Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Adjustable pressing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

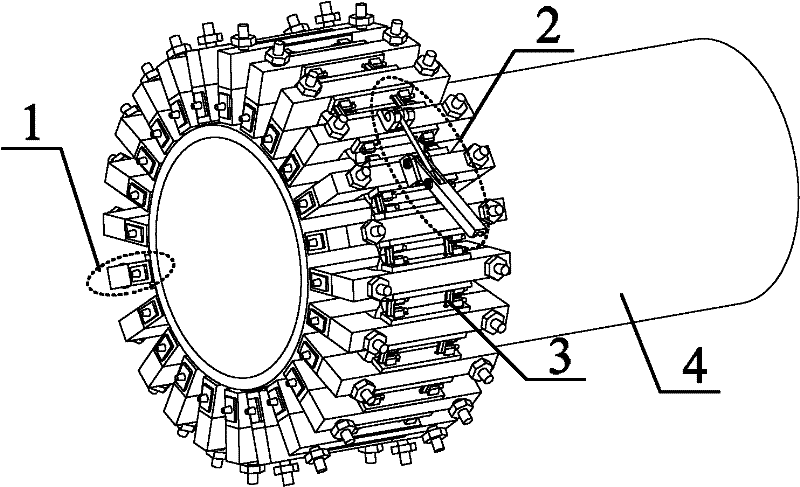

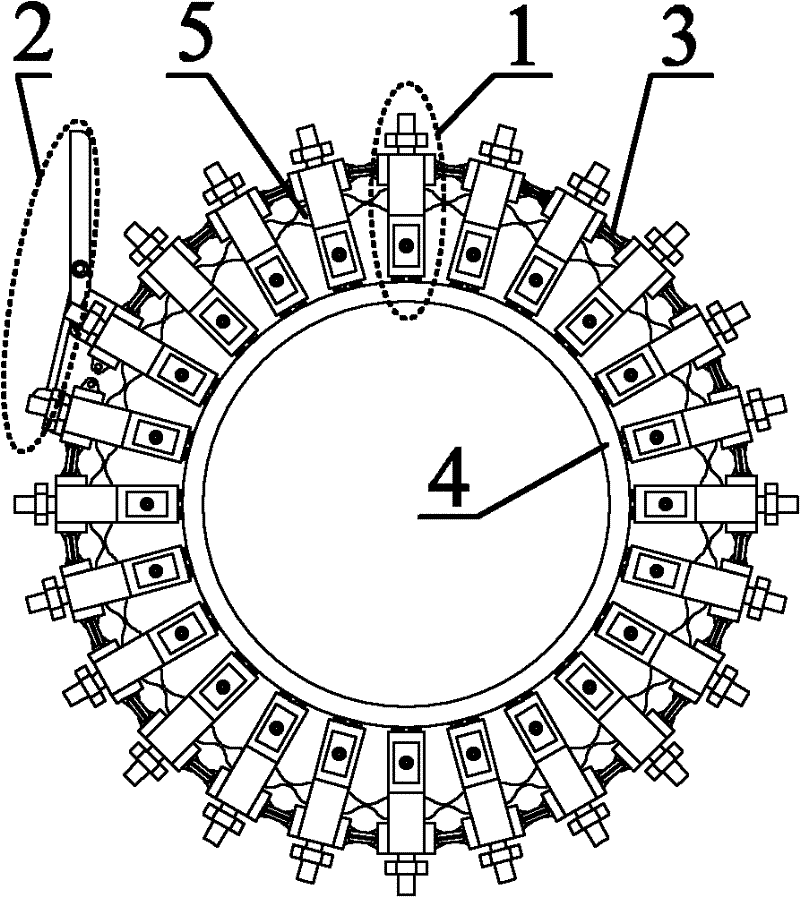

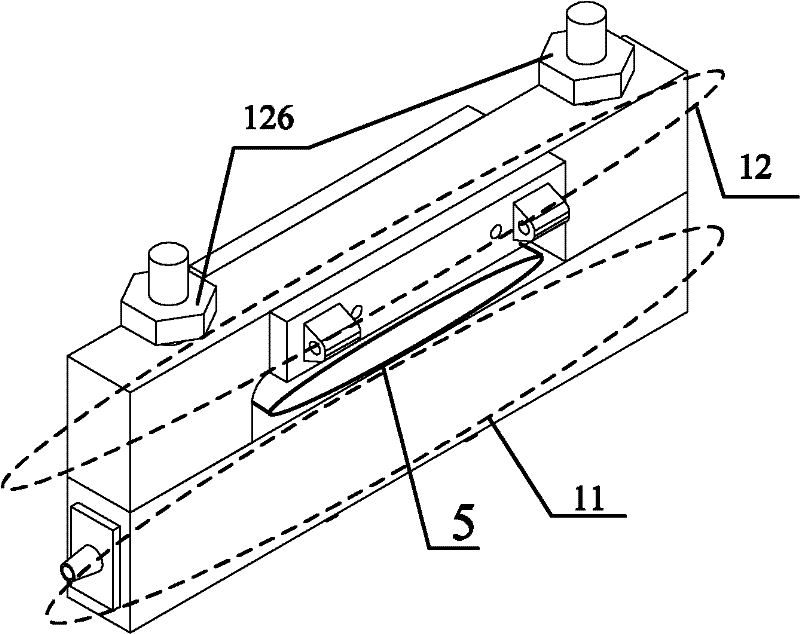

Probe system for ultrasonic guided wave detection of marine pipeline and design method thereof

InactiveCN102175773AWiden detection modeImprove detection accuracy and efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesModular structureWave detection

The invention relates to a probe system for an ultrasonic guided wave detection of a marine pipeline and a design method thereof. The probe system provided by the invention comprises multiple probe system unit modules, quick-locking mechanisms, connecting shafts and air sacs, wherein the air sacs are contained in the probe system unit modules; the probe system unit modules are connected through the connecting shafts; the two adjacent probe system unit modules can rotate around the connecting shafts to form a flexible structure; the probe system unit modules which are connected into a whole encircle the outside surface circumference of the detected marine pipeline; the two probe system unit modules at the head and the tail are connected and clamped through the quick-locking mechanisms so as to be annularly positioned at the outside surface circumference of the detected marine pipeline; and the probe system unit modules are sealed by a waterproof material. In the design method provided by the invention, the probe rings and probe ring clamp systems of probe systems are of a modular structure; the probe rings comprise the multiple probe system unit modules; the probe ring clamp systems comprise clamp modules and are mutually connected through the connecting shafts; and the heads and tails of the probe ring clamp systems are locked through the quick-locking mechanism to form the probe system with certain flexibility.

