Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

207results about How to "Realize automatic demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

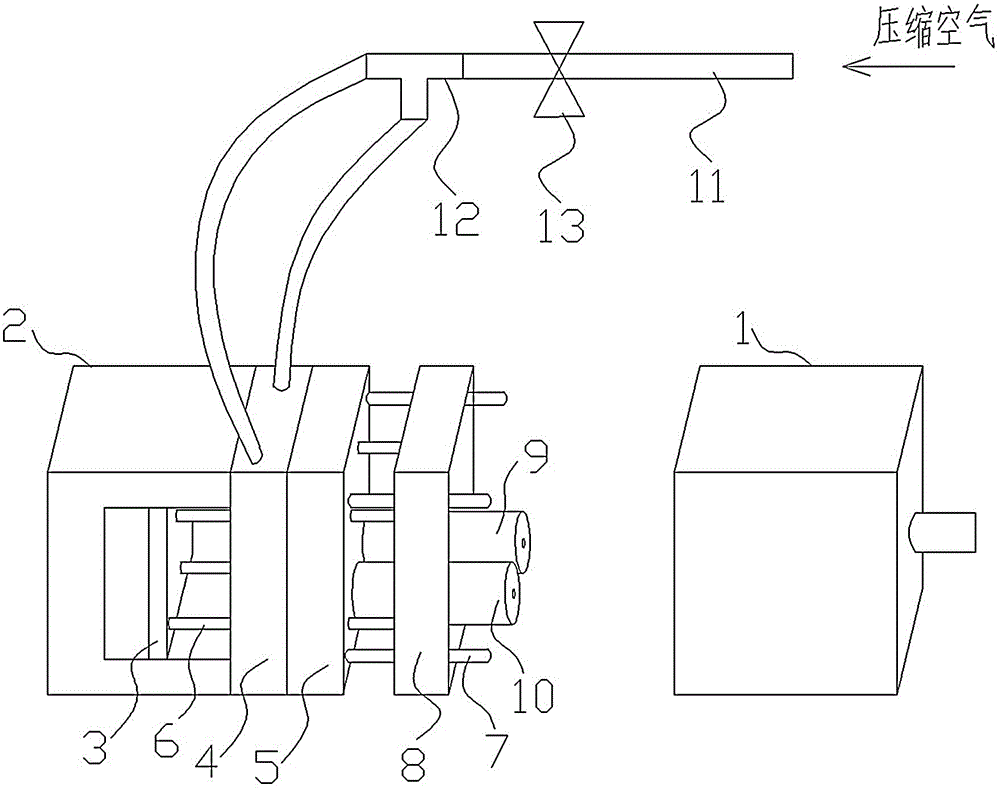

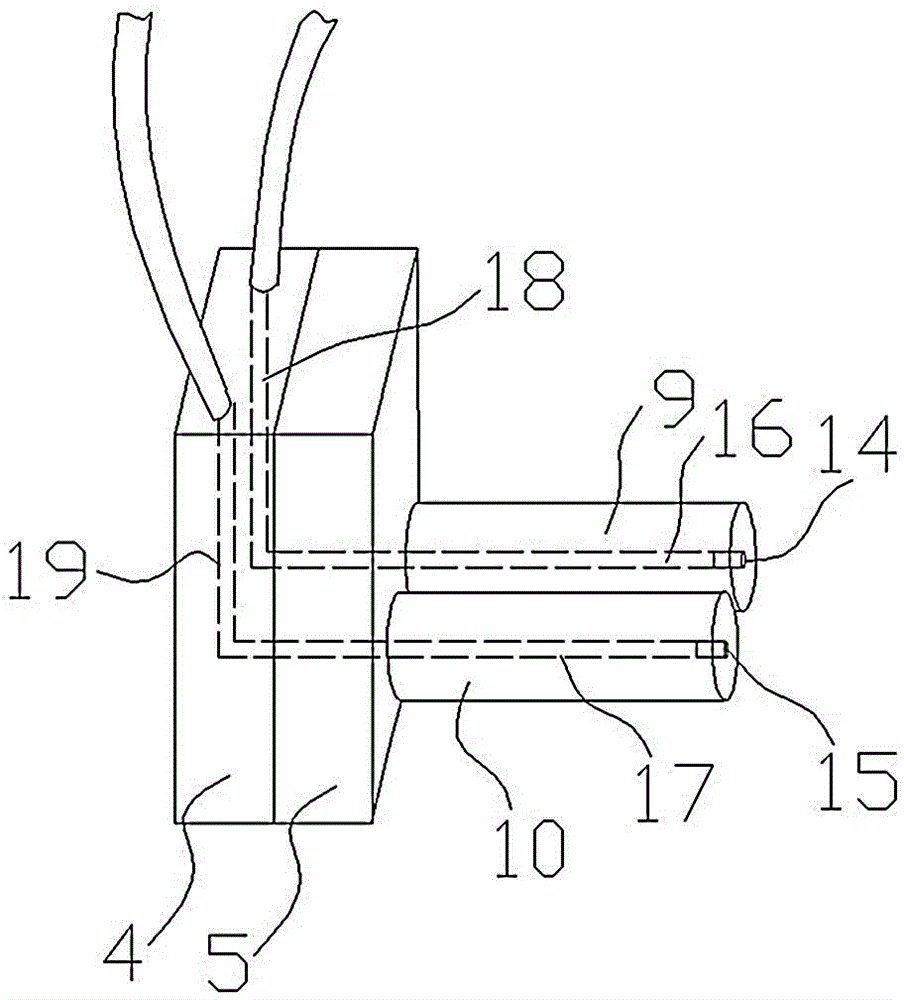

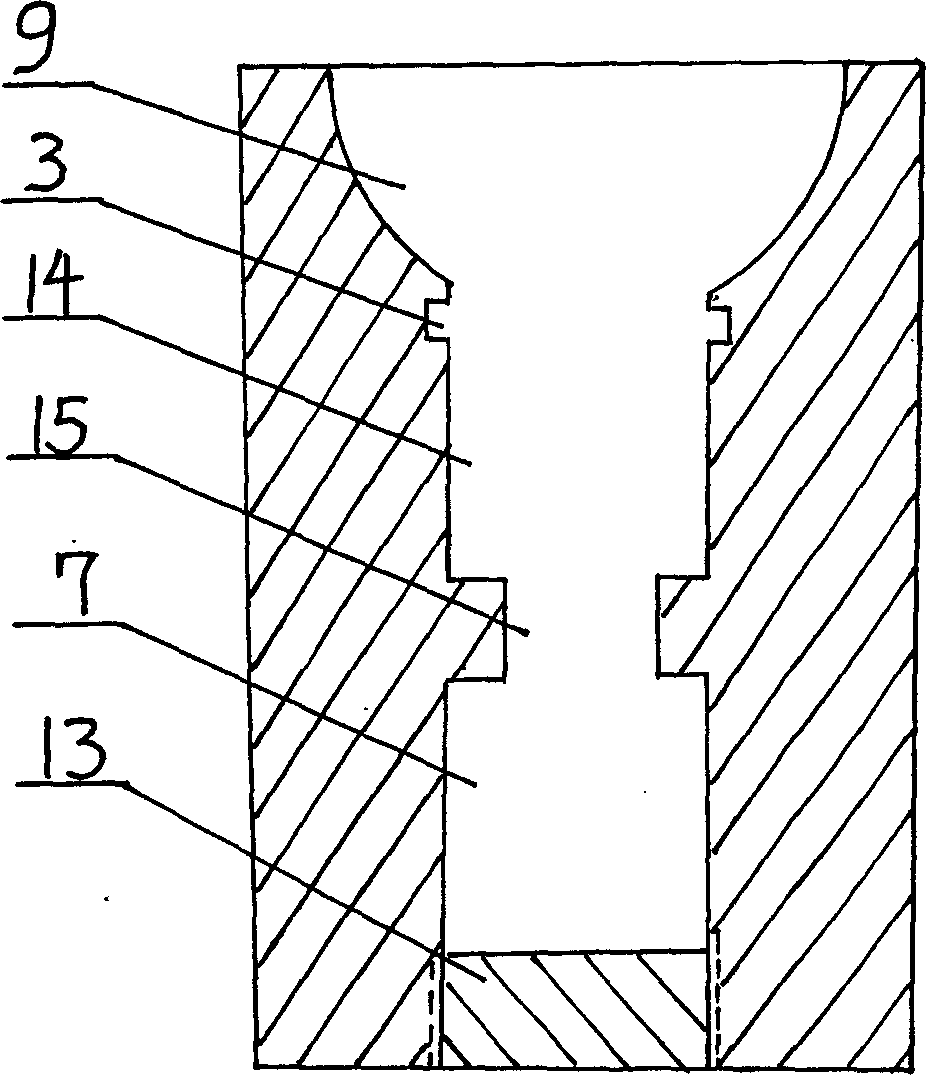

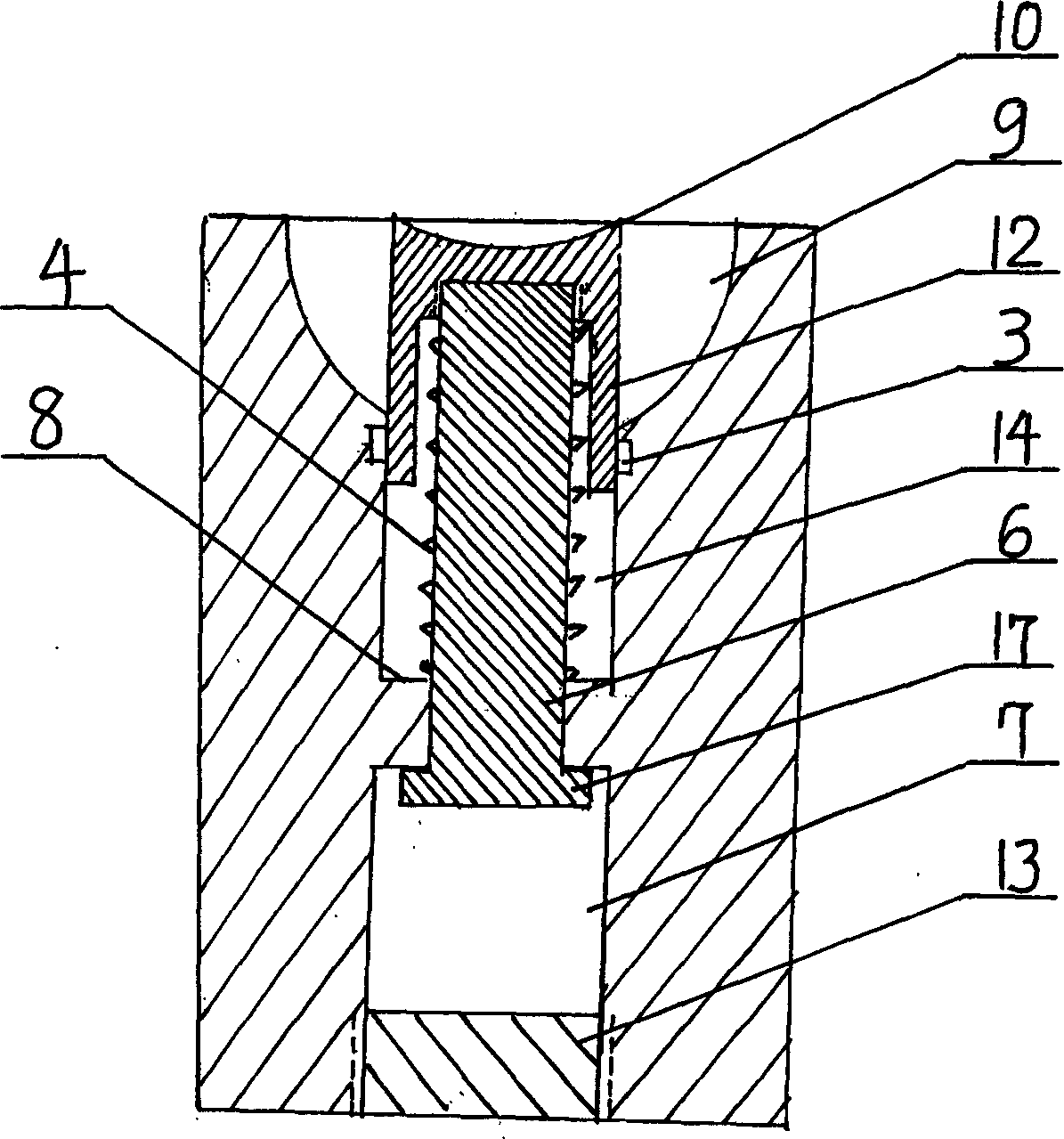

Pneumatic demolding injection molding mold for thermos bottle caps

InactiveCN103950155ARealize automatic demouldingNo manual operationInjection molding machineBottle cap

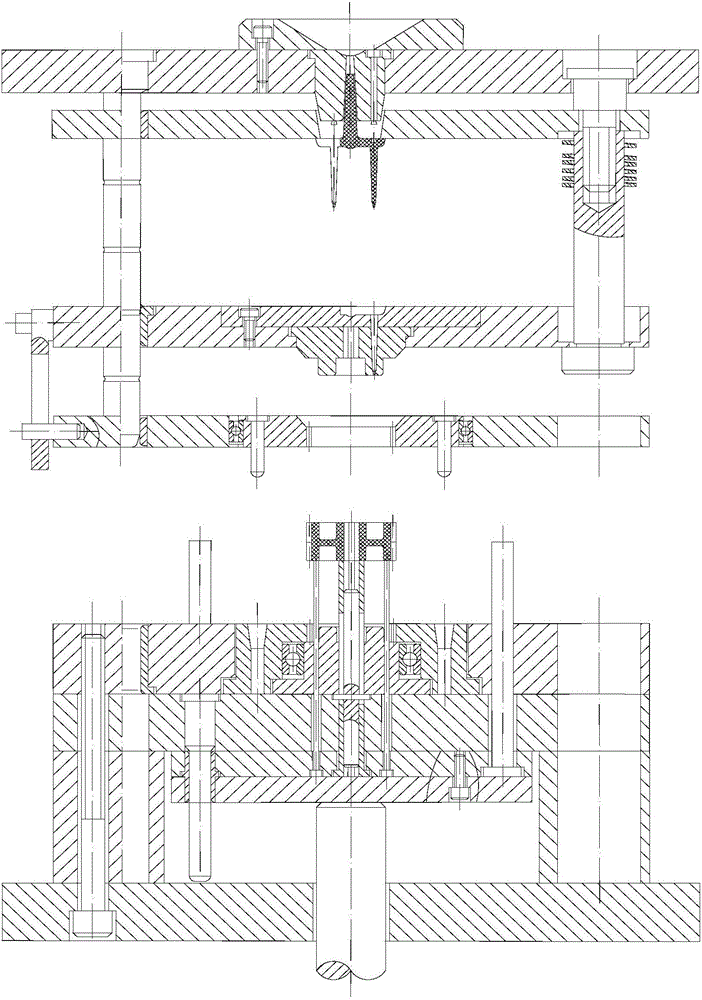

The invention discloses a pneumatic demolding injection molding mold for thermos bottle caps. The pneumatic demolding injection molding mold for thermos bottle caps sequentially comprises a fixed mold and a moving mold; the moving mold comprises a mold leg, an ejection plate, ejector pins, a water distribution plate, a mold core fixing plate, a pushing plate and mold cores; the mold cores are arranged on the mold core fixing plate; the pushing plate is matched with guide rods on the mold core fixing plate in a sliding mode. The pneumatic demolding injection molding mold for thermos bottle caps is characterized in that the mold cores are internally axially provided with air pipes; the end surfaces of the mold cores are provided with air nozzles; one ends of the air pipes are connected with the air nozzles, and the other ends of the air pipes are connected with an air source by air holes in the water distribution plate. Compressed air is sprayed into thermos bottle caps on the mold cores by the air pipes and the air nozzles, so that the thermos bottle caps are removed from the mold to achieve the aim of demolding automatically without manual operation; therefore, the production efficiency is improved.

Owner:蚌埠市万达塑料制品有限公司

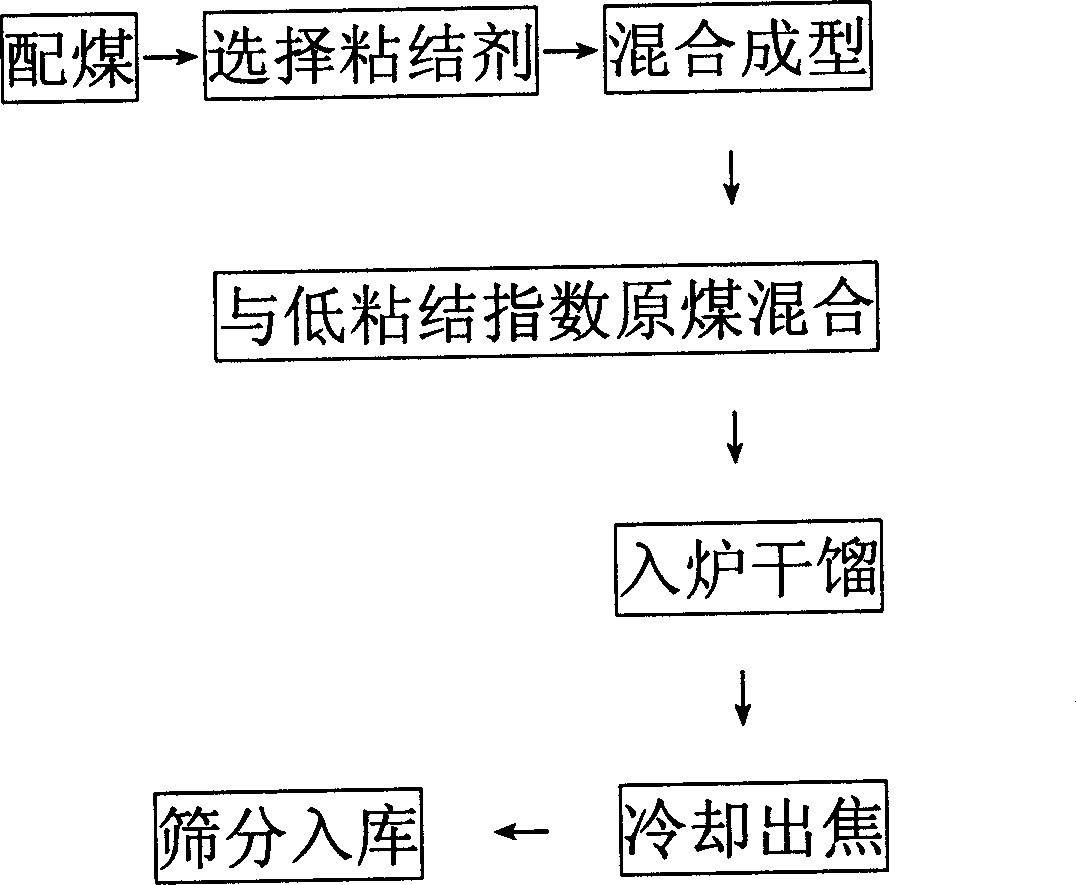

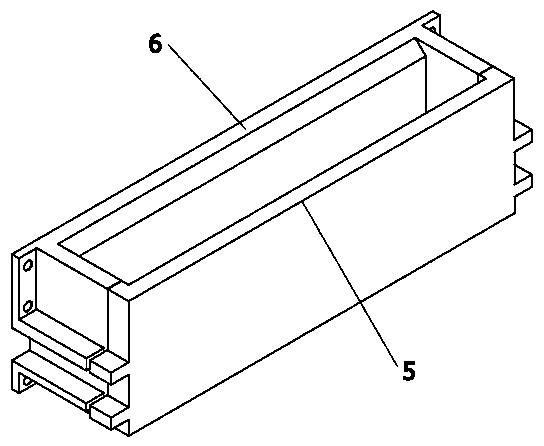

Sectional coke and its production method and pressure forming equipment

InactiveCN1488709ARaise the combustion temperatureIncrease temperatureCoke ovensAdhesiveCarbonization

The present invention relates to a formed coke, it is made up by using raw coal and / or semi-coke and / or coke powder and organic adhesive through the processes of mixing, press-forming and carbonization, and in which the described formed cake is made into the form of spheroid, its diameter is 30-300 mm, and its density is 1.25-1.5 g / cu.cm. Said invention also provides the pressure forming equipment for producing the above-mentioned spheriod formed coke and its production method.

Owner:刘英旺 +1

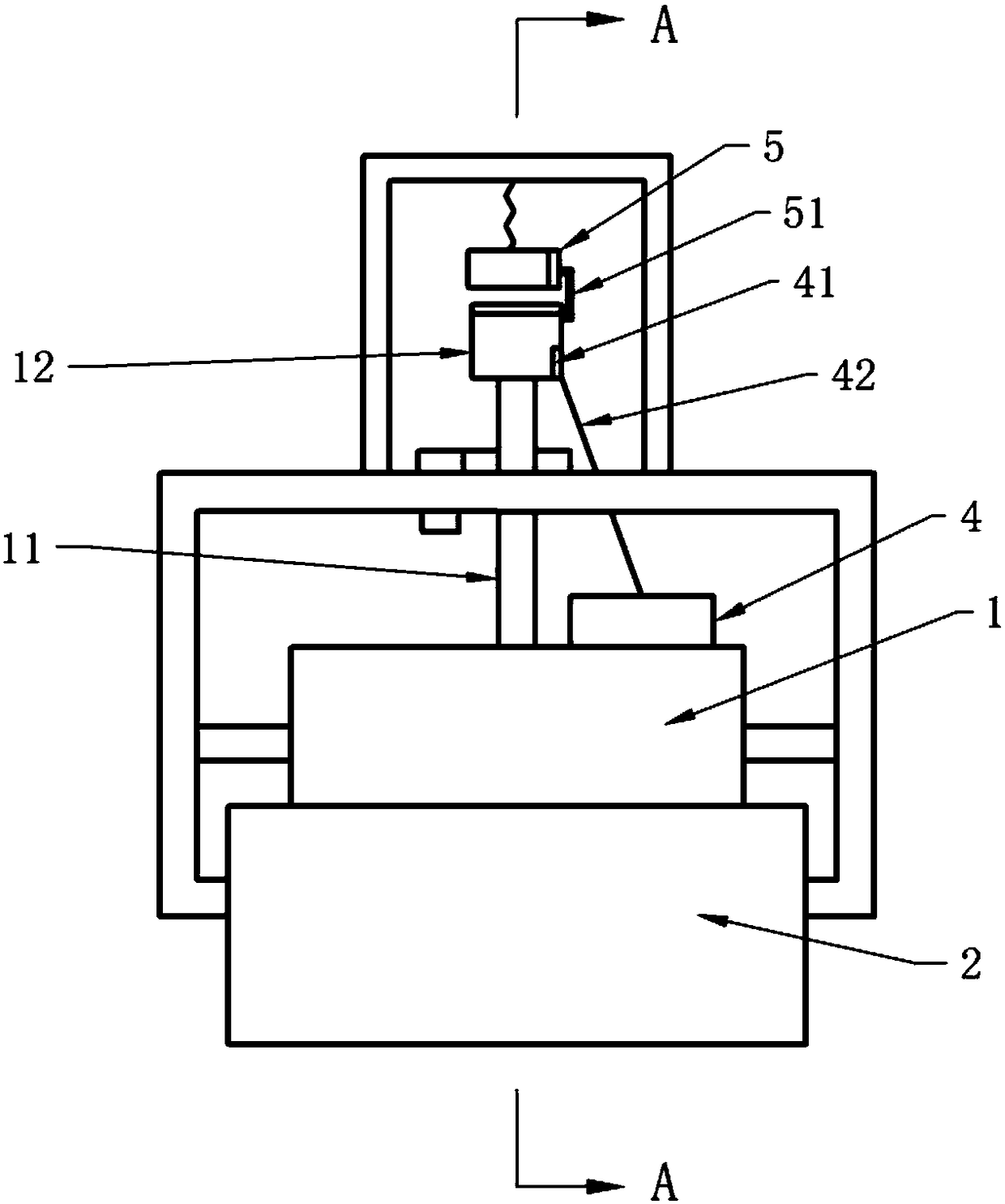

Casting mould structure capable of pulling core firstly and then ejecting

ActiveCN105290331AReduce manufacturing costExtend your lifeFoundry mouldsFoundry coresHydraulic cylinderMolten metal

The invention provides a casting mould structure capable of pulling a core firstly and then ejecting. The casting mould structure comprises a rack as well as a movable mould, a fixed mould, a movable core rod, an ejector board and a hydraulic cylinder which are arranged on the rack, wherein the movable mould and the fixed mould are arranged up and down; the movable mould and the fixed mould are in mutual contact and form a mould cavity; when the mould works, molten metal is firstly poured into the mould cavity from a sprue of the movable mould, and then, the ejector board is pulled down by virtue of the hydraulic cylinder to drive the movable core rod to move downwards and separate from a through hole of a product, so that shrinkage stress is released; after a product is molded, the movable mould and the product are ejected sequentially through a top mould rod and an ejector rod; and the casting mould structure is suitable for mould opening of the product with the through hole, so that the product with the through hole is prevented from a cracking phenomenon during mould opening.

