Rubber forming and trimming device

A rubber molding and trimming technology, which is applied to household components, household appliances, and other household appliances, can solve problems such as low work efficiency, high labor intensity, and damaged soles, and achieve low work efficiency and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

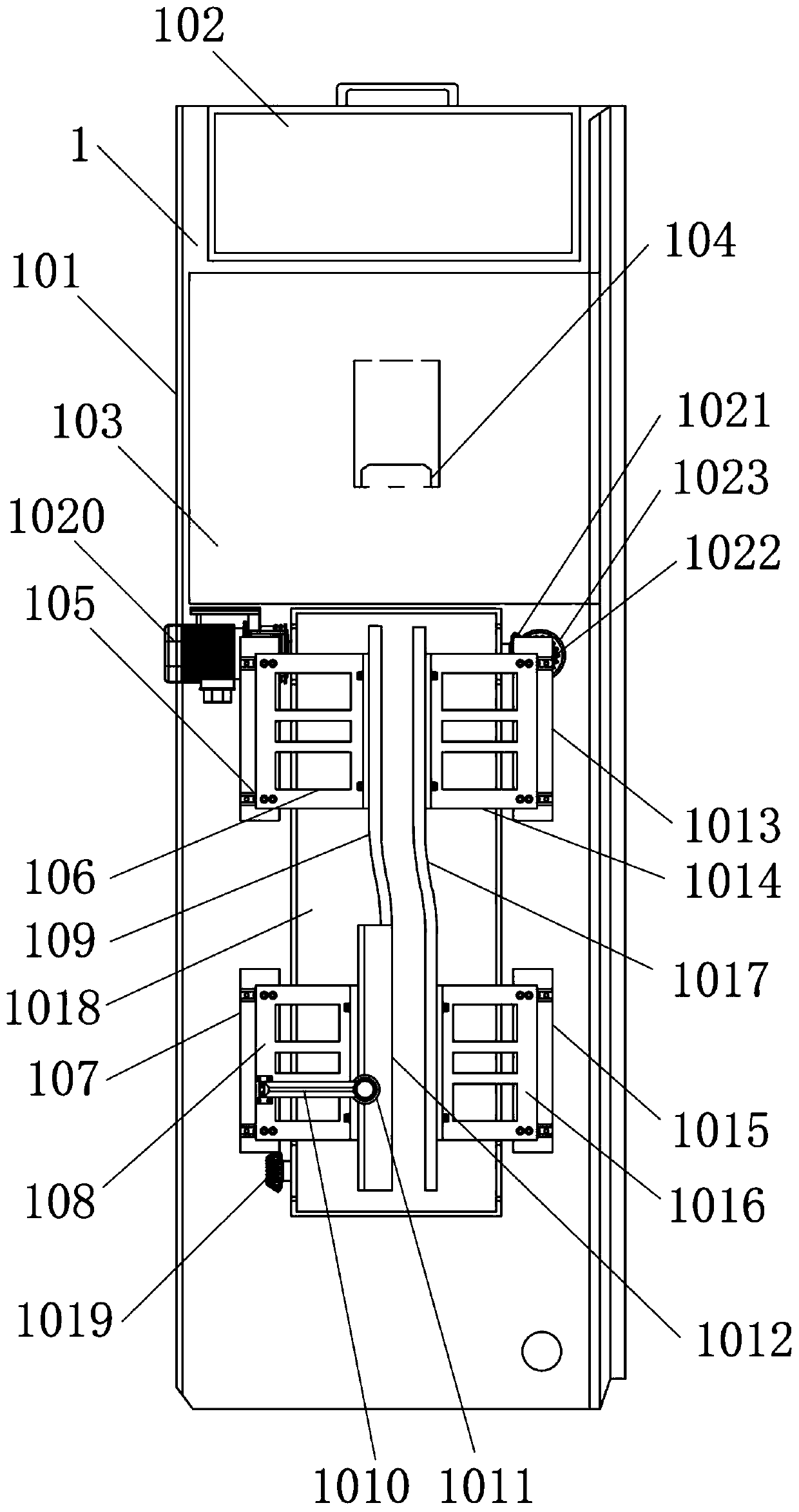

[0028] A rubber molding and trimming device, comprising an overturning transmission mechanism 1, a demoulding transfer mechanism 2, a veneer trimming mechanism 3, a control panel 4 and a shoe sole forming mold 5; A veneer trimming mechanism 3 is arranged in the upper part of the overturning transmission mechanism 1; a control panel 4 is arranged at the left bottom of the overturning transmission mechanism 1; a shoe sole forming mold 5 is arranged at the right end of the overturning transmission mechanism 1.

[0029] When in use, the rubber forming and trimming device is placed on the front side of the sole forming mold 5, the control panel 4 controls the operation, and the manual operation injection molding area is reserved on the front right side of the sole forming mold 5, and then an external power supply is connected. When the sole forming mold 5 is injection molded Finally, open the top cover, turn over the transmission mechanism 1 to drive the demoulding transfer mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com