Capillary viscometer capable of realizing automatic quantification and testing method thereof

A technology of capillary viscometer and capillary tube, which is applied in the direction of direct current flow characteristic measurement, etc., which can solve the problems of difficult cleaning, poor measurement timeliness, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

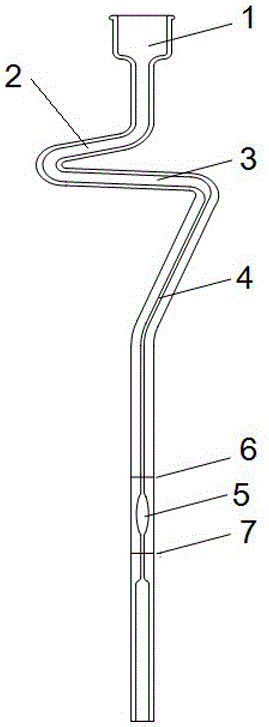

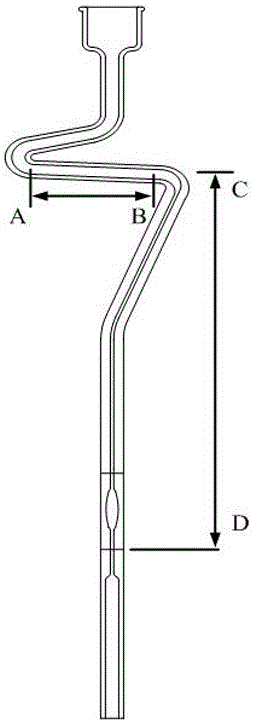

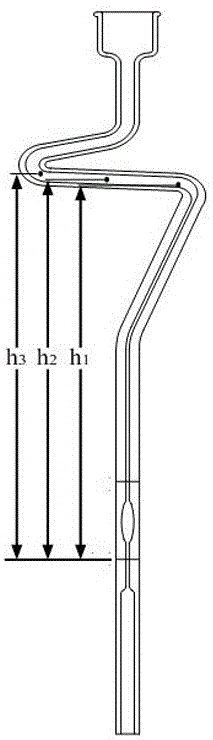

[0067] This embodiment provides a capillary viscometer capable of automatic quantification, including a kinematic viscometer with a folded tube, and the kinematic viscometer with a folded tube includes a sampling cup 1, a draft tube 2, a cross arm 3, and a capillary 4 connected in sequence , the measuring bulb 5, and the upper scale line 6 and the lower scale line 7 respectively positioned above and below the measuring bulb 5, the capillary viscometer also includes a branch pipe 8, and one end of the branch pipe 8 is communicated with the cross arm 2, and it communicates Located on the side near the draft tube 2, the other end of the branch pipe 8 communicates with the closed pipe 9, the inner diameter of the branch pipe 8 is 2mm, the inner diameter of the closed pipe 9 is 4mm, the inner diameter of the capillary 4 is 0.5mm, and the inner diameter of the cross arm 3 is 4mm, The length of branch pipe 8 is 15mm, and valve is established on closed pipe 9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com