Owner:安徽熠辉新材料有限公司

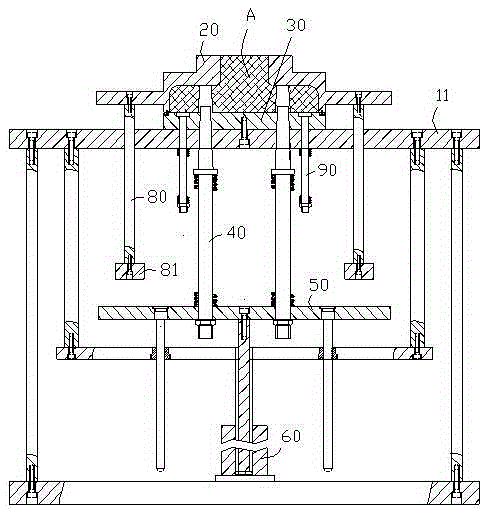

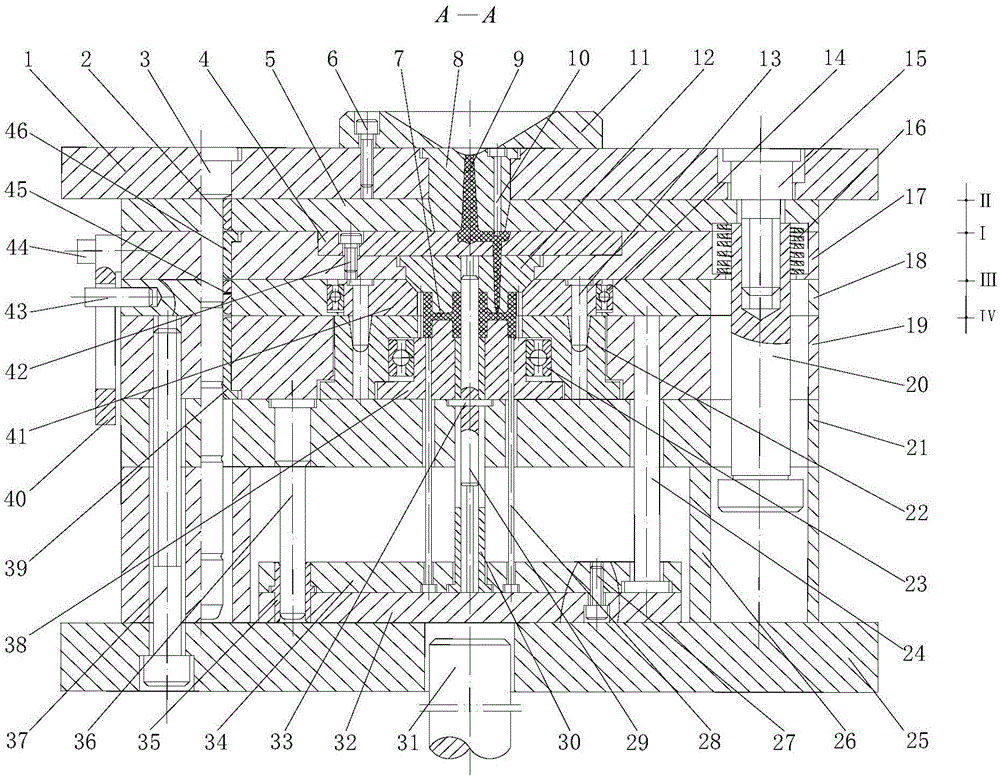

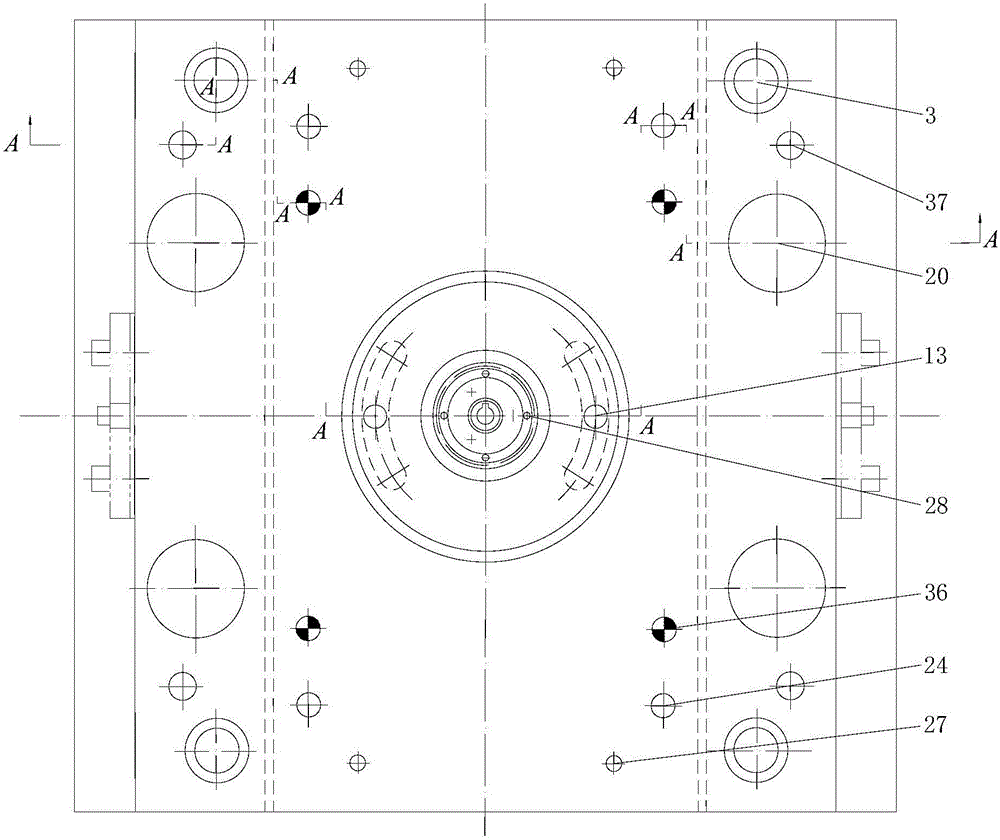

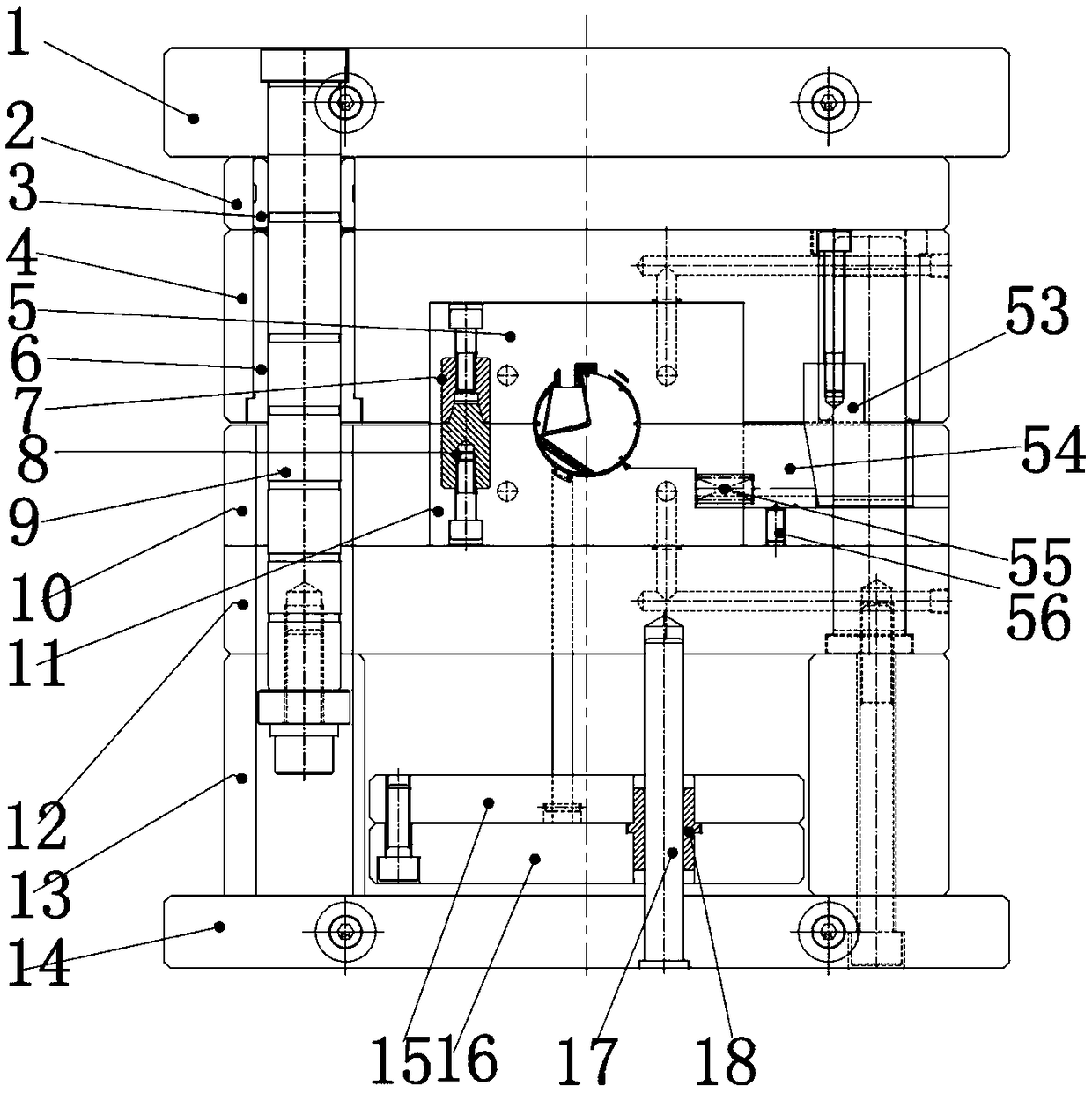

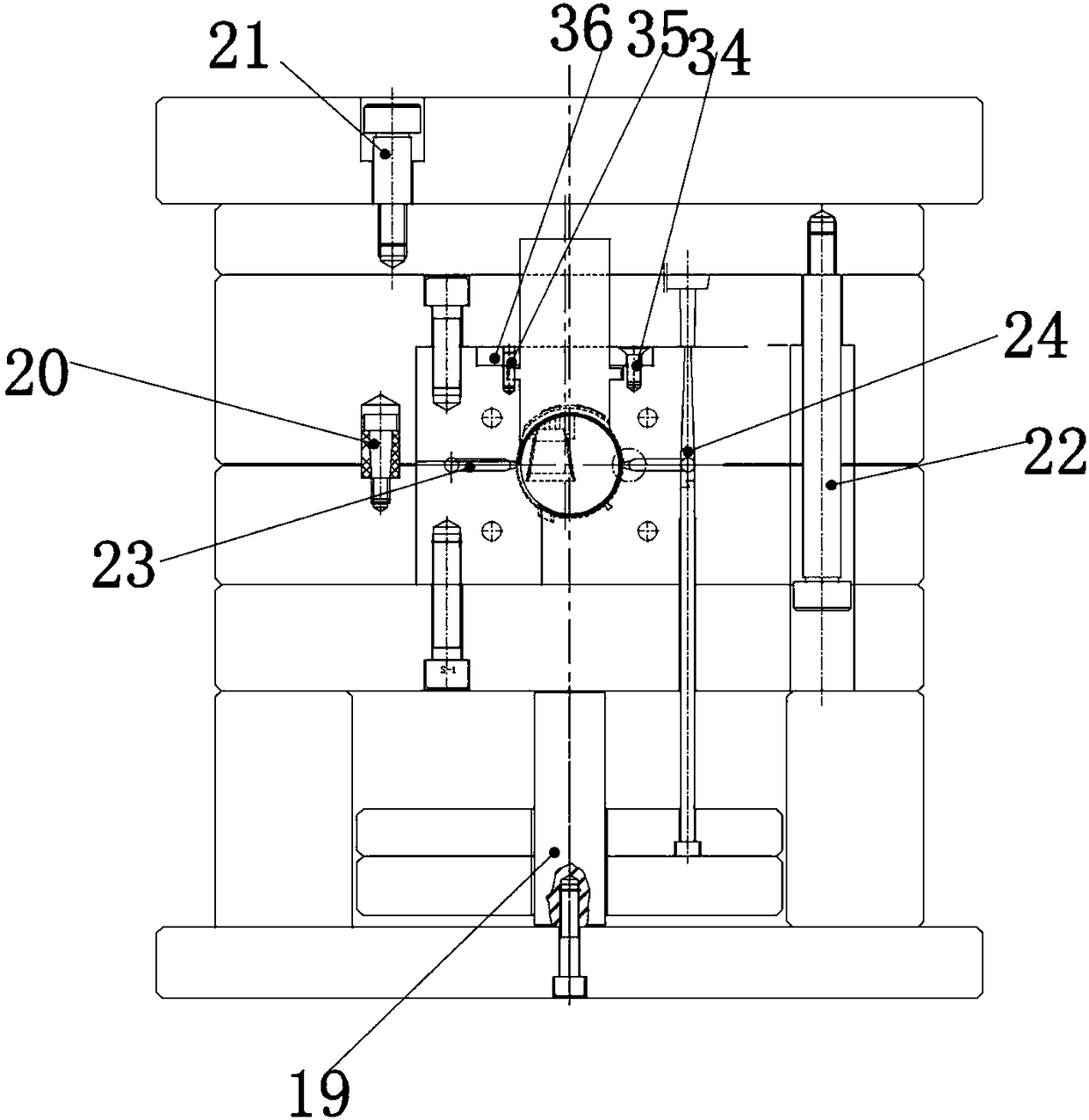

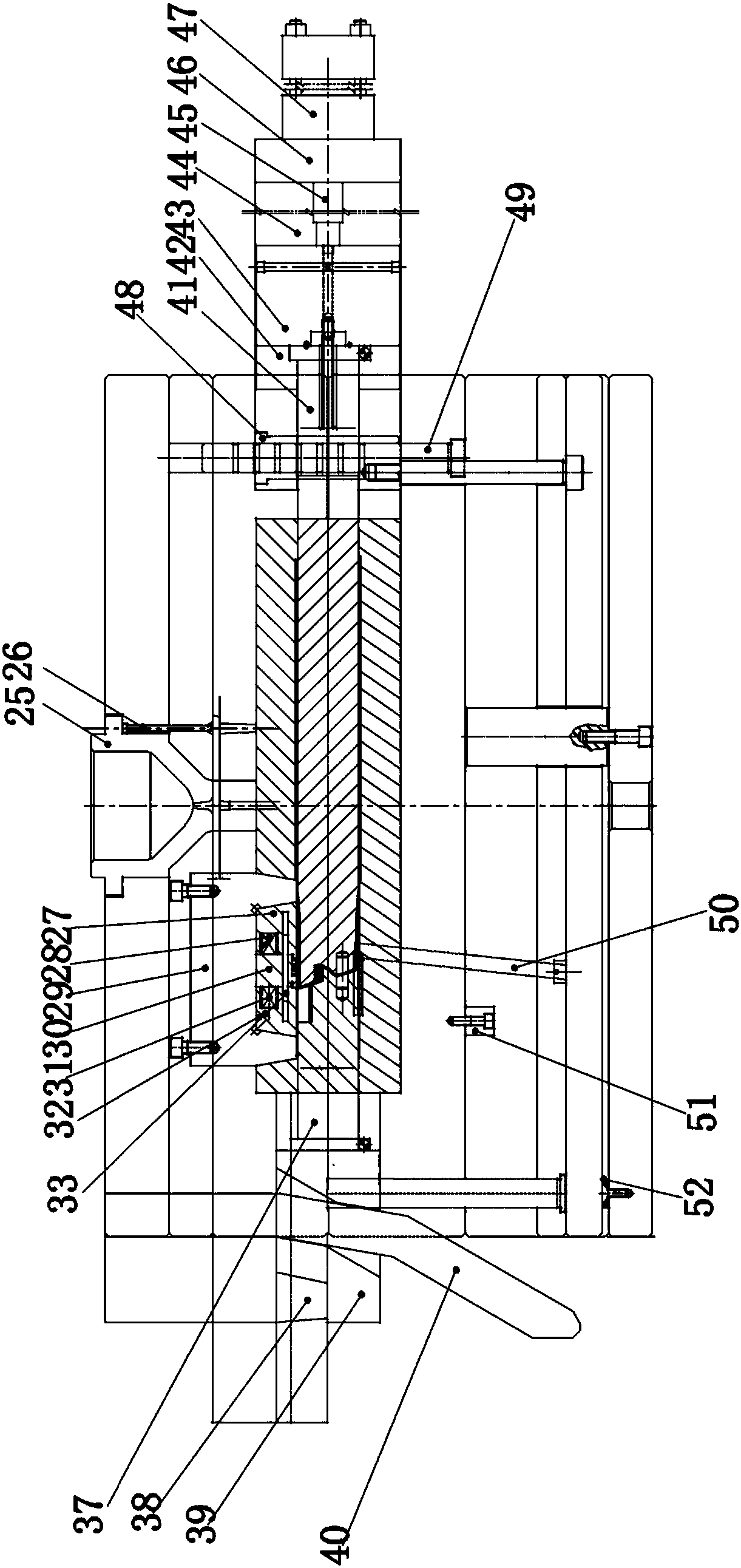

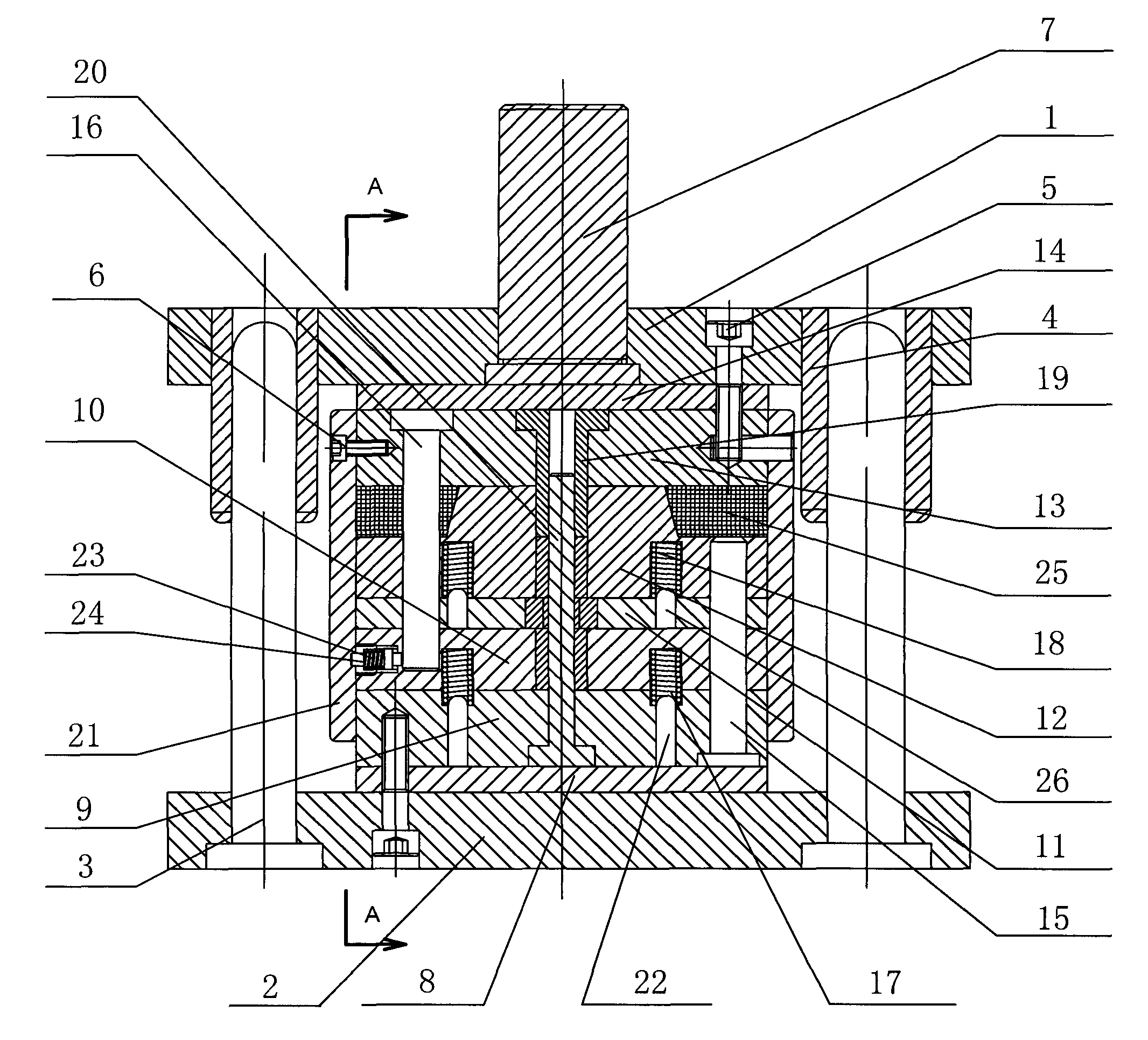

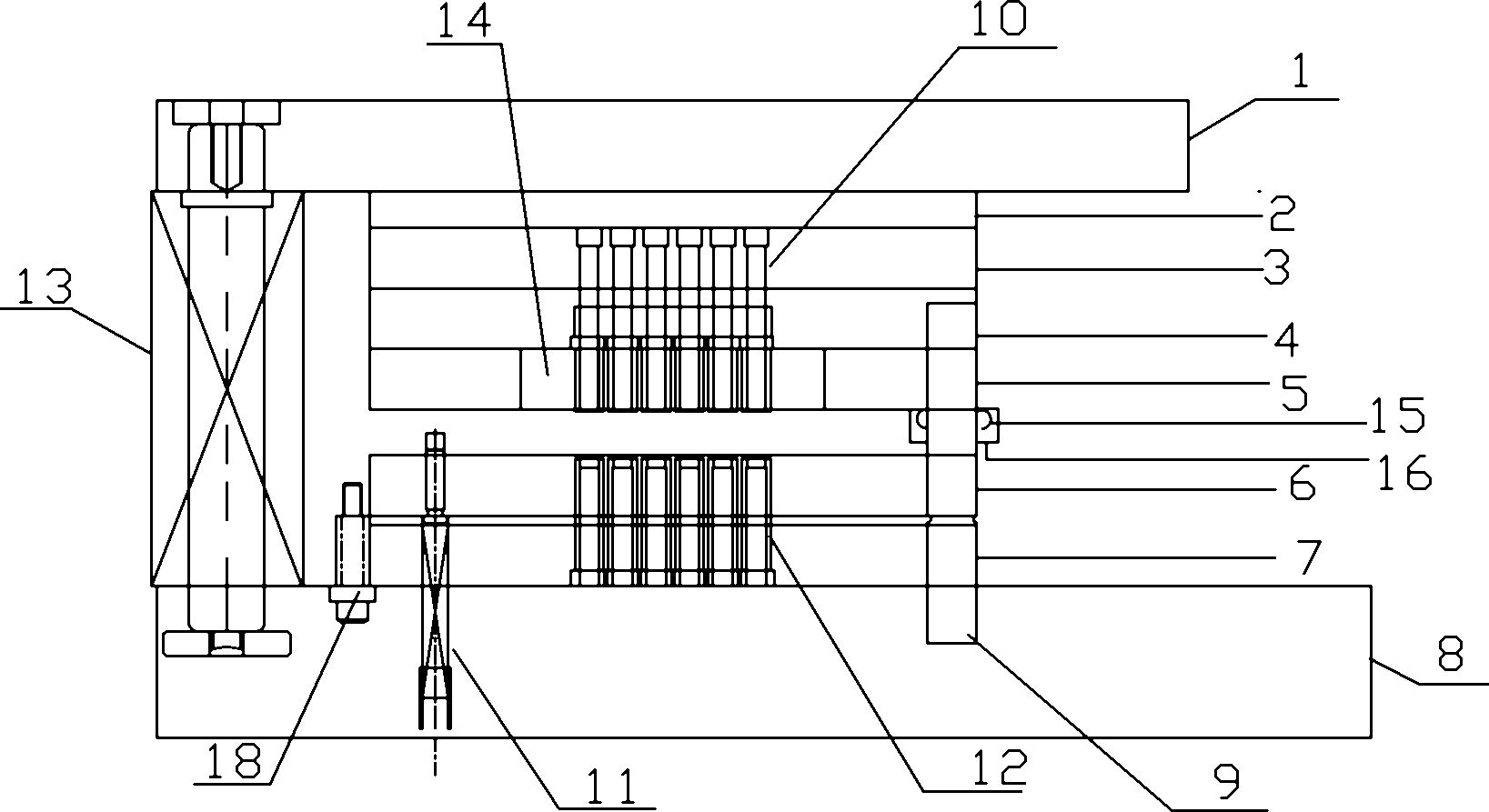

Injection molding die of equal-diameter both-way plastic helical gear

The invention discloses an injection molding die of an equal-diameter both-way plastic helical gear. The injection molding die sequentially comprises a fixed die seat plate, a pouring stopping plate, a mold core fixing plate, a cavity fixing plate, a movable die plate, a bearing plate, a mat block and a movable die base plate from top to bottom; a positioning ring is arranged above the fixed die seat plate; a first centripetal thrust bearing and a first helical gear cavity insert are arranged inside the cavity fixing plate; a second helical gear cavity insert, a second centripetal thrust bearing and a second mold core insert are arranged inside the movable die plate; and a bulb guide pin is installed inside the first helical gear cavity insert, a guide hole is formed inside the second helical gear cavity insert, and the first helical gear cavity insert and the second helical gear cavity insert are subject to helical gear groove position alignment through the bulb guide pin and the guide hole. The injection molding die is perfect in structure, efficient in motion and high in molding quality; multiple parting line sequenced parting achieves material coagulating of a gating system and automatic demolding of a helical gear plastic piece, the molding efficiency of the plastic piece is improved, and the service life of the die is prolonged.

