3D printing hot bed capable of achieving automatic demolding

A 3D printing and automatic demoulding technology, applied in the field of 3D printing, can solve problems such as difficulties, personal injuries, and easily damaged products, and achieve the effect of improving demoulding efficiency and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

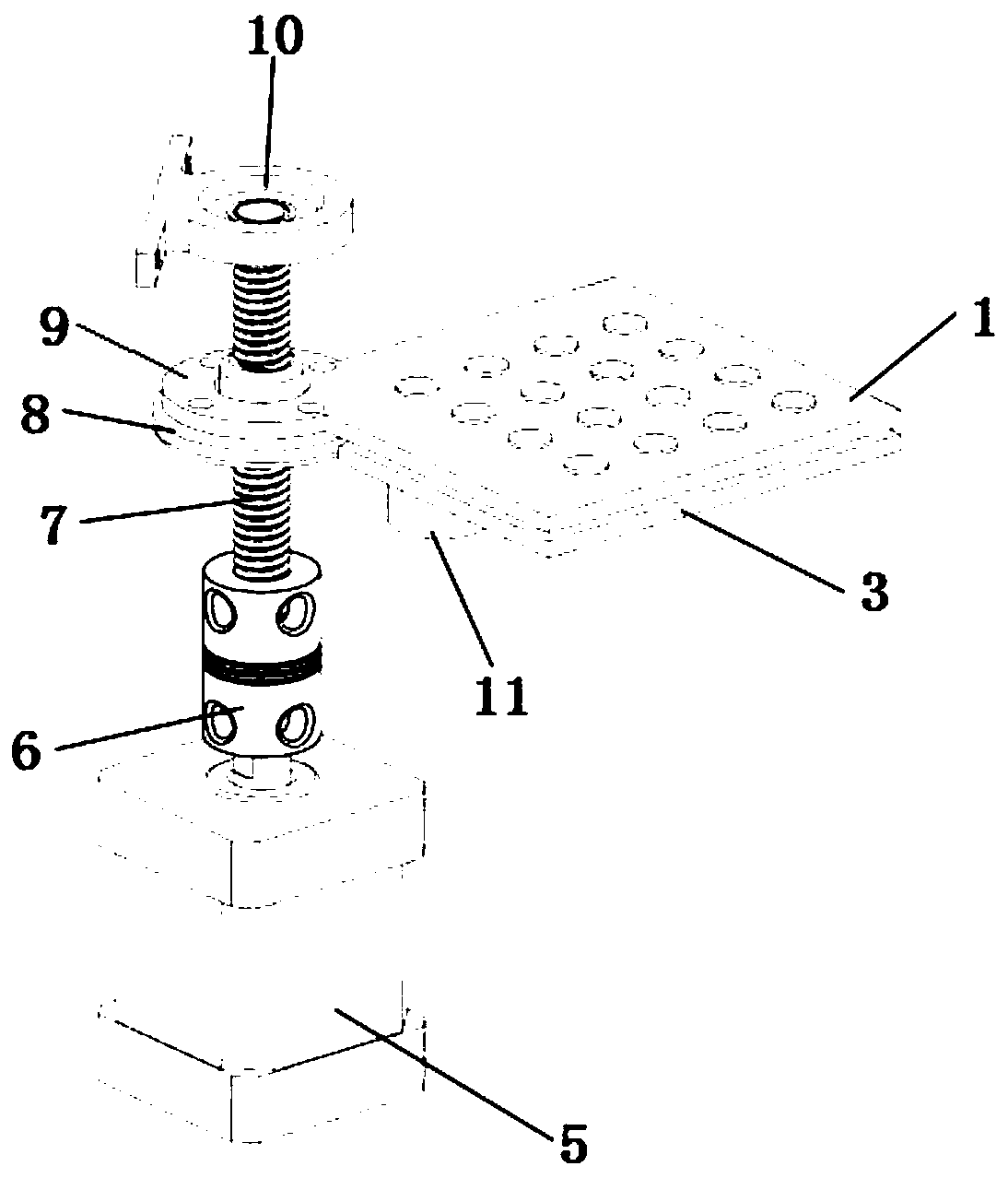

[0022] The 3D printing hot bed capable of automatic demolding of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

