Automatic feeding machine

A technology of automatic feeding and feeding trucks, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of long brick making time, large deviation of material weight, interference of electronic scales, etc., achieve stable product quality, realize automatic quantitative, The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

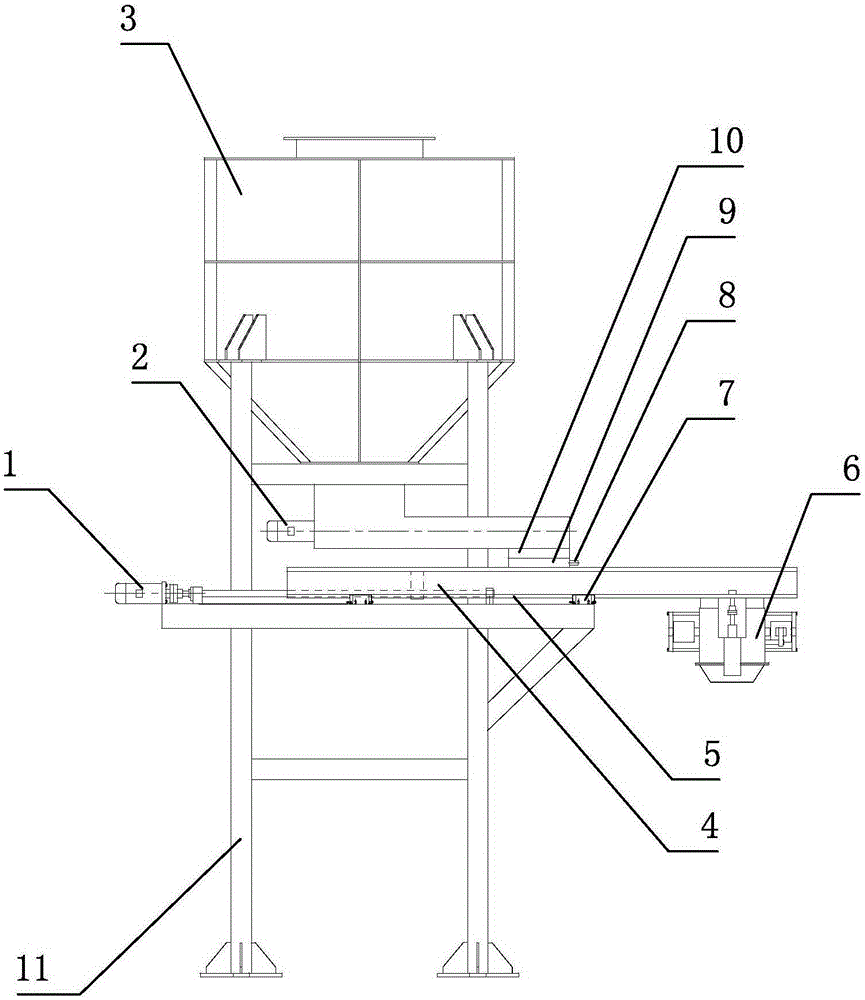

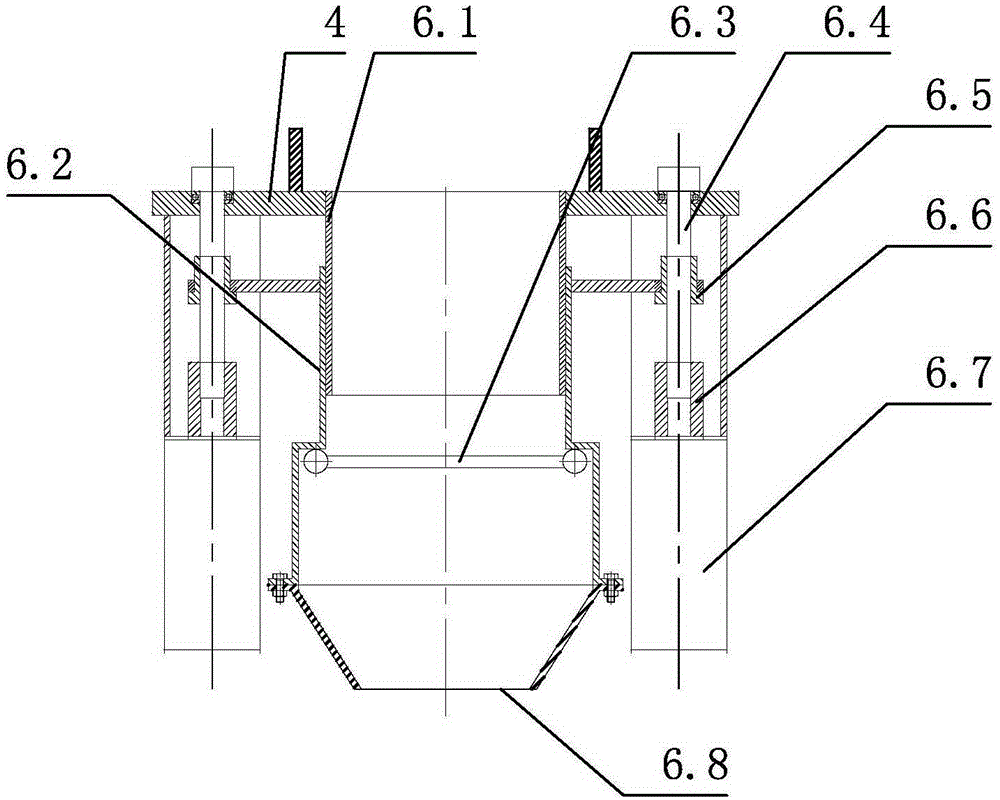

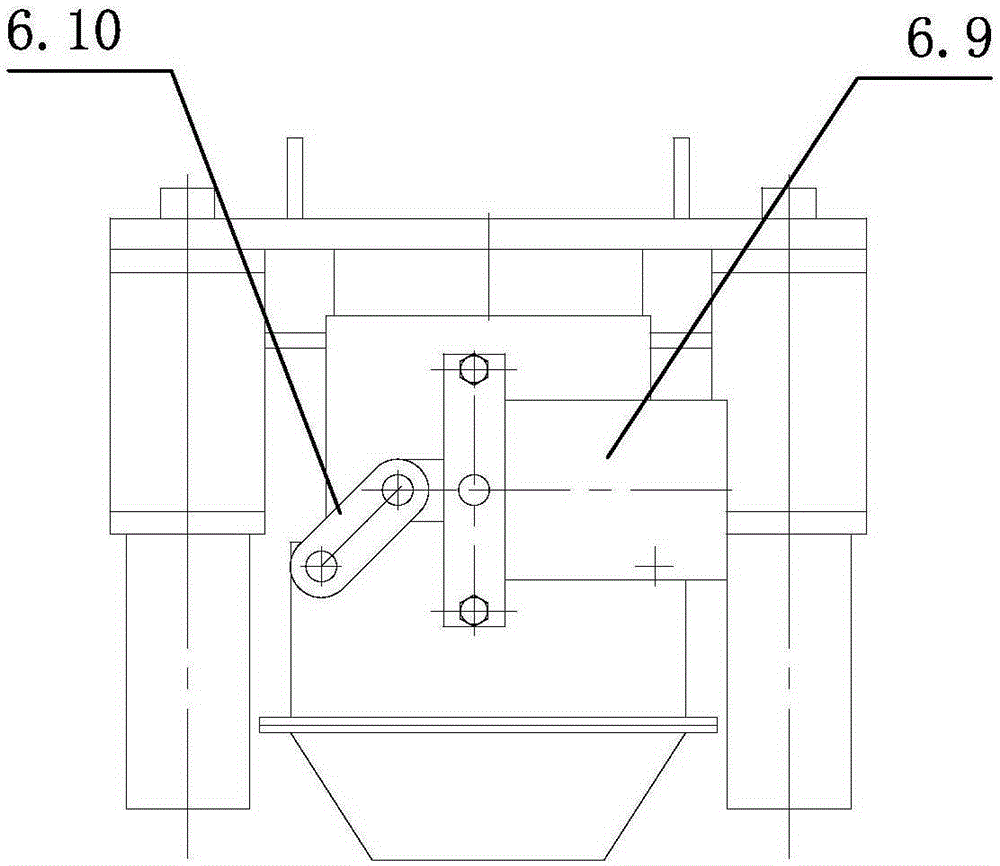

[0024] Such as figure 1 As shown, the automatic feeder includes a frame 11 and a fixed silo 3 arranged on the frame 11, the bottom of the fixed silo 3 is provided with a discharge section, the discharge section is arranged horizontally, and a screw conveyor 2 is provided inside it. , The discharge port 10 is set at the end of the screw conveyor 2, and the material is pushed to the discharge port 10 through the screw conveyor 2, and at the same time, the discharge amount can be conveniently controlled. The discharge port 10 is provided with a material level detector 8 and a scraper 9, and the material level detector 8 can detect the height of the material level. Below the discharge port 10, there is a feeding cart 4, which is connected to the conveying assembly. The conveying assembly includes a servo drive motor 1 and a slider 7. The feeding cart 4 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com