Owner:宁波明旌电子有限公司

Porous plastic product and manufacturing method thereof

InactiveCN108453996ARealize automatic injection molding productionEffective control of demoulding deformationDomestic articlesMechanical engineeringMold removal

The invention provides a porous plastic product. The product is manufactured by a molding device. Regarding the problems that the plastic product is a tube product, core loosing is firstly carried outon the front mold side before a gap is formed in the middle, the middle of the tube is hollow, it is difficult to demold, and demolding easily causes large product deformation, so that the product isscrapped, a corresponding demolding mechanism and a device mechanism are designed, the device mechanism comprises a mold base mechanism component, a molding part assembly component, a left side bentpin core loosing assembly component and a right long core loosing assembly component, and the molding device has the advantages that the structure is simple in design, automatic molding is achieved onfeature positions on which demolding cannot be performed, the structure design is simple, the reliability is high, and the mold manufacture cost is low.

Owner:张剑箫

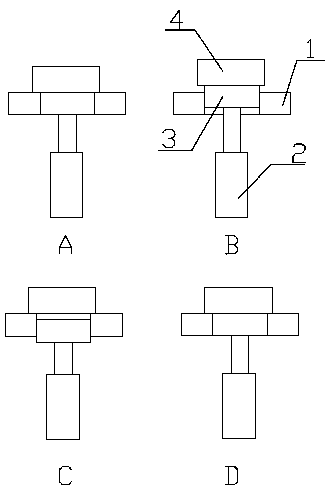

Die for car interior part

ActiveCN108188274ARealize automatic demouldingImprove demoulding efficiencyShaping toolsEngineeringMechanical engineering

The invention belongs to the technical field of die for car parts processing, and discloses a die for a car interior part. The die for the car interior part comprises an upper male die and a lower female die; the lower female die is provided with a support formed by a cross plate and two vertical plates; the upper male die is provided with an electromagnet and a sliding rod penetrating through thecross plate; the cross plate is provided with a drive piece; the top portion of a sliding rod is provided with a support block; the lower portion of the side wall of the support block is provided with a conducting strip; an electric lead is arranged between the conducting strip and the electromagnet; the cross plate is provided with a support frame; a communicating block is arranged between the support frame and the cross plate; an elastic piece is arranged between the top potion of the communicating block and the bottom of the support frame; the communicating block is provided with a power source; the power source is provided with a conductive needle; one end, away from the power source, of the conductive needle is connected with the side wall provided with the conducting strip of the support frame in a sliding mode; the lower female die is internally provided with a cavity; and the cavity is internally connected with an iron block in a sliding mode. The die for the car interior partsolves the problem that the interior parts are tightly attached with the lower die after impact molding to the interior parts in the prior art, leading to the difficulty of removing the car interiorparts.

Owner:CHONGQING YINSHENG MOLD

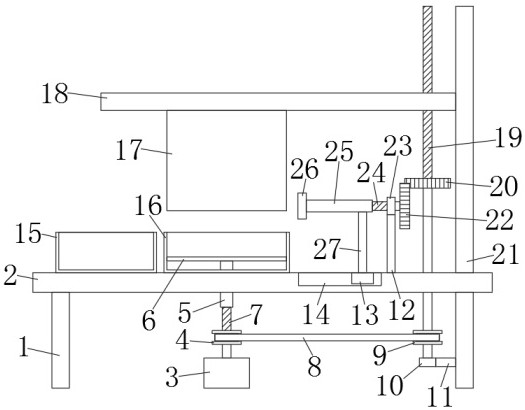

Stamping device for hardware stamping part

InactiveCN112355110AThe solution is not easy to demouldAvoid demouldingMetal-working feeding devicesPositioning devicesMechanical engineeringWork productivity

The invention discloses a stamping device for a hardware stamping part, and relates to the technical field of stamping devices. The stamping device aims at solving the problems that according to an existing stamping device, after stamping, an object is not prone to demolding, the stamped object needs to be collected manually, the whole process wastes time and labor, the labor intensity of workersis increased, and the working efficiency of the workers is reduced. According to the scheme, the stamping device comprises a placing plate, wherein supporting columns are fixedly connected to the twosides of the bottom of the placing plate, a stand column is fixedly connected to the right side of the top of the placing plate, a driving mechanism is arranged at the bottom of the placing plate, a stamping mechanism is arranged at the top of the placing plate, and an automatic material collecting mechanism is arranged at the top of the placing plate. The stamping device is novel in design, simple in structure and convenient to operate, the stamped object can be automatically demolded, the stamped object can be automatically collected, time and labor are saved in the whole process, the laborintensity of the workers is reduced, and the working efficiency of the workers is improved.

Owner:滁州市天鸿冲塑制品有限公司

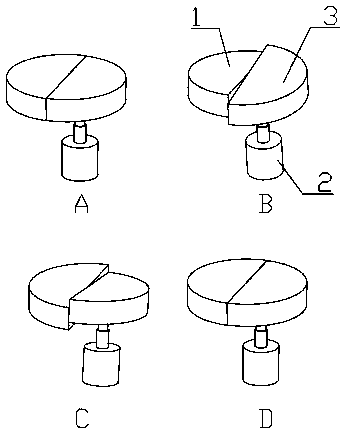

Demolding-convenient wasp nesting barrel molding machine

ActiveCN105269653ARealize mechanized moldingAvoid damageWood working apparatusDomestic articlesMolding machineEngineering

The invention discloses a demolding-convenient wasp nesting barrel molding machine. The machine comprises a base, a bracket, an upper mold, a lower mold, a mold core and an outer cylinder, wherein the bracket is arranged on the base; the upper mold is a cylinder opened at the lower end, and is driven by a first lifting mechanism to vertically move along the bracket; the lower mold comprises a mold core positioning rod; the mold core positioning rod is driven by a second lifting mechanism to vertically move along the base, and the axis of the mold core positioning rod and the axis of the upper mold are positioned on the same straight line; the mold core is a cylinder, and is concavely provided with a positioning hole in the bottom; the mold core sleeves the upper end of the mold core positioning rod through the positioning hole; when the upper mold descends, the mold core is inserted in an inner hole of the upper mold; the outer cylinder comprises two semicircular cylinders, and stands on the base, and the axis of the outer cylinder and the axis of the mold core positioning rod are positioned on the same straight line; and when the upper mold descends, the upper mold is inserted in an inner hole of the outer cylinder. The machine can realize mechanical molding of a wasp nesting barrel, is convenient and simple in demolding, and is high in production efficiency.

Owner:天峨县全盛蜂业科技有限公司

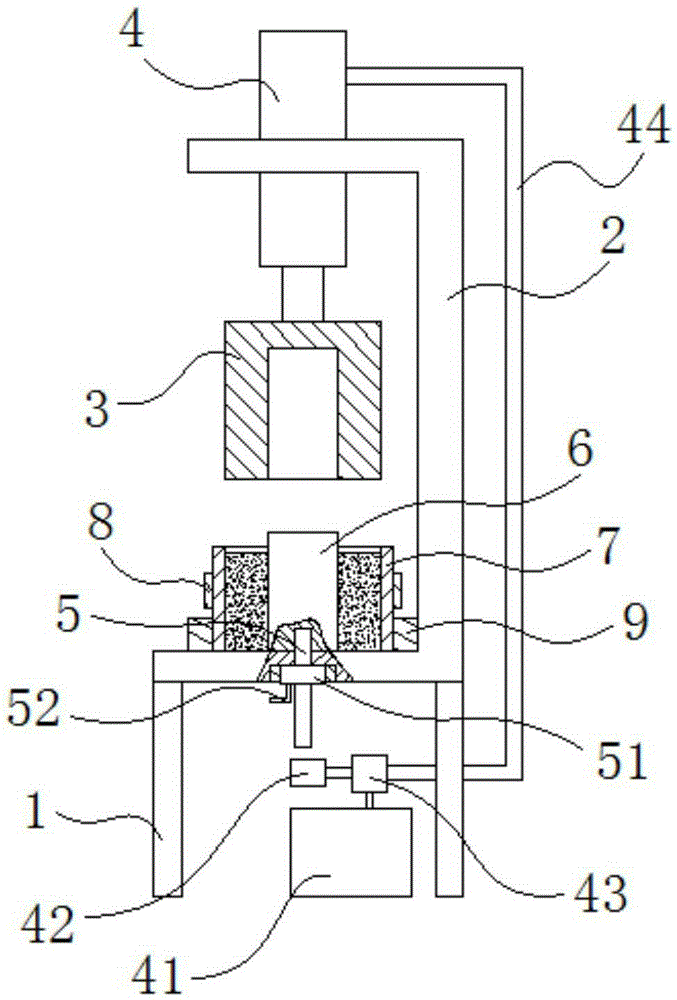

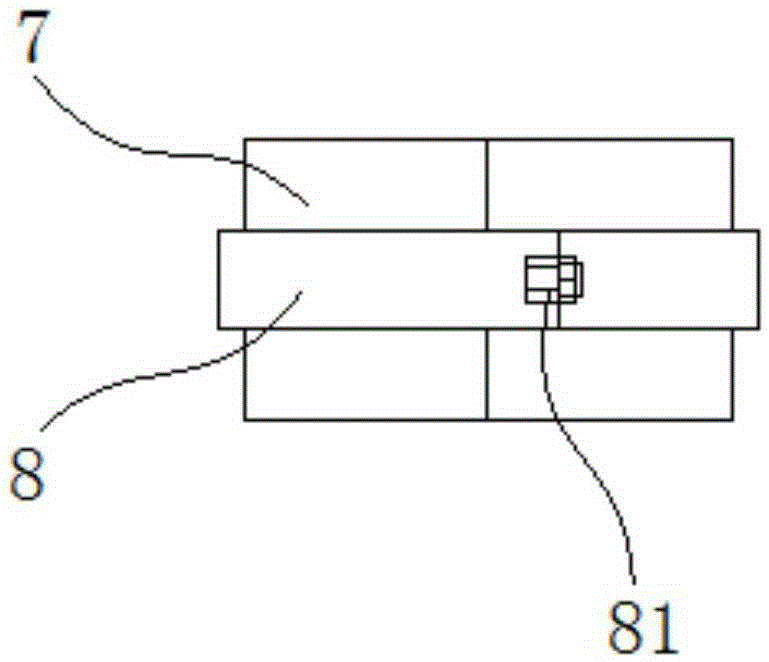

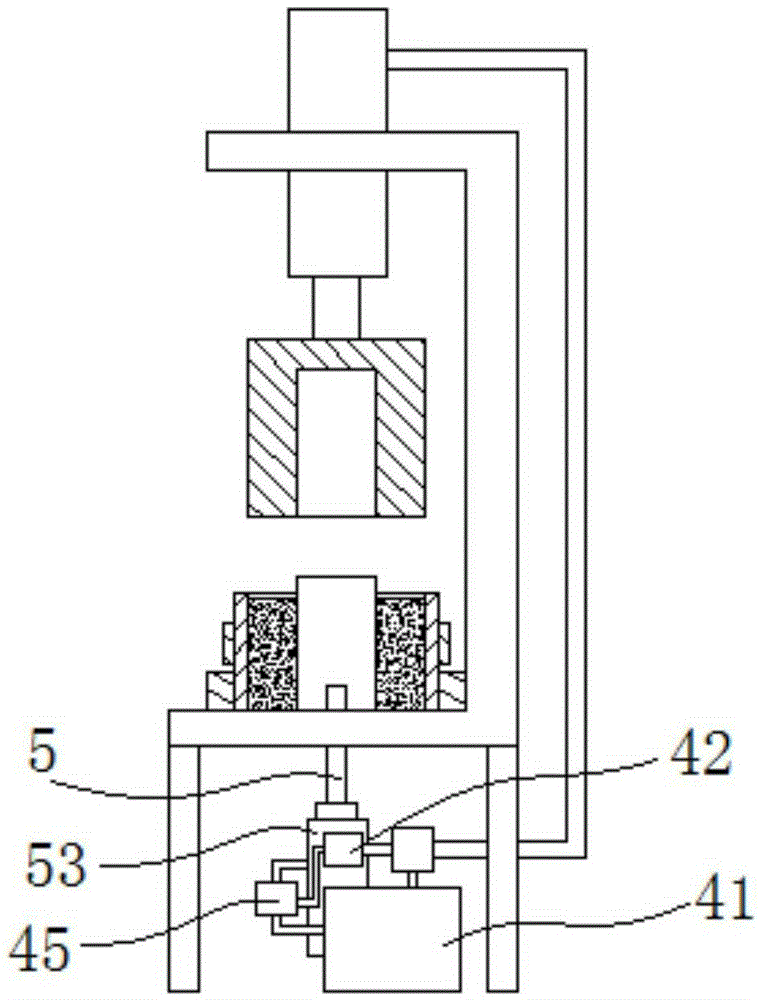

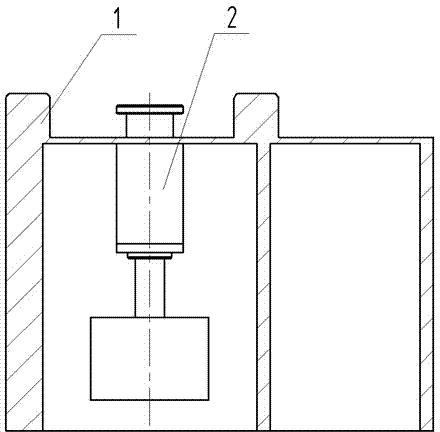

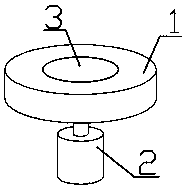

Die for forging production of aluminum alloy control arms

InactiveCN105710268ARapid positioningQuick installationForging/hammering/pressing machinesControl armAluminium alloy

The invention provides a mold for forging and producing an aluminum alloy control arm, and the mold is composed of an upper mold (4), a guide column (3) and a lower mold (2). The beneficial effect of the present invention is that, by designing the connection, guide and positioning structures of the mold design, the requirements of the automatic production of the control arm can be met, and the production of multiple pieces in one mold can be realized.

