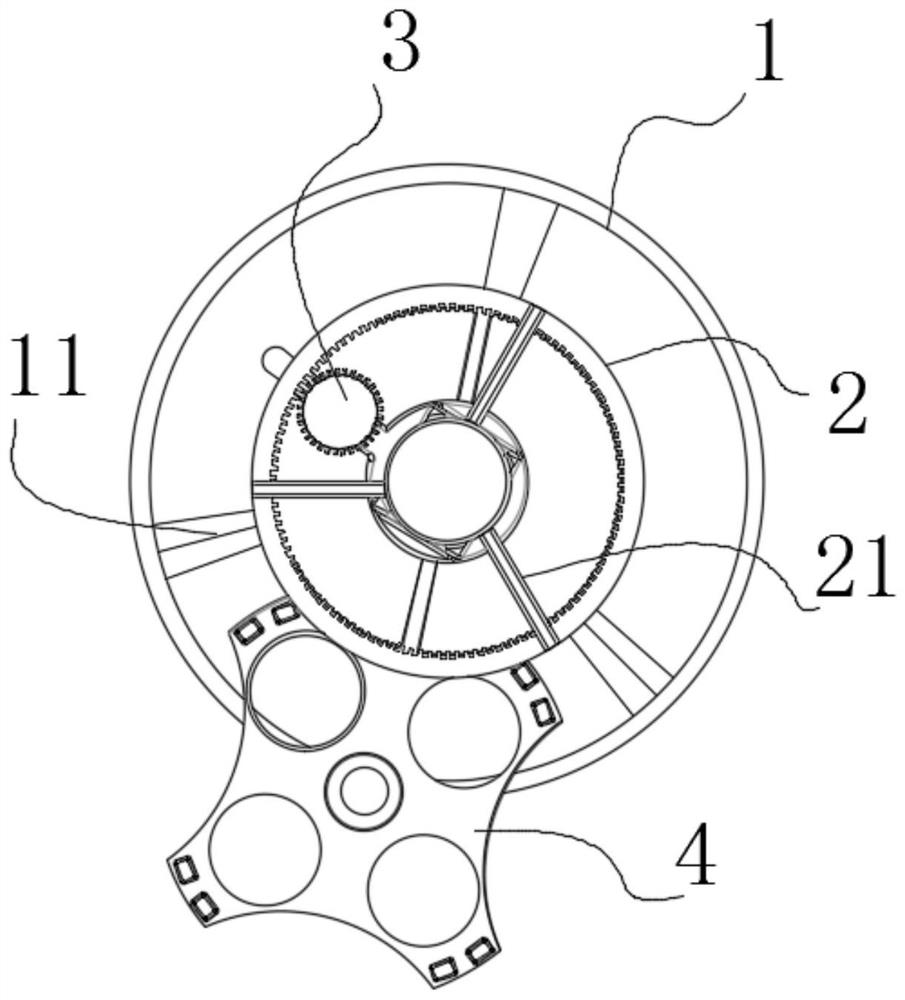

Multifunctional medicine dispensing tank for pharmacy

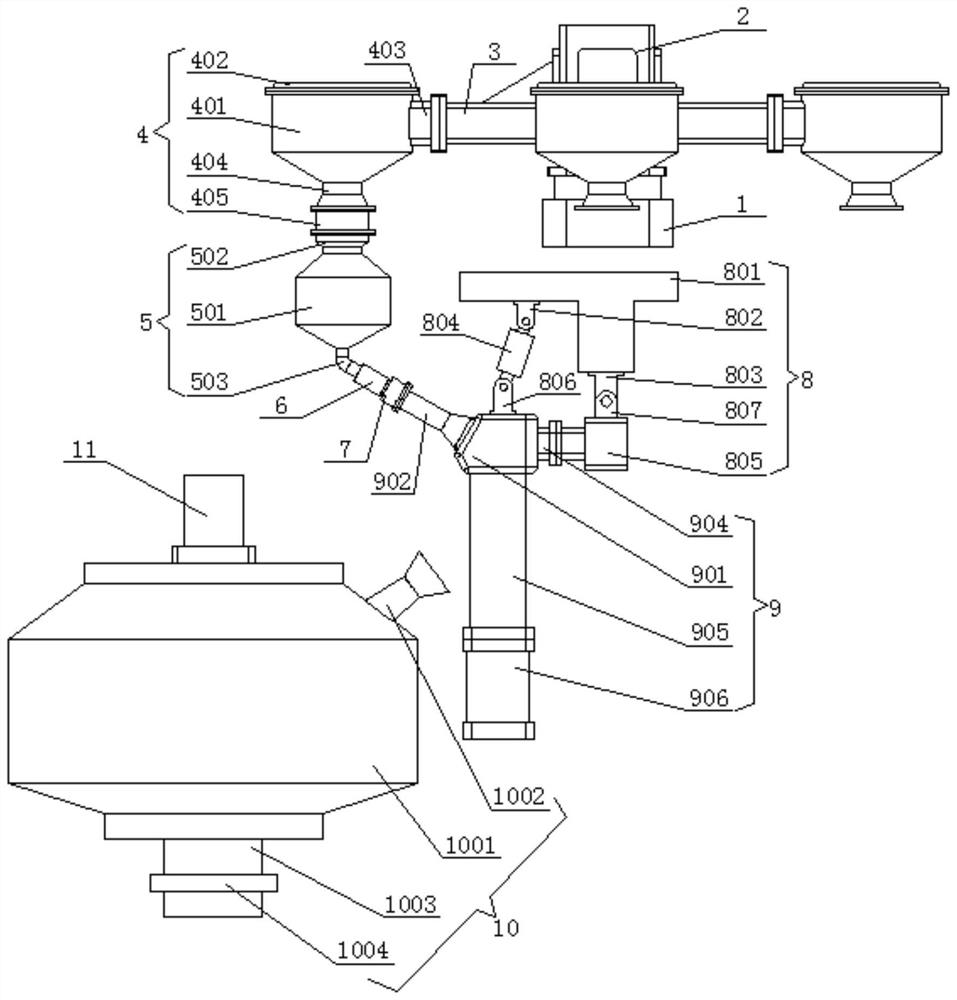

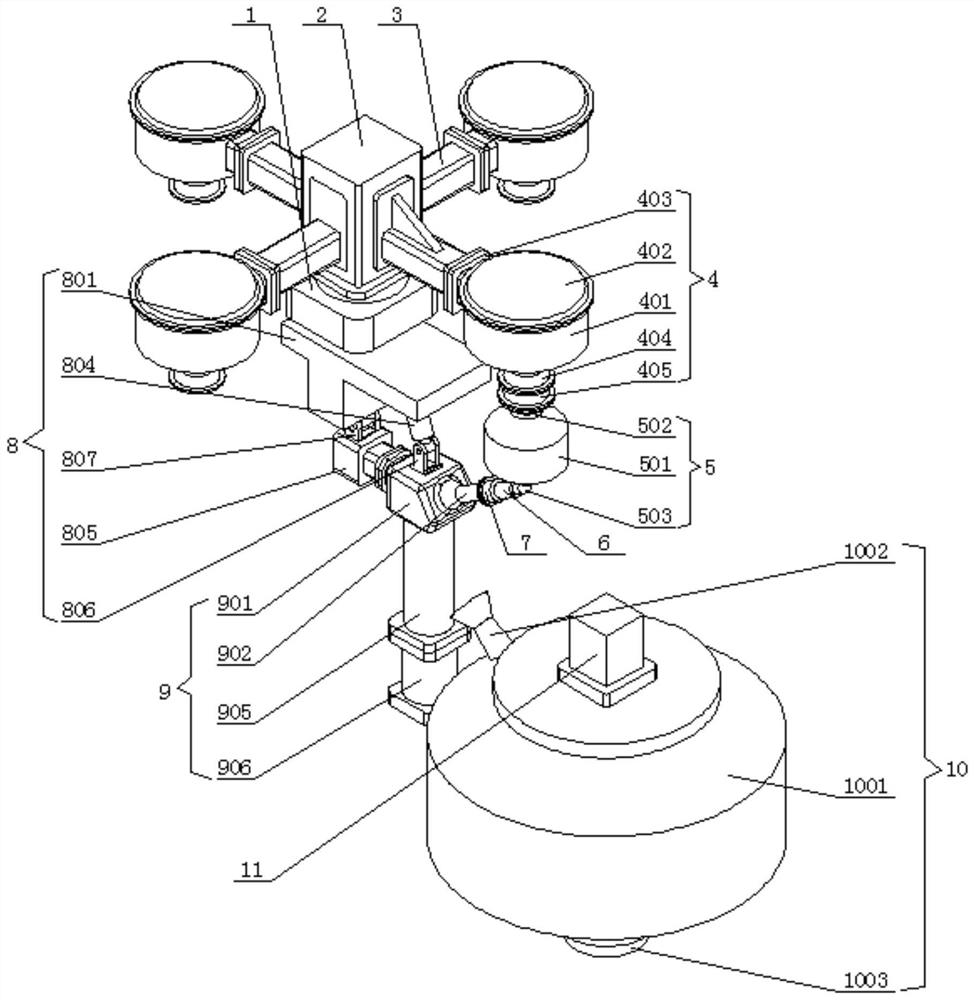

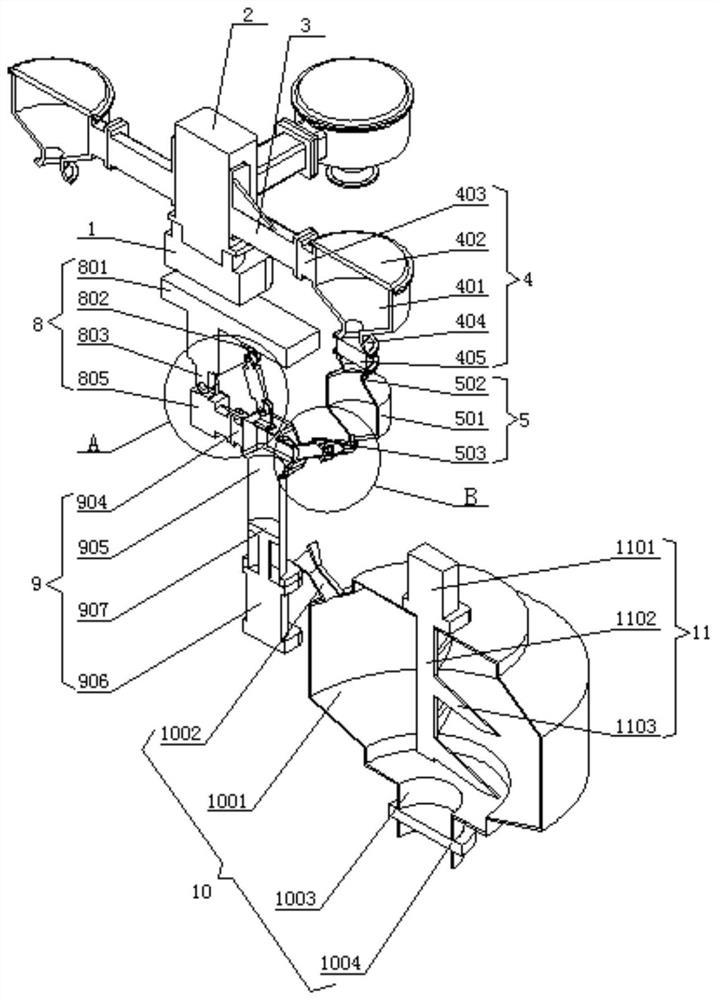

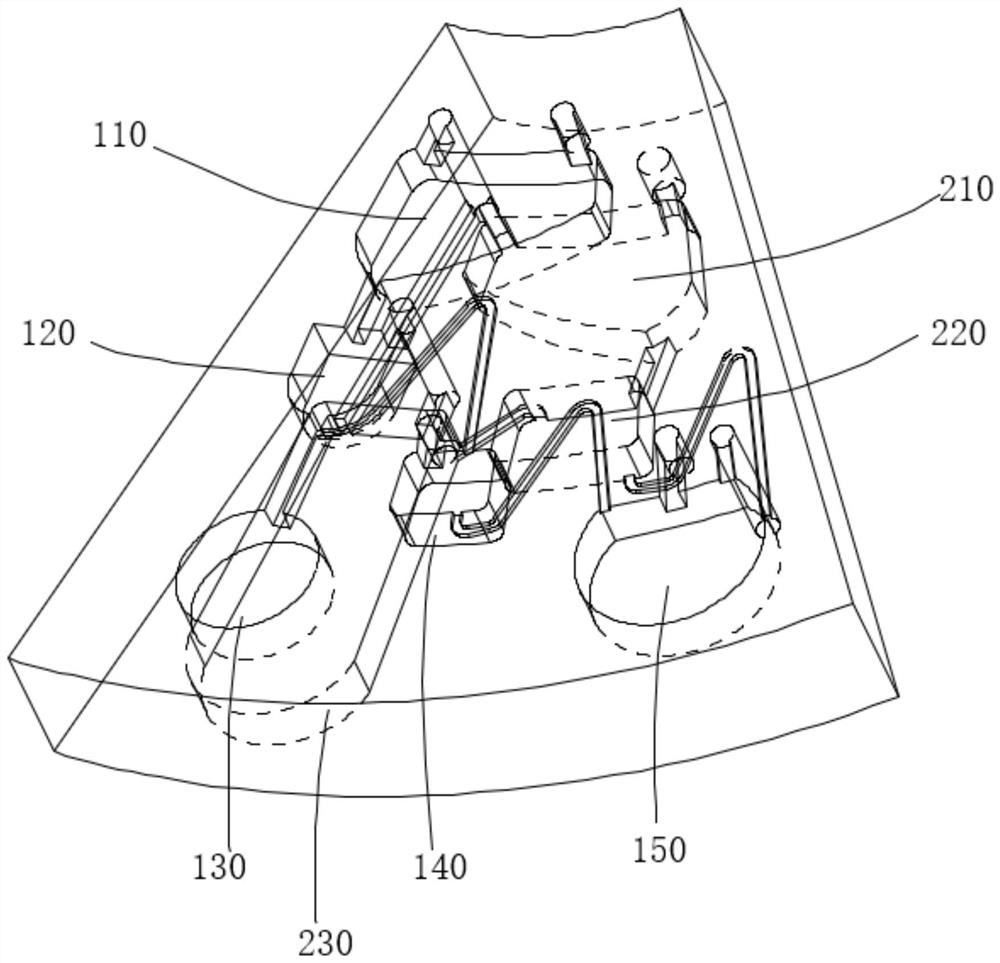

ActiveCN112875024ARealize automatic quantificationImprove dispensing efficiencyDispensing apparatusRotary stirring mixersPharmacyDispensing medications

The invention relates to the technical field of pharmaceutical equipment, and particularly discloses a multifunctional medicine dispensing tank for pharmacy. The medicine dispensing tank comprises a rotary dispensing mechanism, a middle storage mechanism arranged on the side lower portion of the rotary dispensing mechanism, a quantitative dosing mechanism arranged on the side lower portion of the middle storage mechanism and a medicine mixing mechanism arranged on the side lower portion of the quantitative dosing mechanism, wherein the rotary dispensing mechanism is composed of an electrically-driven rotary disc, a rotary supporting seat, a fixed connecting arm and a dispensing tank assembly, and the middle storage mechanism is composed of a middle storage tank assembly, a powder suction device and a guide head I. In the medicine dispensing tank using process, different kinds of medicine powder can be stored in different upper end covers I, automatic quantification of the medicine powder is achieved, and the whole medicine dispensing efficiency is improved; and the relative height position of a quantitative disc in a quantitative pipe is controlled through stretching of a quantitative cylinder, no manual control is needed in the quantitative process, the positioning precision is improved, and the labor cost is reduced.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