Owner:CHINA NAT OFFSHORE OIL CORP +2

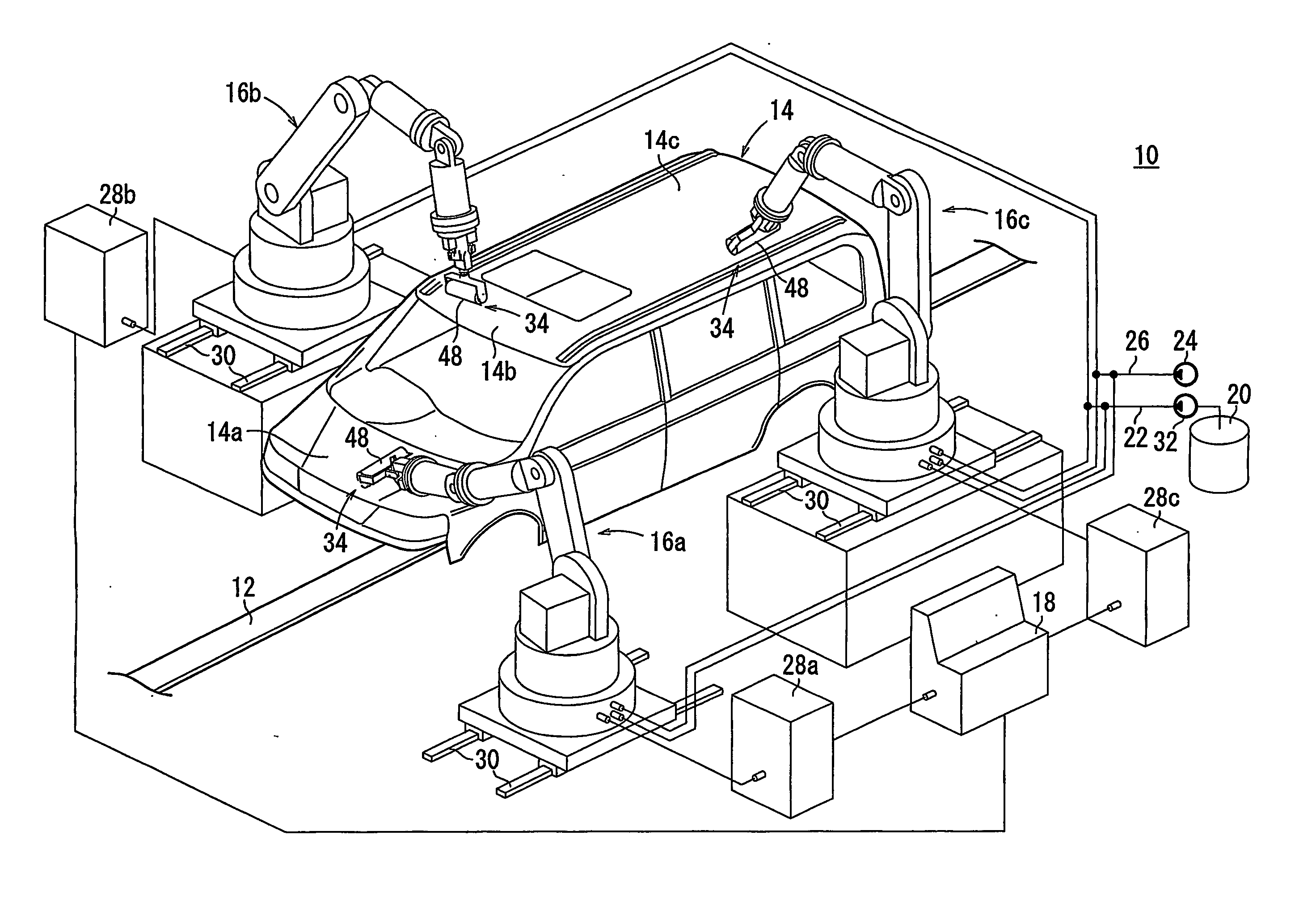

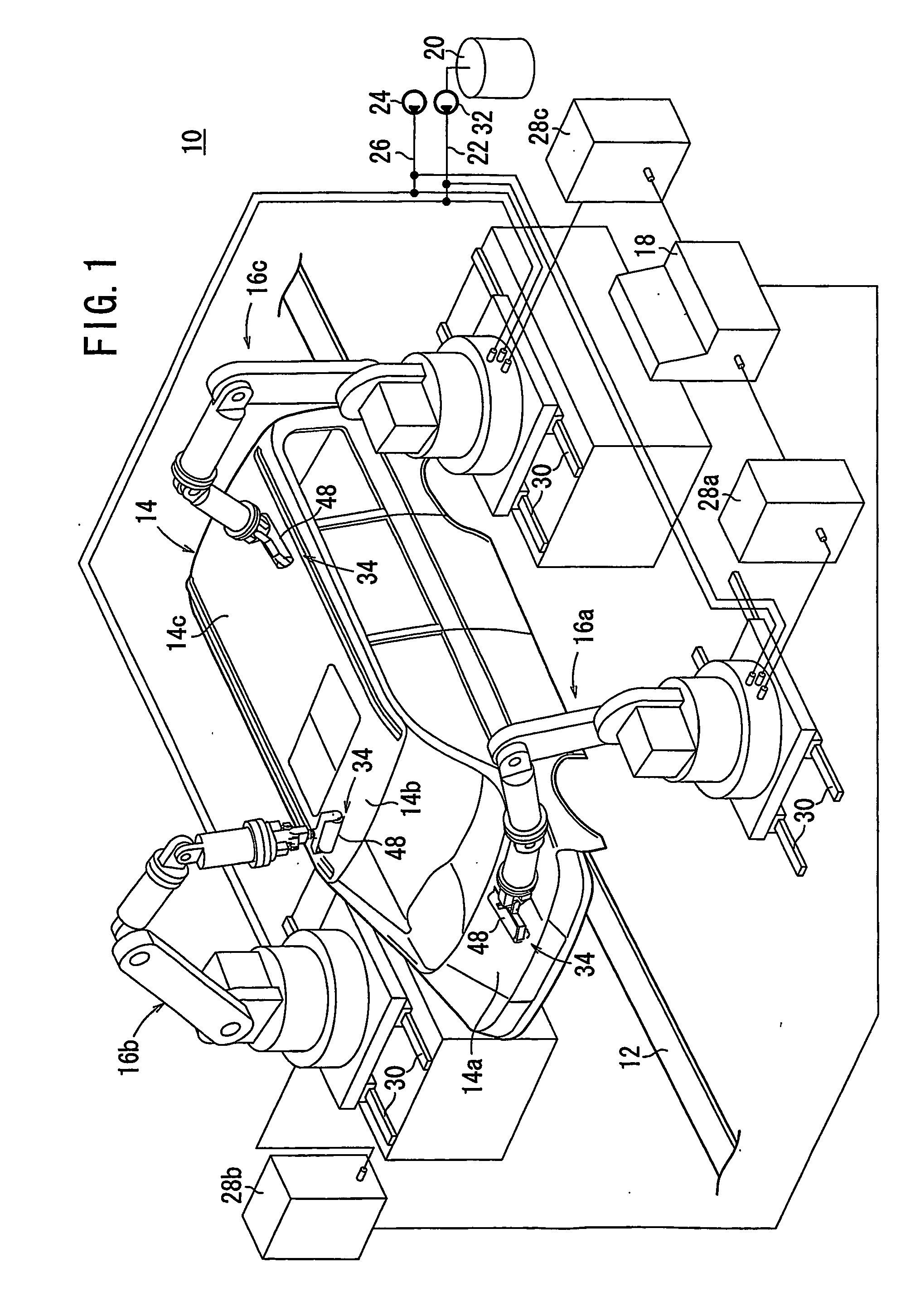

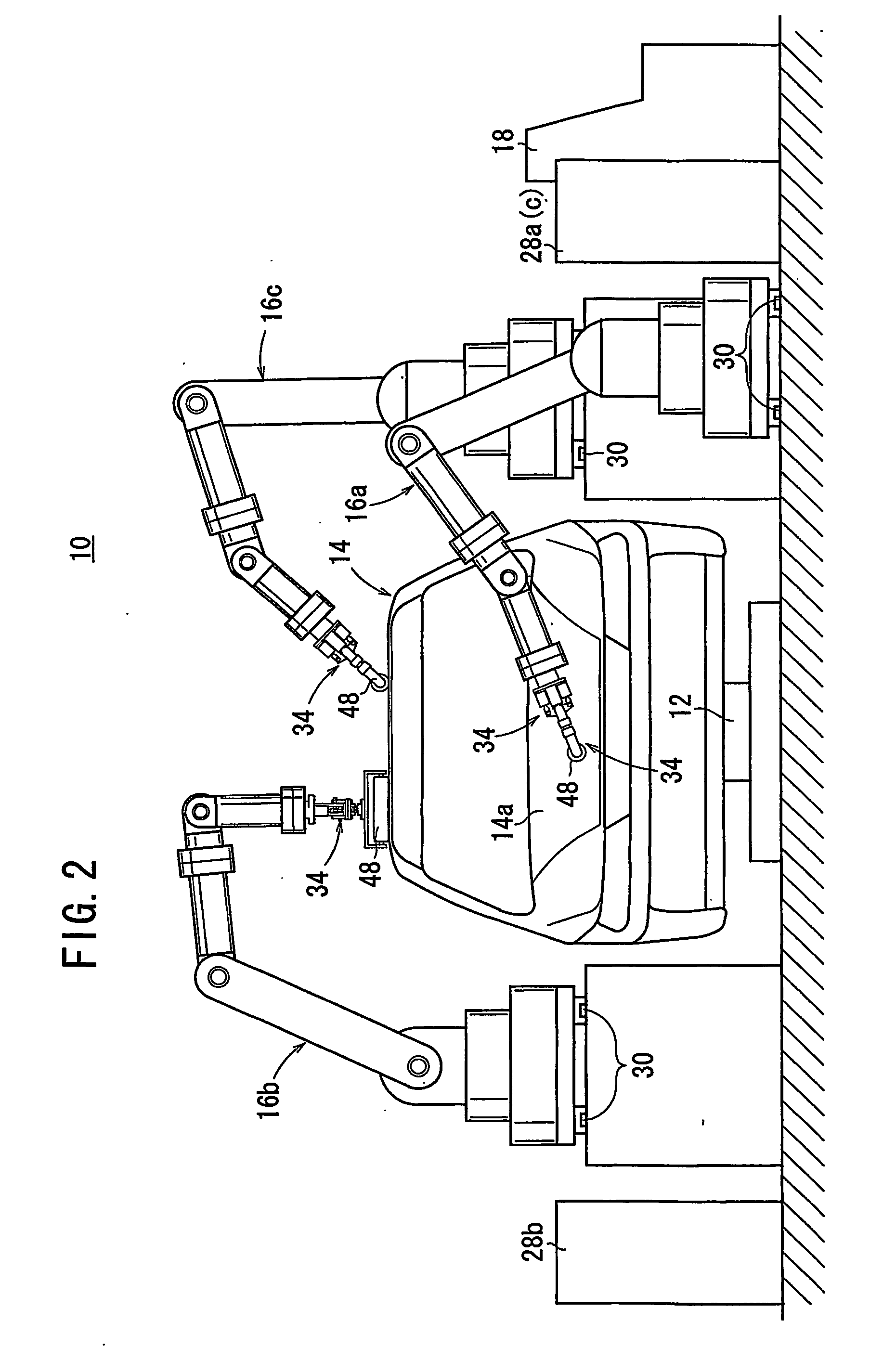

Coating system for forming protective layer

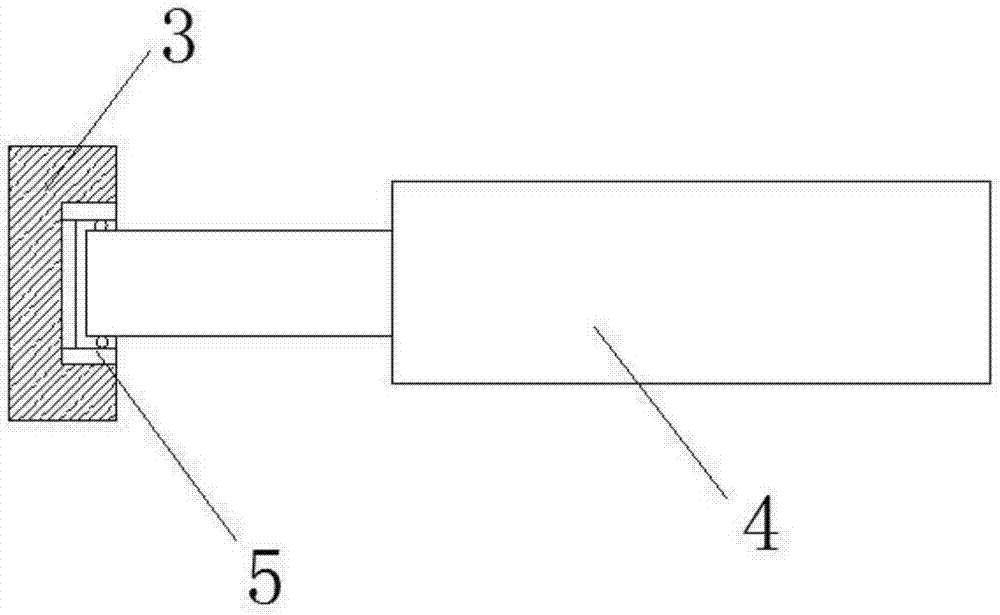

InactiveUS20060191476A1Appropriately appliedAdjustable pressing forceLiquid surface applicatorsSpraying apparatusCoating systemEngineering

A coating system using a protective layer forming material includes a coating device which is movable according to information taught by an operator, and disposed adjacent to a transport line for an object to be coated. The coating system includes a roller mechanism having a roller and a cushion mechanism. The roller is connected to the coating device. The coating system further includes a supply mechanism which supplies liquid material to the roller. The liquid material is dried to form a peelable protective layer on the object. A force is applied to the roller on an external surface of the object through the cushion mechanism. The roller is lifted and lowered corresponding to unevenness of the external surface.