Owner:CITIC DICASTAL

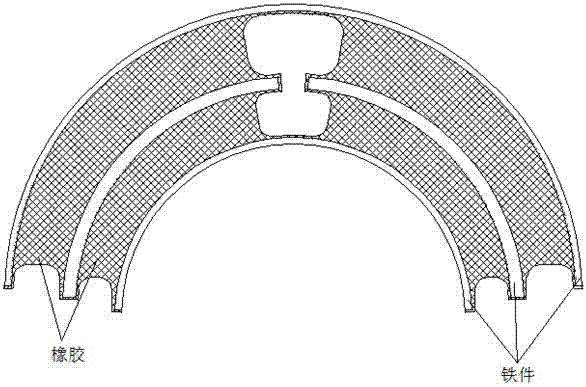

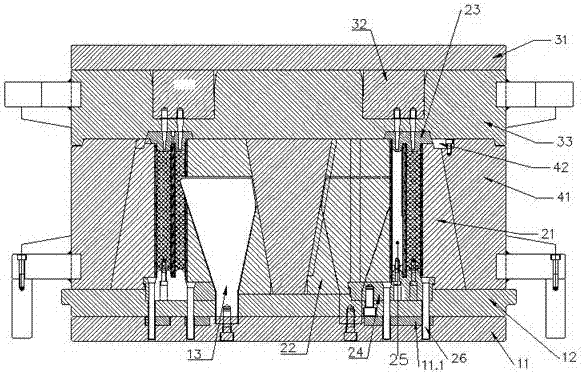

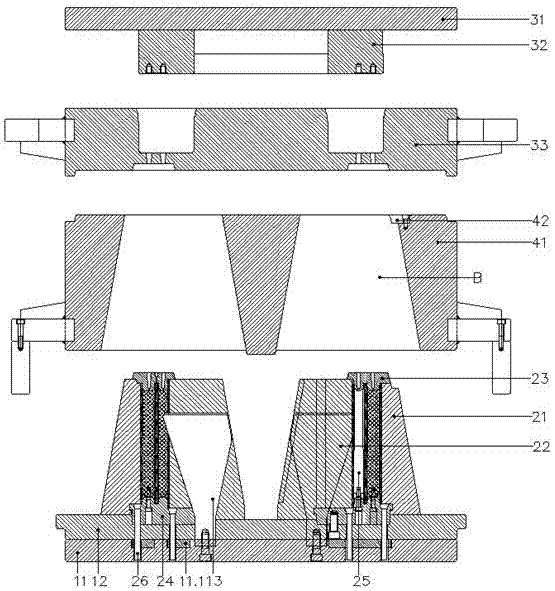

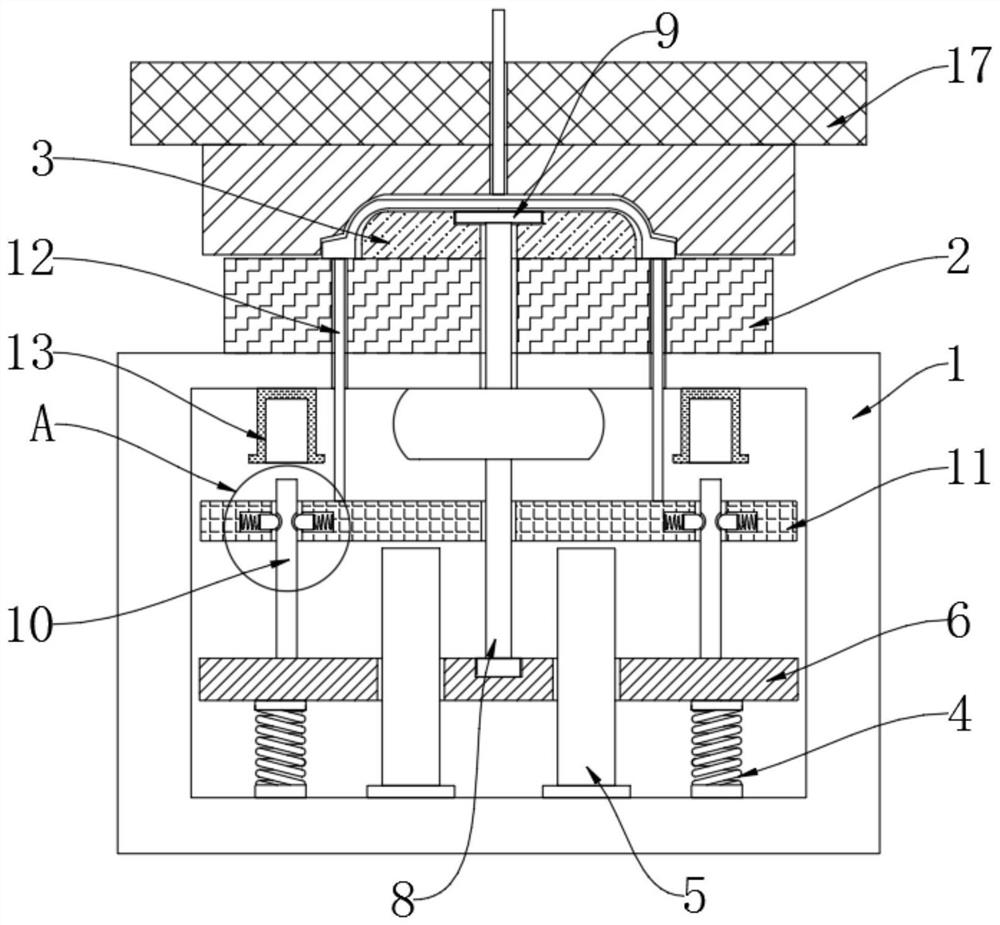

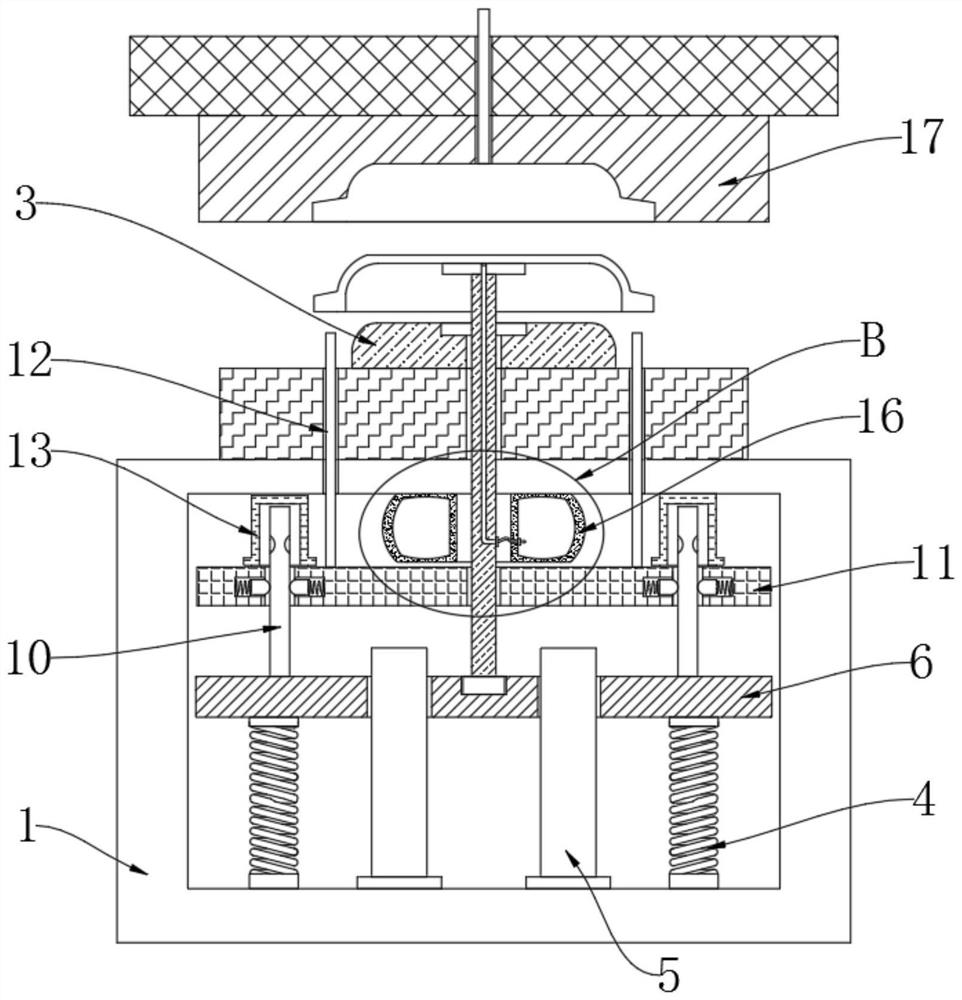

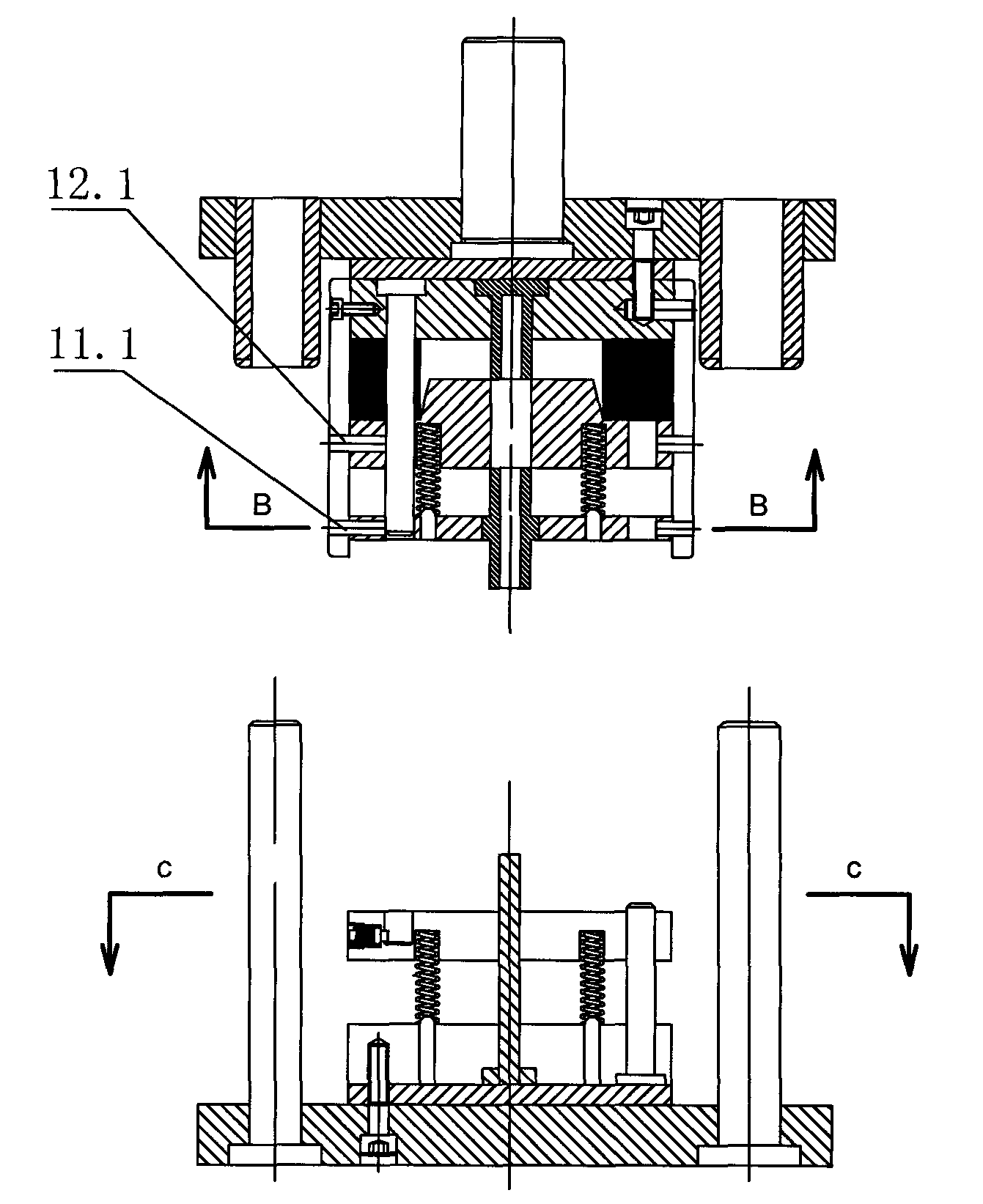

Bearing bush type gearbox elastic supporting automatic ejection die and automatic ejection method thereof

ActiveCN107139361AAchieve reverse movementRealize automatic demouldingVulcanizationPerpendicular direction

The invention discloses a bearing bush type gearbox elastic supporting automatic ejection die and an automatic ejection method thereof. The bearing bush type gearbox elastic supporting automatic ejection die comprises a bottom die assembly, a lower die assembly, an upper die assembly and a middle die assembly. The upper die assembly comprises a top plate, a glue injection stopper and a glue injection cylinder. The bottom die assembly comprises a bottom plate, a supporting plate and a cable-stayed plate. The lower die assembly comprises an outer-section die, an inner-section die, an upper insert, a lower insert, a die core and an ejection rod assembly. The lower insert is arranged between the outer-section die and the inner-section die, and a vulcanization cavity is formed by the lower insert, the outer-section die, the inner-section die and the upper insert. A glue injection hole is formed in the upper insert, and a die core is perpendicularly arranged in the vulcanization cavity, wherein the top of the die core makes contact with the upper insert. The lower insert is matched with the outer-section die and the inner-section die in the perpendicular direction in a draw hook manner. The ejection rod assembly penetrates the lower insert and the supporting plate and is inserted in the bottom plate. The outer-section die and the inner-section die are in conical fit with the cable-stayed plate. The cable-stayed plate penetrates the supporting plate and is fixed to the bottom plate. The middle die assembly is arranged between the supporting plate and the glue injection cylinder, and the lower die assembly is clamped in the middle die assembly.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

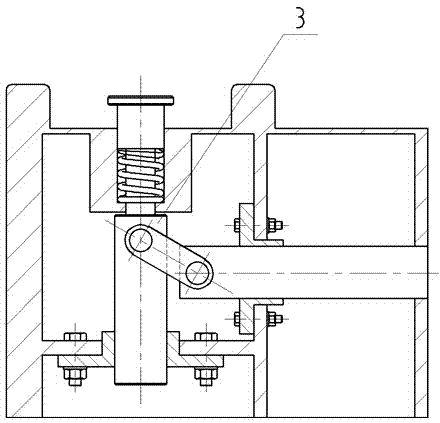

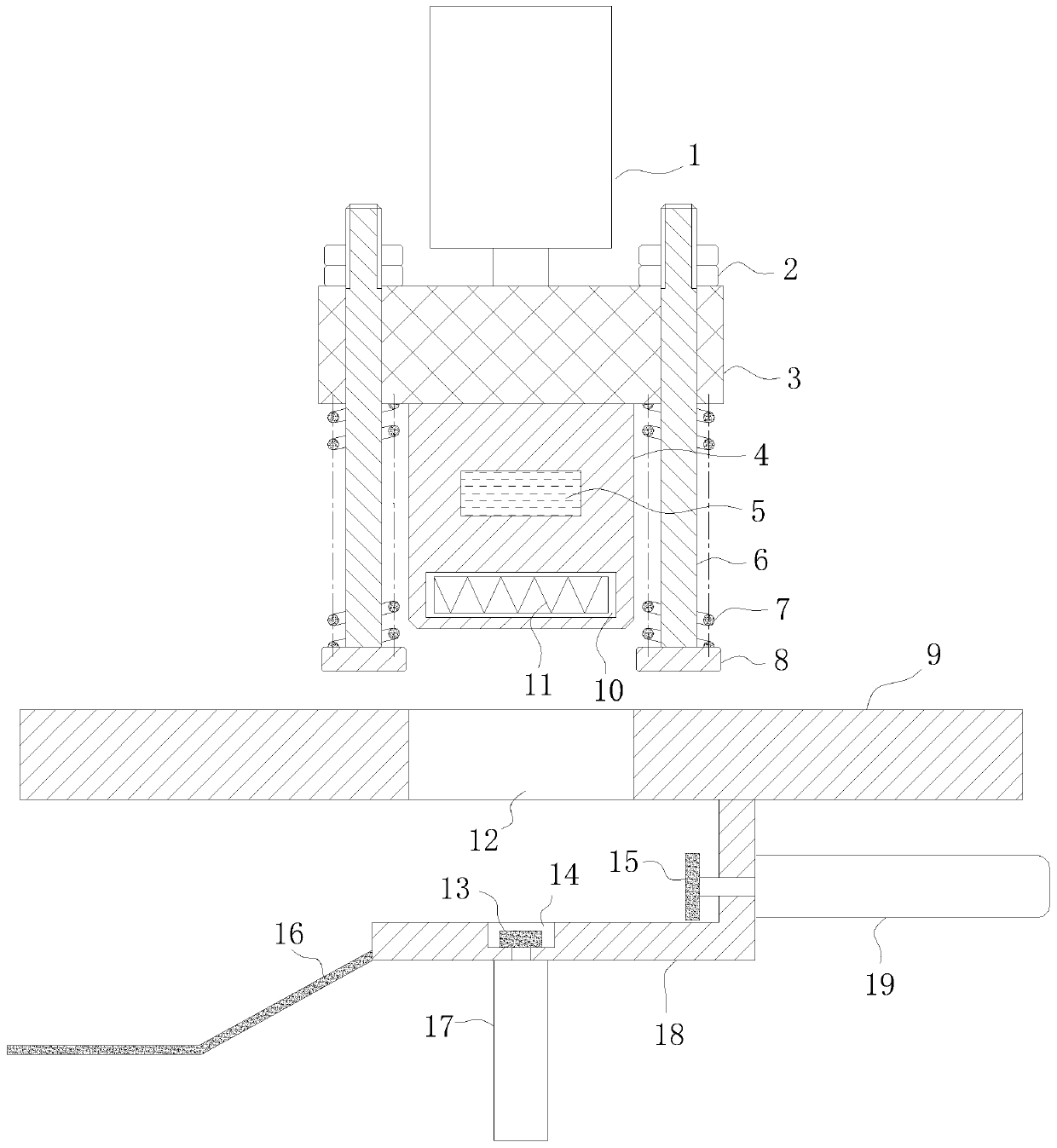

Concrete magnetic side form with form removal device

InactiveCN104328907AAvoid breakingImprove product qualityForming/stuttering elementsForm treatmentArchitectural engineeringPrecast concrete

The invention discloses a concrete magnetic side form with a form removal device, and the concrete magnetic side form is applied to the field of modern construction industry. The concrete magnetic side form consists of a side form body, a magnetic unit and the form removal device, wherein the magnetic unit and the form removal device are fixedly arranged in the side form body, the concrete magnetic side form can be fixedly arranged on a template tray, and the form removal device consists of a mandril cap, a spring, a vertical mandril, an intermediate connecting rod, a horizontal push rod, a push rod guide sleeve, a push rod pin shaft, a mandril pin shaft and a mandril guide sleeve. The horizontal push rod of the form removal device can be ejected out from the interior of the magnetic side form, and directly acts on a precast concrete component, the serious mold damage caused by form removal through dragging and beating is avoided, the precast concrete component damage caused by the form removal is avoided, the product quality of the precast concrete component is improved by virtue of the magnetic side form, meanwhile the form removal is convenient, automatic form removal of a manipulator is realized, the form removal time is effectively shortened, the labor efficiency of the form removal is improved, and the labor intensity of the form removal operation is lowered.

Owner:NORTHERN HEAVY IND GRP CO LTD

Electronic component manufacturing method

ActiveCN108198764AImprove sealingEasy to fixSemiconductor/solid-state device manufacturingElectronic componentInjection molding process

The invention belongs to the technical field of production of electronic products, and specifically relates to an electronic component manufacturing method. An injection mold is adopted to perform plastic package, and the injection mold includes a rack, a mold, a drainage mechanism and an air control mechanism. The steps of plastic package include A, prearranging gas; B, feeding; C, injection; D,cooling molding; and E, demolding. In Step A, a piston rod is pulled downward, so that gas enters into a cylinder; in Step B, chips are put at the bottom of a fixed groove, the piston rod is continuedto be pulled downward, and the chips are fixed; in Step C, molten plastic package resin is injected into the fixed groove from a drainage rod, and at the same time, the piston rod is continued to bepulled downward; in Step D, the piston rod is fixed, the mold is cooled, and the plastic package resin is molded; and in Step E, the piston rod and sliding racks move upward, and demolding is performed. By adoption of the scheme, rein can be effectively prevented from flowing to the bottoms of the chips in the injection molding process, the risk of a chip lead short circuit is reduced, and the product yield is improved.