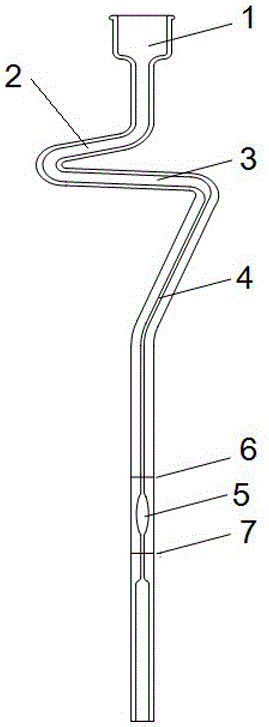

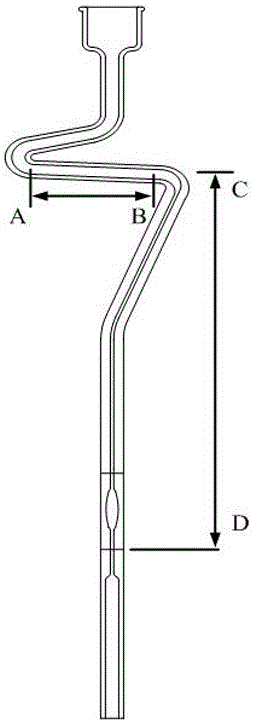

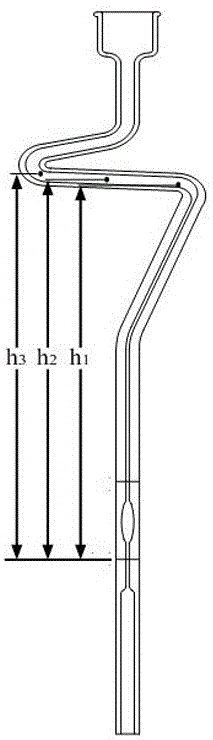

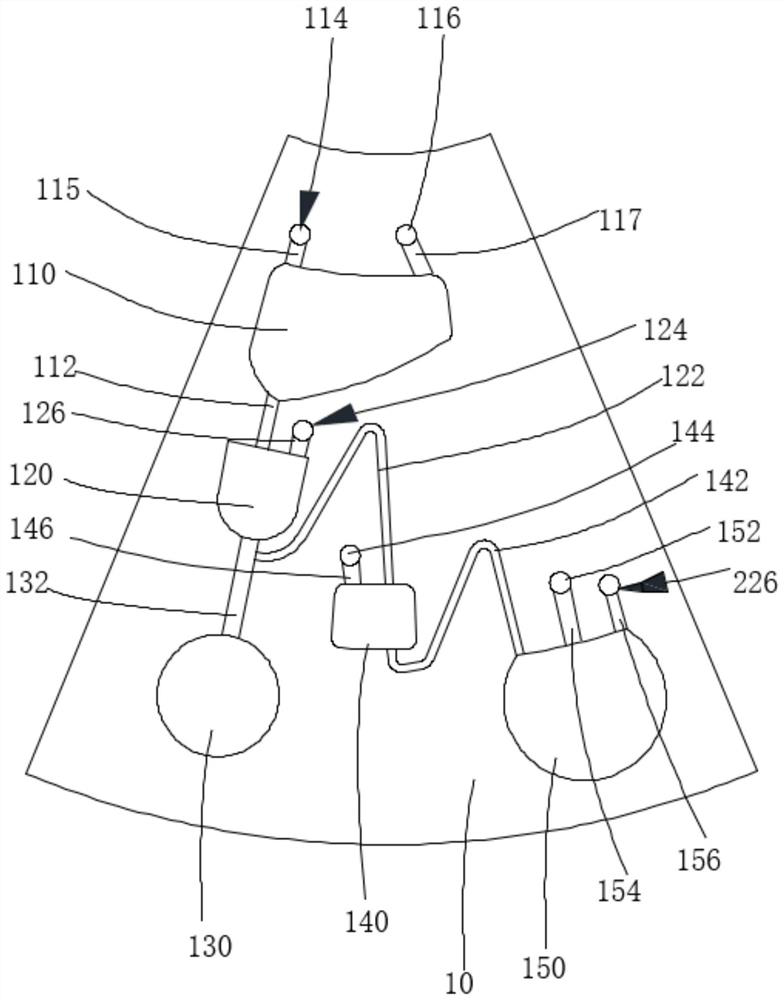

Capillary viscometer capable of realizing automatic quantification and testing method thereof

ActiveCN105928831ARealize automatic quantificationImprove accuracyDirect flow property measurementSufficient timeCapillary Tubing

The invention relates to a capillary viscometer capable of realizing automatic quantification and a testing method thereof. The capillary viscometer comprises a tube-bending type kinematic viscometer; the tube-bending type kinematic viscometer comprises a sample introduction cup, a honeycomb duct, a transverse arm, a capillary tube and a measuring bulb sphere which are successively communicated, and an upper scale mark and a lower scale mark respectively located above and below the measuring bulb sphere; the capillary viscometer further comprises a branch pipe; and one end of the branch pipe is communicated with the transverse arm, and the internal diameter of the branch pipe is smaller than the internal diameter of the transverse arm and greater than internal diameter of the capillary tube. According to the invention, since the branch pipe is arranged on the transverse arm of the viscometer, a sample located between the sample introduction cup and the branch pipe has enough time to thoroughly flow out from the branch pipe before a sample in the capillary tube reaches the upper scale mark, so it is guaranteed that the tail end of the sample is located at the edge of the joint of the branch pipe and the transverse arm, the viscometer is calibrated and the height of a liquid column in testing of a sample each time is identical to the length of the capillary tube; and thus, accuracy and repeatability of viscosity testing are improved.

Owner:湖南慑力电子科技有限公司

Multifunctional automatic batch seasoning batching system

InactiveCN113262666AStir wellGuaranteed qualityRotary stirring mixersTransportation and packagingAir pumpElectric machinery

The invention relates to the technical field of seasoning production, and discloses a multifunctional automatic batch seasoning batching system which comprises a feeding port, a feeding bin is arranged at the bottom of the feeding port, a first motor is arranged in the feeding bin, a stirring mechanism is arranged at one end of the first motor, an air pump is arranged on one side of the feeding bin, a high-pressure air pipe is arranged at one end of the air pump, a feeding pipe is connected to the bottom of the feeding bin, a feeding electromagnetic valve is fixedly installed on the feeding pipe, a metering and weighing device is arranged at one end of the feeding pipe, a discharging electromagnetic valve is arranged at the bottom of the metering and weighing device, a weight sensor is arranged in the metering and weighing device, a mixing groove is formed in the bottom of the metering and weighing device, and a spiral stirring shaft is arranged in the mixing tank. According to the multifunctional automatic batch seasoning batching system, by arranging the weighing mechanism, batch accurate batching can be carried out, and by arranging the automatic cleaning mechanism, the inner wall of the device after batching can be rapidly cleaned, and reuse is facilitated.

Owner:常州华青自动化系统有限公司

Efficient automatic seeding device

InactiveCN111316793ARealize automatic quantificationSimple structureSeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringControl theory

Owner:GUANGDONG ACAD OF AGRI SCI

Improved biological extracting device

The invention discloses an improved biological extracting device. The improved biological extracting device comprises a machining frame; a crushing cavity is formed in the top end surface of the machining frame; a first rotating cavity is formed in the inner wall body of the machining frame on the right side of the crushing cavity; a second rotating cavity is formed between the first rotating cavity and the crushing cavity; a first rotating shaft extending left and right is arranged in the crushing cavity; a first spline groove is formed in the left side end surface of the first rotating shaft; a first spline rod is in spline cooperative installation in the first spline groove; the extension tail end on the left side of the first spline rod is rotationally matched and connected with the inner wall on the left side of the crushing cavity; an extension section on the right side of the first rotating shaft is rotationally matched and connected with the machining frame, and extends into the second rotating cavity; multiple sets of rotating paddles are peripherally fixed on the outer surface of the first rotating shaft in the crushing cavity; multiple sets of crushing blades are fixedlyarranged on the end surfaces on the left and right sides of the rotating paddles; and a second spline shaft is fixedly mounted at the extension tail end on the right side of the first rotating shaft.

Owner:广州程科电子科技有限公司

Intelligent refrigerator

InactiveCN107421228AEasy accessImprove automationLighting and heating apparatusSupportElectricityRefrigerated temperature

The invention relates to an intelligent refrigerator. The intelligent refrigerator comprises a refrigerating chamber and a control unit and is characterized in that a mounting part of a storage bin and the storage bin matched with the mounting part are arranged in the refrigerating chamber, a discharging opening is formed in the storage bin, an opening communicating with the exterior is formed in the refrigerating chamber, an automatic feeding mechanism is arranged on the opening, the area of the opening is larger than or equal to 49 square centimeters, and the automatic feeding mechanism seals the opening and is electrically connected with the control unit. When materials need to be conveyed to the exterior of the refrigerator, the control unit controls the automatic feeding mechanism to open the opening, the automatic feeding mechanism communicates with the storage bin, and therefore the materials in the storage bin are conveyed to a container outside the refrigerator. Compared with the prior art, the refrigerator has the beneficial effects that materials subject to freshness preservation storage can be conveyed out of the refrigerator automatically, a user does not need to perform operation of door opening, closing and the like at the position in front of the refrigerator, good automation is achieved, and taking and putting of materials in the refrigerator by people are greatly facilitated.

