Adjustable corner arch support clamping mechanism

A clamping mechanism and adjustable technology, applied in vertical shaft equipment, shaft lining, mining equipment, etc., can solve the problems of inability to install, time-consuming, labor-intensive, safety, and insecurity, and achieve convenient position adjustment and positioning, and the overall structure is simplified and practical. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

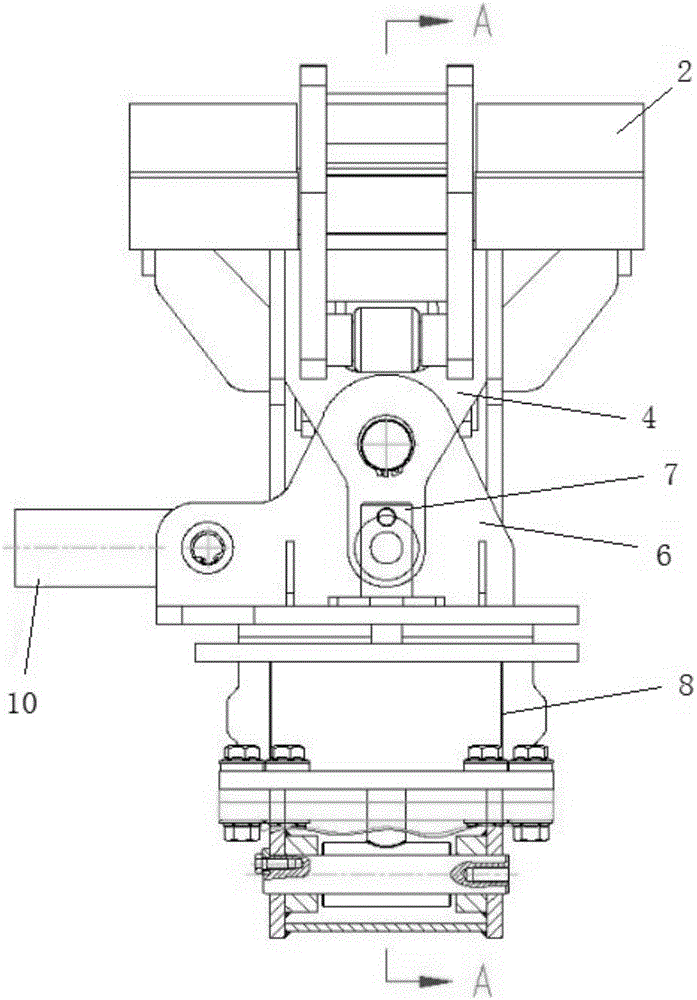

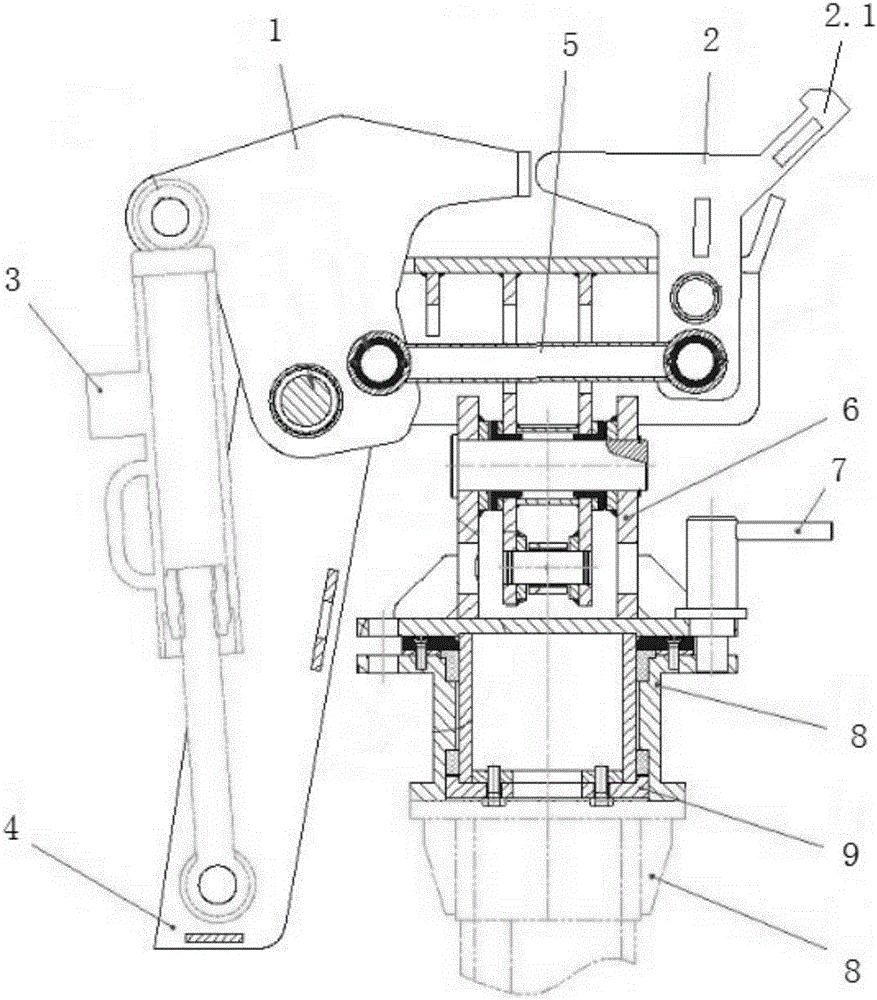

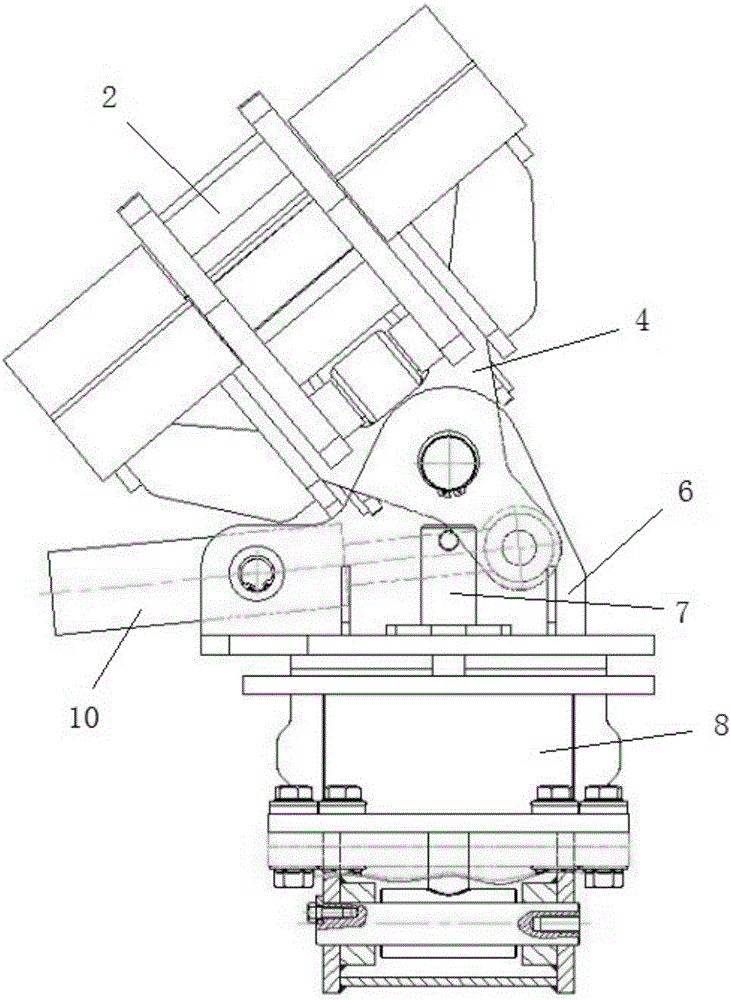

[0033] See Figure 1-Figure 6 , An adjustable corner arch clamping mechanism, including an active chuck 1, a passive chuck 2, a clamping cylinder 3, a fixed base 4, a connecting rod 5, a corner fixing seat 6, an adjustment and positioning component 7, a sleeve assembly 8 , Limit block 9 and corner cylinder 10.

[0034] The connection relationship of each component is as follows:

[0035] Both the active chuck 1 and the passive chuck 2 are movably arranged on the fixed base 4 through a pin, and the active chuck 1 and the passive chuck 2 are connected by a connecting rod 5, The connecting rod 5 is used for driving the passive chuck 2 to follow the active chuck 1 to move to achieve clamping and loosening of the arch.

[0036] The clamping cylinder 3 is used to control the active chuck 1 to move, one end of which is connected to the active chuck 1, and the other end is connected to the fixed base 4.

[0037] The fixed base 4 and the corner fixing base 6 are connected in a relatively rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com