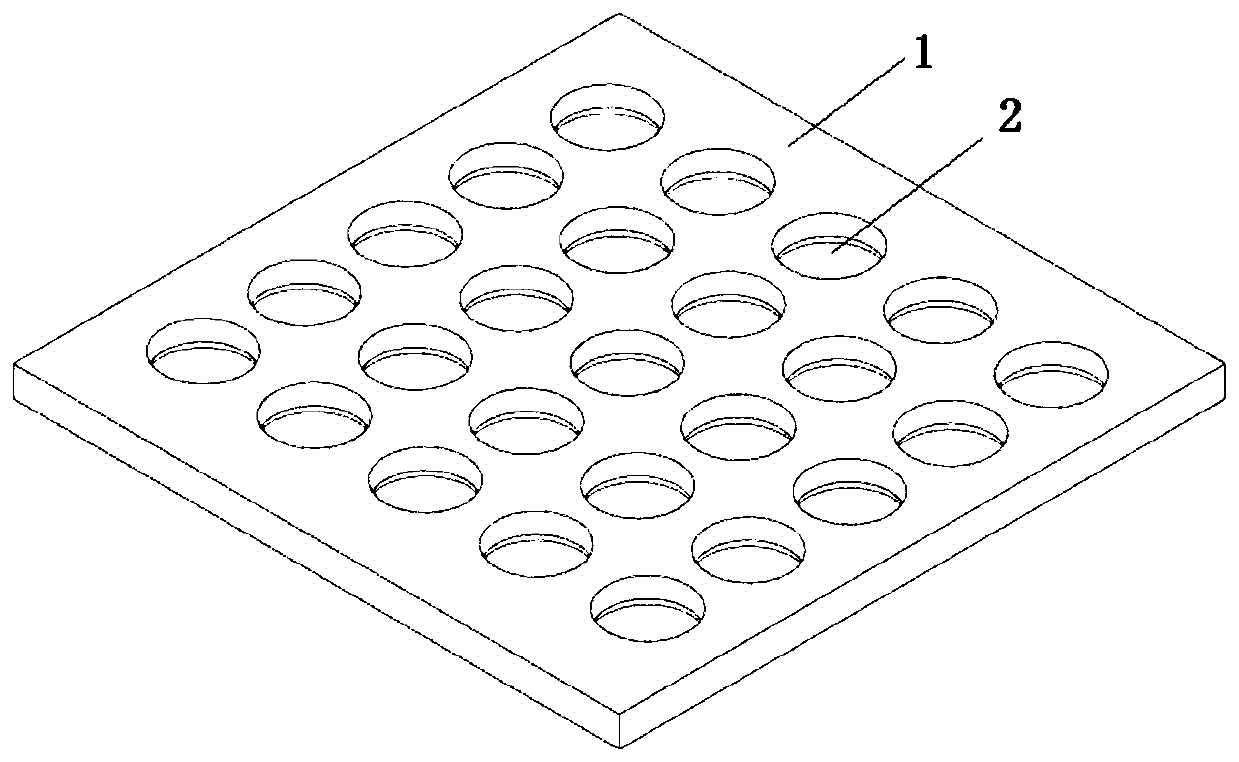

[0023] Such as figure 1 The 3D printing hot bed that can be automatically demolded includes an upper hot bed 1, a lower hot bed 3 horizontally arranged directly below the upper hot bed 1, and a device for driving the upper and lower hot beds to move up and down. Lifting drive device. See figure 2 with image 3 , The upper heating bed 1 is evenly provided with a number of vertical through holes 2 and the upper end surface of the lower heating bed 3 is integrally vertically provided with columnar protrusions 4 that are equal in number to the through holes 2 and matched in one-to-one correspondence, and each columnar protrusion 4 The top surface is the same height, and the height of each columnar protrusion 4 is greater than the thickness of the upper heating bed 1. When the top surface of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com