Owner:JOYOUNG CO LTD

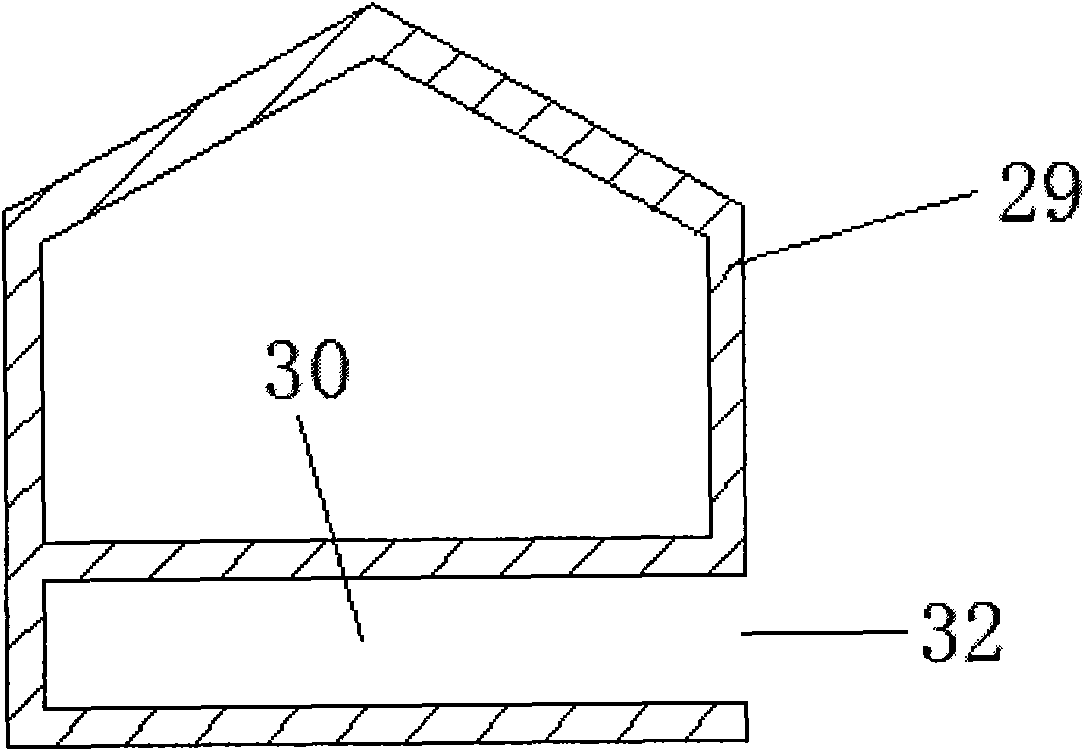

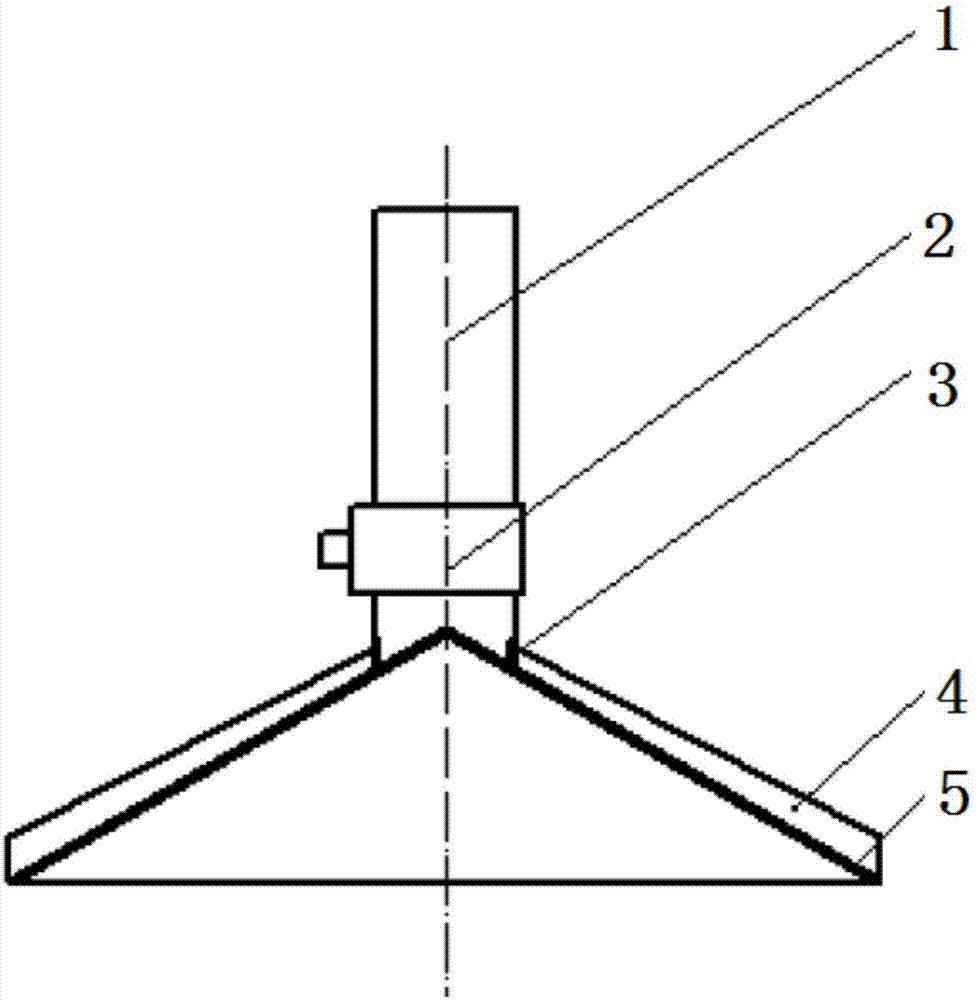

Feeding device

PendingCN107877711ASimple structureEasy to manufactureDischarging apparatusStructural engineeringPipe

The invention provides a feeding device. The feeding device comprises a material conveying pipeline, a hopper, bin gates and a controller; the material conveying pipeline is a hollow pipe with the twoopen ends; the hopper is in a conical shape, and the top of the conical shape is connected to one end of the material conveying pipeline so as to close the end of the material conveying pipeline; thebin gates are arranged on the side wall of one end of the material conveying pipeline so as to enable materials in the material conveying pipeline to pass through the bin gates to flow out along theouter surface of the hopper; and the controller is connected with the bin gates so as to control opening and closing of the bin gates. By using the feeding device in the feeding process of self-compacting concrete used for pouring members, gas in the self-compacting concrete can be discharged, and accordingly the quality of the poured members is improved.

Owner:SUZHOU CONCRETE CEMENT PROD RES INST +1

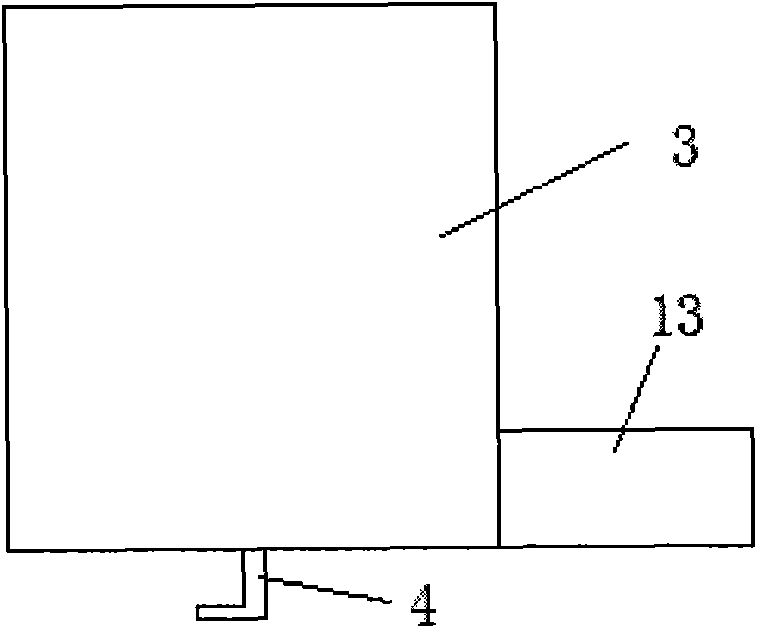

Rice packing device

ActiveCN108688838BRealize automatic quantificationSimple structureSolid materialAgricultural engineeringStructural engineering

The invention specifically discloses a rice packaging device. The rice packaging device comprises a machine frame, a balance, a feeding box and a packaging box, wherein the balance comprises a base, atray frame and a cross beam; the tray frame is fixed on the base, and a first tray and a second tray are arranged at the two ends of the cross beam; one side of the bottom end of the first tray is rotatably matched with the cross beam, and an electromagnet is installed between the bottom of the first tray and the cross beam; a permanent magnet is arranged at the bottom of the first tray, and a screw rod is arranged on the cross beam corresponding to the first tray; a first gear and a second gear are rotatably connected to the machine frame, the first gear meshes with the second gear, and thesecond gear is located below the first tray; the screw rod penetrates through the first gear and is matched with the first gear in a threaded mode, and the second gear is provided with a first groovefor placing packing boxes; a baffle is hinged to the side wall of the first tray, the baffle is slidably connected to the side wall of the feeding box, and the baffle is provided with a through hole;and an outlet is formed in the side wall of the feeding box, and the through hole communicates with the outlet to feed the first tray. According to the rice packaging device, rice can be continuouslyand quantitatively packaged circularly, and the packaging efficiency is improved.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

Take-up device capable of automatically adjusting take-up radius

InactiveCN103332530AAvoid consistent take-up radiiRealize automatic quantificationFilament handlingElectrical controlFrequency conversion

The invention provides a take-up device capable of automatically adjusting a take-up radius, and solves the problem of inconsistent take-up radii of copper rods as the existing manual adjusting device can not quantificationally regularly adjust. The take-up device comprises a support, a positioning rod, a line arranging screw and a line arranging nut; the positioning rod and the line arranging screw are mounted on the support in parallel; the line arranging nut and the line arranging screw are in thread connection; the upper end of the line arranging nut is clamped in the positioning rod and can slide along the positioning rod; and the lower end of the line arranging nut is provided with a line arranging guide wheel by a bearing. The take-up device capable of automatically adjusting the take-up radius is characterized in that the line arranging screw is connected with the output end of a worm wheel-worm rod speed reducer, and the worm wheel-worm rod speed reducer is in electrical control connection with a three-phase asynchronous motor in electrical control connection with a frequency conversion controller.

