Welding method for thermoplastic composite material

A composite material and welding method technology, which is applied in the field of welding, can solve the problems of unsmooth welding process and poor welding quality, and achieve the effect of fast heating speed, good welding quality and uniform weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Grinding and roughening the surface to be welded of the aluminum alloy workpiece, cleaning it with acetone and blowing it dry;

[0052] (2) Clean and dry the surface to be welded of the PE-polyethylene workpiece reinforced by carbon fiber;

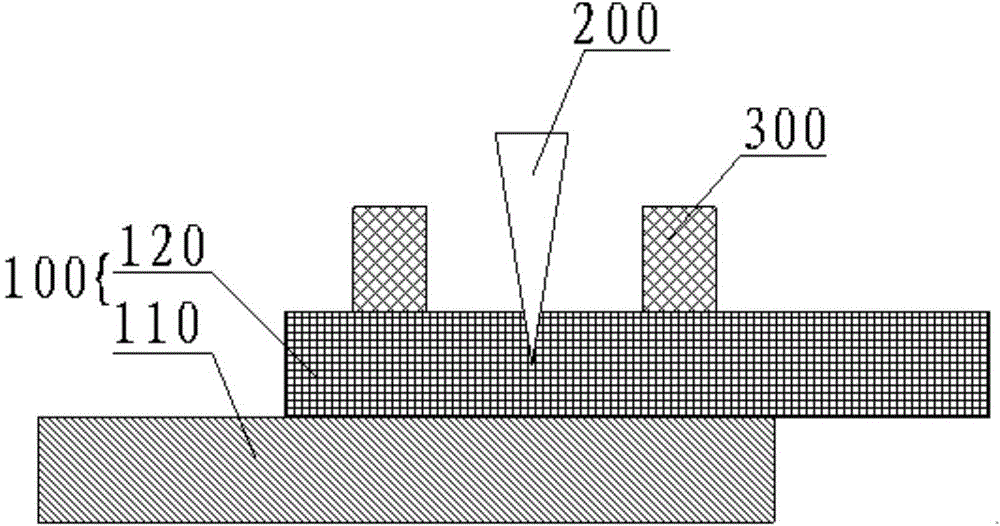

[0053] (3) According to figure 1 In the way shown, the aluminum alloy workpiece is placed on the carbon fiber reinforced PE-polyethylene workpiece for lap joint, so that the surfaces to be welded of the two are in contact with each other;

[0054] (4) Fix the aluminum alloy workpiece to be welded and the PE-polyethylene workpiece reinforced by carbon fiber with a clamp, and apply a pressure of 20N to the aluminum alloy workpiece and the PE-polyethylene workpiece reinforced by carbon fiber by the clamp;

[0055] (5) Focus the laser and heat it on the surface of the aluminum alloy, and scan along the preset path at a speed of 5m / s;

[0056] (6) After scanning, turn off the laser, remove the fixture, and complete the welding proc...

Embodiment 2

[0058] (1) The surface to be welded of the PC-polycarbonate workpiece reinforced by boron fiber and the polyphenylene ether workpiece reinforced by graphite fiber is cleaned and dried with acetone;

[0059] (2) Grinding and roughening the surfaces of two aluminum alloy transition pieces with a thickness of 3 cm, cleaning them with acetone and blowing them dry;