Owner:重庆市长寿区普爱网络科技有限公司

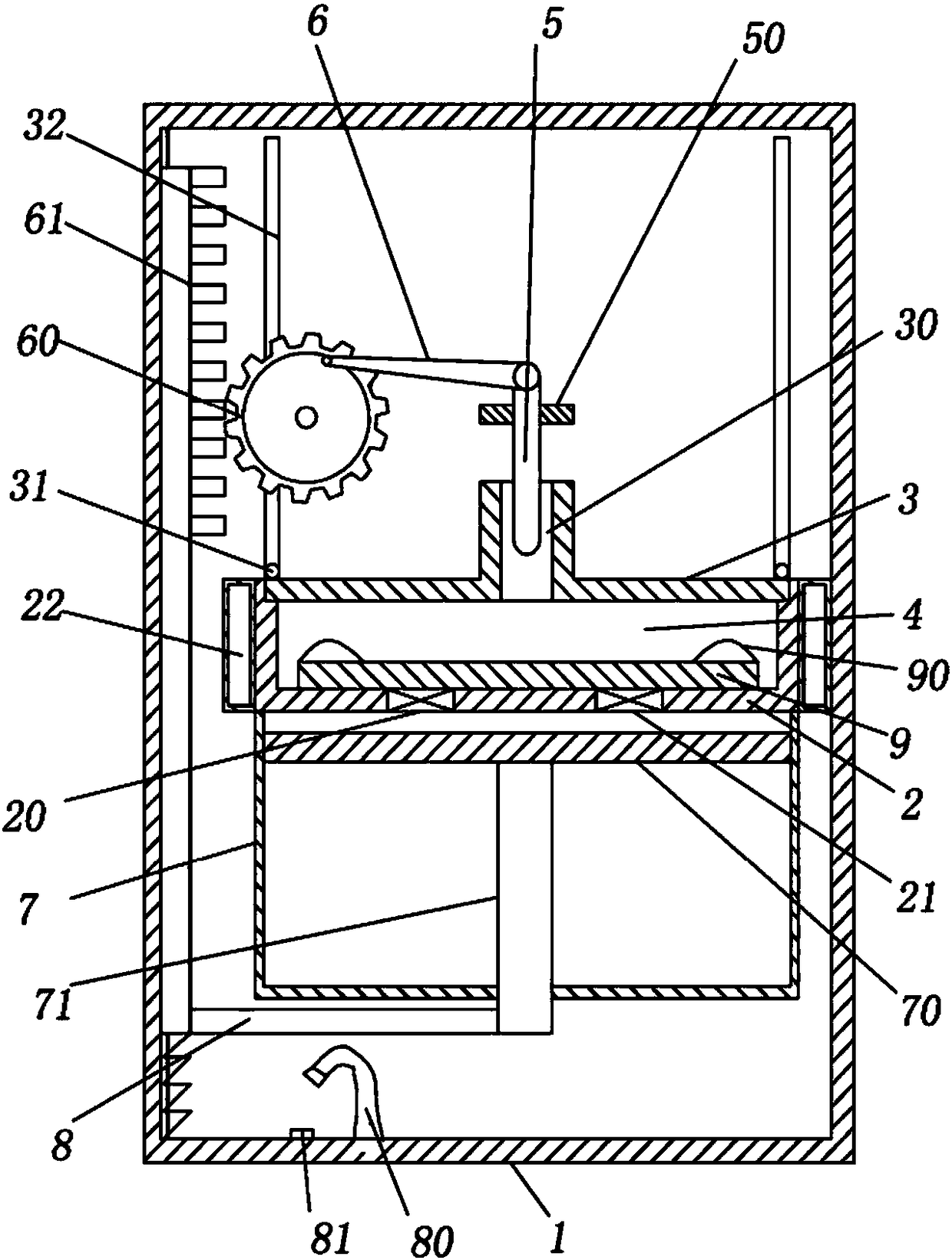

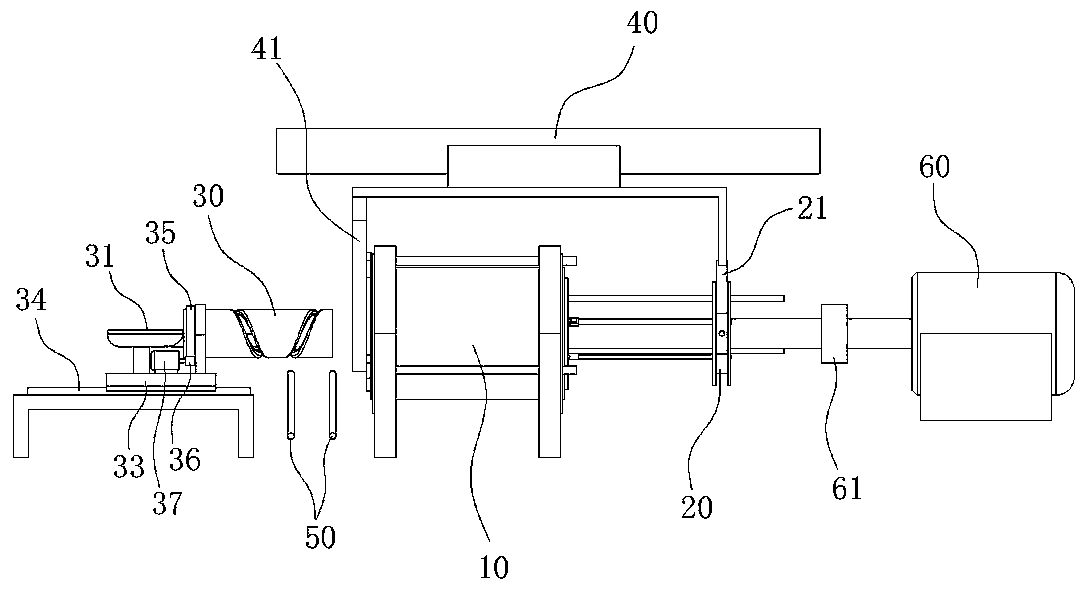

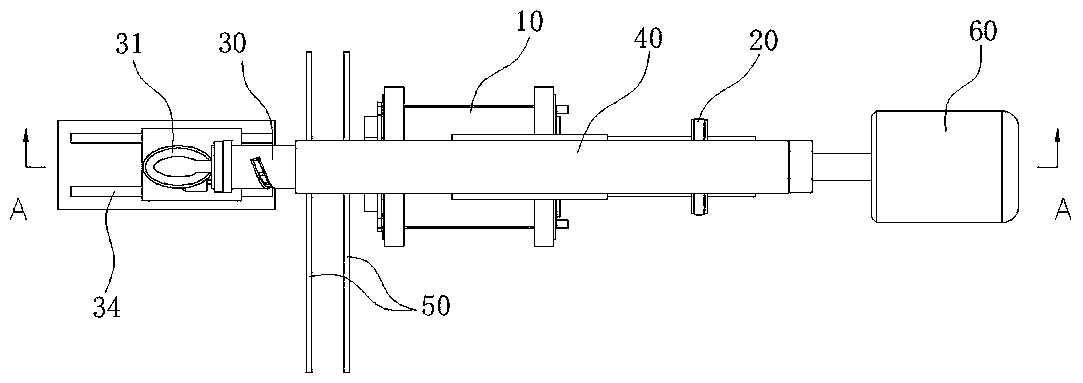

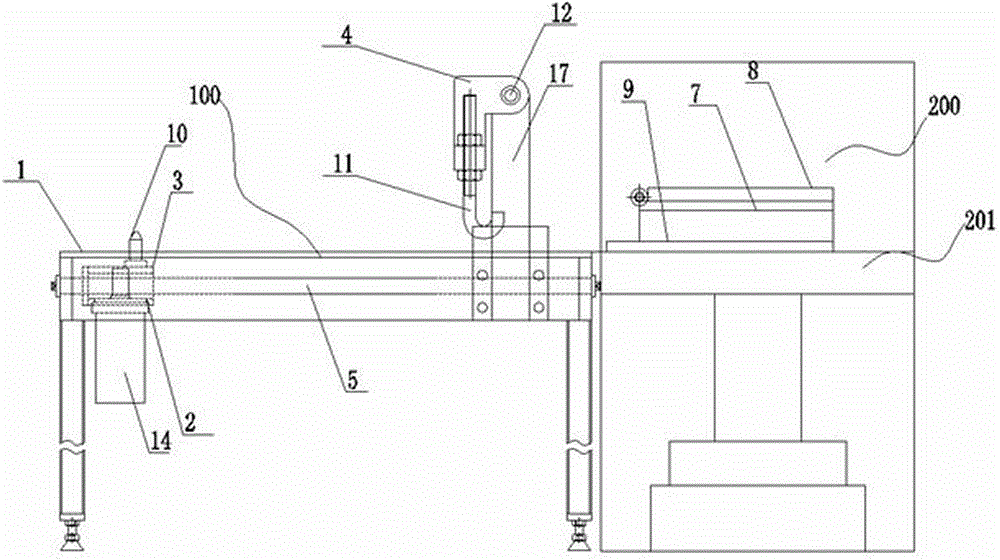

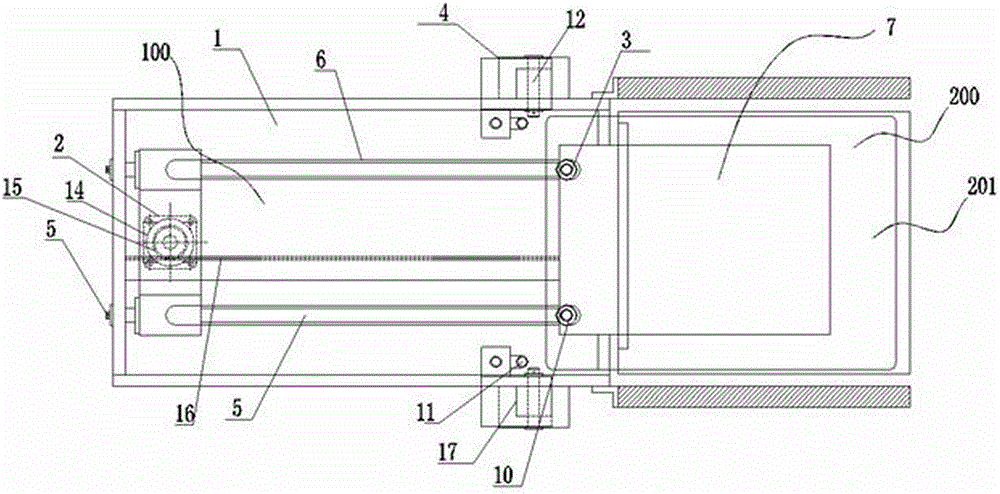

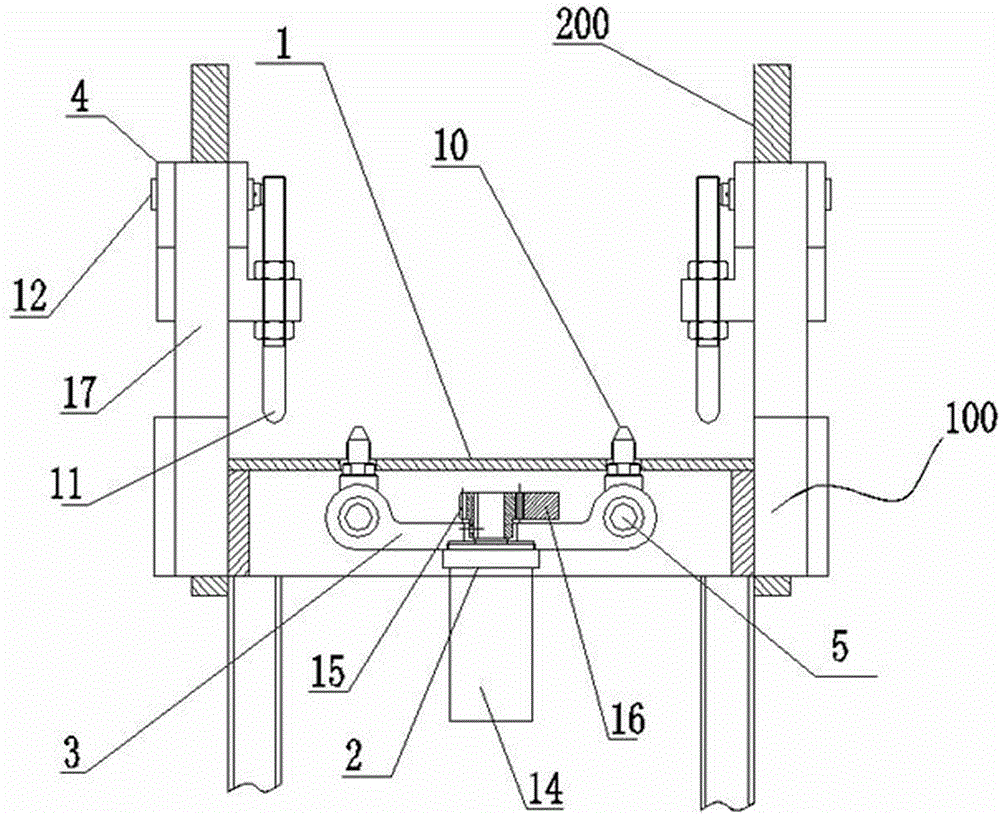

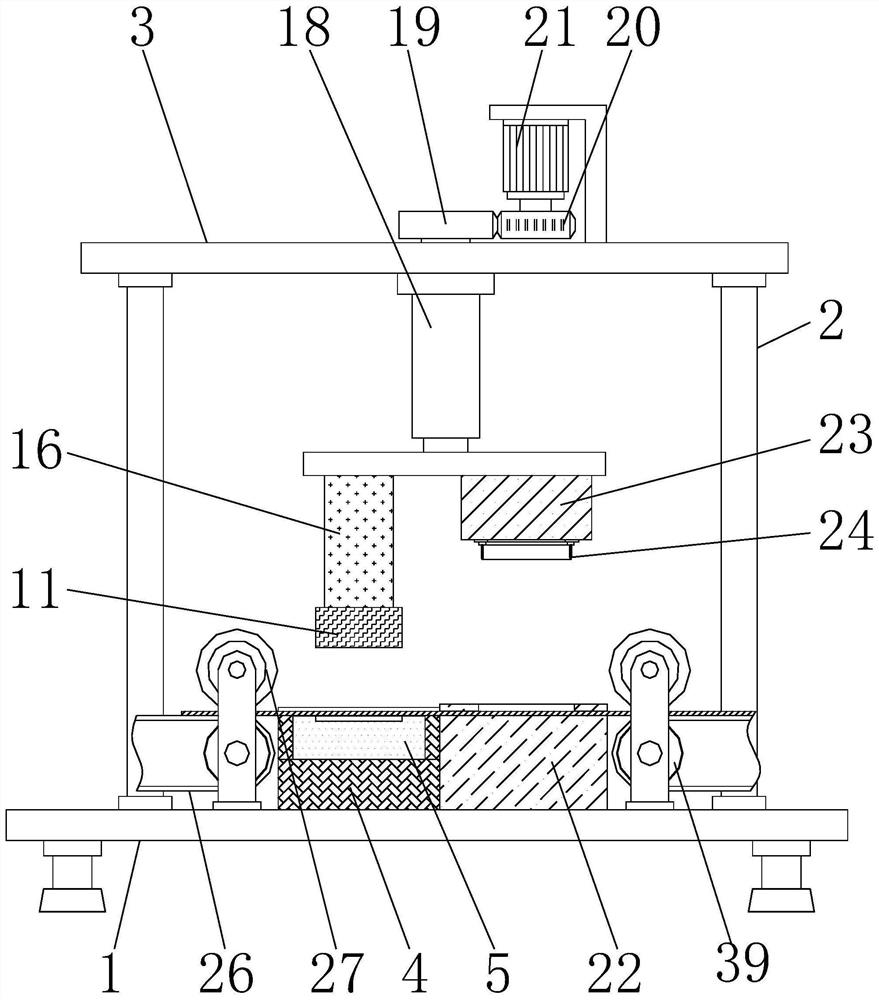

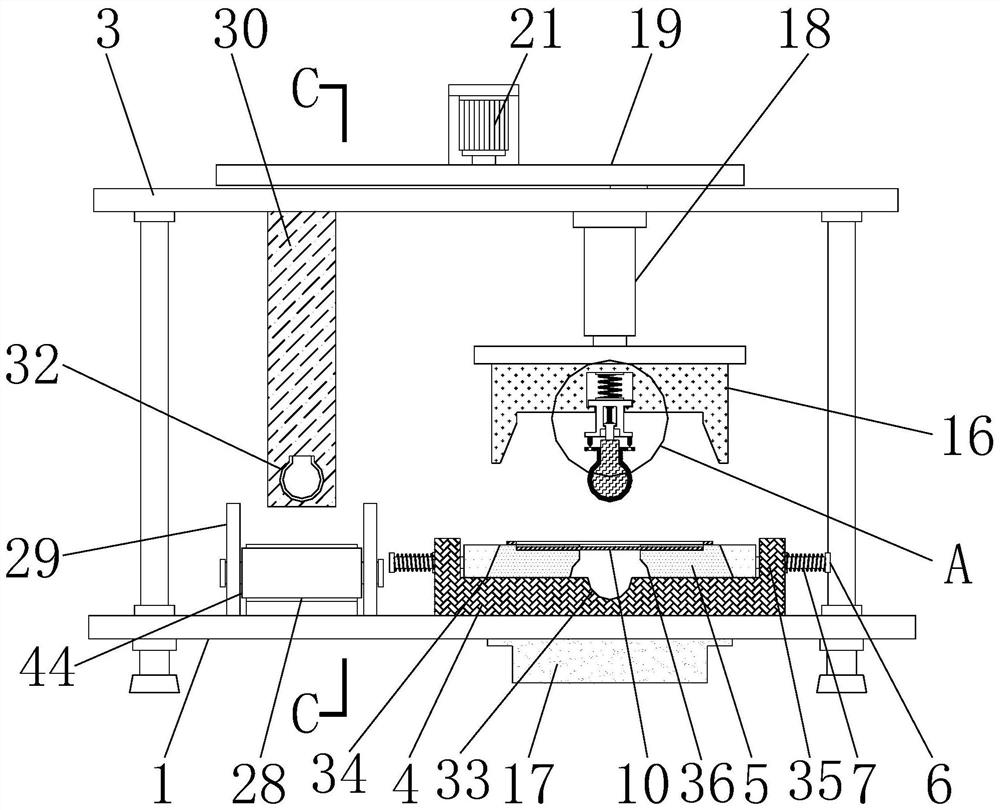

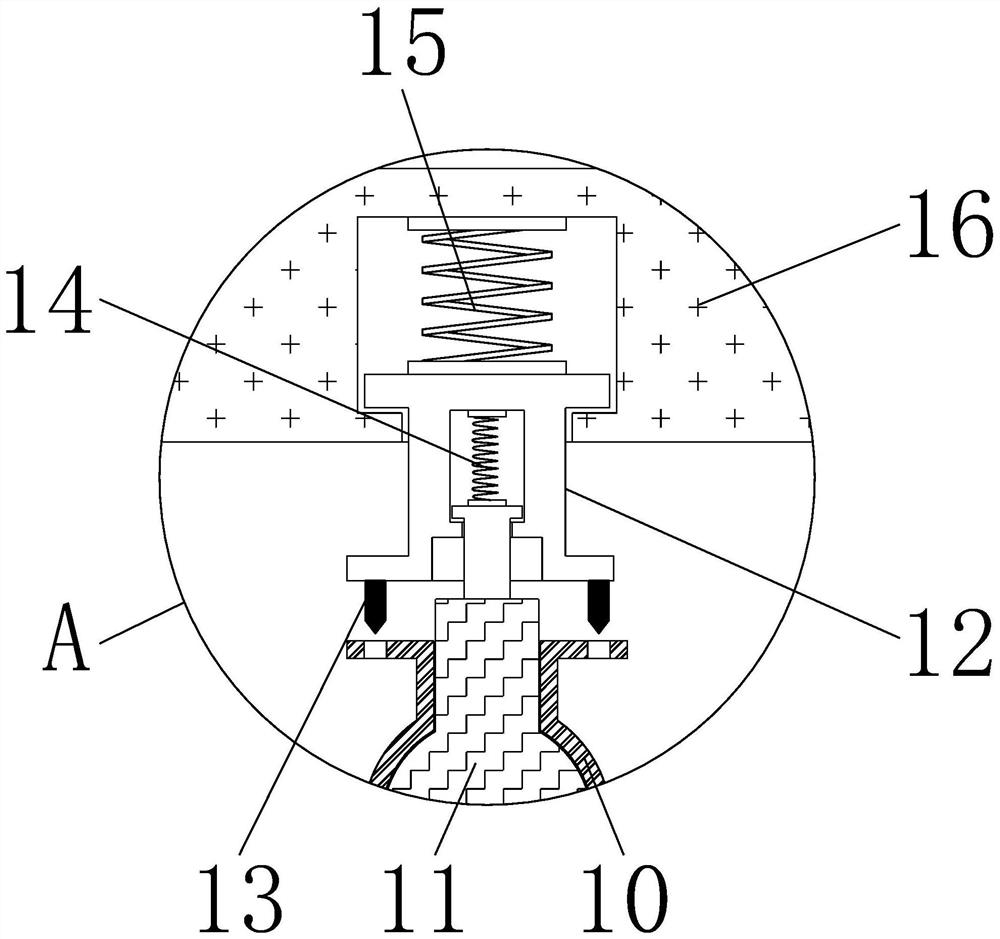

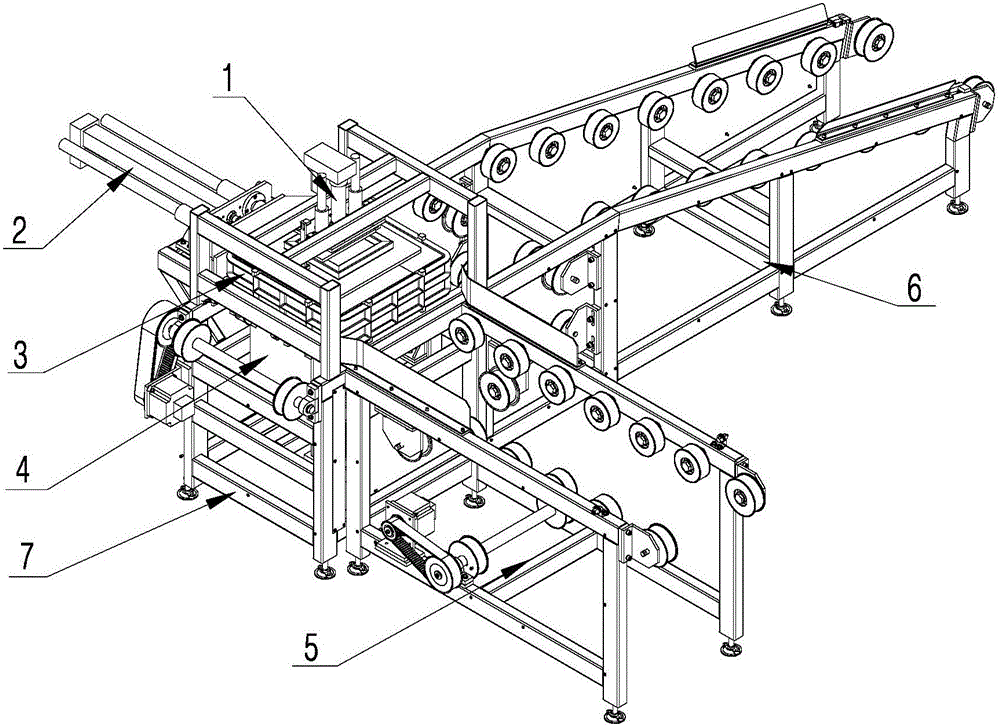

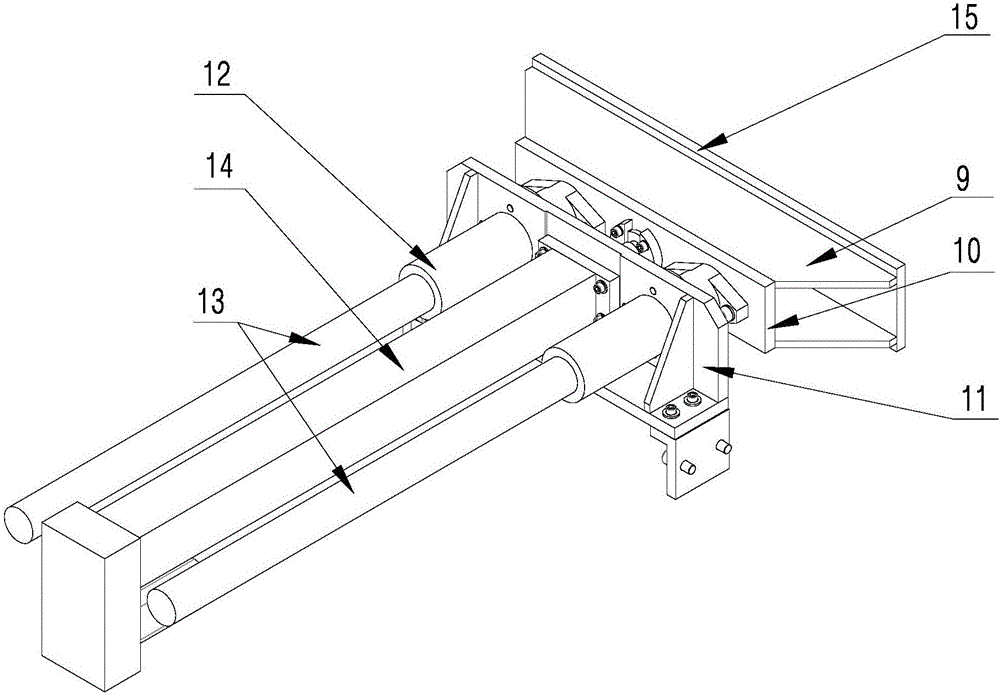

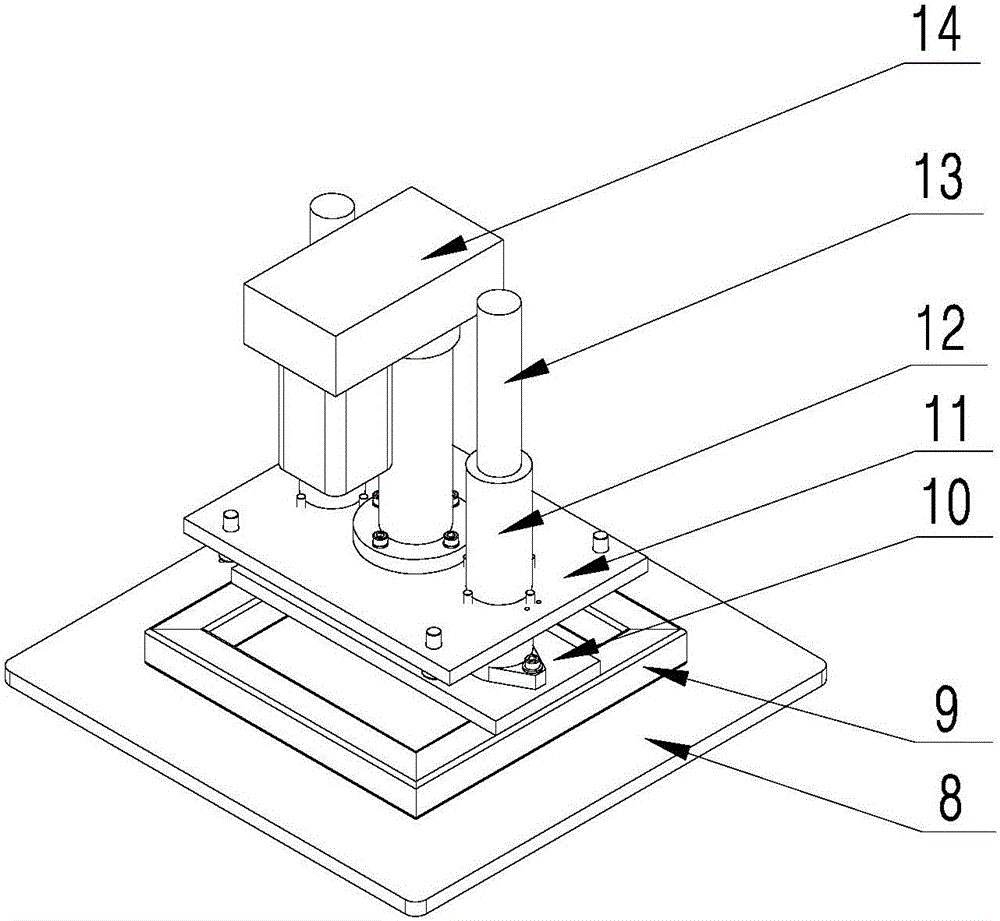

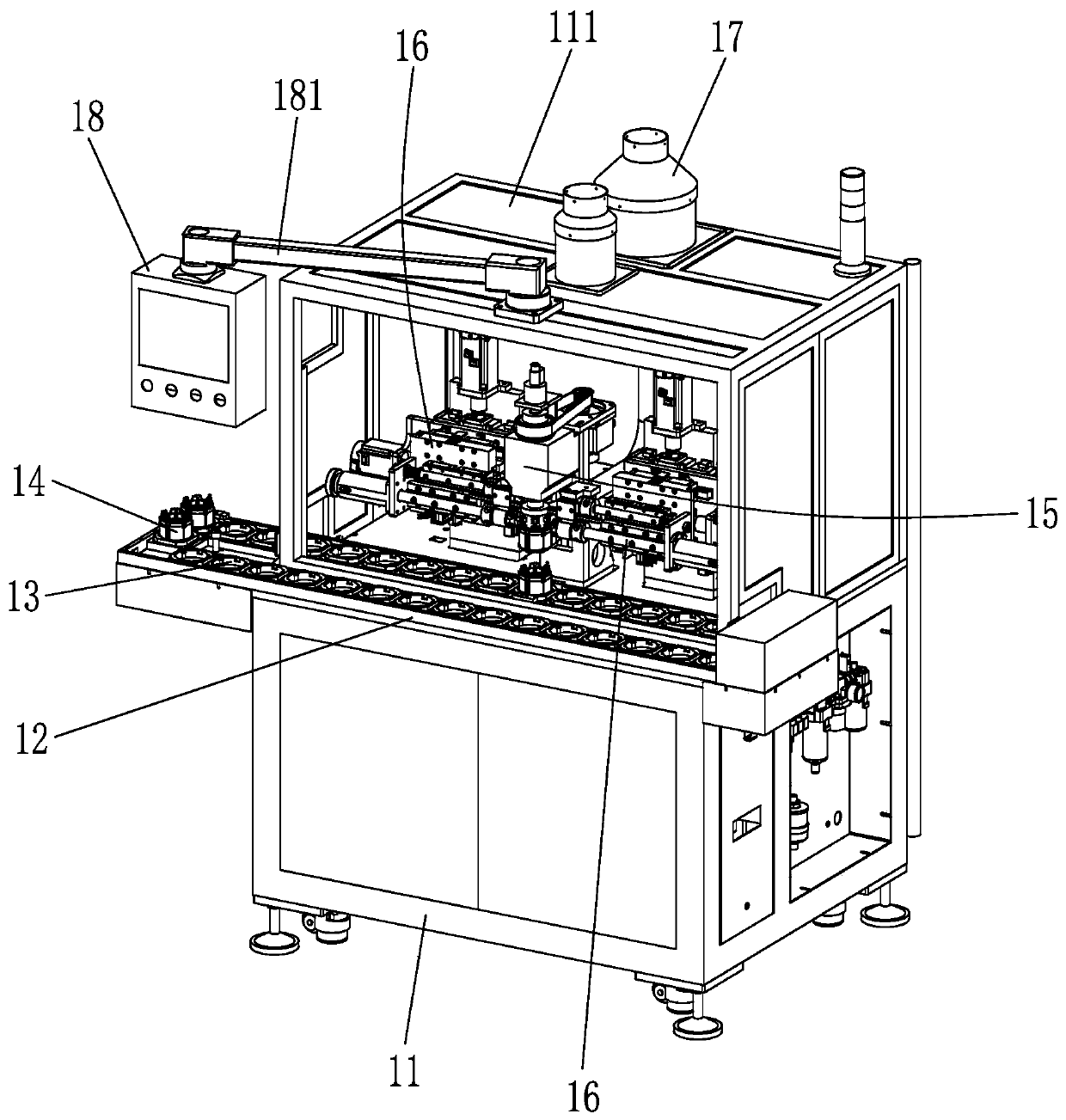

Automatic demoulding device of multi-station die-casting machine

The invention discloses an automatic demoulding device of a multi-station die-casting machine. The automatic demoulding device comprises the die-casting machine, a multi-station mould and a demoulding device body; a feeding device is arranged between the die-casting machine and the demoulding device body, and comprises a rack erected above the die-casting machine and the demoulding device body; a sliding mechanism is arranged on the rack in the feeding direction, and a grabbing mechanism is arranged at the lower end of the sliding mechanism; the demoulding device comprises a working table, and a vertically-through mould base which is matched with the multi-station mould is fixed to the working table; a vertical pushing mechanism is arranged below the mould base; a material pushing mechanism is arranged on one side above the mould base, and a material receiving mechanism is arranged on the other side above the mould base; and a horizontal pushing mechanism is fixed to the position, corresponding to the mould base, of the working table. The feeding device and the demoulding device body are arranged, and therefore the multi-station die-casting machine can achieve automatic demoulding of a casting; and potential safety hazards are reduced, manpower resources are saved, and the working efficiency is improved.

Owner:宁波耐达机械设备有限公司

Vehicle punching mold convenient to demold

InactiveCN110681772AReduce resistanceRealize automatic demouldingShaping toolsEjection devicesPunchingStructural engineering

The invention relates to the technical field of punching equipment, in particular to a vehicle punching mold convenient to demold. The vehicle punching mold comprises a punching base plate, a punchinggroove, a hydraulic driving mechanism, a convex mold, a fixed base, a slide column, a nut, an ejector block and an elastic piece. The vehicle punching mold convenient to demold has the following beneficial effects: after punching, through ejection of the ejector block by the elastic piece, punched parts sleeving the convex mold are ejected out of the convex mold by the ejector block, so that theautomatic demolding of the punched parts is realized; meanwhile, under ejection by the elastic piece, the ejector block can be leant against the edges of punched positions of the punched parts, so that the warpup and deformation phenomenon of the edges of the punched positions of the punched parts is reduced to at least a certain extent; and a high-frequency induction heating coil is provided andelectrified to quickly generate high temperature, so that the edges of the punched positions of the punched parts are quickly heated, the resistance suffered by the convex mold in the punching processis reduced, the punching efficiency is conveniently improved, and the damage to punching equipment is reduced.

Owner:HEFEI CHANGQING MACHINERY

Automatic demolding transformer shell profiling device for new energy automobile

InactiveCN109365669ARealize automatic demouldingImprove processing efficiencyPressesEjection devicesTransformerNew energy

The invention discloses an automatic demolding transformer shell profiling device for a new energy automobile. The automatic demolding transformer shell profiling device comprises a lower mold, an upper mold located above the lower mold, and a first driving mechanism which is used for driving the upper mold to move up and down so that the upper mold and the lower mold can cooperate to carry out mold opening / closing action, wherein the upper mold is internally provided with an air channel, and the side, close to the lower mold, of the air channel communicates with the outside world; and the upper mold is provided with a negative pressure generator which communicates with the air channel so that the interior of the air channel can generate negative pressure. According to the automatic demolding transformer shell profiling device, a workpiece can be directly taken out of a cavity by moving the upper mold upwards so that automatic demolding can be achieved.