Owner:WUXI XIZHOU MAGNET WIRES

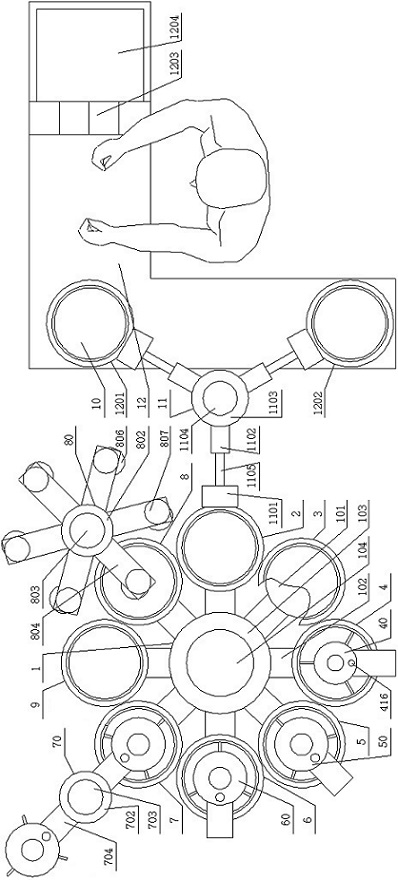

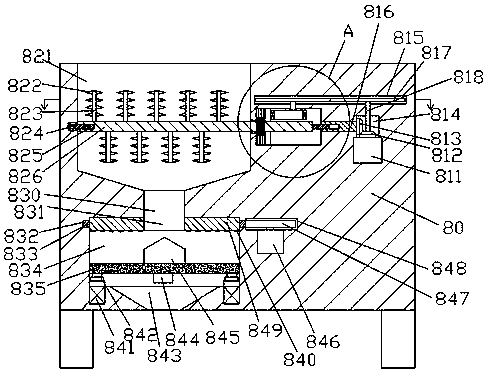

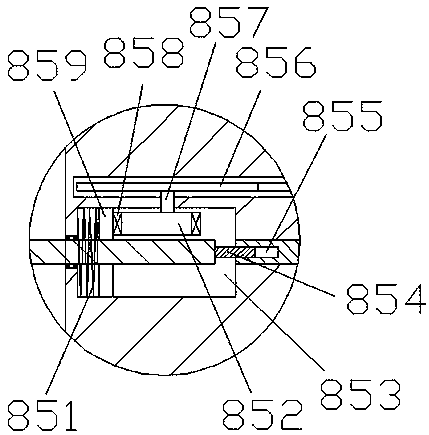

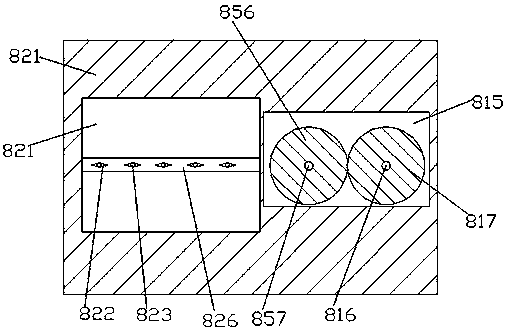

Machine for continuously producing soft pancakes

ActiveCN111903724AIncrease productivityReduce labor intensityOil/fat bakingFood coatingProcess engineeringFrying-pans

The invention discloses a machine for continuously producing soft pancakes. The machine is characterized in that a plurality of electromagnetic heating frying pan brackets are arranged at the periphery of a frying pan rotating frame, and respectively rotate around the center of the frying pan rotating frame, and frying pans are respectively placed on the frying pan brackets; a frying pan turnoverstation, a preheating station, an oil brushing station, a cake spreading station, an egg spreading station, a sauce brushing station and a material spreading station are sequentially arranged around the frying pan rotating frame, and the oil brushing station, the cake spreading station, the egg spreading station, the sauce brushing station and the material spreading station are correspondingly provided with an oil brushing device, a cake spreading device, an egg spreading device, a sauce brushing device and a material spreading device respectively; and the frying pan turnover station is connected with a pancake wrapping operation table through the frying pan turnover device, and a frying pan discharging station and a frying pan cleaning station are arranged on a pancake wrapping operationtable and correspond to the frying pan turnover device. Known from the structure, the machine for continuously producing soft pancakes disclosed by the invention realizes continuous production and manufacturing of automatic oil brushing, pancake spreading, egg layer spreading, sauce brushing and fermented grain spreading during soft pancake production.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

