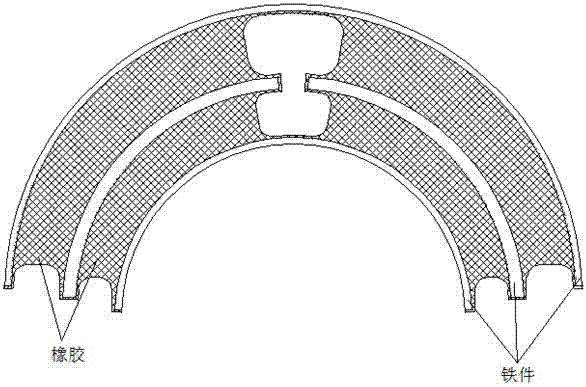

Bearing bush type gearbox elastic supporting automatic ejection die and automatic ejection method thereof

An elastic support and automatic demoulding technology, applied in the field of metal rubber product manufacturing, can solve the problems of high labor intensity, low product qualification rate, product surface damage, etc., to reduce labor intensity, simple demoulding operation, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

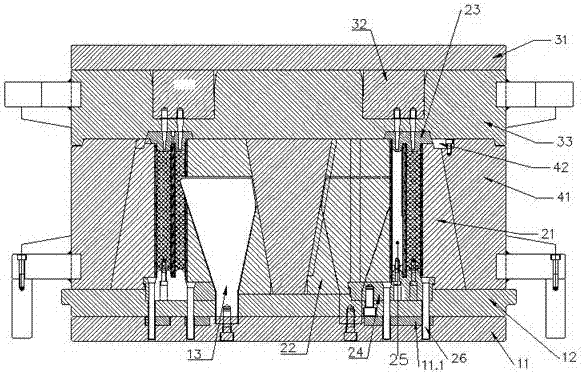

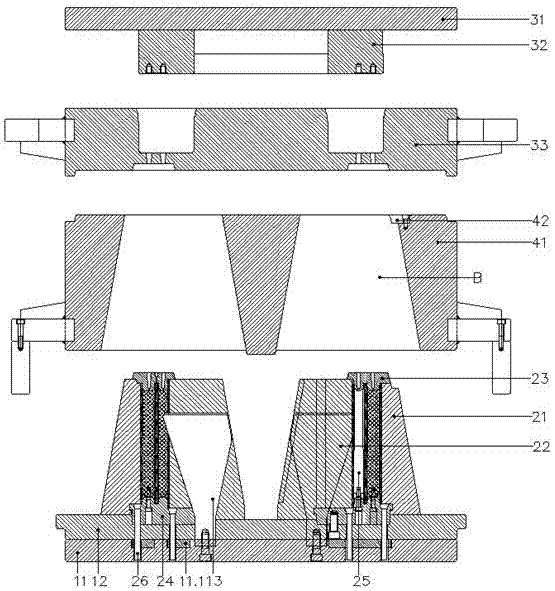

[0043] Attached below Figures 2 to 9 Embodiments of the present invention are described in detail.

[0044]The bearing pad type gearbox elastically supports the automatic demoulding mold, including a bottom mold assembly 1, a lower mold assembly 2 placed on the bottom mold assembly, an upper mold assembly 3 placed on the lower mold assembly 2 and a bottom mold assembly placed on the bottom mold assembly. Between the mold assembly 1 and the upper mold assembly 3, the middle mold assembly 4 for clamping the lower mold assembly, the upper mold assembly 3 includes a horizontally arranged top plate 31, a rubber injection plug 32 fixed below the top plate 31 and The glue injection cylinder 33 matched with the glue injection plug 32 is characterized in that the bottom mold assembly 1 includes a horizontal bottom plate 11, a supporting plate 12 placed on the bottom plate 11, and a vertically arranged and fixed bottom plate 11. The lower mold assembly 2 includes an outer petal mold 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com