Owner:合肥森隆环保科技有限公司

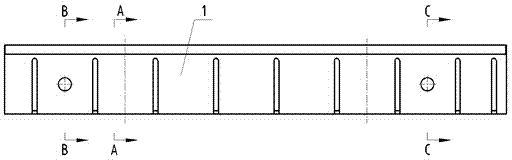

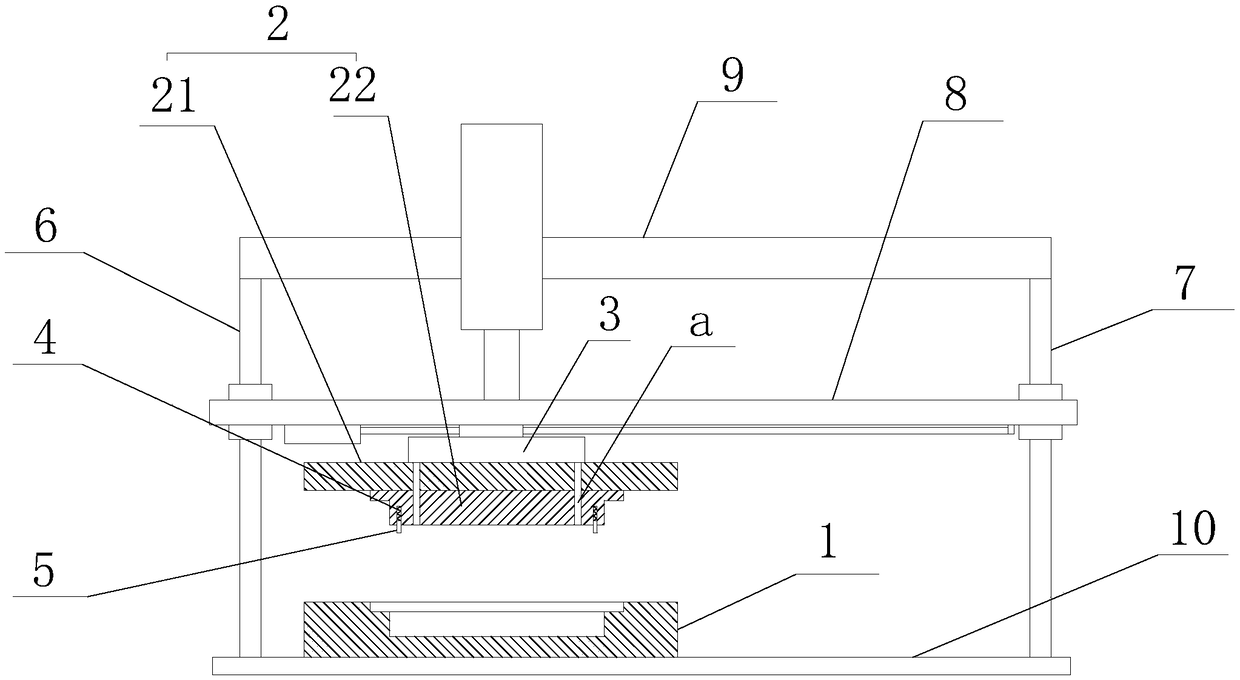

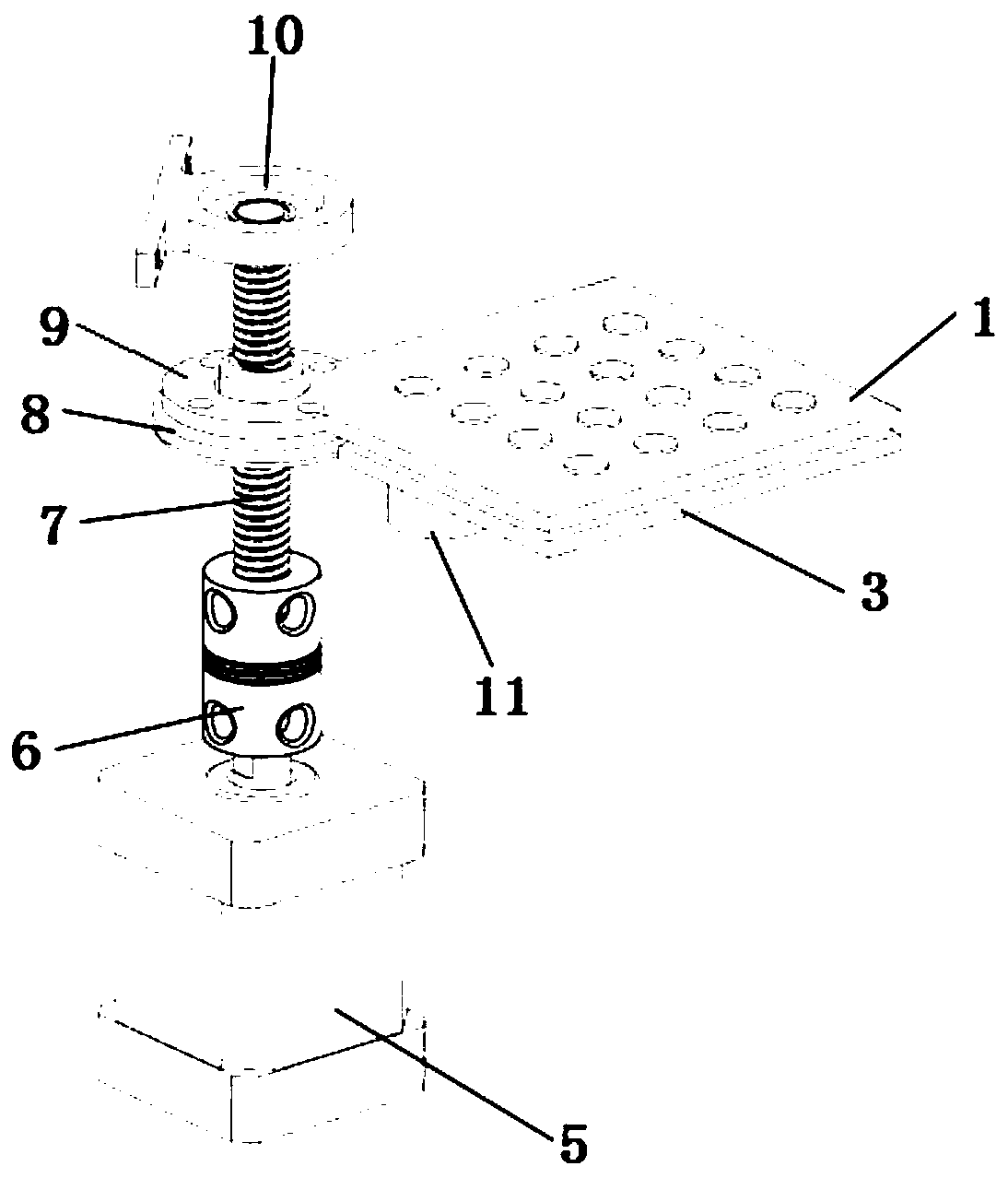

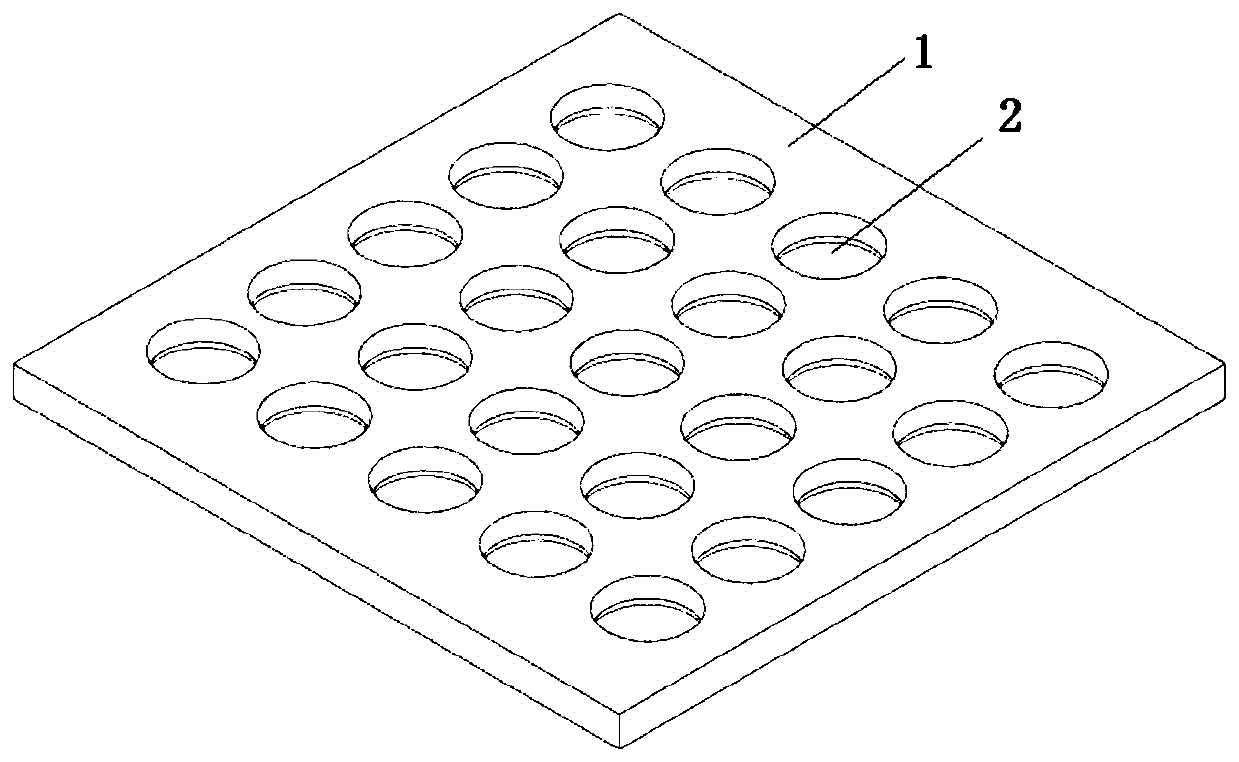

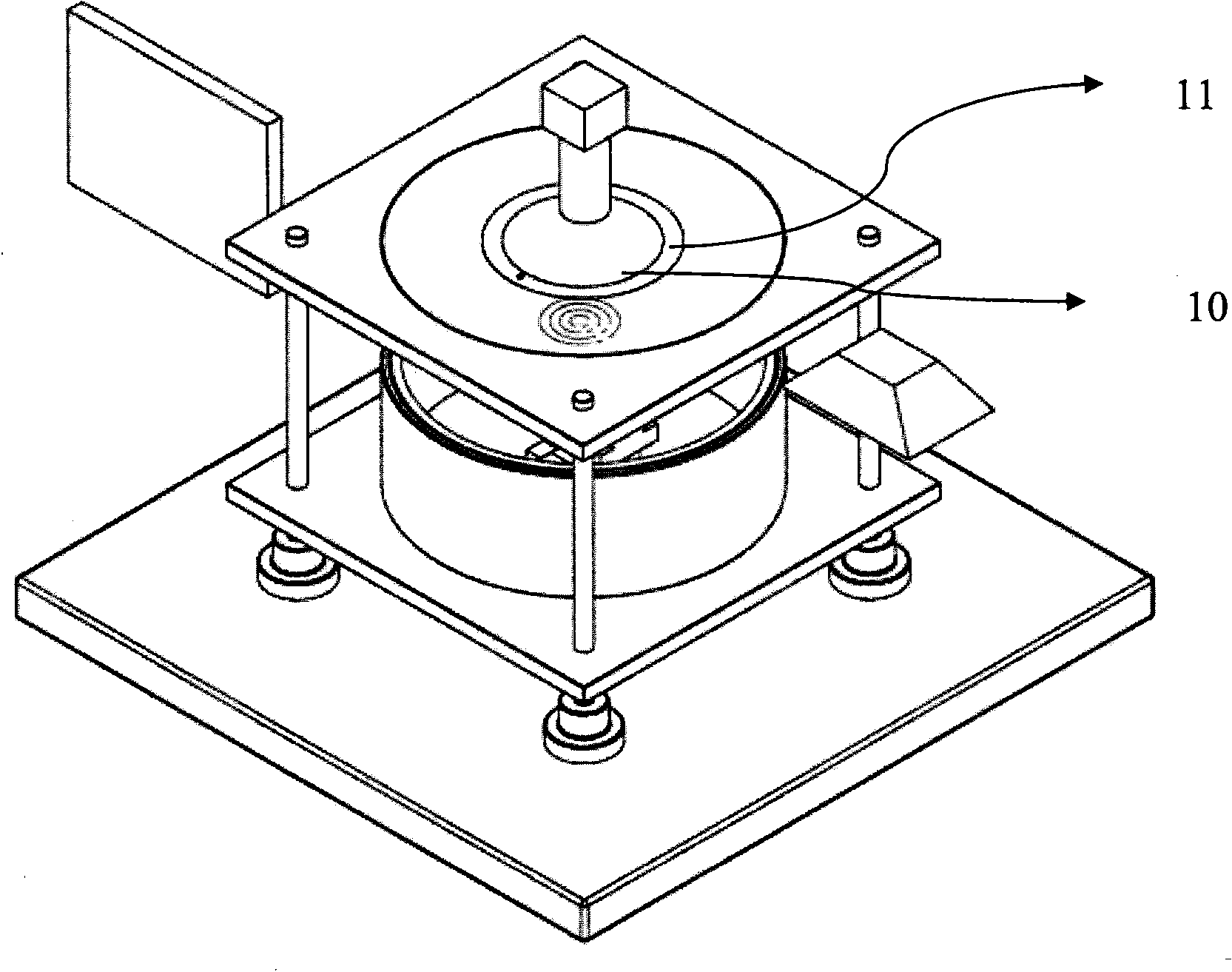

3D printing hot bed capable of achieving automatic demolding

InactiveCN111002586AImprove demoulding efficiencyReduce scrap rateManufacturing platforms/substratesManufacturing heating elementsEngineeringMechanical engineering

The invention relates to a 3D printing hot bed capable of achieving automatic demolding. The 3D printing hot bed comprises an upper hot bed horizontally arranged, a lower hot bed horizontally arrangedunder the upper hot bed, and a lifting driving device used for driving the upper hot bed and the lower hot bed to move up and down relatively. A plurality of through holes in the vertical direction are uniformly formed in the upper hot bed, columnar protrusions which are equal to the through holes in number and matched with the through holes in a one-to-one correspondence mode are integrally andvertically arranged on the upper end face of the lower hot bed, the top faces of the columnar protrusions are equal in height, the height of the columnar protrusions is larger than the thickness of the upper hot bed, and when the top faces of the columnar protrusions align at the upper end face of the upper hot bed, a complete printing bed face is formed. An existing single hot bed structure is improved into a split structure, the upper hot bed and the lower hot bed are matched with each other, the lifting driving device drives the upper hot bed and the lower hot bed to move up and down relatively, so that automatic demolding is achieved. According to the 3D printing hot bed, the demolding efficiency can be greatly improved, and the rejection rate is reduced. The 3D printing hot bed is particularly suitable for large-scale additive manufacturing.

Owner:NANJING INST OF TECH

Die for flaring of pipe fitting

PendingCN109622787AImprove efficiencyIncrease productivityShaping toolsEjection devicesEngineeringMachining

The invention discloses a die for flaring of a pipe fitting, relates to the technical field of dies, and solves the problems that a common pipe fitting is easily clamped with a stamping head, the clamped pipe fitting needs to consume a lot of time and energy of the workers during demoulding, and the machining efficiency of an enterprise can be dramatically reduced due to the large-batch to-be-machined pipe fitting. According to the technical scheme, a die body is arranged between an upper template and a lower template, the die body includes a convex die and a concave die, a stamping head is fixedly arranged on the convex die, a stripping plate in elastic connection with the convex die is in sliding connection between the convex die and the concave die, a machining through hole is formed inthe position, in the axial direction of the stamping head, of the concave die, a third guiding column is arranged between the concave die and the lower template, the outer wall of the third guiding column is in sliding connection with an ejecting plate, a die core is arranged on the ejecting plate, the die core is in sliding connection within the machining through hole. The purposes that by achieving the automatic demoulding of the pipe fitting, the efficiency of the flaring machining of the large-batch pipe fitting can be conveniently improved, and the flaring yield of the pipe fitting can be further improved are achieved.

Owner:佛山市景和汽配有限公司

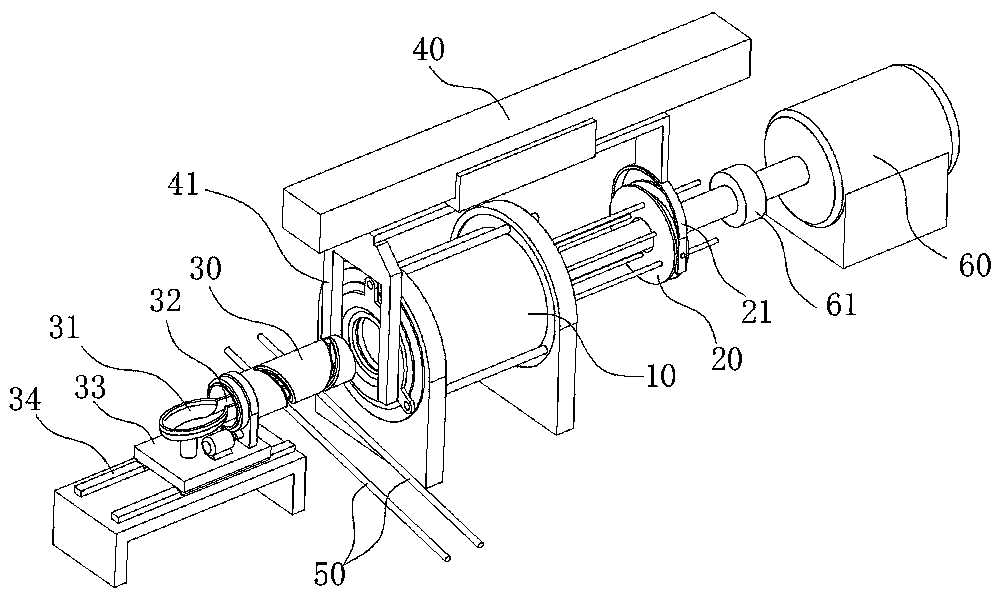

Cylinder sleeve centrifugal casting machine

The invention belongs to the technical field of automobile part casting machining, and particularly relates to a cylinder sleeve centrifugal casting machine. The cylinder sleeve centrifugal casting machine comprises a casting unit and a centrifugal unit, wherein the centrifugal unit comprises a cylindrical mold body rotationally arranged along the horizontal axis; the casting unit is used for guiding casting liquid into the cylindrical mold body and is movably arranged in the axial direction of the cylindrical mold body; the centrifugal unit comprises a demolding device; the demolding device is used for ejecting a formed cylinder sleeve out of the cylindrical mold body; and a cylinder sleeve guiding-out device is further arranged below the outer side of a casting channel and used for guiding, conveying and collecting the ejected cylinder sleeve. According to the cylinder sleeve centrifugal casting system, a first end plate and a second end plate are arranged to be of a movable structure, after the cylinder sleeve is formed, the first end plate is used for ejecting the cylinder sleeve out of a mold, automatic demolding of a casting is achieved, and the cylinder sleeve casting machining efficiency is improved.

Owner:ANHUI PROVINCE YUEXI CYLINDER

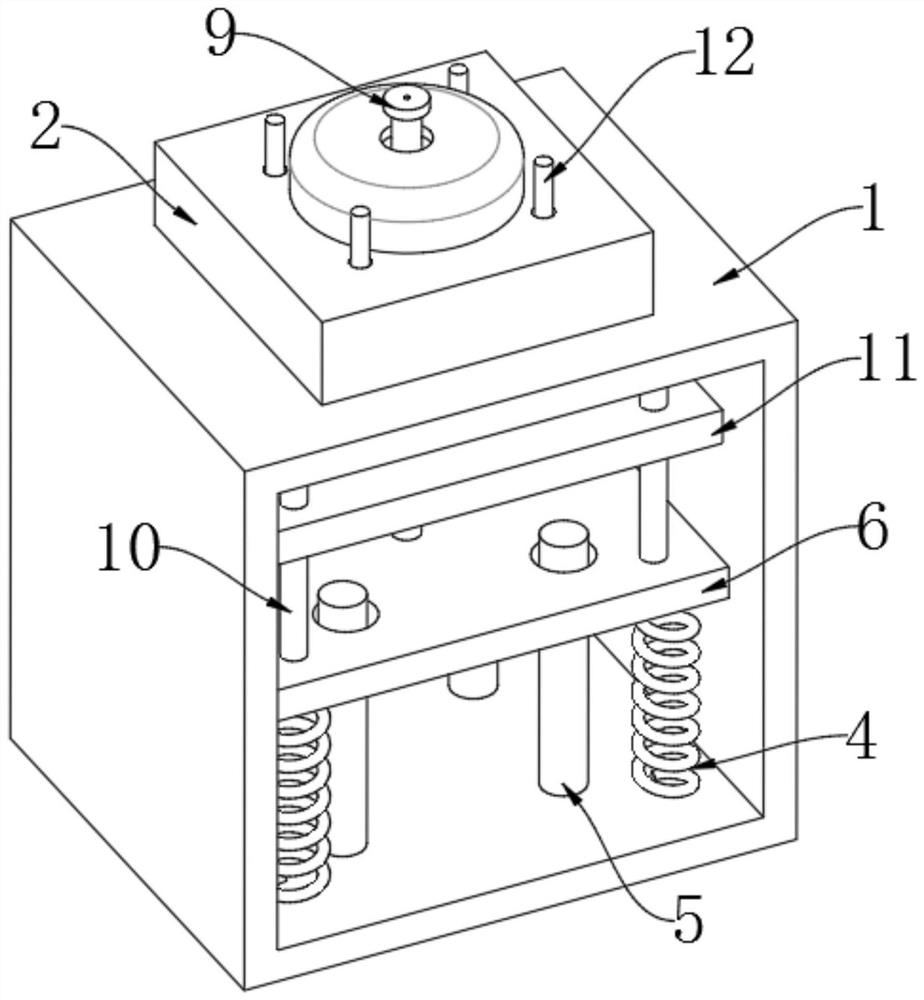

Secondary ejection structure for mould

InactiveCN113386313AAvoid unautomated demouldingRealize the effect of the second top moldStructural engineeringInjection moulding

The invention discloses a secondary ejection structure for a mould, which comprises a movable mould assembly and a fixed mould frame; a fixed mould mounting block is fixedly mounted on the upper surface of the fixed mould frame through bolts; a fixed mould core is fixedly connected to the upper surface of the fixed mould mounting block; and the inner bottom wall of the fixed mould frame is fixedly connected with four compression springs and sliding guide columns respectively. According to the secondary ejection structure for the mould provided by the invention, through the arrangement of a first push plate, a first ejector rod, a second push plate and a second ejector rod, after injection moulding is completed, when the movable mould assembly ascends and is separated from the fixed mould core, the first push plate and the second push plate are driven to move upwards under the resilience force action of the compression spring; meanwhile, the first ejector rod and the second ejector rod are driven to complete two times of ejection operation in sequence, so that the effect of secondary mould ejection is achieved; the situation that a workpiece cannot be completely ejected out of a mould core due to traditional single mould ejection is avoided; manual assistance is not needed; automatic remoulding is achieved; and the machining efficiency is improved.

