Clamp special for nanoindenter

A technology of nano-indentation instrument and special fixture, which is applied in the direction of instruments, scientific instruments, measuring devices, etc. It can solve the problems of no specific fixture, damage the workpiece, and affect the analysis results of material mechanics, so as to improve accuracy and flexibility, clamp The effect of tightness and uniform force, simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

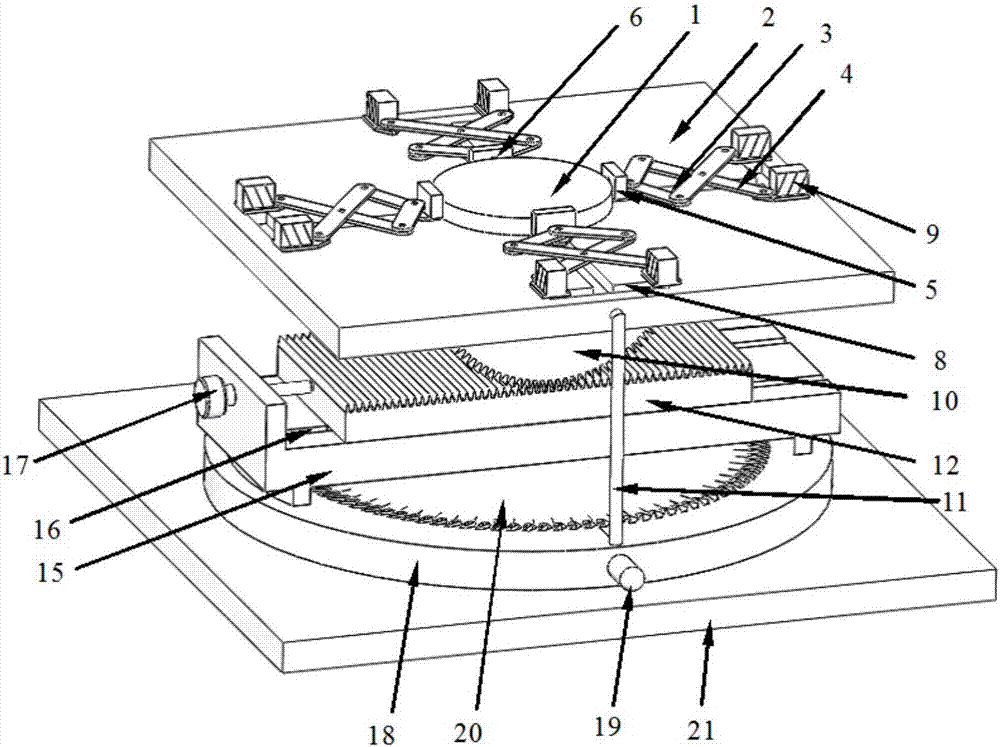

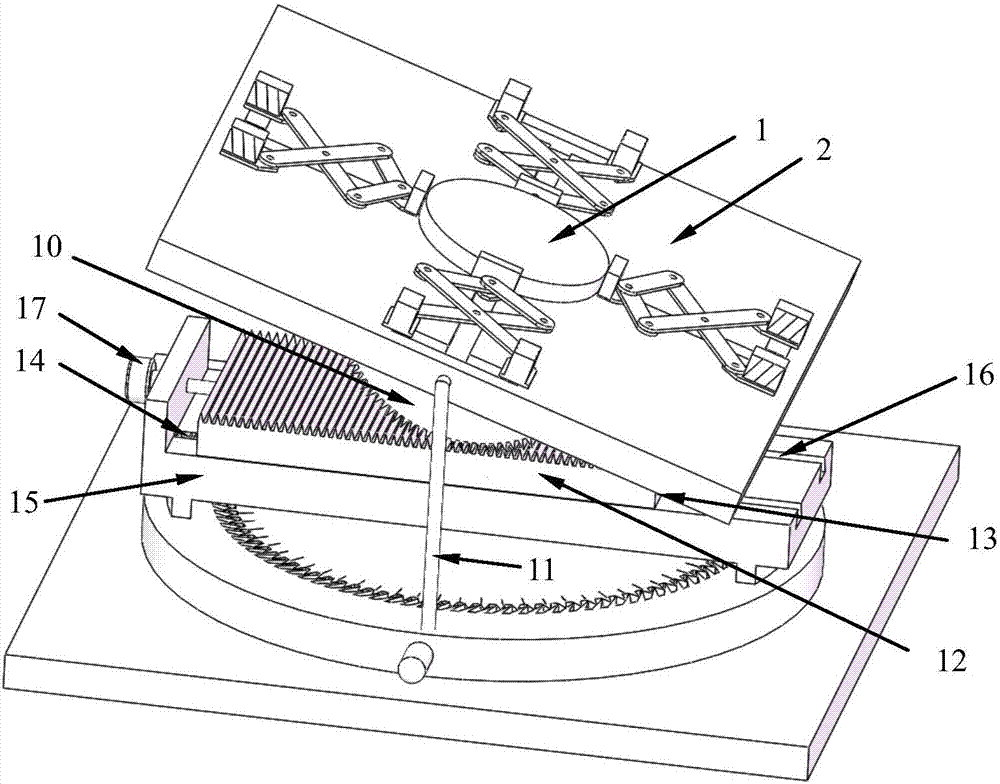

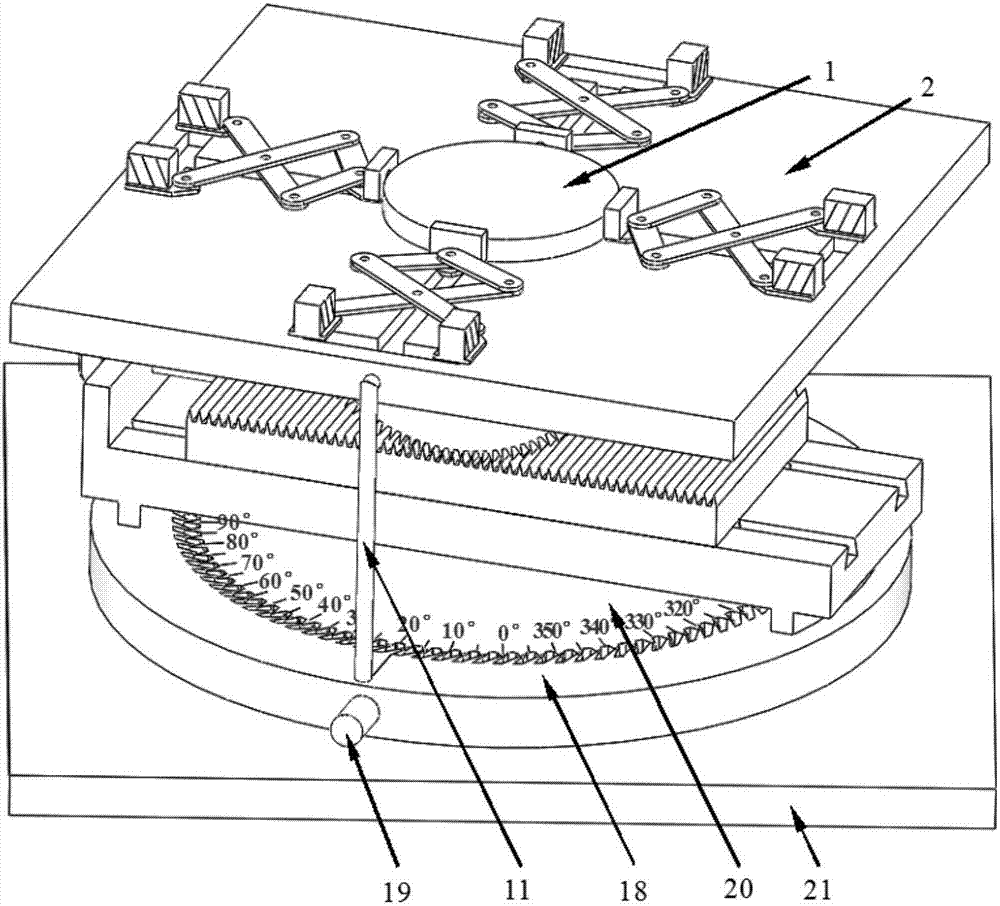

[0018] Such as Figure 1 to Figure 3 As shown, the special fixture for nano-indentation instrument of the present invention is mainly composed of workpiece support plate 2, telescopic chute 3, telescopic frame 4, workpiece clamping block 5, piezoelectric sensor 6, telescopic slider 7, adjustment chute 8, Electromagnet 9, tilting gear 10, rotating support frame 11, tilting rack 12, moving slide bar 13, spring 14, rack rack 15, moving chute 16, micrometer 17, rotating disc 18, rotating handle 19, fixed circle Disk 20, fixture base 21 etc. composition.

[0019] On the workpiece support plate 2, four telescopic frames 4 are evenly distributed along the circumferential direction of the workpiece 1 to be measured. The top of the telescopic frame 4 is connected with a workpiece clamping block 5, and a piezoelectric sensor 6 is placed outside the workpiece cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com