Combine for harvesting peanut

A combined harvester and peanut technology, applied in excavating harvesters, harvesters, mechanical equipment, etc., can solve the problems of poor soil and fruit separation effect, complex machine structure, non-conformity, etc., so as to reduce soil content and improve cleanliness. Reasonable effect of selection efficiency and structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

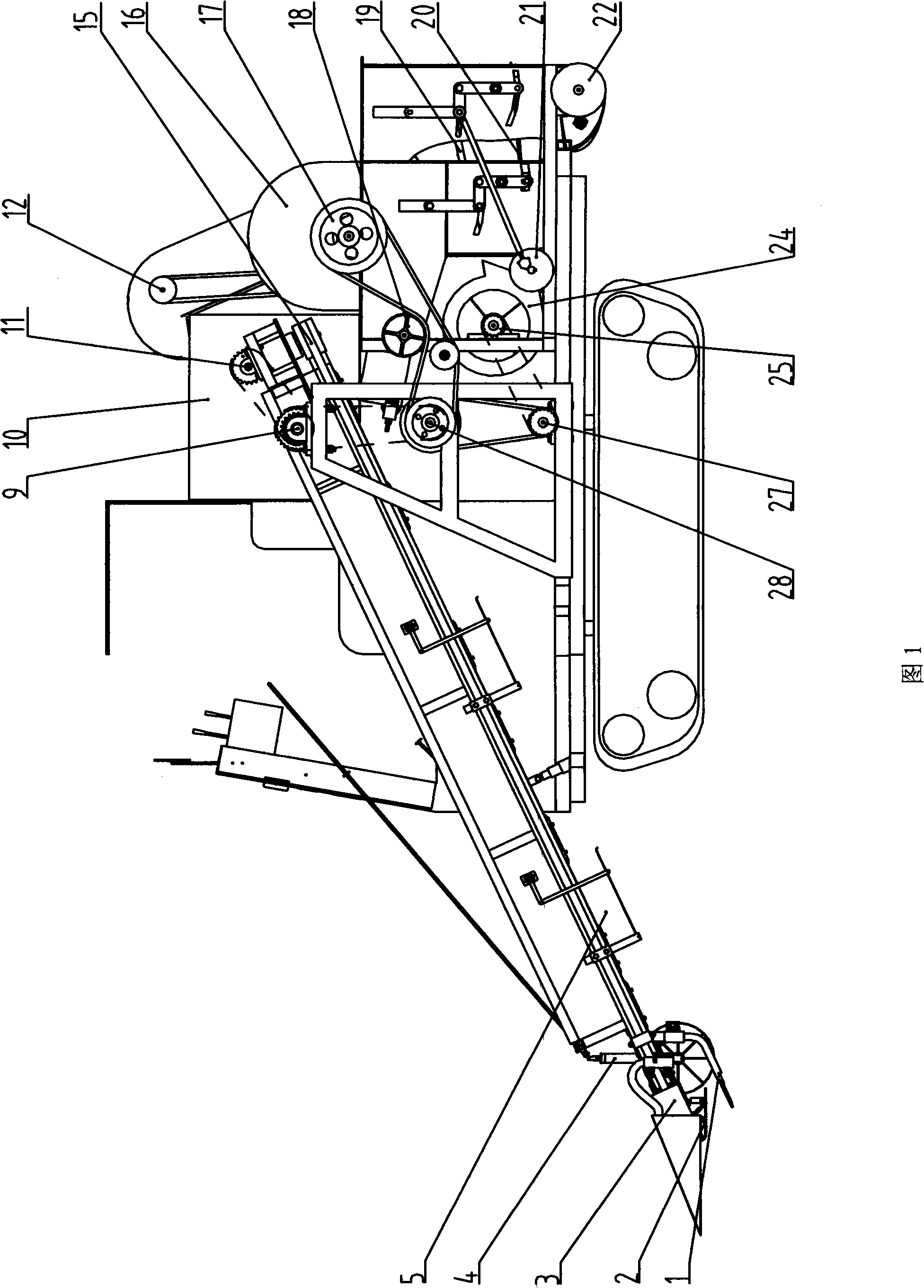

[0020] A peanut combine harvester, the machine body is equipped with a power walking mechanism, an excavating mechanism, a clamping and conveying mechanism, a fruit picking mechanism, a cleaning mechanism, a horizontal conveying lifting storage mechanism, and the lower part of the body is equipped with a power walking mechanism. The front part is provided with a clamping and conveying mechanism, and the front end of the clamping and conveying mechanism is provided with an excavating mechanism. One side of the excavating mechanism and the end of the clamping and conveying mechanism are provided with a limited depth wheel 4. Soil mechanism 5, the rear part of the clamping and conveying mechanism is a fruit-picking mechanism, an auxiliary feeding mechanism 18 is arranged between the clamping and conveying mechanism and the fruit-picking mechanism, the lower part of the fruit-picking mechanism is a cleaning mechanism, and one side is equipped with a lifting storage device; The powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com