Feeding device

A blanking and hopper technology, which is applied in the field of blanking devices, can solve the problems of uneven blanking, difficulty in venting, and a large number of pores on the outer wall of concrete, and achieve good durability, easy manufacturing and operation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The illustrative and non-limiting embodiments of the present invention will be described in detail below with reference to the accompanying drawings, and the unloading device according to the present invention will be further described.

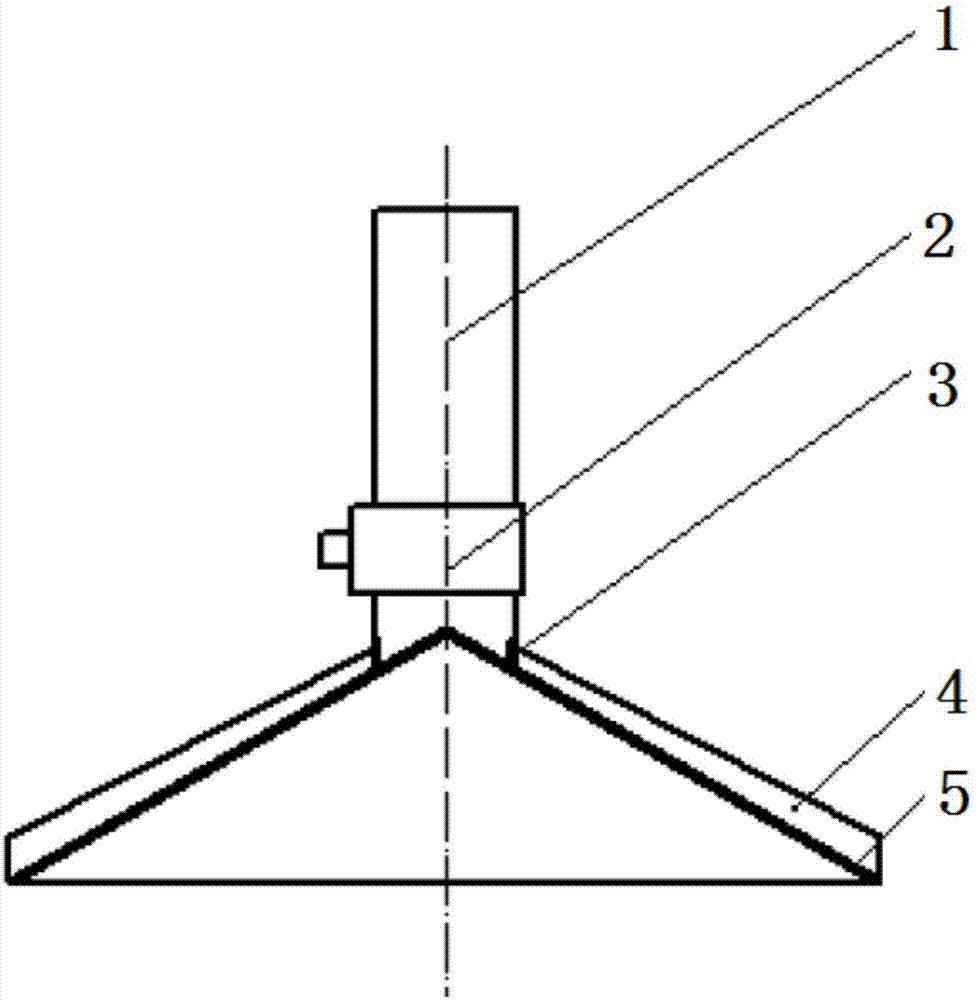

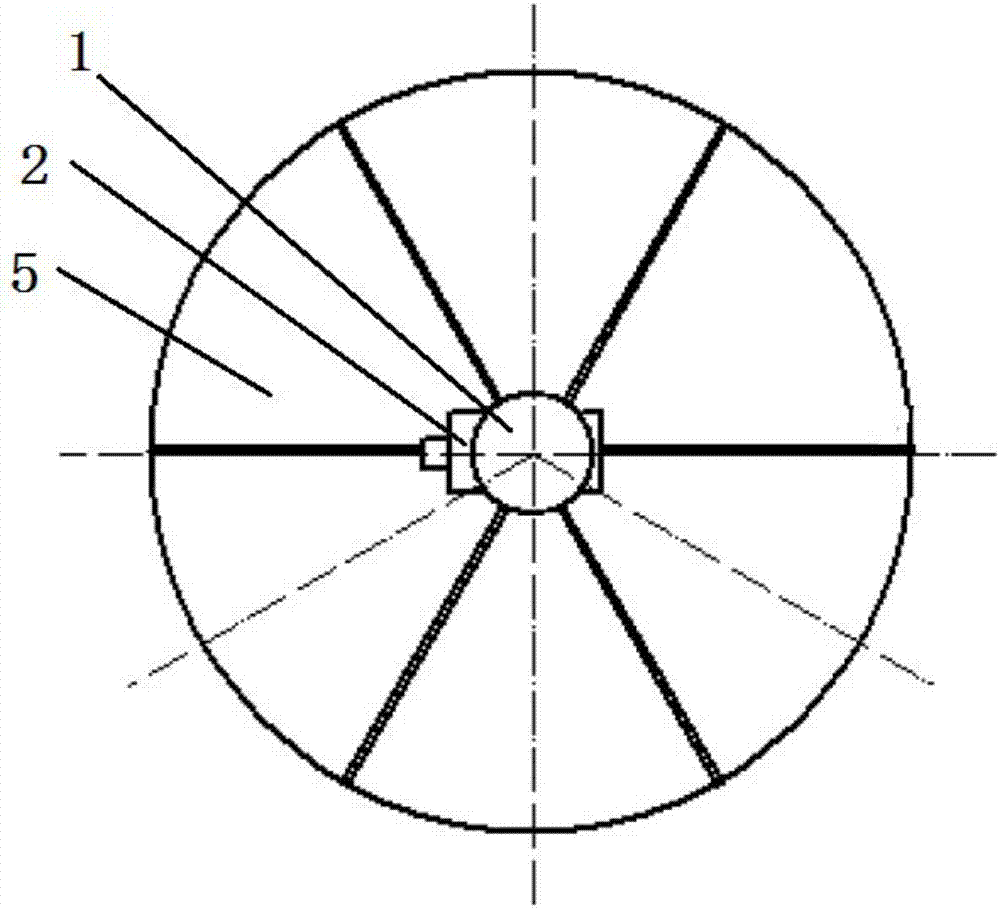

[0022] refer to figure 1 and 2 , the unloading device disclosed in the present invention comprises feed pipe 1, hopper 5, door 3 and controller (not shown in the figure), wherein feed pipe 1 is connected with hopper 5, and door 3 is arranged on feed pipe 1 and hopper 5, the controller is connected with the door 3 to control the opening and closing of the door 3.

[0023] The feeding pipeline 1 is a hollow tube with two ends open, which is used for conveying materials. The hopper 5 is a closed structure with a conical shape, and the top of the conical shape is connected to the one end of the feeding pipeline 1 to close the one end of the feeding pipeline 1, so that the material dropped from the other end of the feeding pipeline 1 will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com