Composite bevel clamping system

A compound slope and clamping technology, which is applied in the field of metallurgical equipment, non-ferrous and ferrous metal processing, can solve the problems of unreliable clamping, error of the contact position between the clamping jaw and the material, and failure to clamp, etc., to achieve clamping control and The effect of simple detection, uniform clamping and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

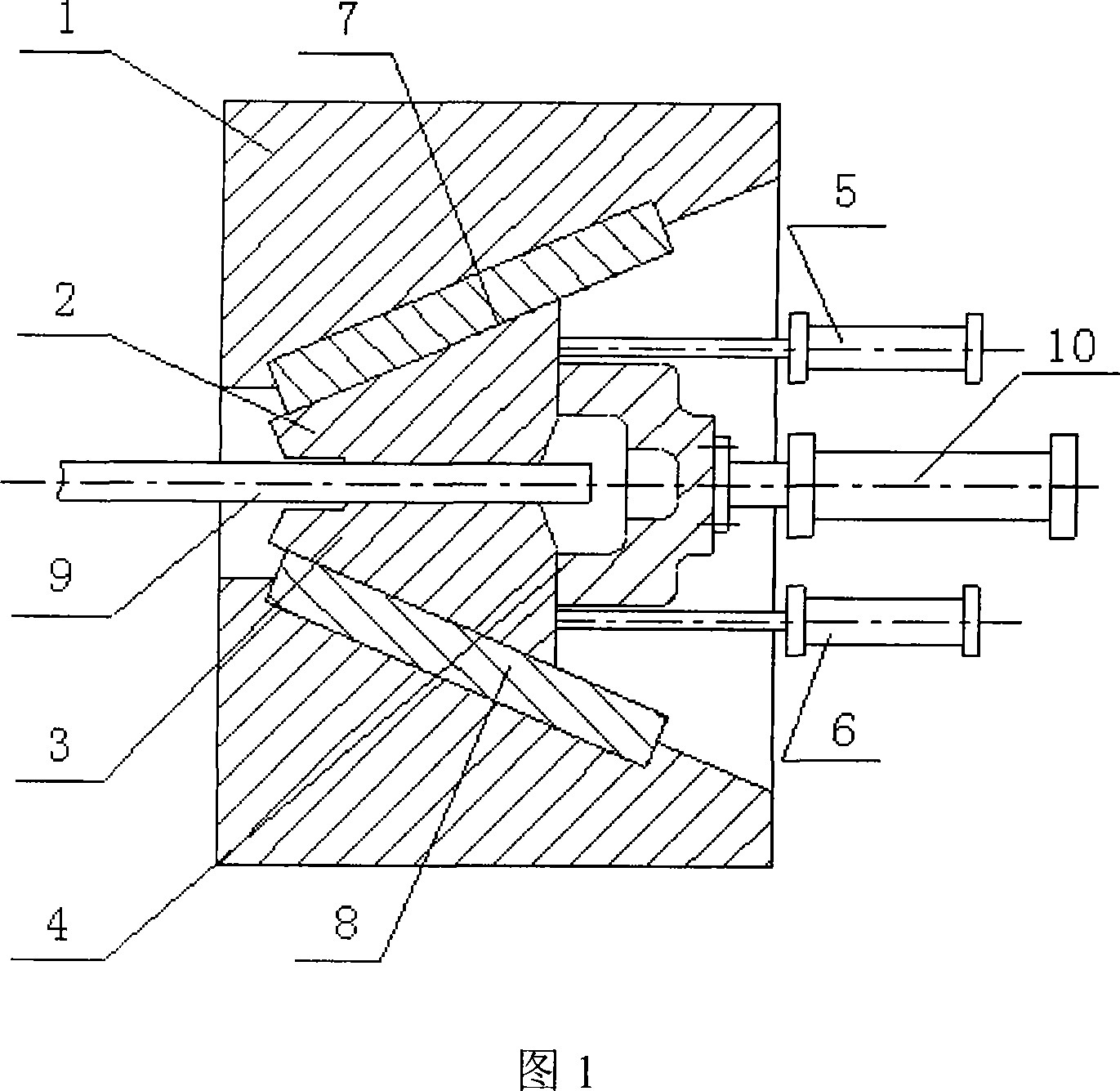

[0014] As shown in Figure 1, the device used in this system includes clamping body 1, upper clamp 2, lower clamp 3, synchronous clamping device 4, upper clamp clamping drive device 5 and lower clamp clamping drive device 6 , the upper slide plate 7 and the lower slide plate 8; the upper clamp 2 is connected with the upper slide plate 7 through a chute, the upper slide plate 7 is connected to the clamping body 1, and the upper clamp 2 moves along the inclined plane of the upper slide plate 7 to finish stretching the sheet material 9 The lower clamp 3 is connected to the lower plate 8 through a chute, the lower plate 8 is connected to the clamping body 1, and the lower clamp 3 completes the upward clamping of the stretched plate 9 by moving along the slope of the lower plate 8 tight; the upper clamp 2 and the lower clamp 3 jointly form a clamping jaw to realize the stretching of the stretched sheet 9; the rear ends of the upper clamp 2 and the lower clamp 3 are respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com