Owner:HONDA MOTOR CO LTD

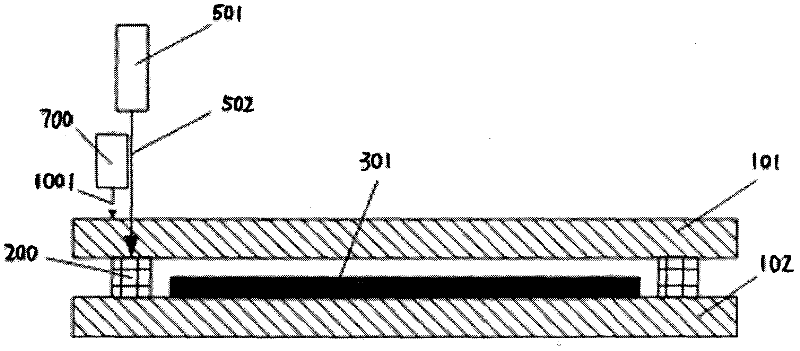

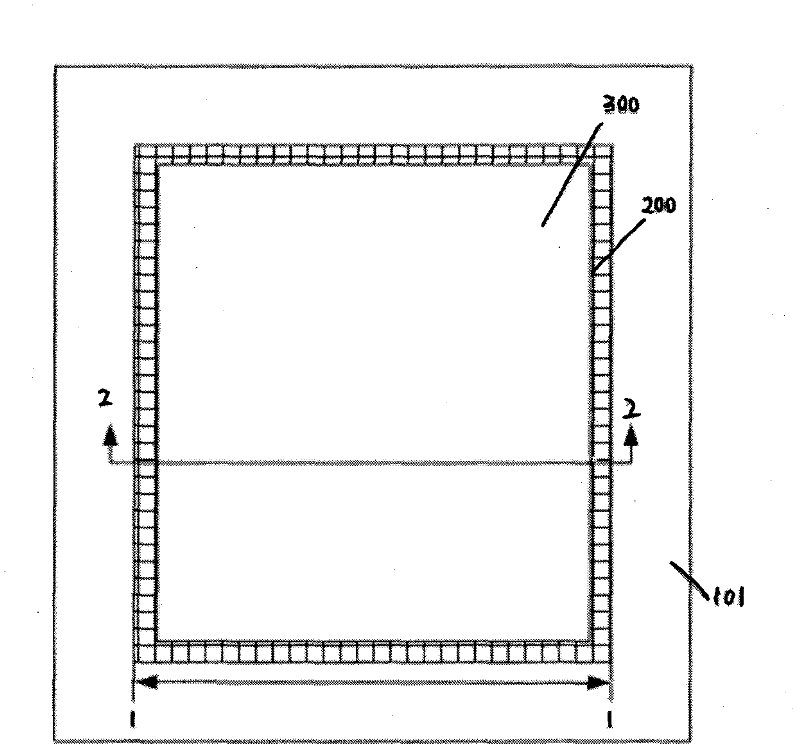

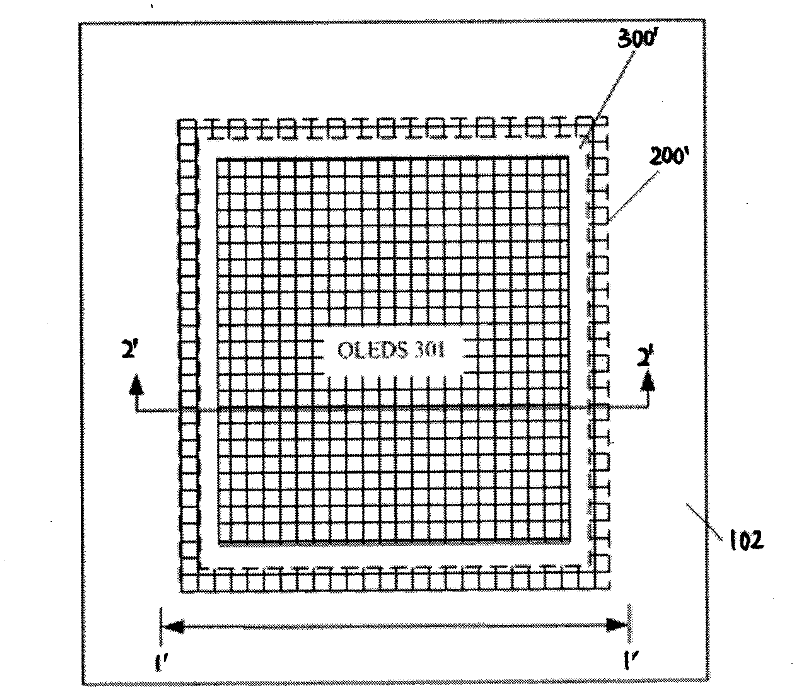

Packaging device and packaging method

InactiveCN102690045AGood technical effectAdjustable pressing forceSolid-state devicesSemiconductor/solid-state device manufacturingHermetic packagingMaterials science

The invention provides a packaging device which comprises a stage, a radiation source and a fluid source. The stage is used for bearing a packaging structure for assembly, wherein the packaging structure is provided with a first substrate, a second substrate, and a molten material which is arranged between the first substrate and the second substrate to form at least one cavity; the radiation source is used for heating the molten material so that the molten material combines with the connecting surface of the first substrate and the second substrate and the cavity forms a hermetic packaging structure; and the fluid source provides a fluid beam, wherein the fluid beam acts on the first substrate and is used for pressing the a molten material between the first substrate and the second substrate.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

