Wind power blade demoulding hoisting clamp and wind power blade demoulding method

A technology for wind power blades and blades, which is applied in the field of wind power blade stripping lifting fixtures and wind power blade stripping, and can solve the problem of belt or spreader blade tripping, suspension belt or spreader not being able to effectively clamp the suspended blade, blade slipping, etc. problems, to achieve the effects of improving reliability and safety, improving blade demoulding efficiency, and elastically recovering the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

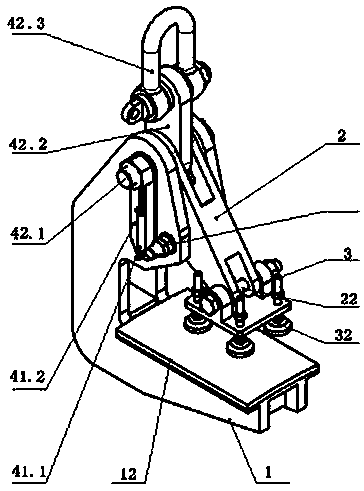

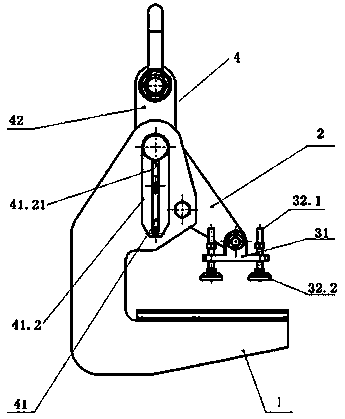

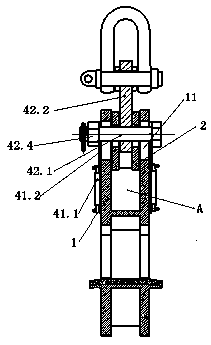

[0030] Attached below Figure 1~4 Embodiments of the present invention are described in detail.

[0031] The wind power blade stripping and lifting fixture includes a C-shaped seat 1, a slanted and swingable pressing block connecting rod 2 mounted on the C-shaped seat 1, and a lower end of the pressing block connecting rod 2 for pressing the blade on the C-shaped The pressing block assembly 3 on the seat 1 is characterized in that it also includes an elastic lifting assembly 4 that can drive the pressing block connecting rod 2 to swing. The elastic lifting assembly 4 is movably mounted on the C-shaped seat 1 and positions the pressing block by elastic force. The initial inclination angle of the connecting rod 2 maximizes the initial distance between the briquetting block assembly 3 and the C-shaped seat 1, and the blades extend between the C-shaped seat 1 and the briquetting block assembly 3, and are lifted up with the elastic lifting assembly 4 The blade gravity loads on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com