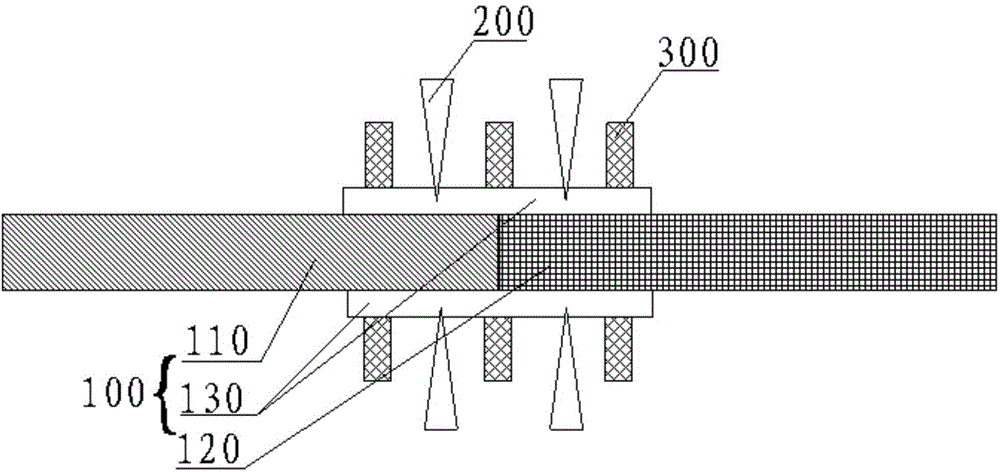

[0060] (3) According to figure 2 In the manner shown, the surfaces to be welded of the boron fiber-reinforced PC-polycarbonate workpiece and the graphite fiber-reinforced polyphenylene ether workpiece are butted; and aluminum alloy transition pieces are attached to both sides of the butt joint area and fixed with a clamp. At the same time, apply a pressure of 10N to the metal transition piece through the clamp;

[0061] (5) After focusing the laser, heat the surface of the aluminum alloy transition piece on both sides of the docking area in turn, and scan along the preset path at a speed of 8m / s;

[0062] (6) After ...

Embodiment 3

[0064] (1) The surface to be welded of the PE-polyethylene workpiece reinforced by boron fiber and the PE-polyethylene workpiece reinforced by graphite fiber is cleaned and dried with acetone;

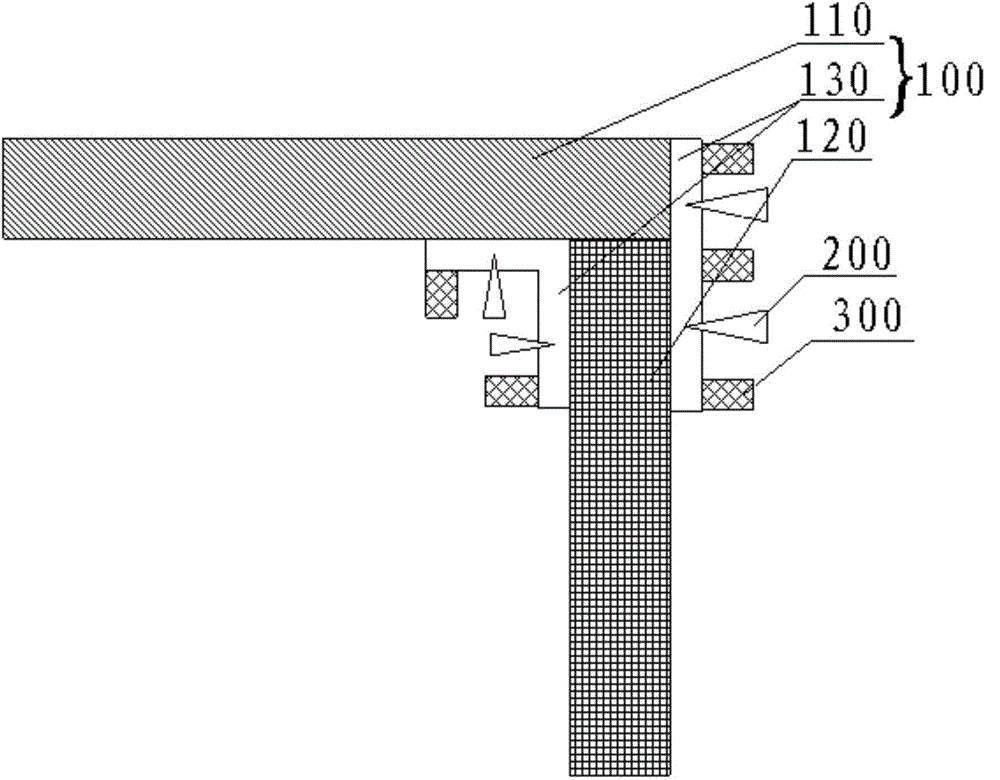

[0065] (2) Polish the surface of two aluminum alloy transition pieces with a thickness of 3 cm, clean them with acetone and dry them. One of the aluminum alloy transition pieces is a straight piece, and the other aluminum alloy transition piece has a certain bending angle;

[0066] (3) According to image 3 In the manner shown, fillet joint the surfaces to be welded of the boron fiber reinforced PE-polyethylene workpiece and the graphite fiber reinforced PE-polyethylene workpiece; and attach aluminum alloy transition pieces on both sides of the junction area, and fix them with clamps , while applying a pressure of 25N to the metal transition piece through the clamp;

[0067] (4) After the laser is focused, it is sequentially heated on the surface of the aluminum alloy transition piece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com