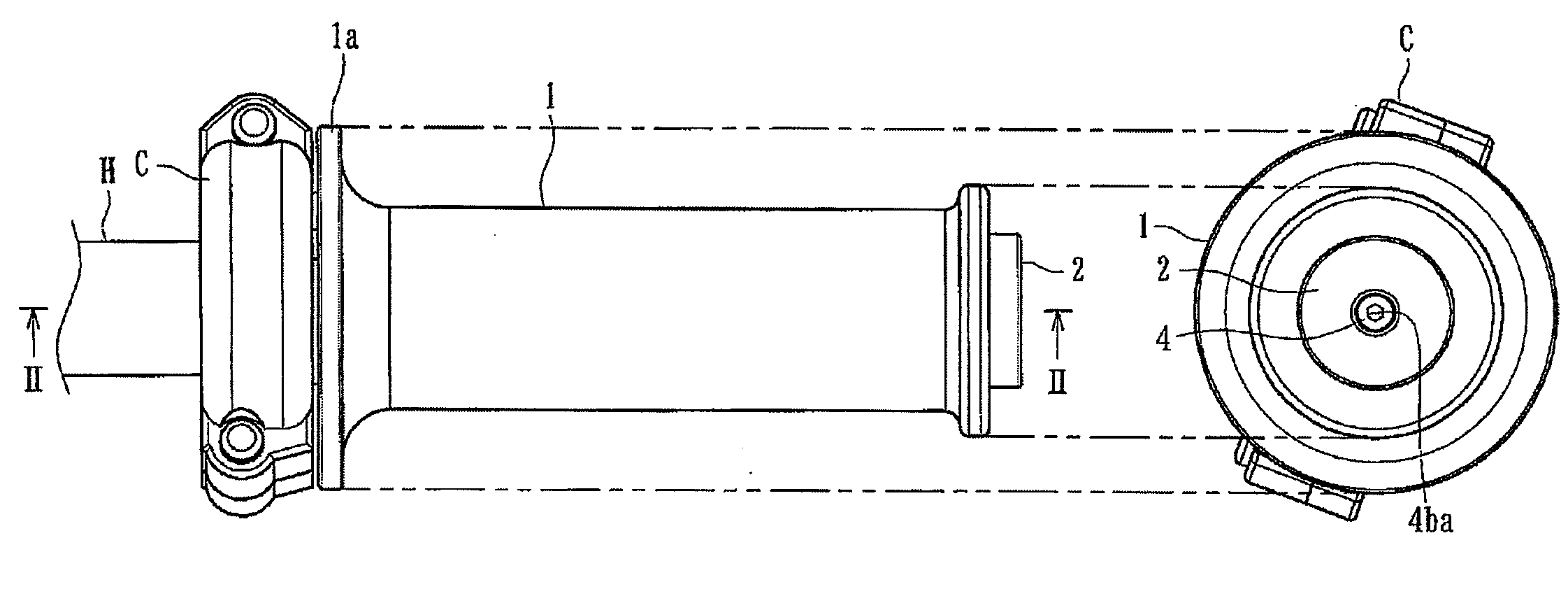

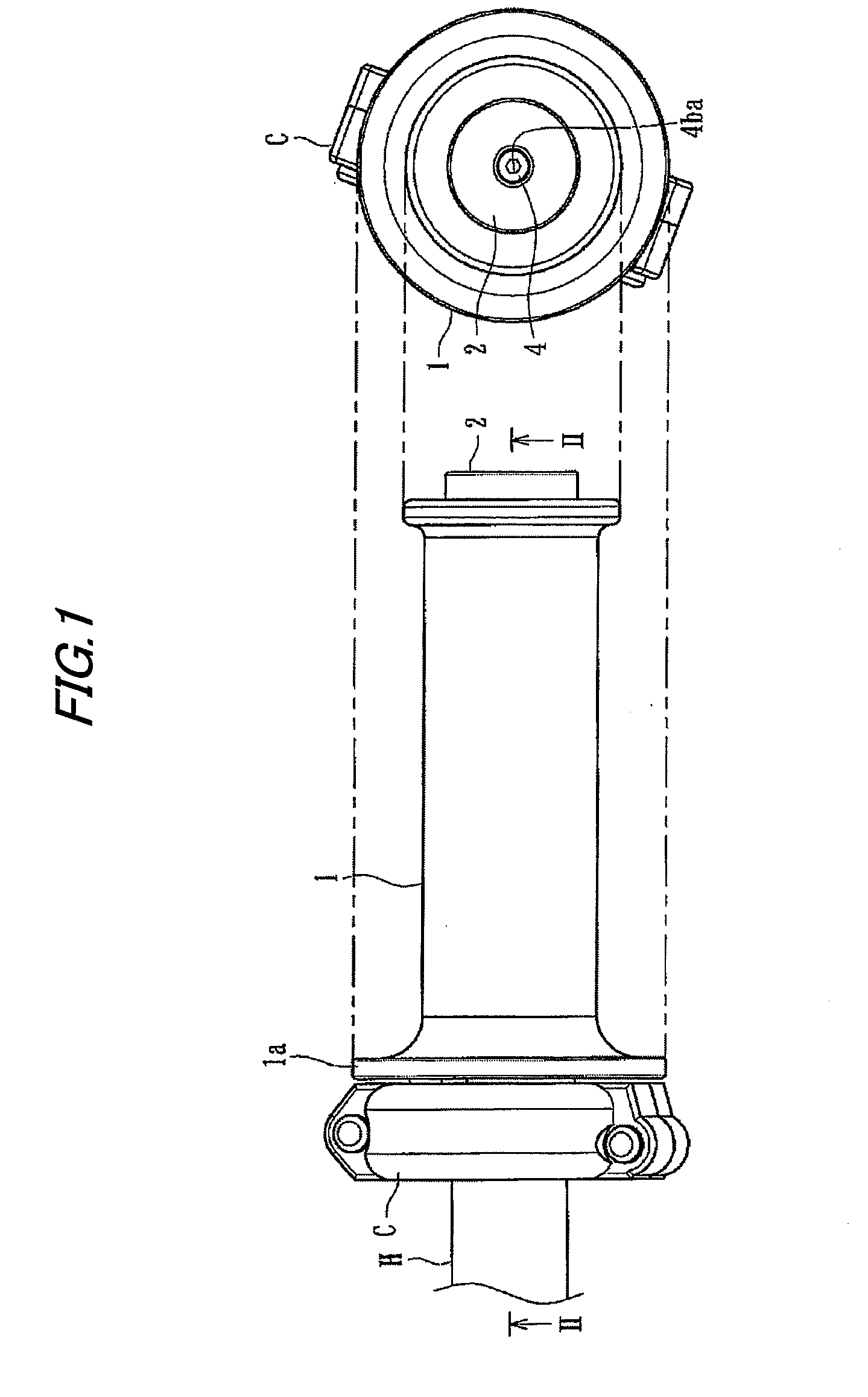

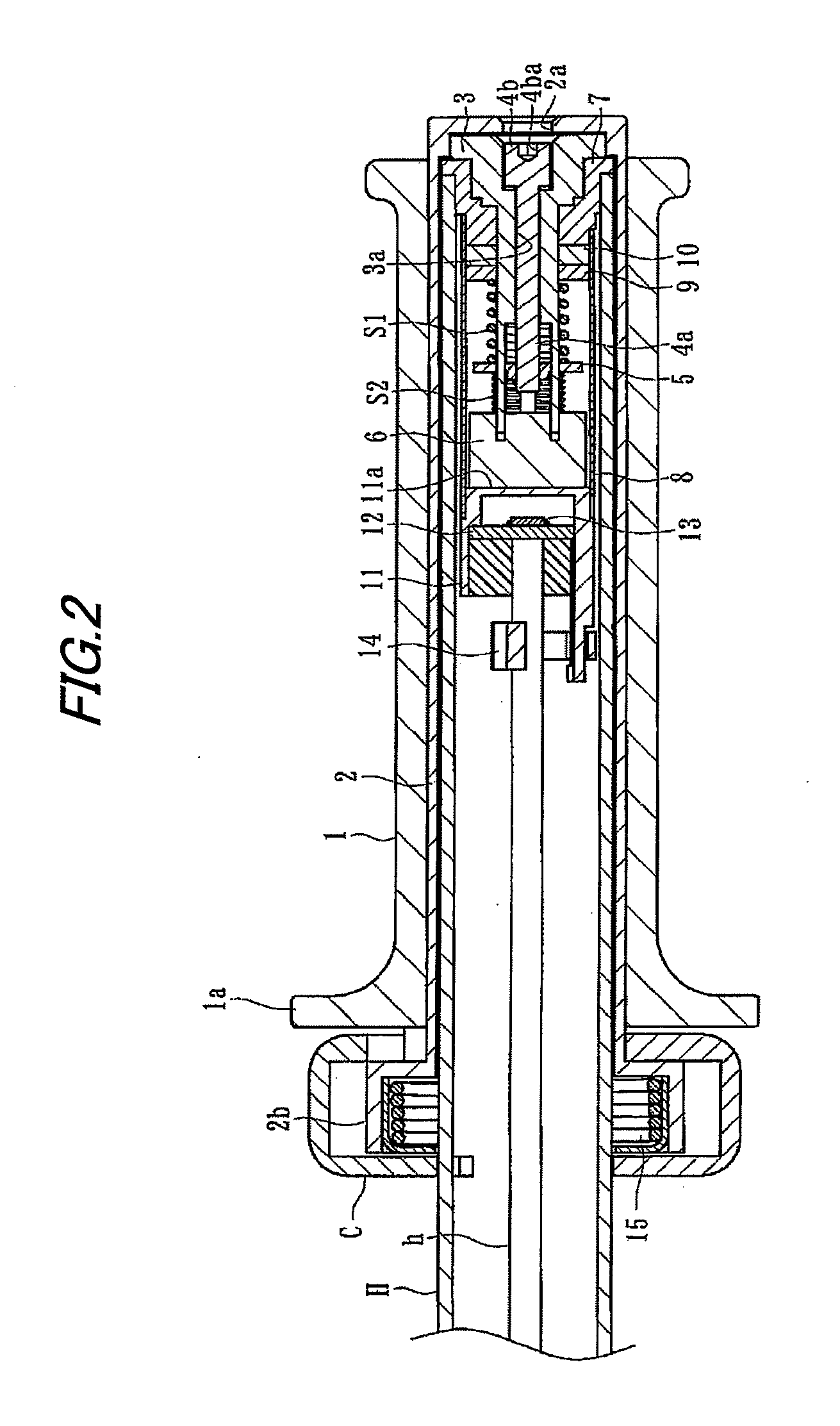

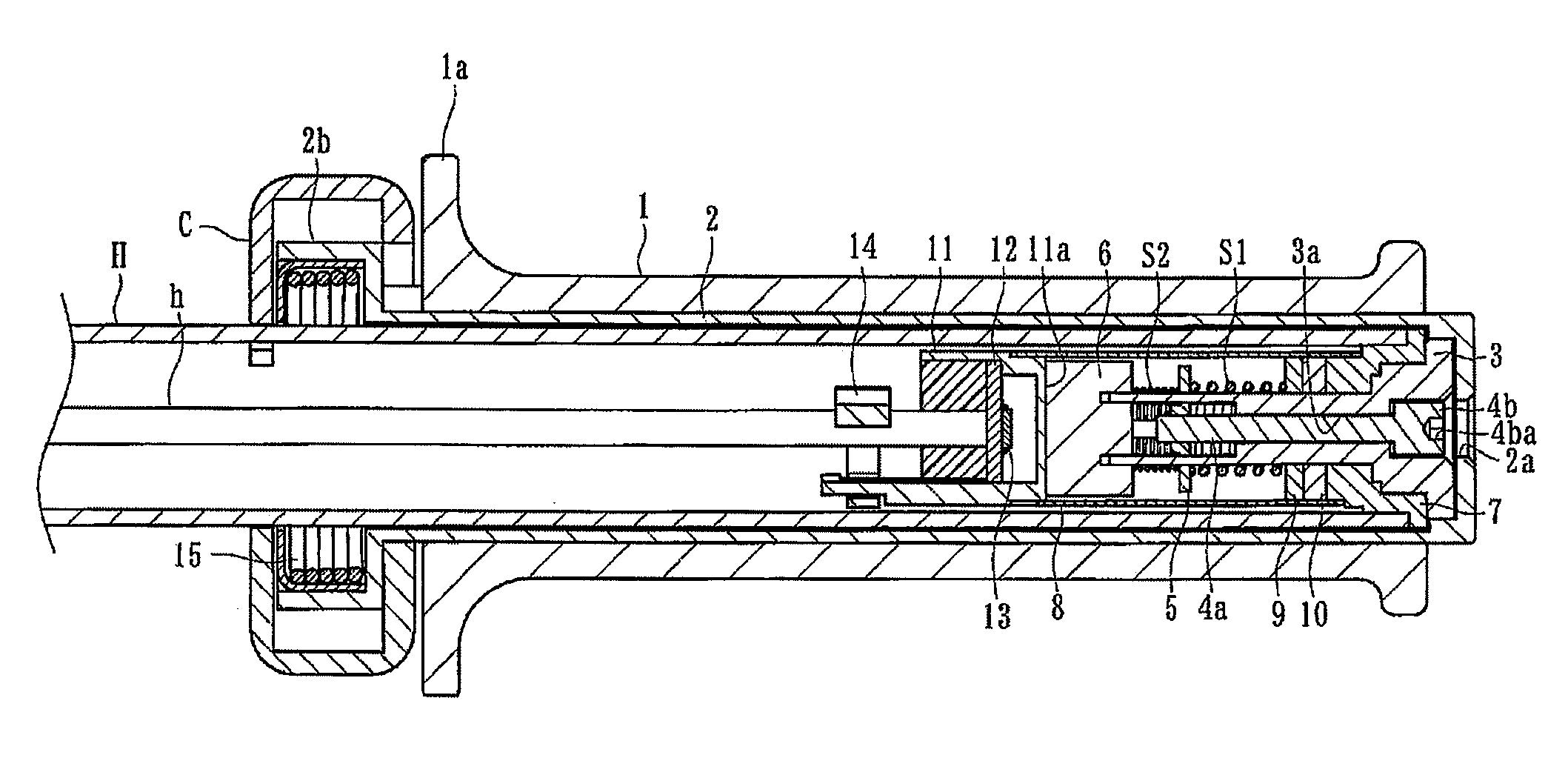

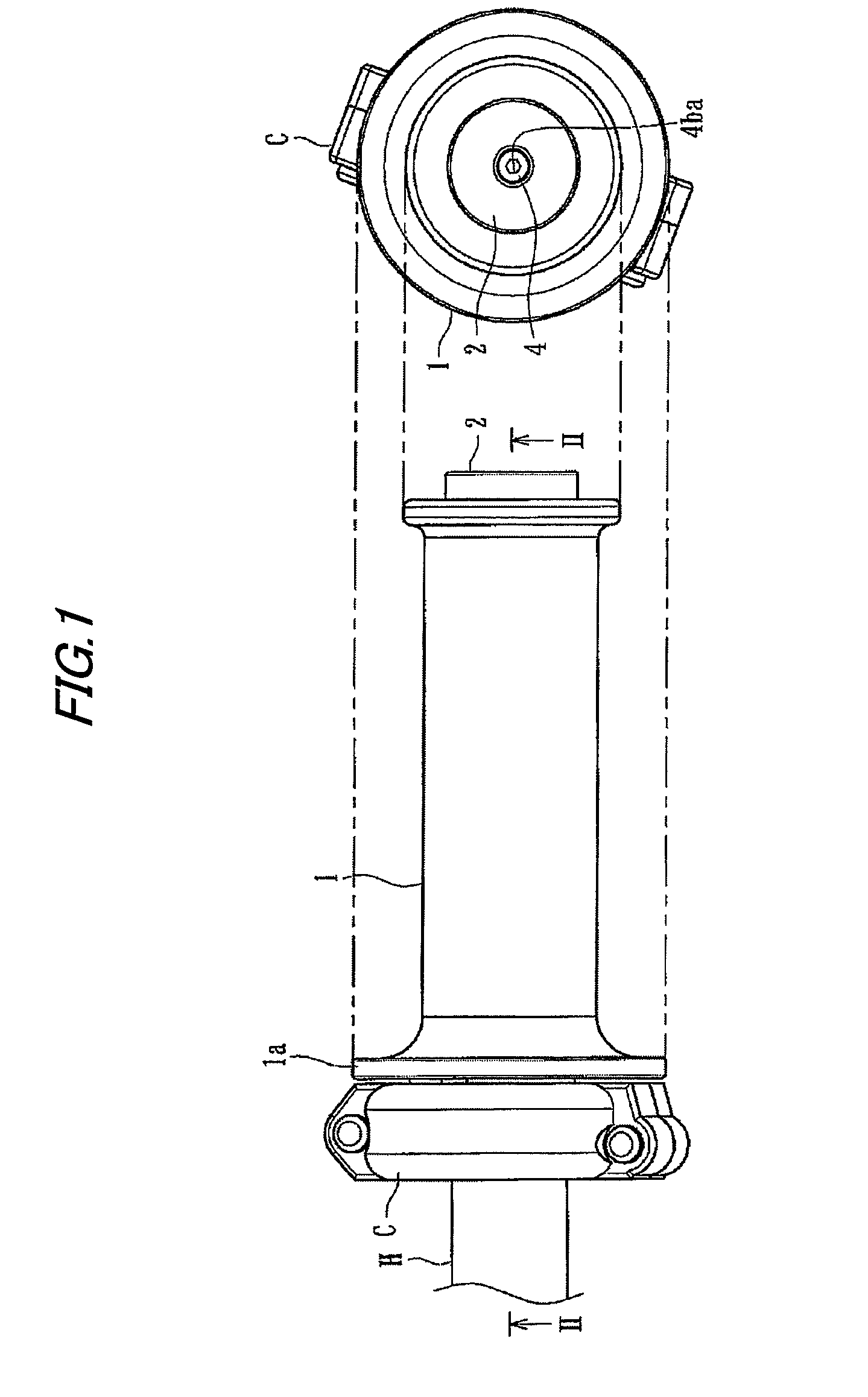

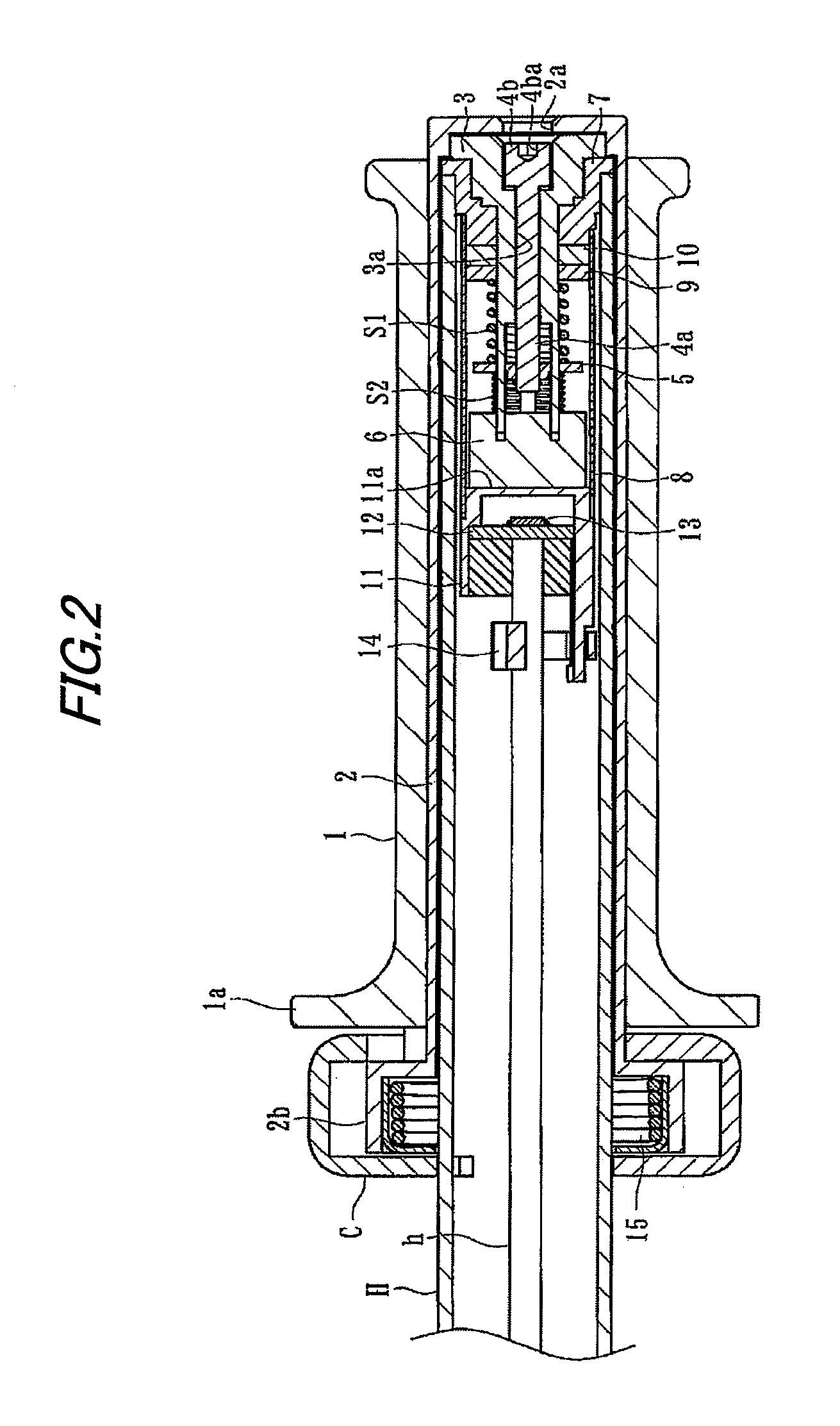

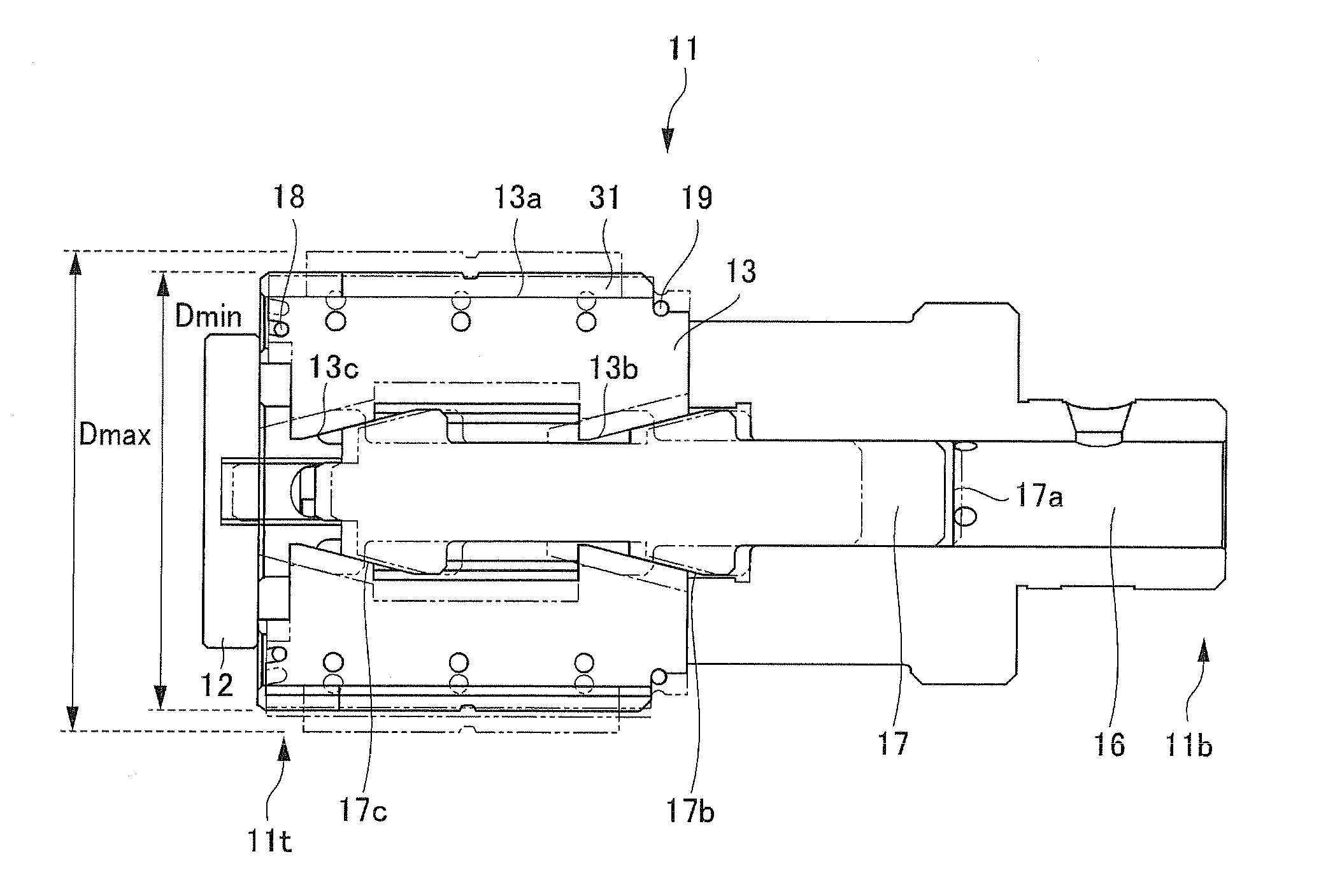

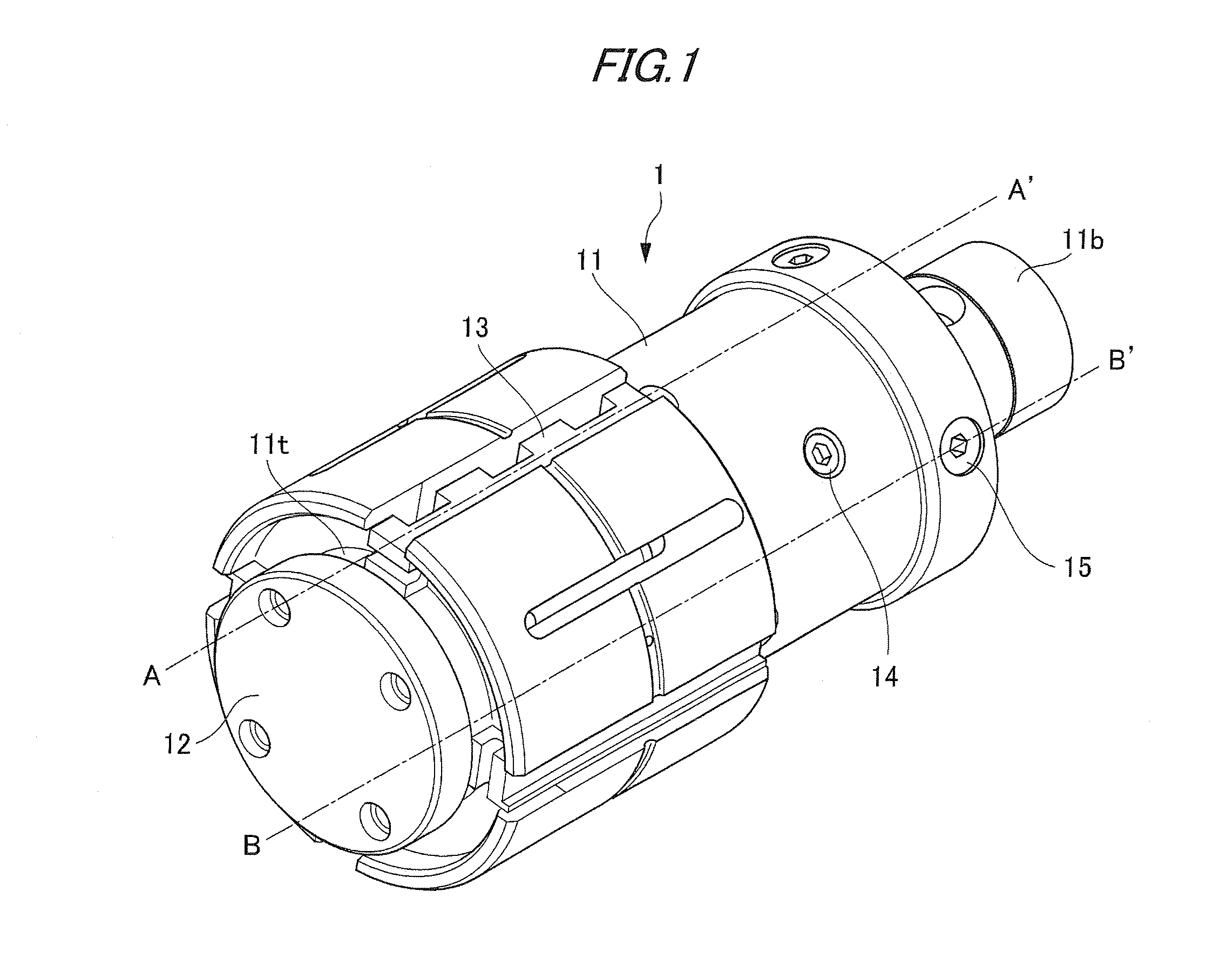

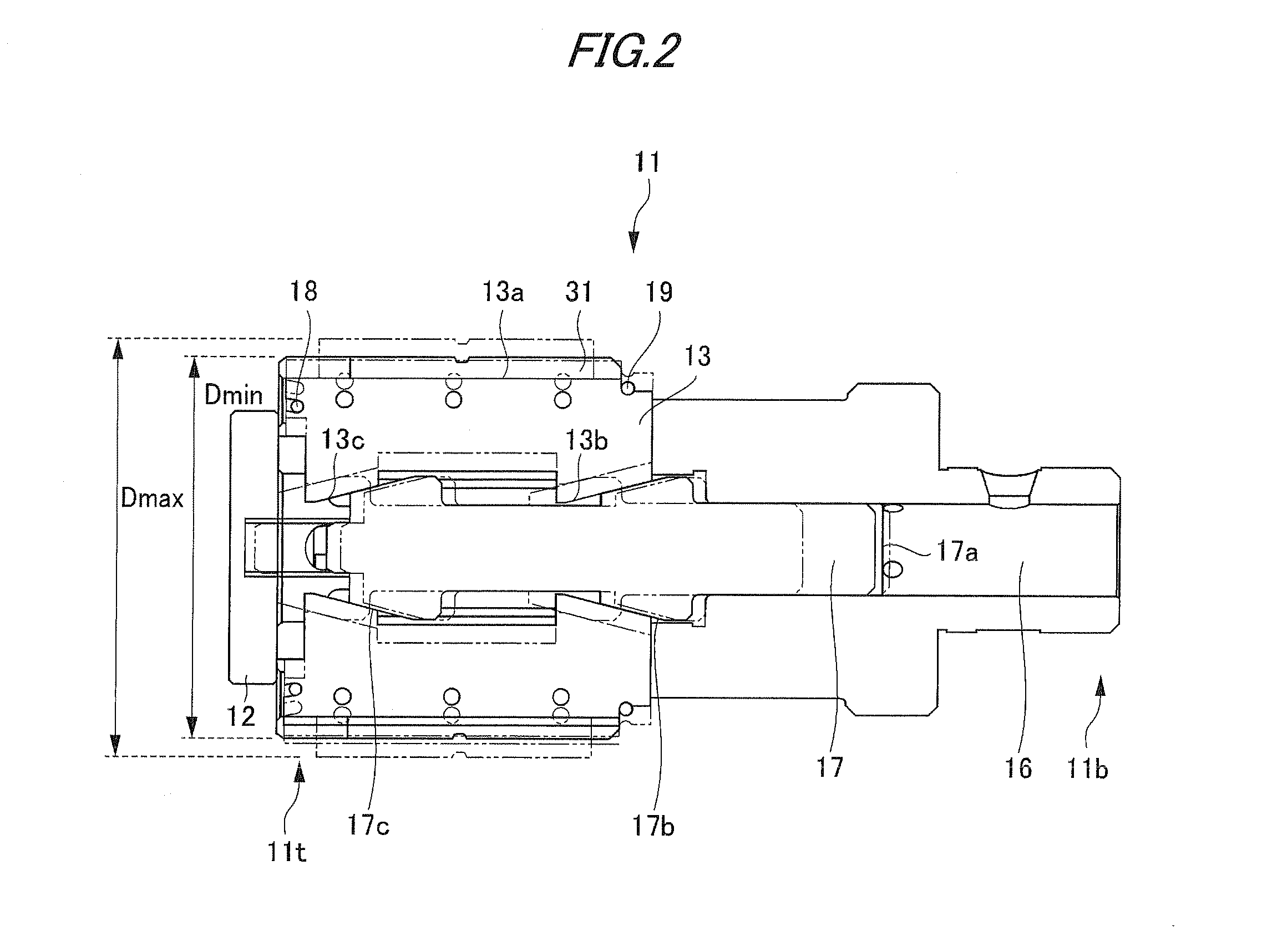

Throttle grip apparatus

ActiveUS20100162848A1Reduce in sizeSmall sizeControlling membersCycle control systemsMagnetEngineering

A throttle grip apparatus is provided with: a throttle grip (1) rotatably mounted on a leading end of a handle bar (H) of a