Owner:鲲彤智能科技(芜湖)有限公司

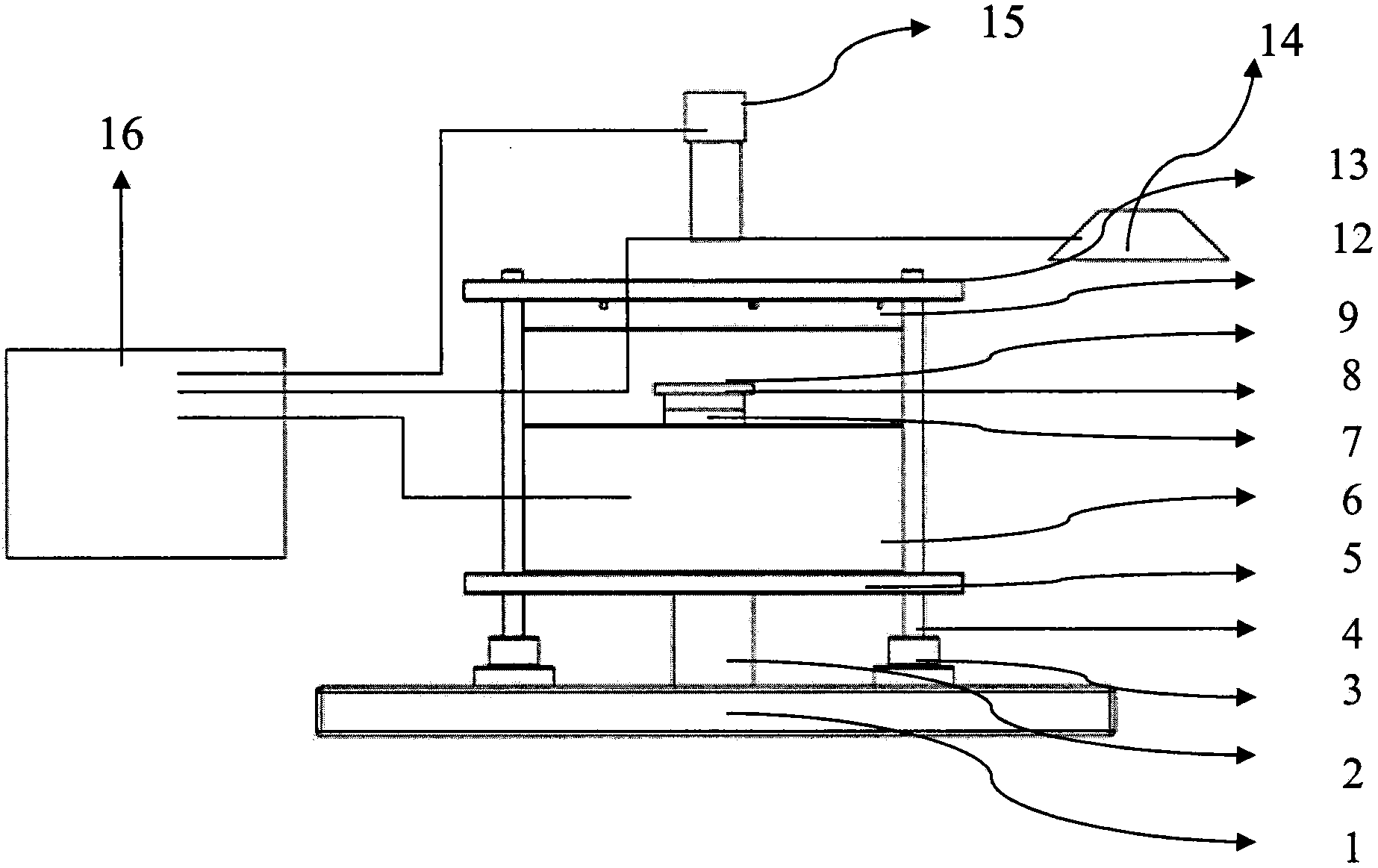

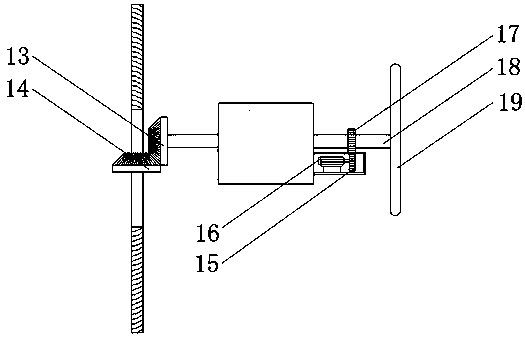

Alignment type automatic de-molding ultraviolet nano impressing device and method

InactiveCN103926790AEasy to eliminateGuaranteed fidelityPhotomechanical apparatusControl systemUltraviolet lights

The invention relates to an alignment type automatic de-molding ultraviolet nano impressing device and a method. The alignment type automatic de-molding ultraviolet nano impressing device mainly comprises following mechanisms: a marble shock absorption platform, a Z-axis platform, a directed guide rod base, a guide rod, a lower cavity fixing bottom plate, a lower cavity, an XYZT four-axis platform, a base fixing platform, a wafer coated with an anti-etching agent, an impressing template, an impressing head, an upper cavity, an impressing head supporting base, an ultraviolet light source and an alignment mechanism. With the adoption of a movement mechanism, an optical system, the alignment mechanism, a control system and the like, a pattern of the impressing template is transferred to the wafer coated with the anti-etching agent.

Owner:李宁 +1

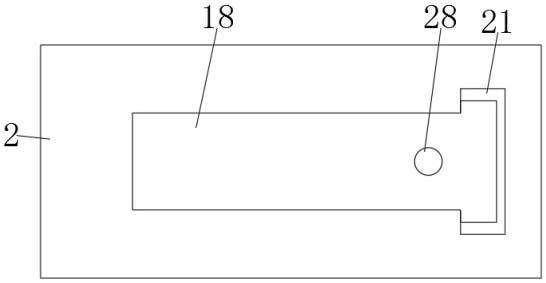

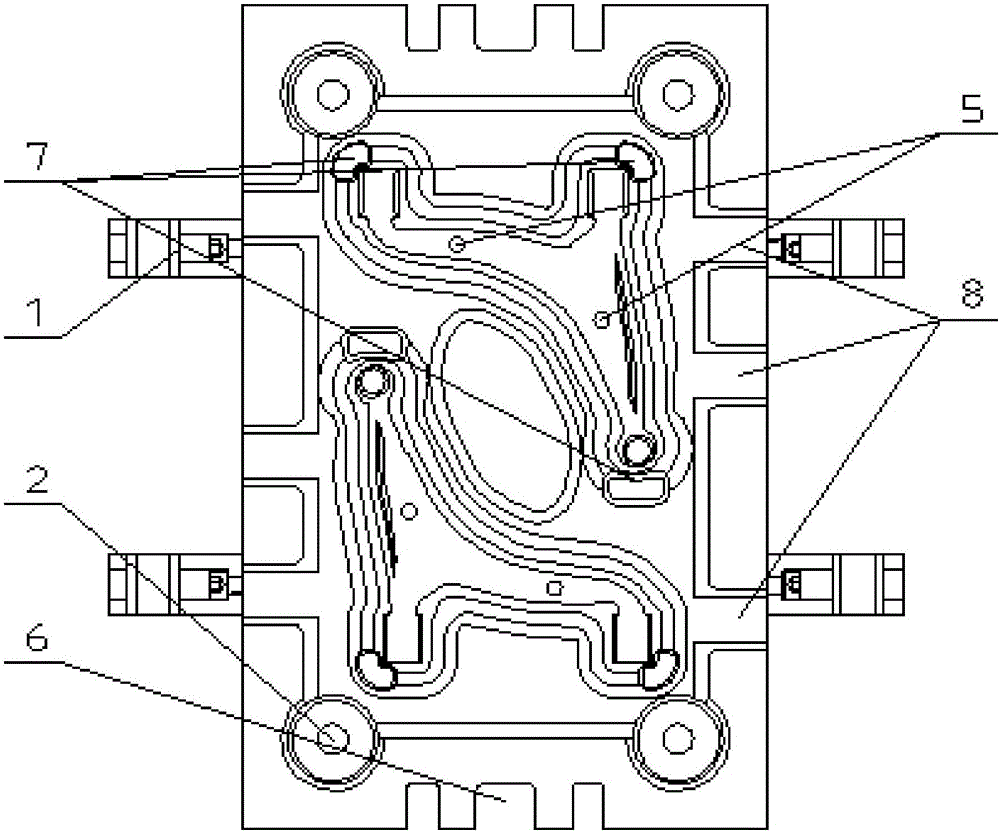

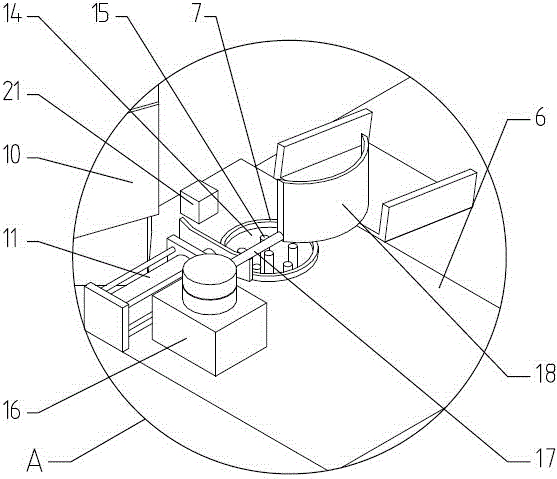

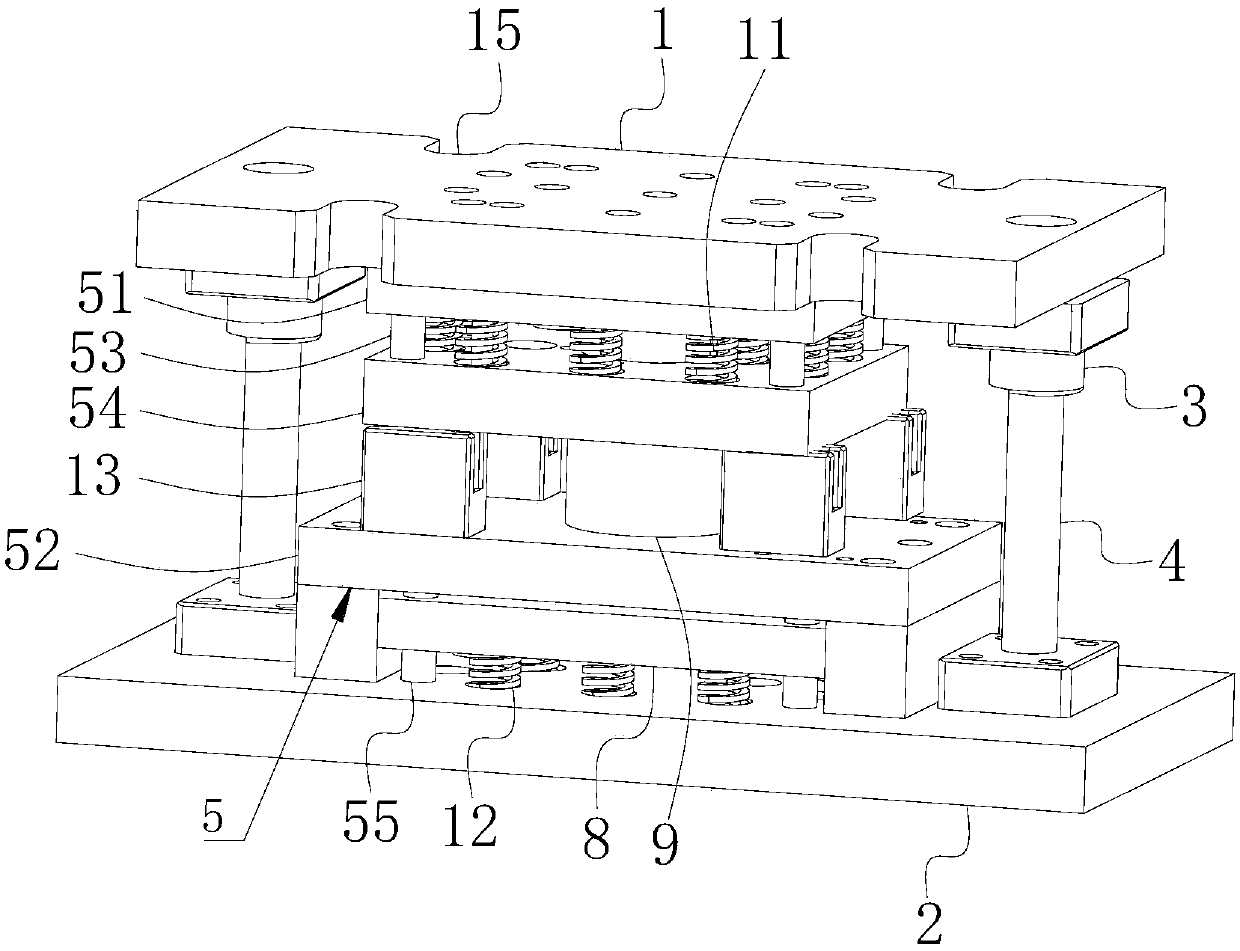

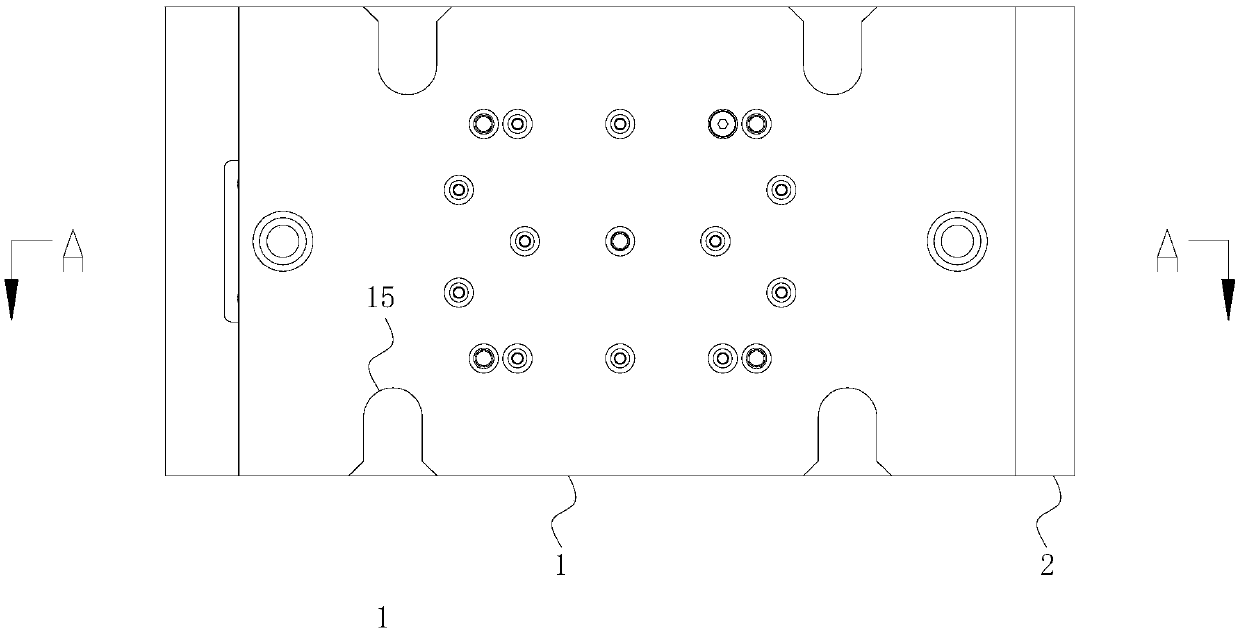

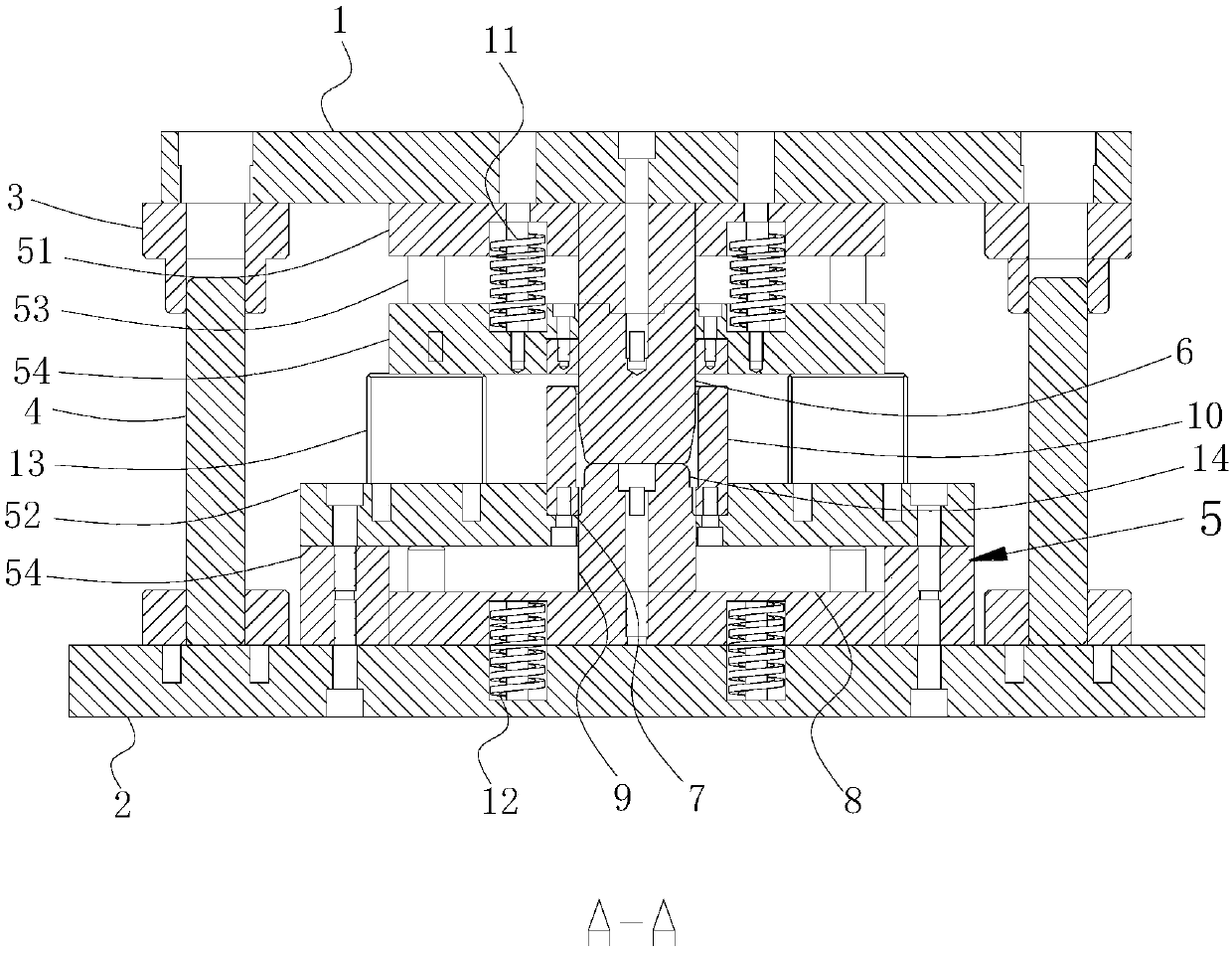

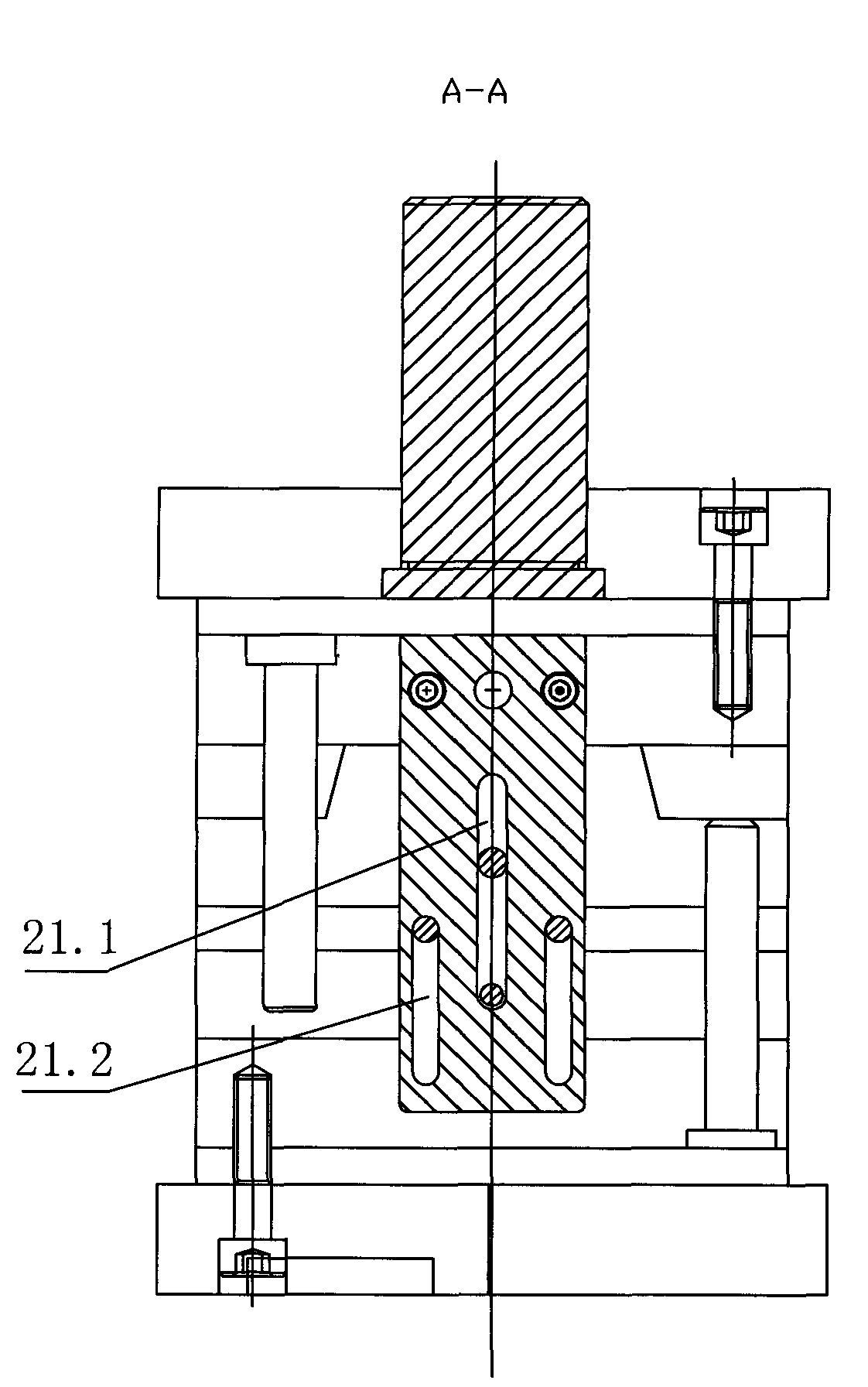

Cold extrusion mould for double-head pipe joint

The invention discloses a novel cold extrusion mould for a double-head pipe joint, which comprises an upper mould (1), a lower mould plate (2), guide posts (3), guide sleeves (4), bolts (5), screw nails (6) and a shank (7), wherein the cavity cross section of a medium mould sleeve (11) is pentagonal; ejection devices are arranged between a lower mould fixing plate (9) and a lower mould sleeve (10) and between a medium mould sleeve (11) and an upper mould sleeve (12); the right and left sides of an upper mould fixing plate (14) are fixed with supporting plates (21); the right and left supporting plates (21) extend downwardly and are respectively arranged at the left and right sides of the upper mould sleeve (12), the medium mould sleeve (11) and the lower mould sleeve (10); and the supporting plate (21),is matched with the upper mould sleeve (12), and the medium mould sleeve (11) in a sliding manner and connected with each other. The invention has high production efficiency and can automatically demould.