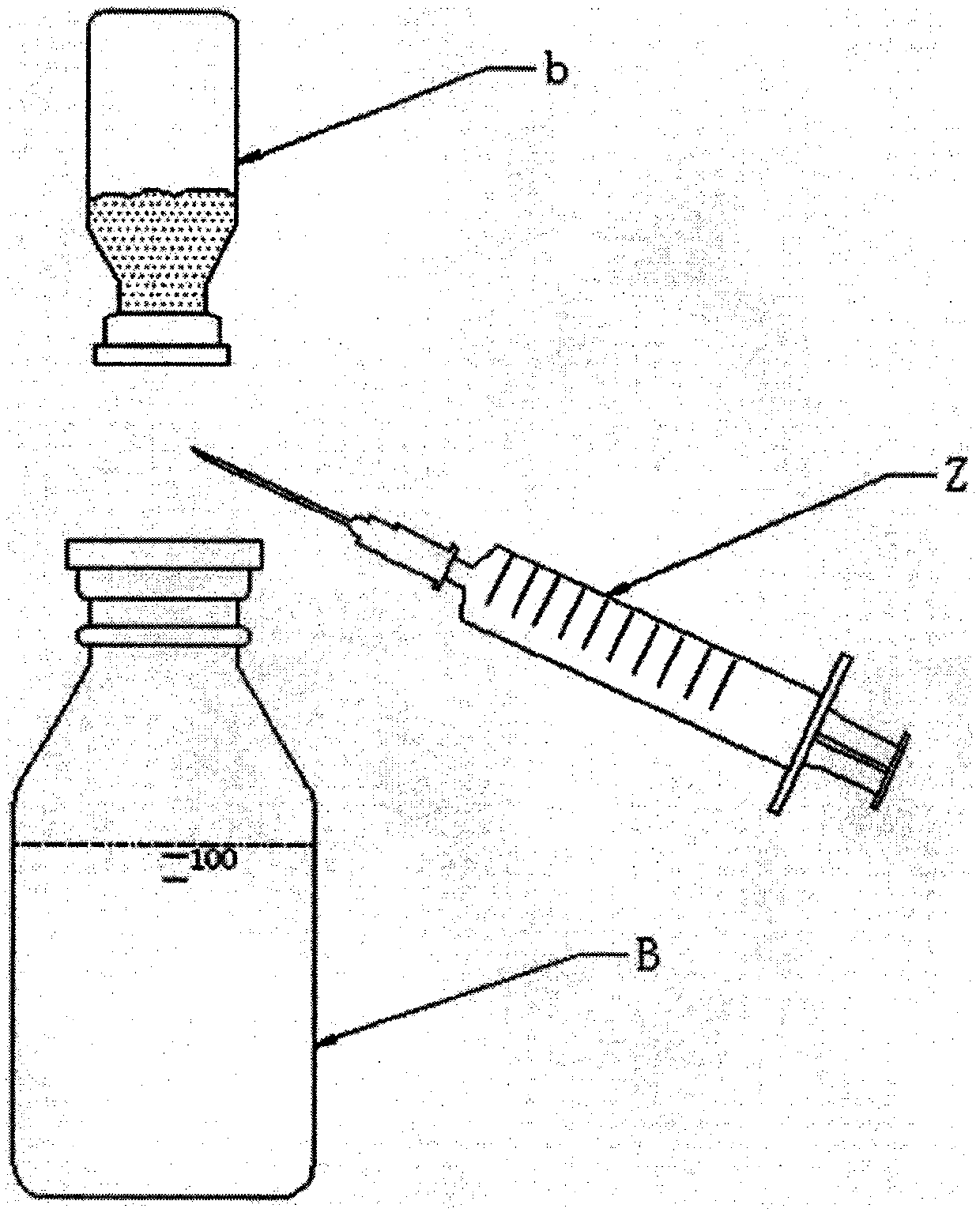

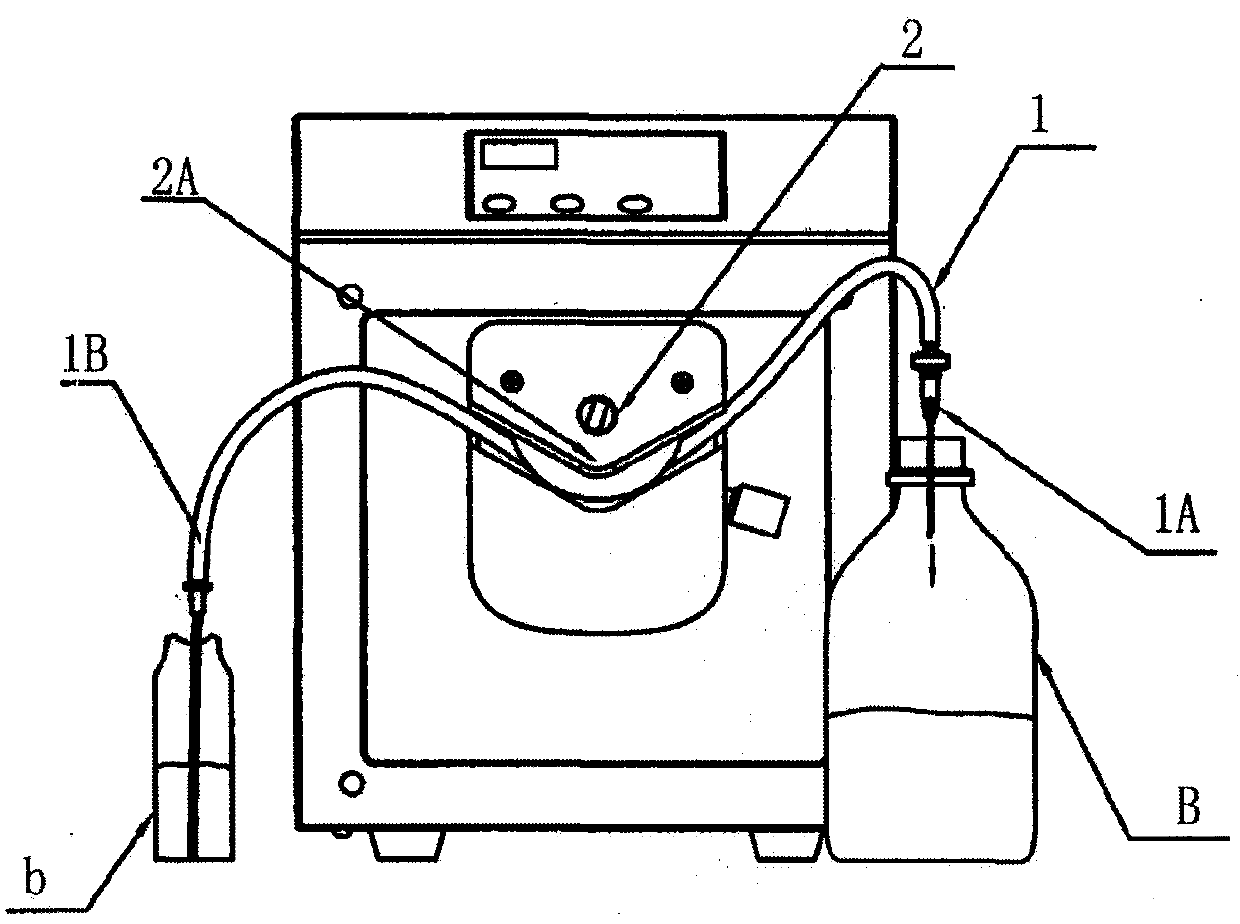

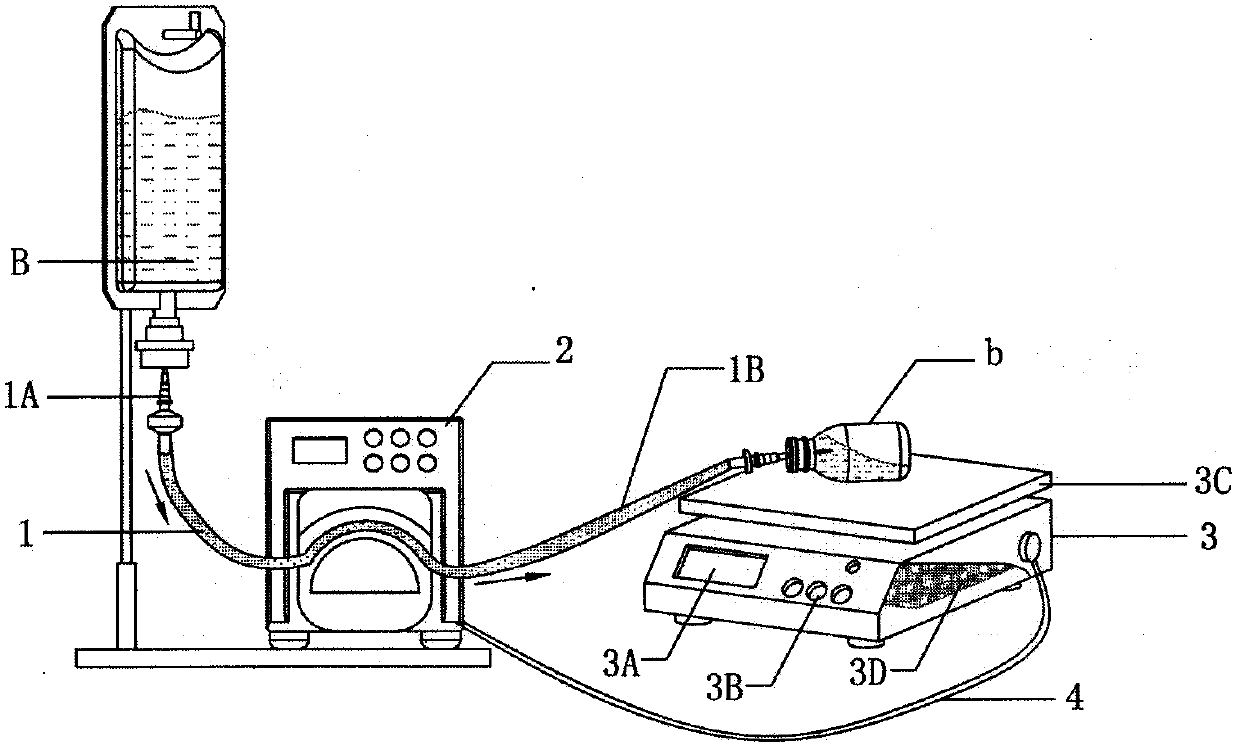

Quantitative medicine dispensing device and method for direct medicine liquid transfer

PendingCN110960423ARealize automatic quantificationMeet the needs of centralized and rapid quantitative dispensing and dispensingPharmaceutical containersMedical packagingPeristaltic pumpProcess engineering

The traditional method for quantitative dispensing is to use a graduated syringe to repeatedly suck the medicine liquid in the liquid bag to complete the dispensing process. The needle is easy to be contaminated during the dispensing process, and the operation is complicated. The direct medicine liquid transferring method can not meet the clinical quantitative use requirements. The invention relates to a quantitative medicine dispensing device and a method for direct medicine liquid transfer. The peristaltic pump is directly connected to an electronic scale with a connecting wire, the medicinedispenser is placed in the peristaltic pump, the medicine dispenser establishes a direct transfer channel between the liquid bag and the medicine bottle, and then the medicine bottle is placed at theelectronic scale to zero. The electronic scale is set to quantify the required amount of medicine liquid into the medicine bottle, and the peristaltic pump is started to perform the dispensing work.When the medicine liquid in the medicine bottle reaches the set value, the peristaltic pump is stopped working immediately and completed the quantitative dispensing process. The device improves the dispensing efficiency and speed, realizes the automatic quantification of the liquid medicine in the process of quantitative liquid dispensing, and better satisfies the demand of concentrated, rapid, massive and quantitative liquid dispensing of hospitals.