vehicle; a magnet (6) rotatable together with the throttle grip (1); a detector (13) for detecting variations in a magnetic field of the magnet (6) in a non-contact manner to detect a rotation angle of the throttle grip (1); and a frictional plate (9, 10) for generating a rotation load of the throttle grip (1). An engine of the vehicle is controlled based on a detected value of the detector (13). The frictional plate (9, 10) is disposed within the handle bar (H).

Owner:ASAHI DENSO KABUSHIKI KAISHA

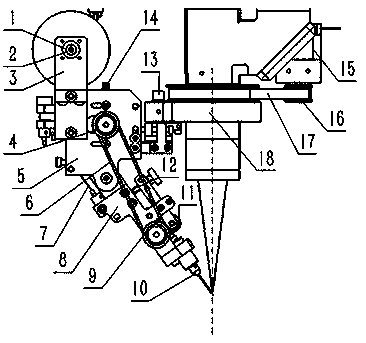

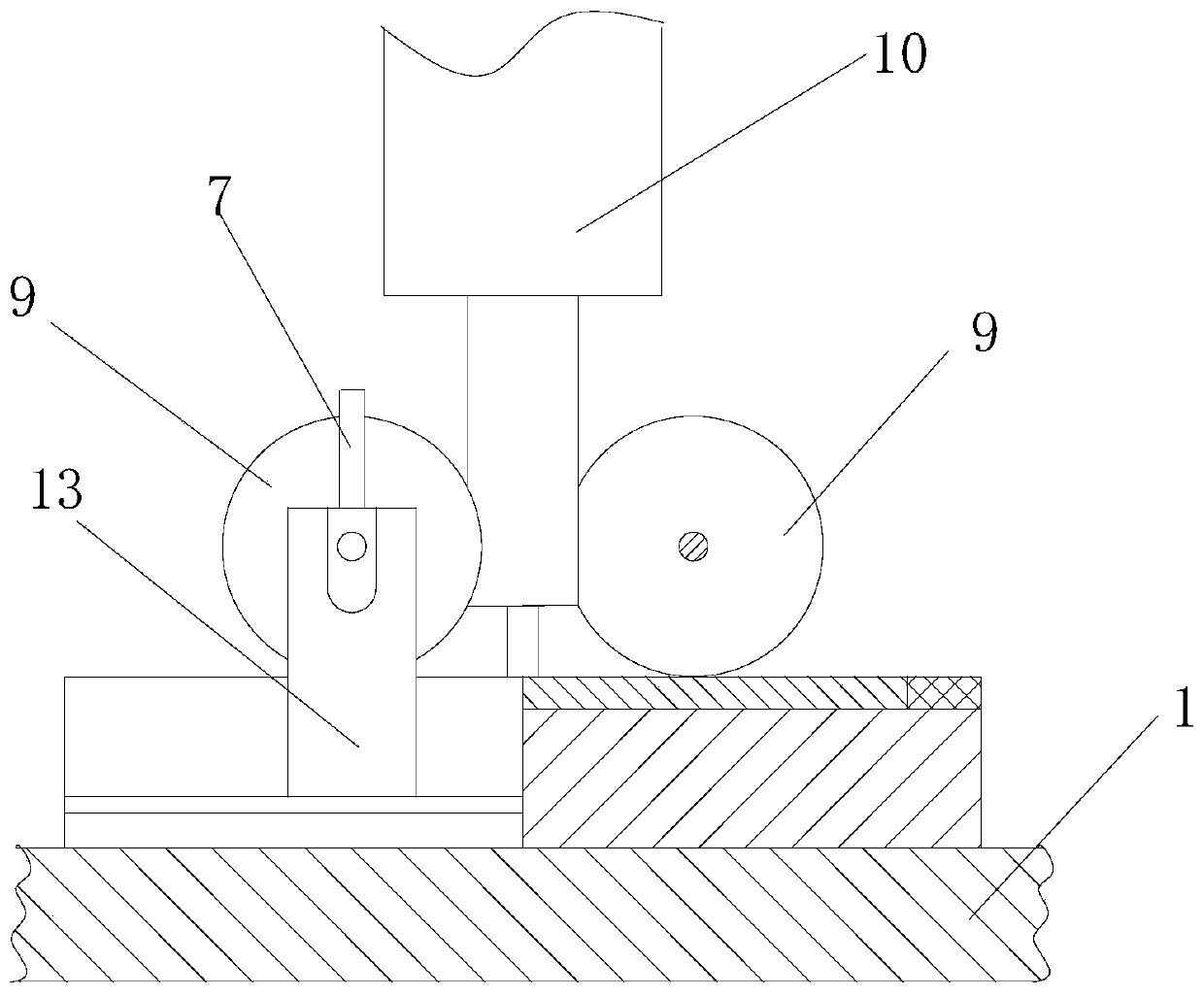

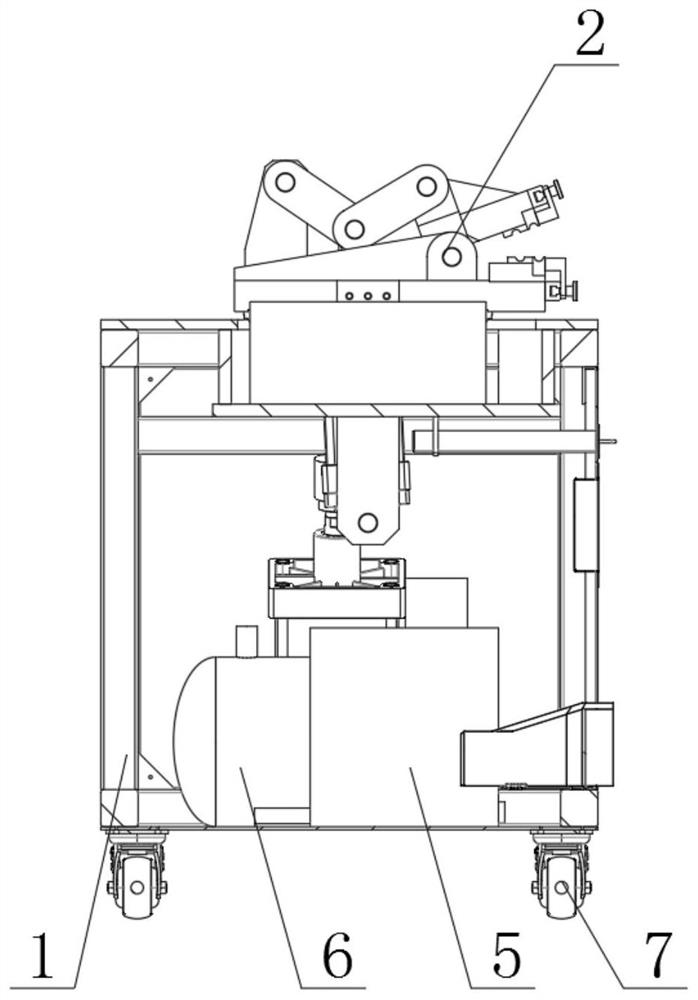

Automatic tin wire feeding device for laser welding

PendingCN109365936ASolve stress deformationSolve the cloggingSolder feeding devicesEngineeringArc welding

The invention discloses an automatic tin wire feeding device for laser welding. The automatic tin wire feeding device comprises a wire feeding mechanism and a welding rotating mechanism, wherein the wire feeding mechanism is formed by connecting a tin wire fixing device, a tin wire transmission device, a tin wire guide device, and a tin wire pressing regulating device; the welding rotating mechanism is fixedly connected with the wire feeding mechanism through a lifting mechanism; after the welding head centre line of the welding rotating mechanism is superposed with the centre line of a seconddriven wheel, the welding rotating mechanism and a wire feeding nozzle outlet are positioned on the same welding position. In this way, when the wire feeding mechanism has an angle of deflection, thewire outlet position is ensured to be kept consistent with a laser welding spot all the time; and moreover, wire feeding resistance can be prevented from being too great, stress deformation generatedby a tin wire during wire feeding is avoided, and a wire blocking phenomenon further can be prevented.

