Pin tube automatic set submerged arc welding set

A submerged arc welding and nail head technology, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problems of high labor intensity, low degree of automation, low production efficiency, etc., and achieve the effect of stable welding parameters and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] The specific embodiment: the present invention will be further described below in conjunction with accompanying drawing:

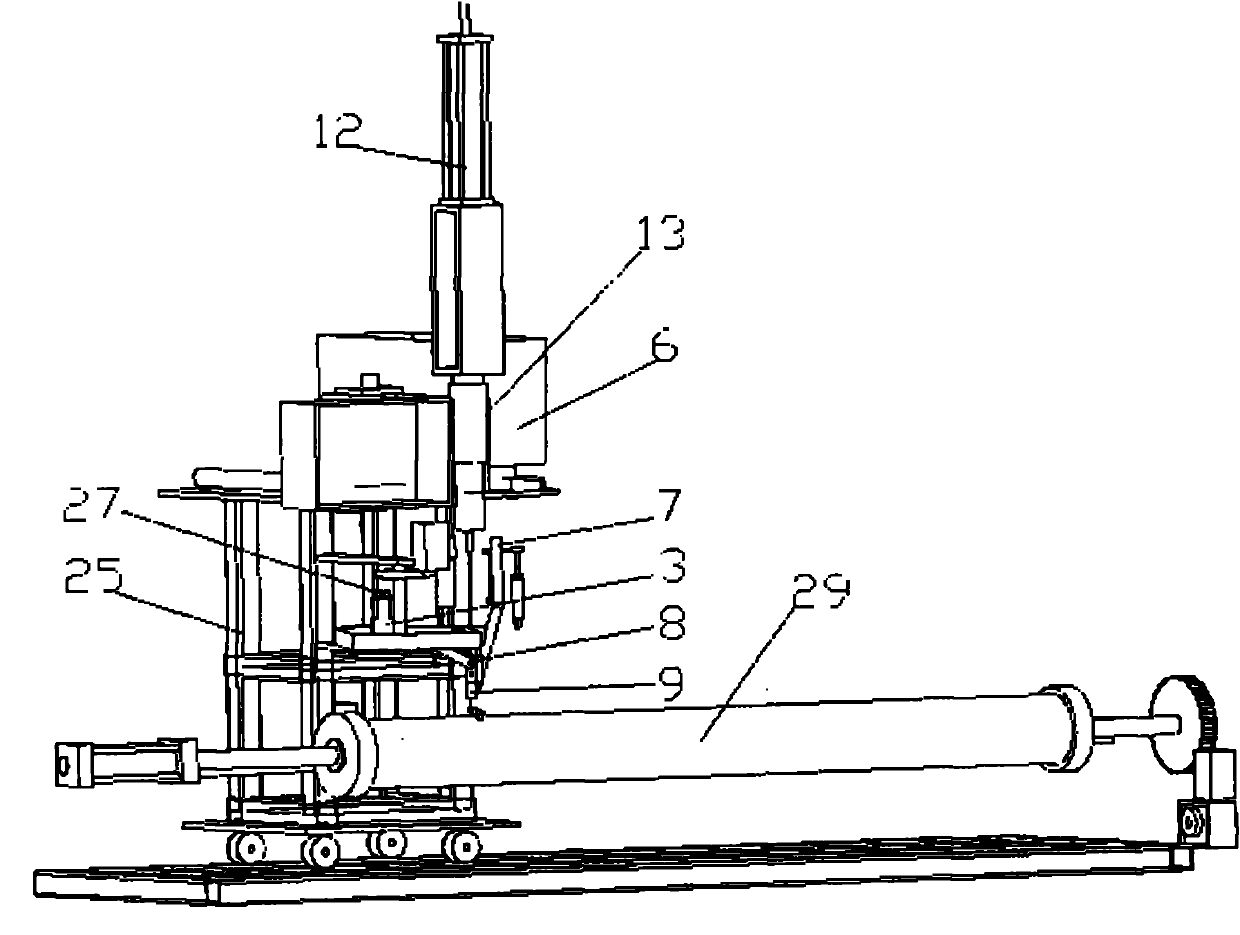

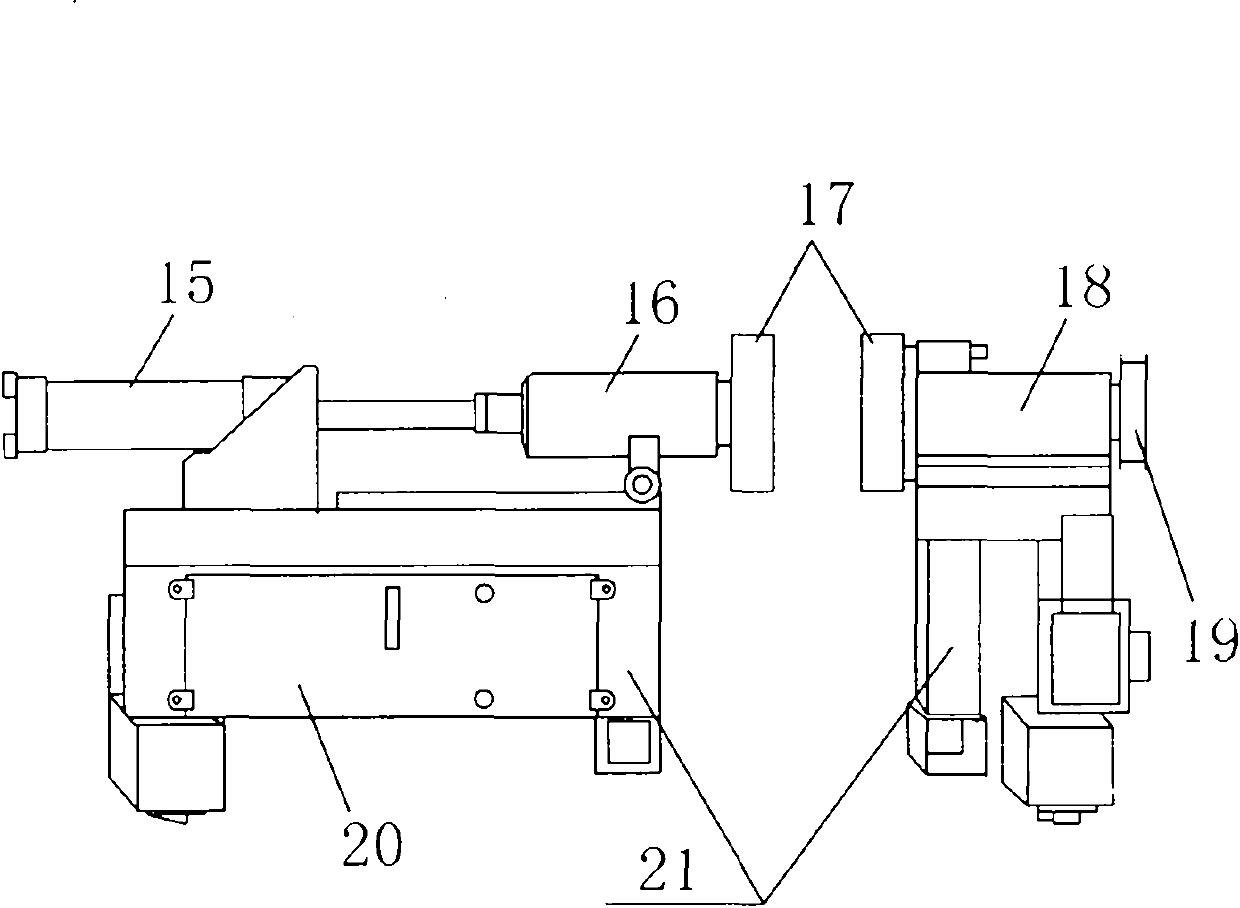

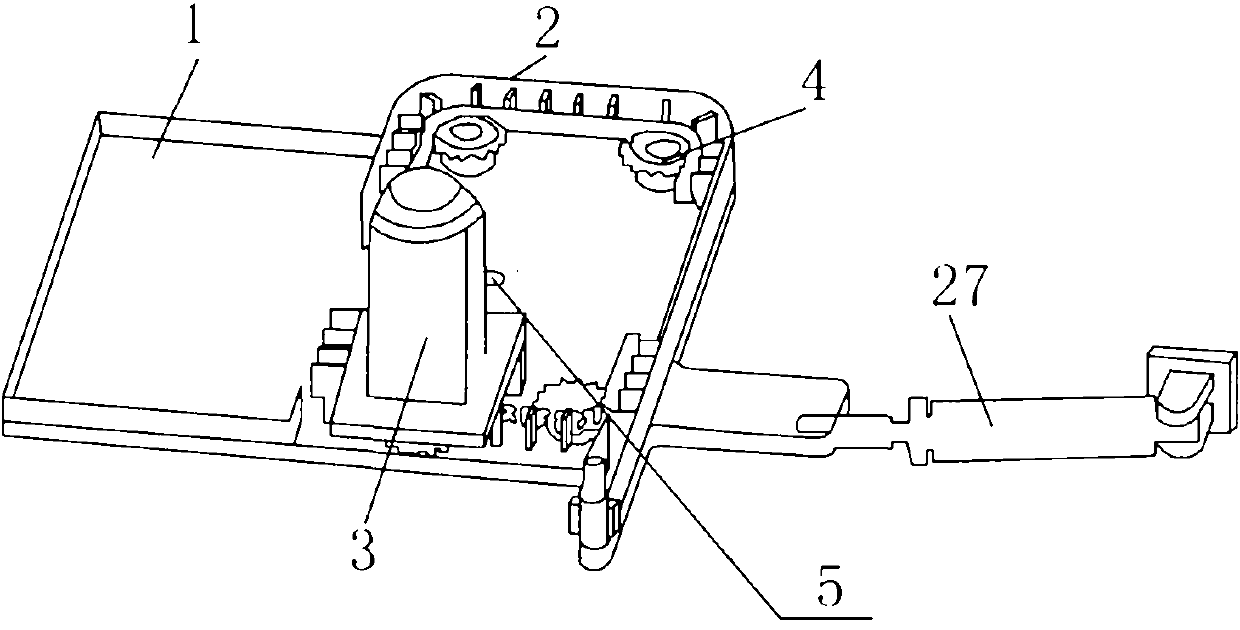

[0028] exist Figure 1-11 Middle, 1 auxiliary tray, 2 conveyor chain, 3 nail feeding motor, 4 transmission gear, 5 nail outlet hole, 6 flux box, 7 flux feeding motor, 8 welding torch, 9 flux outlet, 10 flux pipeline, 11 fourth cylinder, 12 fifth cylinder, 13 third cylinder, 15 oil cylinder, 16 jacking mechanism, 17 clamping chuck, 18 support block, 19 belt drive wheel, oil tank 20, 21 bracket, 22 second servo motor, 23 second servo driver , 24 first servo motor, 25 welding head, 26 head transmission system. 27 first cylinder, 29 nail head tube.

[0029] like figure 1 As shown, the present invention provides a complete set of automatic submerged arc welding equipment for nail head tubes, which includes an automatic nail head loading and unloading system, a welding system, automatic nail head tube feeding and centering mechanism, automatic flux qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com