Owner:LANZHOU WENHE MEDICAL EQUIP RES & DEV CO LTD

A kind of Zongzi and its production process

The invention discloses a rice dumpling which, from inside to outside, sequentially comprises a dumpling body, an inner plastic film, a dumpling leaf and an outer plastic film. The invention also discloses a preparation process of the rice dumpling, which comprises the following steps of hermetically wrapping the dumpling leaf between the inner plastic film and the outer plastic film, taking the cooked dumpling body, attaching the inner plastic film of the dumpling leaf to the dumpling body, folding, and sealing so as to obtain the rice dumpling. According to the invention, through pre-wrapping the dumpling leaf between food-grade plastic films with an easily-torn tape, the dumpling leaf is kept in a clean state; no poaching process is required to be performed, so that the delicate fragrance of the dumpling leaf is kept more completely, and before the rice dumpling is eaten, through a short-term reheating process, the delicate fragrance of the dumpling leaf is emitted; and when the rice dumpling is eaten, an operation of removing the easily-torn tapes is only required to be performed, thereby not only realizing the easy stripping of the dumpling leaf, but also keeping the delicate fragrance of the dumpling leaf well, so that the dumpling leaf is kept in a clean state, and the rice dumpling is eaten more conveniently; and the whole technological process can achieve automated production.

Owner:ZHEJIANG WUFANGZHAI INDAL

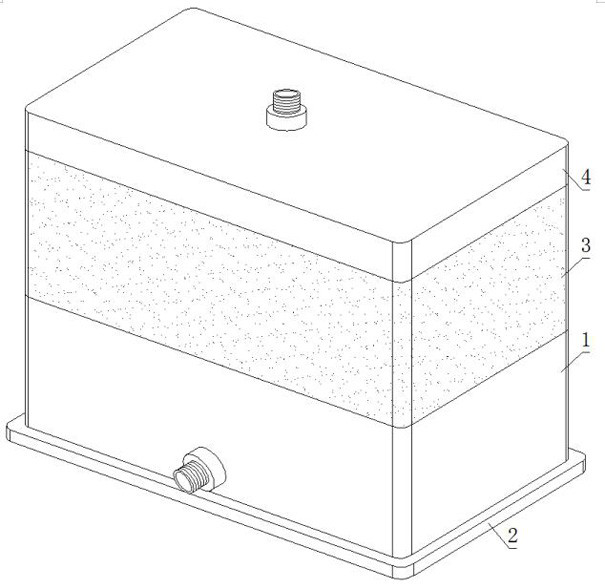

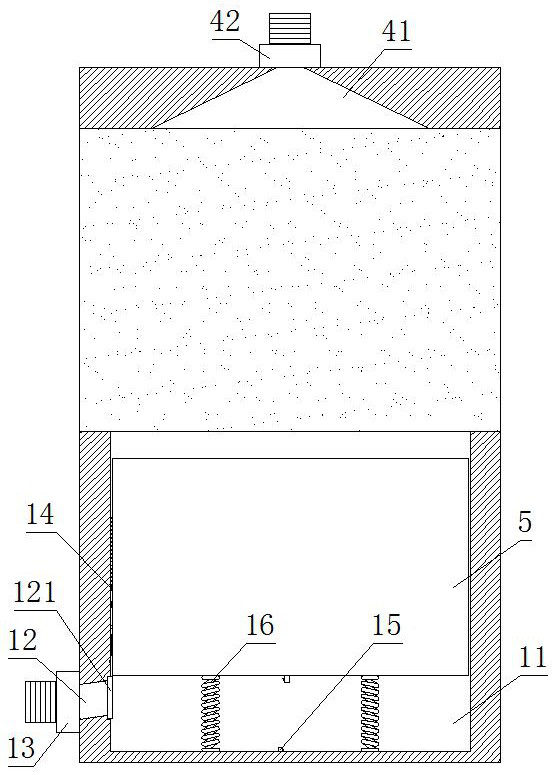

Ammonia nitrogen gas recovery device

ActiveCN114377508AIngenious structural designRealize automatic quantificationGas treatmentDispersed particle separationAmmoniacal nitrogenProcess engineering

The invention discloses an ammonia nitrogen gas recovery device, belongs to the technical field of urban garbage treatment, and aims to solve the problems that a discharging mode of the ammonia nitrogen gas recovery device consumes manpower during operation, and meanwhile, the whole recovery step is low in efficiency and inconvenient to use. The ammonia nitrogen gas recovery device comprises a collection box and a stable bottom plate fixedly mounted on the bottom surface of the collection box, a filter is fixedly installed on the top face of the collecting box, a gas inlet cover is fixedly installed on the top face of the filter, and a storage box is slidably arranged in an inner cavity of the collecting box. The device ingeniously applies the gravity gradual change effect when liquid containing ammonia nitrogen is accumulated, meanwhile, automatic quantitative complete discharging of the device is also achieved, the structural design is ingenious, and the device is convenient to use. And various effects can be automatically completed, and use is convenient.

Owner:茂名市民兴气体有限公司

Full-automatic fresh and wet rice noodle production device and application thereof

The invention discloses a full-automatic fresh and wet rice noodle production device and an application thereof. The device mainly consists of a rice slurry shunting hopper, an edible stainless steel conveying belt, a high-temperature stewing box, a belt supporting drum, a water cooling box with a spraying device, transverse and vertical roller cutting knives, a speed-adjustable row cutting knife, a lifting conveyor, a packaging machine, a main mechanism motor, a water pump, a water pipe connected with the cooling water tank, a circulating water tank, a rack, a driving roller, an adjusting and tensioning device, a bearing and a main driving roller. The full-automatic fresh and wet rice noodle production device disclosed by the invention has the following advantages: 1. the whole production line is simple to manufacture, the slice stewing, cooling, slicing and quantifying procedures are finished by just one stainless steel belt, the device is easy to clean during the application process, and the manufacturing cost is low; and 2. the device can be used for greatly improving the production capacity and is low in defective percentage.