Owner:NANTONG JINDE STEEL STRUCTURE CO LTD

Sole manufacturing equipment with automatic die taking and die sinking capability

InactiveCN106273159AReduce labor intensityReduce worker laborDomestic articlesManufacturing engineering

Owner:SICHUAN YUANXING RUBBER

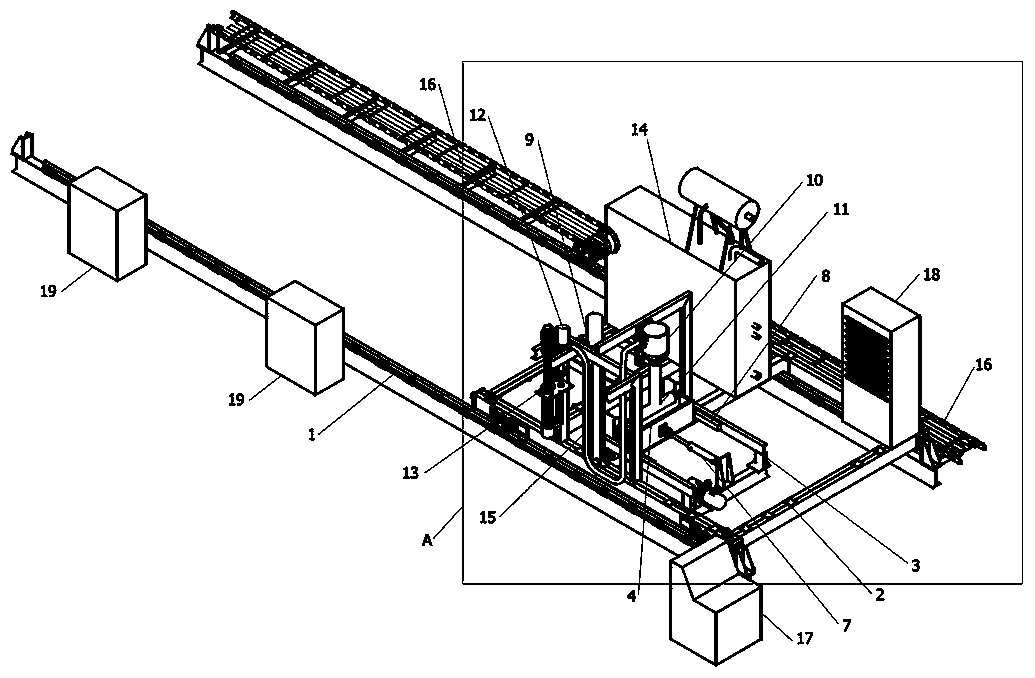

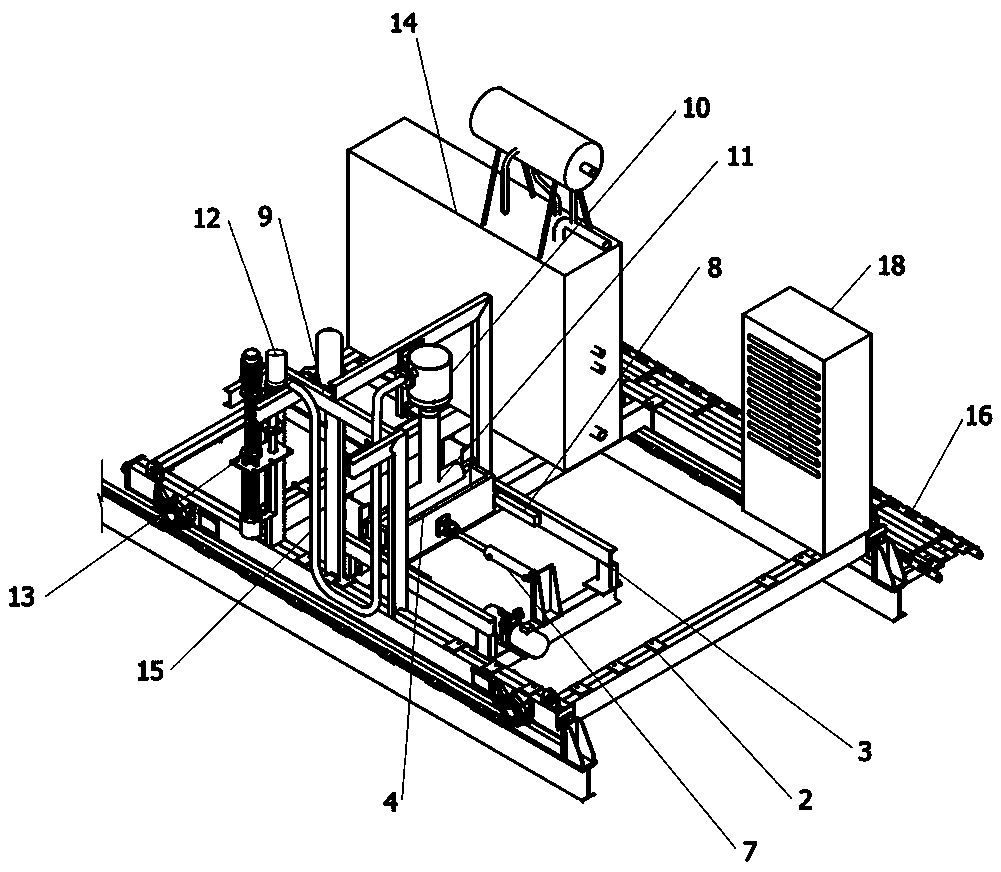

Mobile metal liquid automatic casting device

ActiveCN109014157ARealize automatic demouldingReduce cooldownMolten metal supplying equipmentsMould handling equipmentsTemperature controlCasting mold

The invention discloses a mobile metal liquid automatic casting device. The mobile metal liquid automatic casting device comprises operation rails symmetrically arranged on the ground or a mounting foundation of a workshop, and a carrying trolley arranged on the operation rails; a mold bracket and a mold temperature control device are arranged on the carrying trolley; a casting mold and a mold opening and closing control mechanism are arranged on the mold bracket; the mold opening and closing control mechanism is connected with the casting mold so as to control opening and closing of the casting mold; a suspension bracket is arranged on the carrying trolley across the mold bracket; a casting mechanism and a liquid supply pump connected with the casting mechanism are arranged on the suspension bracket; and the mold temperature control device is connected to the casting mold through a heat exchange pipeline. Automatic casting of metal solutions is achieved, the casting mold can be preheated and subjected to accelerated cooling, automatic opening and closing of the casting mold and casting demolding are controlled, the casting quality is stable and reliable, continuous operation can be conducted, safety and convenience are achieved, the operator safety is greatly improved, the labor intensity is relieved, casting time and cooling time are shortened, and the casting production efficiency is improved.

Owner:YUNNAN HEAVY EQUIP MFG GRP

Machining stamping device facilitating automatic ejection of waste

InactiveCN111760961AEasy stampingEasy to collectMetal-working feeding devicesStripping-off devicesStructural engineeringMachining

The invention relates to a machining stamping device facilitating automatic ejection of waste. The device comprises a bottom plate, the top of the bottom plate is connected with a top plate through avertical rod, a stamping female die unit is arranged in the middle of one side of the bottom plate, machined workpiece conveying units are installed at the positions, at the two ends of the stamping female die unit, on the bottom plate, and a machined workpiece conveying unit is installed at the position, on one side of the stamping female die unit, of the bottom plate; and an automatic demoldingunit is fixedly arranged at the position, corresponding to the top of the machined workpiece conveying unit, of the lower portion of the top plate, a movable male die stamping unit and a to-be-machined workpiece cutting unit are arranged on the lower portion of the top plate, and the male die stamping unit and the to-be-machined workpiece cutting unit are of an integrated structure. The machiningstamping device has the advantages that the purposes of conveying, cutting, stamping and demolding workpieces and conveying the machined workpieces can be achieved, and stamping and demolding efficiency is improved while the safety risk of manual work is prevented; and meanwhile, the characteristic of effectively collecting the waste can be achieved.

Owner:河南工学院

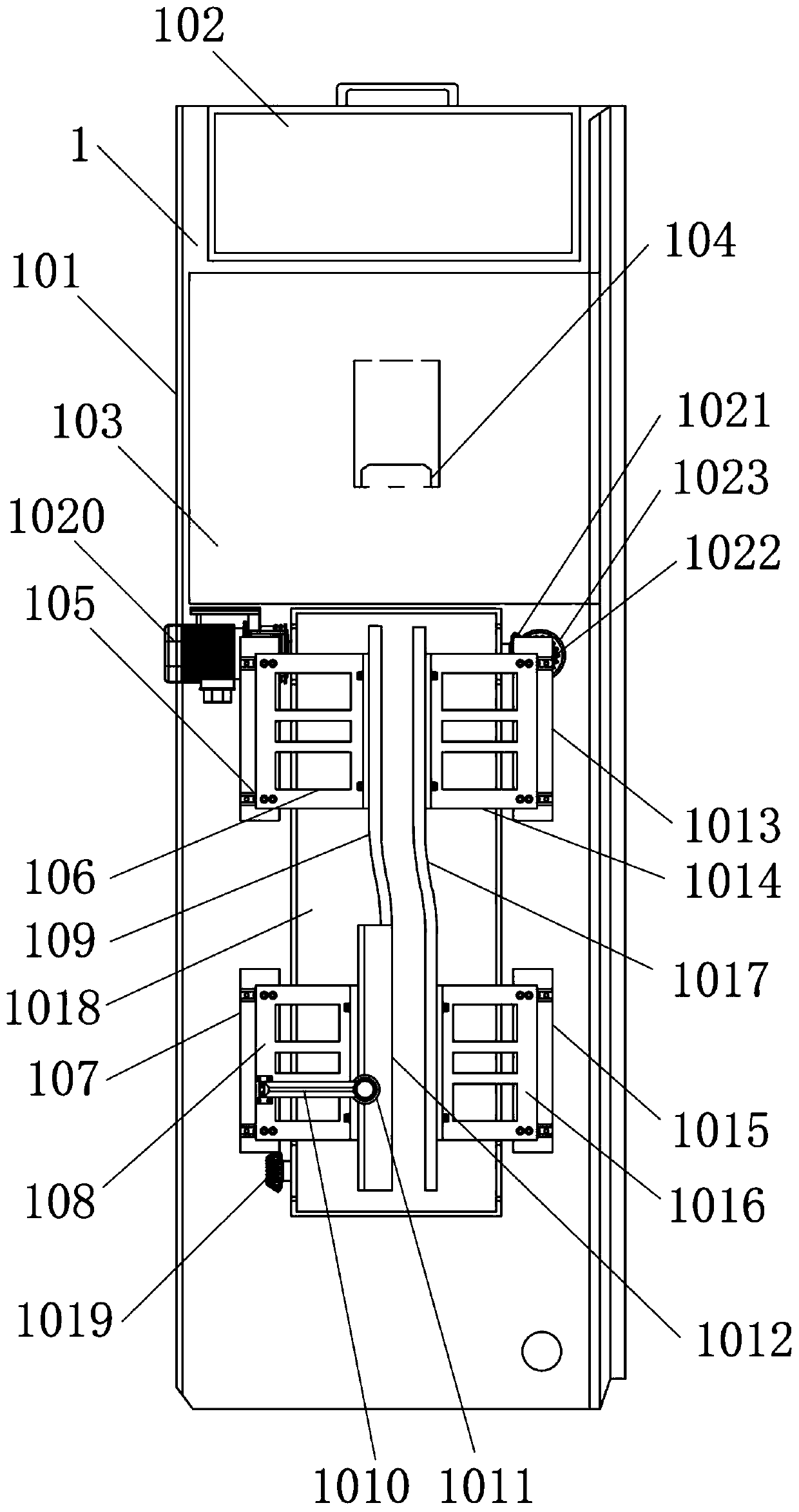

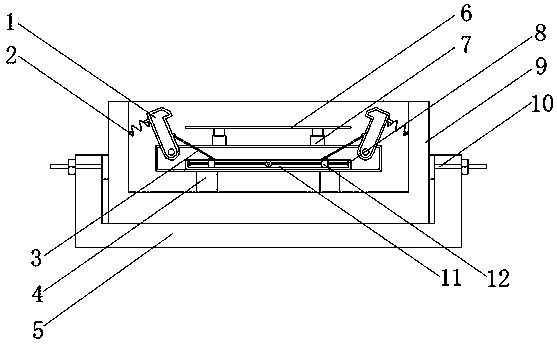

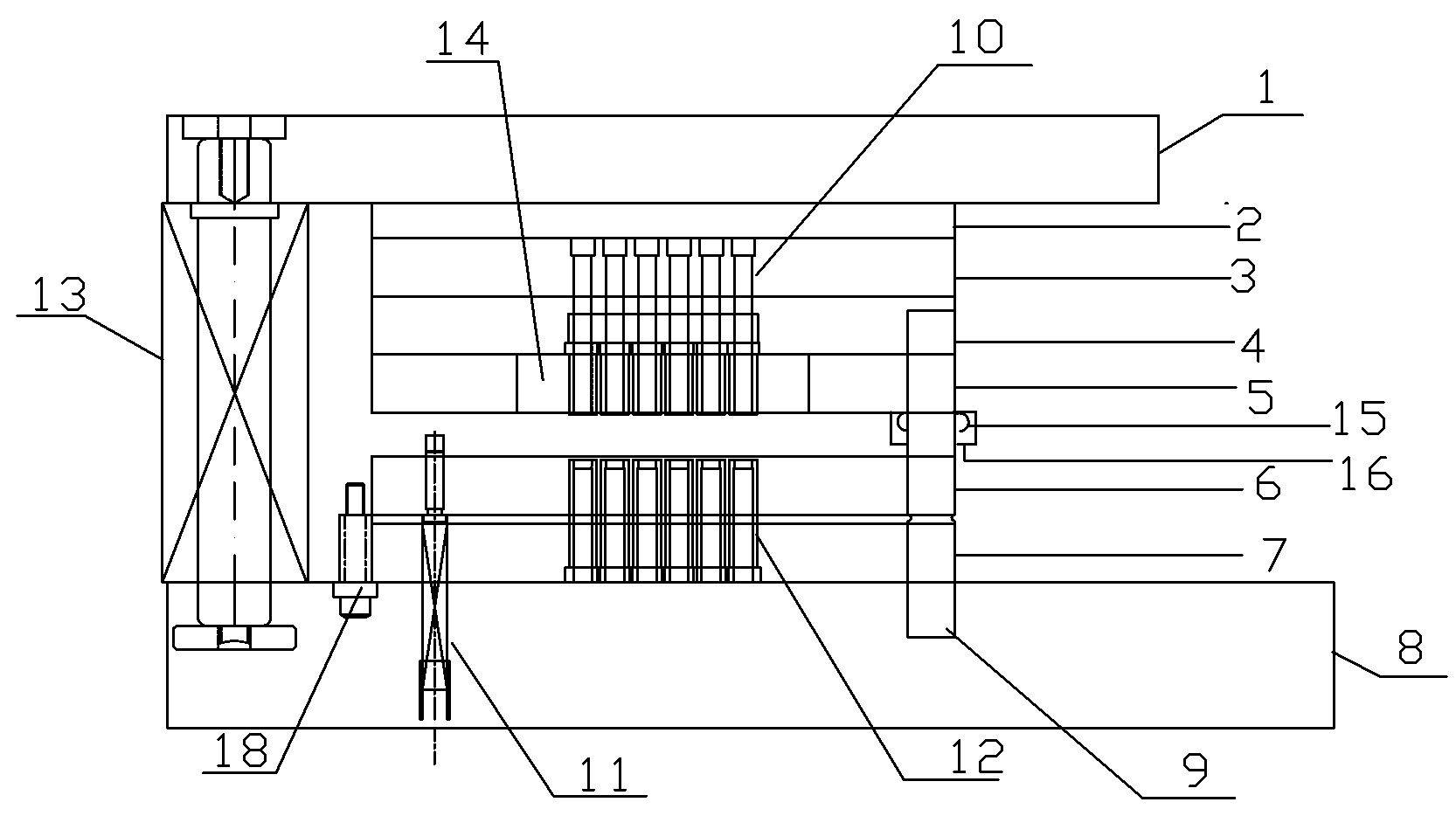

Automatic donkey-hide gelatin block demolding device and demolding method

The invention provides an automatic donkey-hide gelatin block demolding device and a demolding method. The demolding device comprises a mold upper part pressurization pushing device, a donkey-hide gelatin block pushing device, a demolding side frame pushing device, a feeding conveying device, a donkey-hide gelatin discharging conveying device and a frame. According to the automatic donkey-hide gelatin block demolding device and the demolding method, a donkey-hide gelatin block can be automatically separated from a mold, and automatic demolding of the donkey-hide gelatin block is realized.

Owner:JIANGSU HAGONG PHARMA MACHINE TECH CO LTD

Rubber forming and trimming device

ActiveCN111055427ARealize automatic demouldingNo fratricideDomestic articlesTransfer mechanismManual handling

The invention relates to rubber forming processing, in particular to a rubber forming and trimming device. The technical problem to be solved by the invention is to provide the rubber forming and trimming device. The rubber forming and trimming device comprises an overturning conveying mechanism, a demolding transferring mechanism, a veneering trimming mechanism, a control screen and a shoe sole forming mold. The demolding transfer mechanism is arranged at the front bottom of the overturning conveying mechanism; and the veneering trimming mechanism is arranged at the middle upper part of the overturning conveying mechanism. According to the invention, automatic demoulding of the rubber sole is realized; the rubber soles are overturned and conveyed after being transferred; meanwhile, veneering trimming is carried out in a matched mode, the trimming veneering degree is high, redundant overflow edges cannot be generated, no manual operation is needed in the whole process, labor consumption is greatly reduced, efficient and automatic trimming is achieved, meanwhile, the percent of pass is high, accidental injury to operators or accidental injury to rubber soles cannot be caused, and opposite trouser edges cannot be abraded during wearing.

Owner:湖南芭其拉鞋业有限公司

3D printing bearing platform and full-automatic printing method based on bearing platform

ActiveCN109228343ARealize automatic demouldingHigh degree of automationManufacturing platforms/substrates3D object support structures3d printEngineering

The invention relates to the field of 3D printing and specifically discloses a 3D printing bearing platform and a full-automatic printing method based on the bearing platform. The 3D printing bearingplatform comprises a fixed platform and a moveable platform which are spliced with each other; the moveable platform is connected with a driving device used for driving the working surface of the moveable platform to lift or stagger relative to the working surface of the fixed platform; the bearing platform is capable of automatically de-molding through the relative motion of the moveable platformand the fixed platform, so as to increase the degree of automation of printing.

Owner:SHINING 3D TECH CO LTD

Demolding device for injection mold

The invention discloses a demolding device for an injection mold. The demolding device comprises a base. A limiting groove is formed in the upper end of the base. A bearing box is arranged at the bottom inside the limiting groove and provided with a containing groove. Four support blocks are fixed to the bottom inside the containing grove. A protection box is jointly fixed to the upper ends of thesupport blocks and internally provided with a cavity. A fixing box is arranged at the bottom inside the cavity and provided with a sliding groove. Two sliding blocks are mounted in the sliding groove. Threaded rods are rotatably connected to opposite side walls inside the sliding groove correspondingly. A fixing rod is fixed between the two threaded rods. A second conical gear is fixed to the fixing rod. A rotating rod is arranged at one side of the base in a penetrating manner. By means of the injection mold demolding device, automatic demolding of the mold is achieved in the injection molding processing process; processing can be conducted conveniently; efficiency is improved; meanwhile, manual demolding can be conducted according to the circumstance; and the demolding device is convenient to use and suitable for being popularized.

Owner:郑州星联新创信息科技有限公司

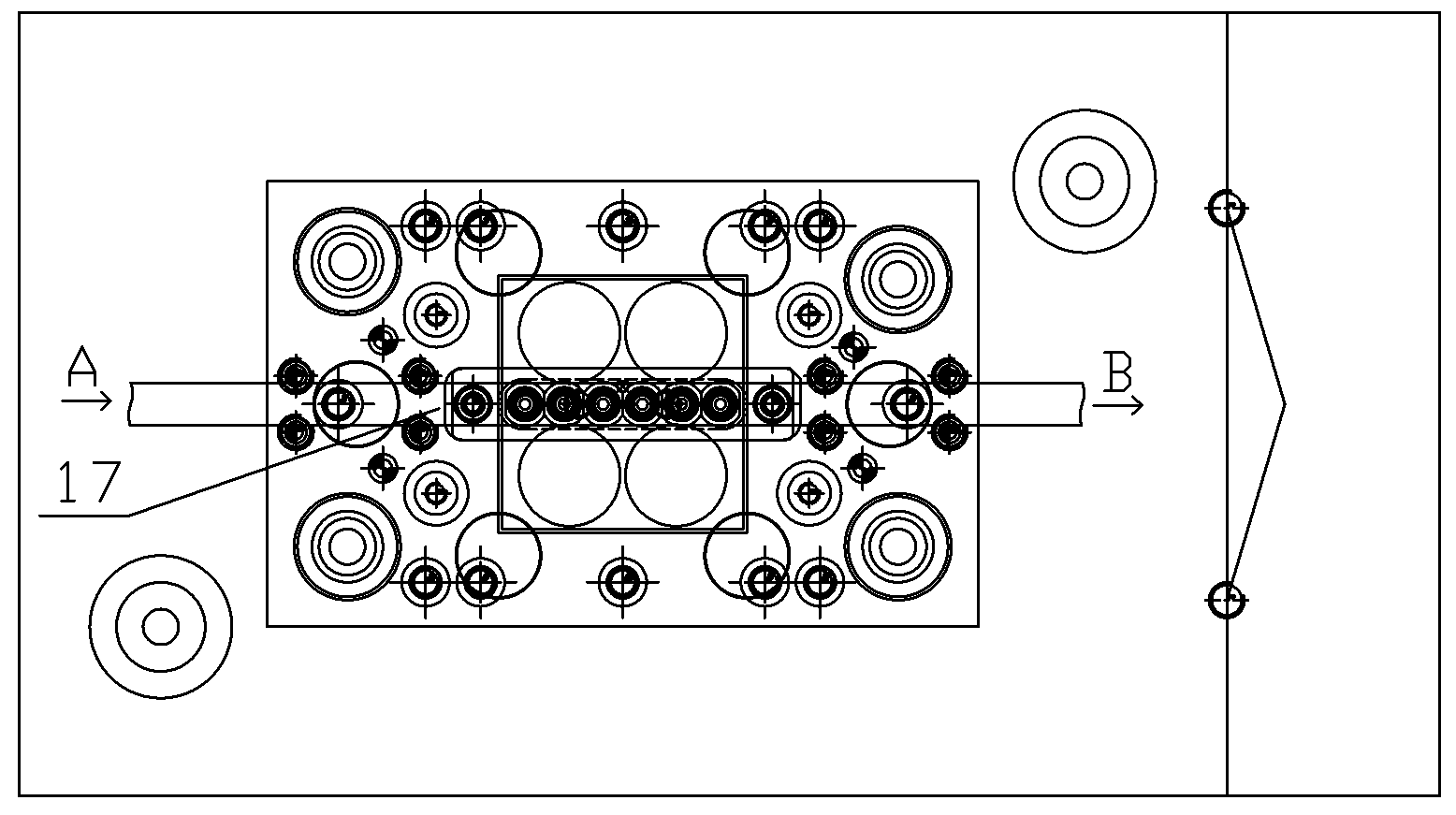

Full-automatic stator spot welder

ActiveCN110315182ARealize automatic deliveryAchieve weldingResistance welding apparatusEngineeringMechanical engineering

The invention provides a full-automatic stator spot welder which comprises a conveyor line body, a positioning mold, a servo indexing mechanism, a pressurizing mechanism and a feeding mechanism, wherein the positioning mold is slidably arranged on the conveyor line body, a positioning groove for positioning and placing a stator is formed in the positioning mold, the servo indexing mechanism is located above the conveyor line body to be connected to the stator so as to drive the stator to rotate according to a set journey, the pressurizing mechanism is arranged above the conveyor line body andis located on one side of the servo indexing mechanism for welding a lug in a pressurized manner on the stator, and the feeding mechanism is located below the conveyor line body for pushing the positioning mold and the stator in the positioning mold to ascend to be connected to the servo indexing mechanism, so that the pressurizing mechanism welds the lugs on the peripheral side of the stator in apressurized manner, and therefore, the stator is conveyed and welded automatically. The full-automatic stator spot welder is stable to weld and good in effect, and improves the production efficiency.

Owner:璋祐科技(深圳)有限公司

Continuous ultraprecise stamping die

The invention discloses a continous ultraprecise stamping die, comprising an upper die base, an upper base plate, an upper clamping plate, an upper baffle and a lower die base which are sequentially arranged from top to bottom. The stamping die also comprises a punch, a blanking cutter matched with the punch, a floating dual-purpose pin and an insert; the punch is arranged on the clamping plate, the blanking cutter is arranged on the lower die base, wherein the blanking cutter is arranged below the punch, the floating dual-purpose pin is arranged on the lower die base, and the insert is arranged on a concave mouldboard; and the edge of the blanking cutter is provided with a guide pillar between the upper baffle and the lower die base. Balls are arranged at the edge of the guide pillar, a certain stamping gap is guaranteed, and no error is produced, thus ultraprecise stamping below 0.04mm can be realized; a spring is arranged between the upper die base and the lower die base for realizing automatic demoulding, thus the stamping die is simple and convenient to use; the punch, the edge of the blanking cutter and the insert which are all made of tungsten steel have the advantages of abrasion resistance and impact resistance and can realize powerful stamping; with low production cost, the stamping die can be quickly put into production and can generate good economic benefit.

Owner:SUZHOU RISING CREATION PRECISION TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com