Owner:阙之和

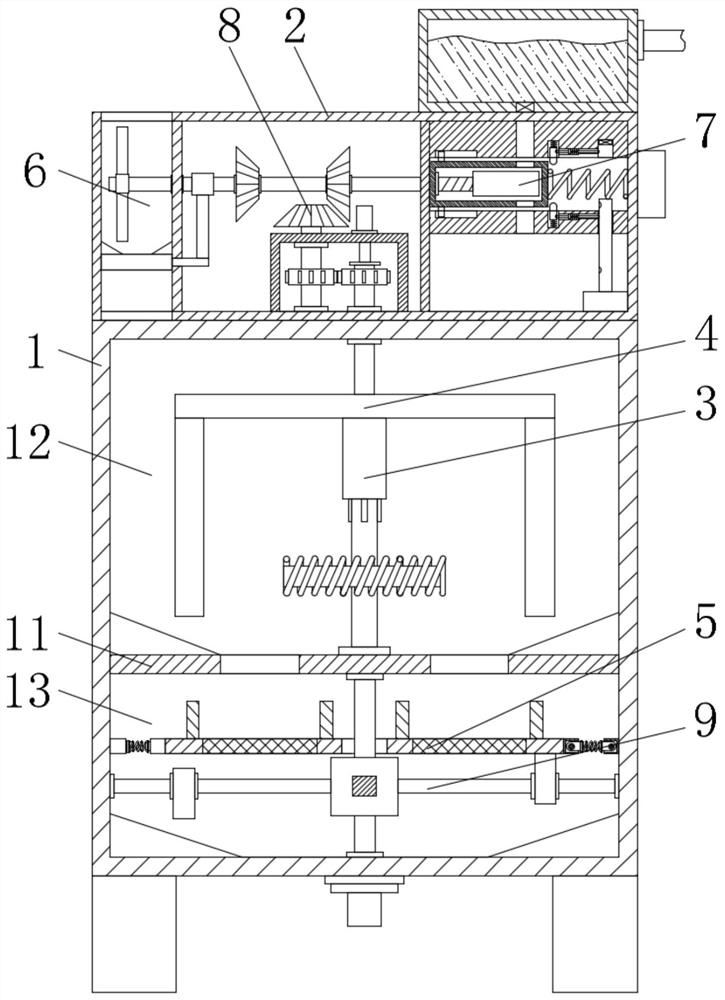

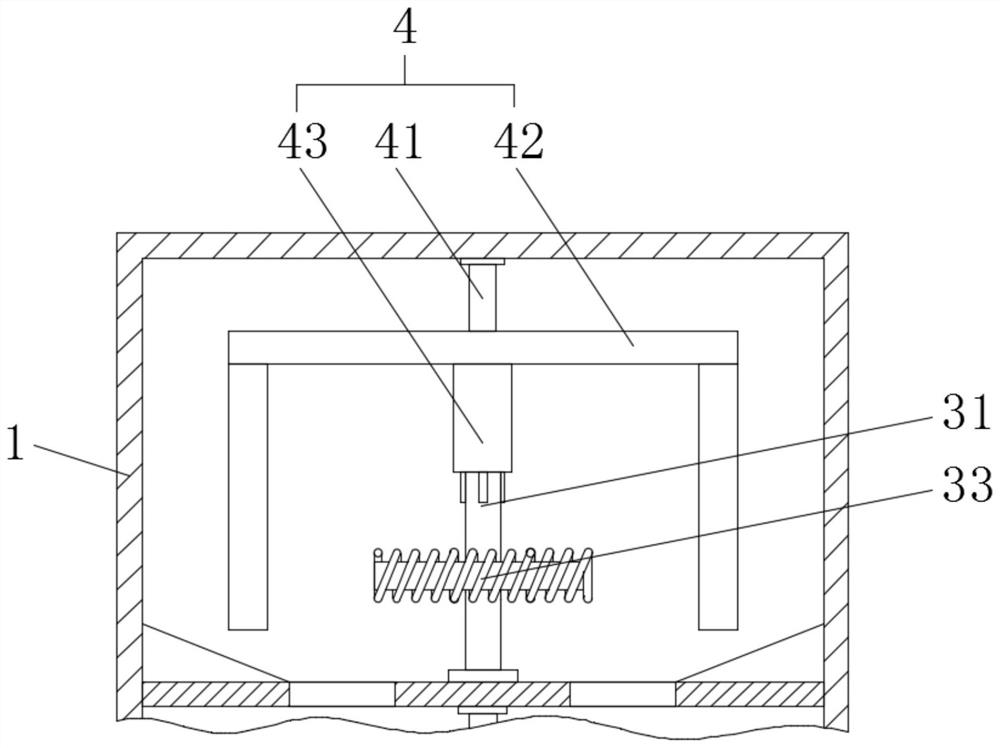

Device and method for detecting dispersion rate of soybean protein isolate product

InactiveCN114112618AEfficient mixingIncrease filtration rateWeighing by removing componentPreparing sample for investigationProcess engineeringMechanical engineering

The invention discloses a device and method for detecting the dispersion rate of a soybean protein isolate product, the device comprises a stirring barrel, a partition plate arranged in the middle of the stirring barrel and a feeding box arranged at the upper end of the stirring barrel, the stirring barrel is provided with a stirring cavity above the partition plate, and the stirring barrel is provided with a filtering cavity below the partition plate; a stirring mechanism and a transmission assembly used for transmitting power to the feeding box are arranged in the stirring cavity, a filtering mechanism is arranged in the filtering cavity, a solid discharging mechanism is arranged on the left side of the interior of the feeding box, and a liquid quantitative discharging mechanism is arranged on the right side of the interior of the feeding box; the bottom of the feeding box is provided with a power device used for driving the solid discharging mechanism and the liquid quantifying mechanism to work, the stirring mechanism, the filtering mechanism and the vibrating mechanism are matched with one another, so that solid and liquid can be effectively mixed, the filtering rate of mixed liquid can be increased, the mixing time and the filtering time are greatly shortened, and the mixing efficiency is improved. Operation of operators is simplified, and the structure is simple.

Owner:钱玉梅

Novel biological extraction device

The invention discloses a novel biological extraction device comprising a machining rack. A cut-up cavity is formed in the top end face of the machining rack, and a first rotating cavity is formed inposition, on the right side of the cut-up cavity, of the inner wall body of the machining rack; a second rotating cavity is formed between the first rotating cavity and the cut-up cavity, a first rotating shaft is arranged in the cut-up cavity in a left-right extending mode, and a first spline groove is formed in the end face of the left side of the first rotating shaft; a first spline rod is mounted in the first spline groove in a spline fit mode, the extending tail end of the left side of the first spline rod is in rotating fit connection with the inner wall of the left side of the cut-up cavity, and the extending section of the right side of the first rotating shaft is in rotating fit connection with the machining rack and extends into the second rotating cavity; a plurality of sets ofrotating propellers are fixedly arranged on the position, in the cut-up cavity, of the outer surface of the first rotating shaft in the circumferential direction; a plurality of sets of cut-up bladesare fixedly arranged on the end faces of both the left sides and the right sides of the rotating propellers; and a second spline shaft is fixedly mounted at the extending tail end of the right side ofthe first rotating shaft.

Owner:CIXI XINCHANG IND PROD DESIGN

A drug-dosing on-line dilution device with automatic quantitative

ActiveCN113019249BAchieve normal workFlexible dispensing modeRotary stirring mixersTransportation and packagingControl engineeringElectric machinery

Owner:浙江创世纪环保科技有限公司

An efficient automatic seeding device

InactiveCN111316793BRealize automatic quantificationSimple structureSeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringControl theory

Owner:GUANGDONG ACAD OF AGRI SCI

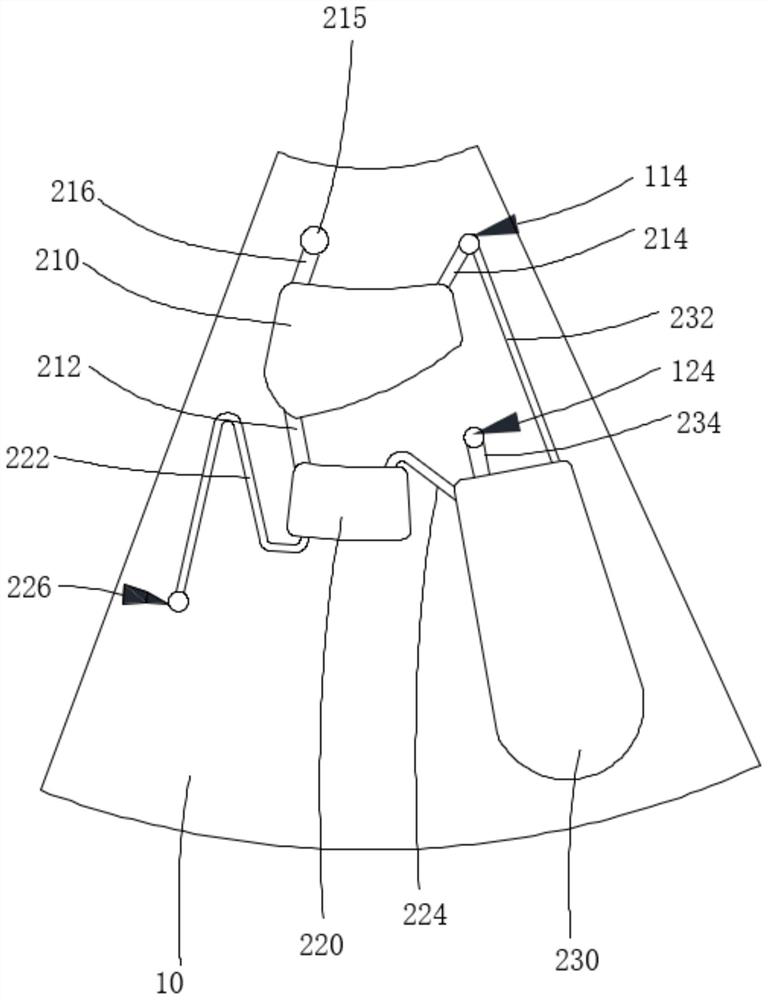

Homogeneous test micro-fluidic chip and detection system

PendingCN114433259ARealize automatic quantificationImprove accuracyTransportation and packagingChemiluminescene/bioluminescenceChip sizeCapillary Tubing

The homogeneous test micro-fluidic chip comprises a main body, a first liquid storage cavity, a first quantitative cavity, a mixing cavity, a first flow channel and a first capillary tube are arranged on the front surface of the main body, and a second liquid storage cavity, a second quantitative cavity, a waste liquid cavity, a second capillary tube, a second flow channel and an overflow channel are arranged on the back surface of the main body; the first liquid storage cavity is communicated with the first quantitative cavity through a first flow channel, the first quantitative cavity is communicated with the mixing cavity through a first capillary tube, the second liquid storage cavity is communicated with the second quantitative cavity through a second flow channel, the second quantitative cavity is communicated with the waste liquid cavity through an overflow channel, and the first quantitative cavity is communicated with the waste liquid cavity through a first through hole. The second capillary tube is communicated with the mixing cavity through the second through hole. A sample and a diluent flow on the front side and the back side, so that automatic operation and control of each detection process are realized, the detection process is more convenient and efficient, the whole detection process can be realized on a smaller main body, the size of a chip is effectively reduced, and the cost is reduced.

Owner:GUANGZHOU WONDFO BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com