Owner:威克锐光电科技(苏州)有限公司

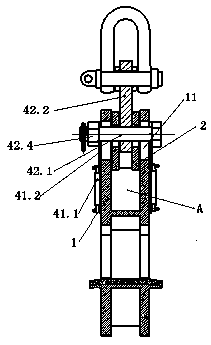

Self-locking casing head

ActiveCN113006731APrevent rotationPrevent bouncing up and downSealing/packingStructural engineeringPetroleum oil

The invention relates to the technical field of petroleum drilling and production equipment, and provides a self-locking casing head. The self-locking casing head comprises a casing head body, wherein the casing head body is provided with a mounting hole; a hanger is arranged in the mounting hole; a sealing assembly is arranged between the hanger and the mounting hole; the casing head body is further provided with a mounting groove; the mounting groove communicates with the mounting hole; a plurality of clamping pieces are uniformly distributed at intervals in the circumferential direction of the mounting hole; the clamping pieces are provided with inverted teeth; the end of the hanger is provided with positive teeth; the inverted teeth are matched with the positive teeth; the clamping pieces are provided with vertical long-strip holes; a rotating shaft penetrates through the long-strip holes; reset elastic pieces are arranged on the clamping pieces; the upper ends of the clamping pieces are connected with the mounting groove through the reset elastic pieces; the lower ends of the clamping pieces abut against the inner wall of the bottom surface of the mounting groove; the bottom surface of a locking piece mounting groove is provided with a locking hole; a locking piece is arranged in the locking hole in a sliding mode in the vertical direction; and the clamping piece is jacked up after sliding. According to the technical scheme, the problem that an oil pipe is prone to loosening in the prior art is solved.

Owner:京鸿石油钻采工程技术有限公司

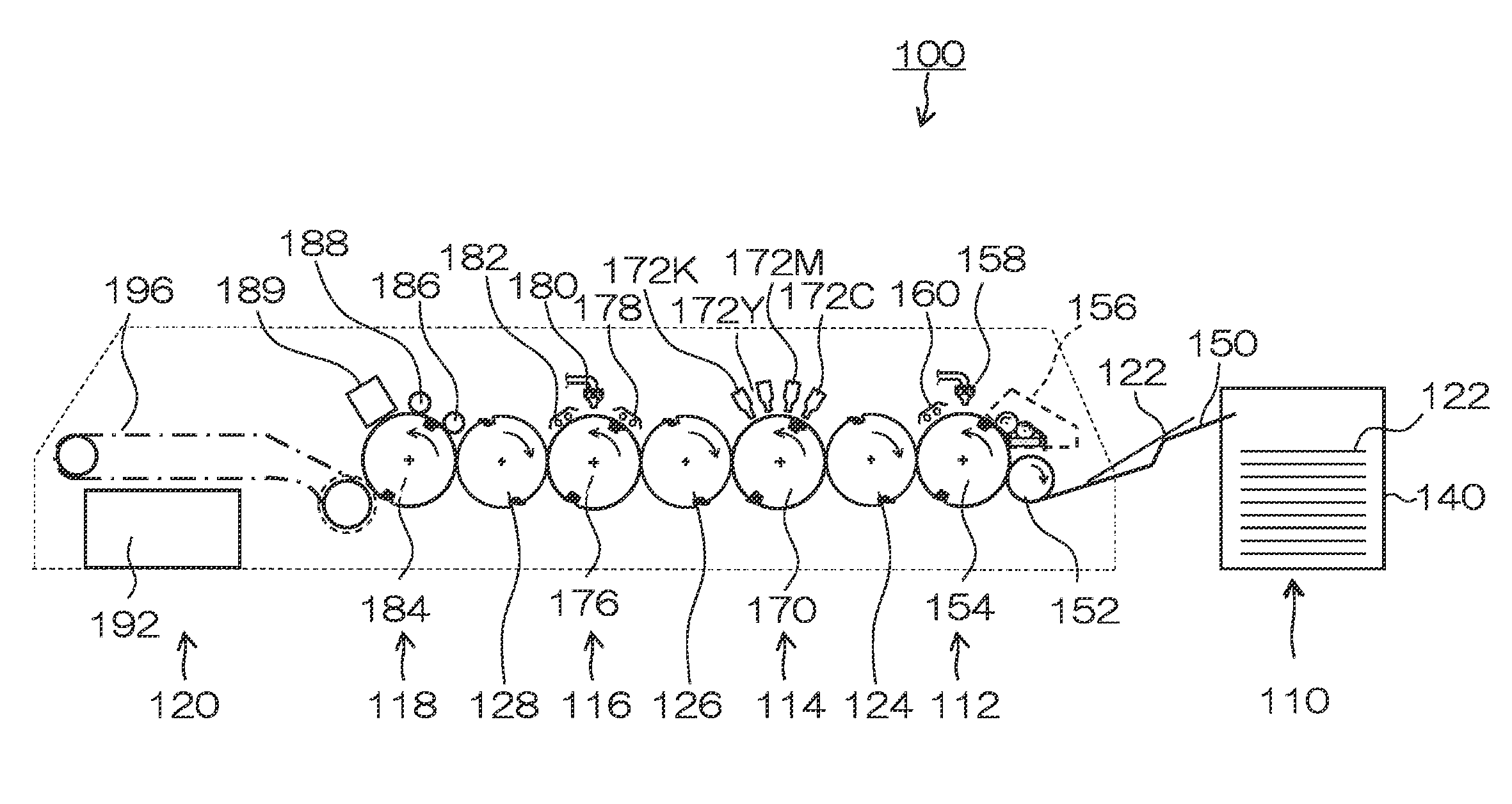

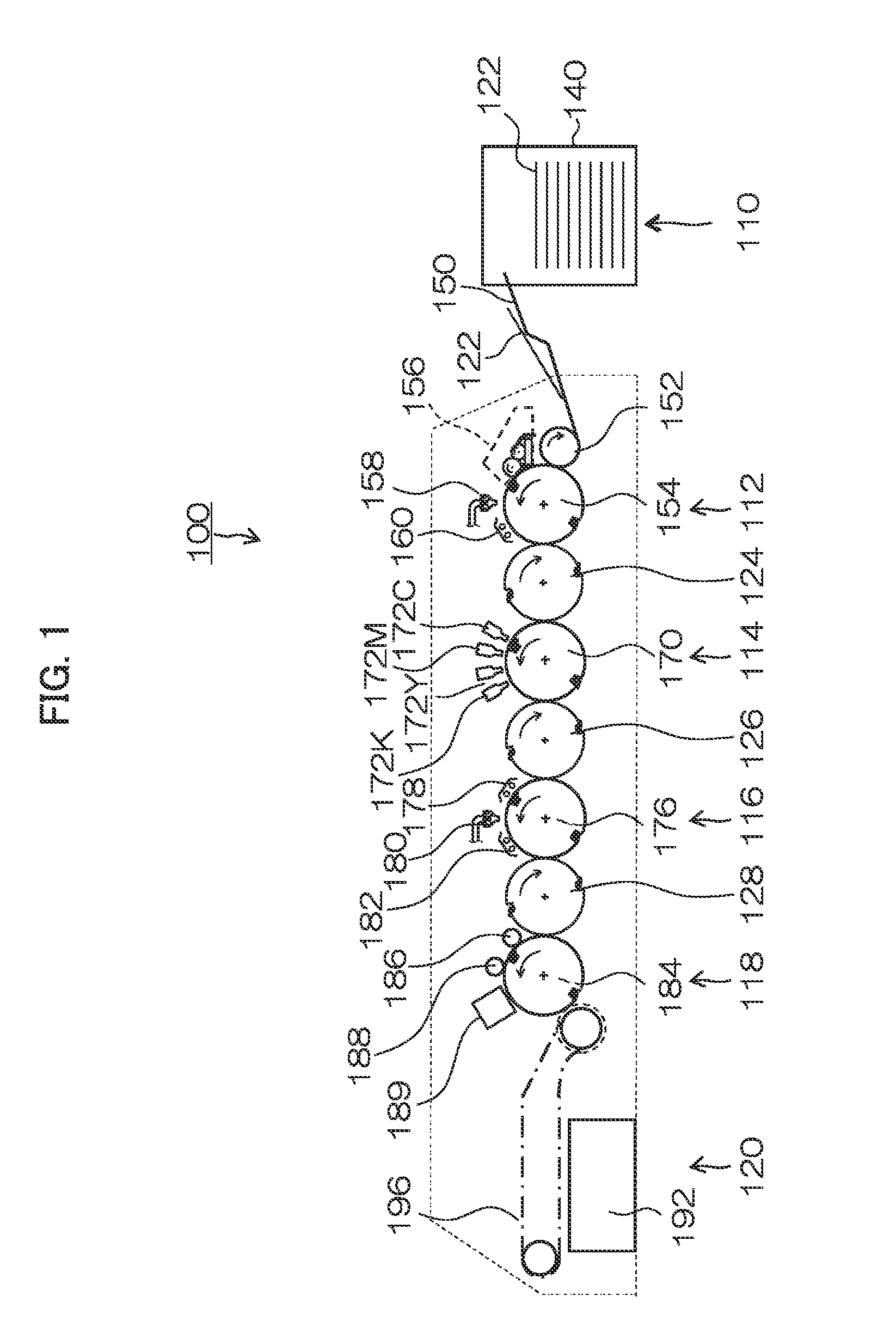

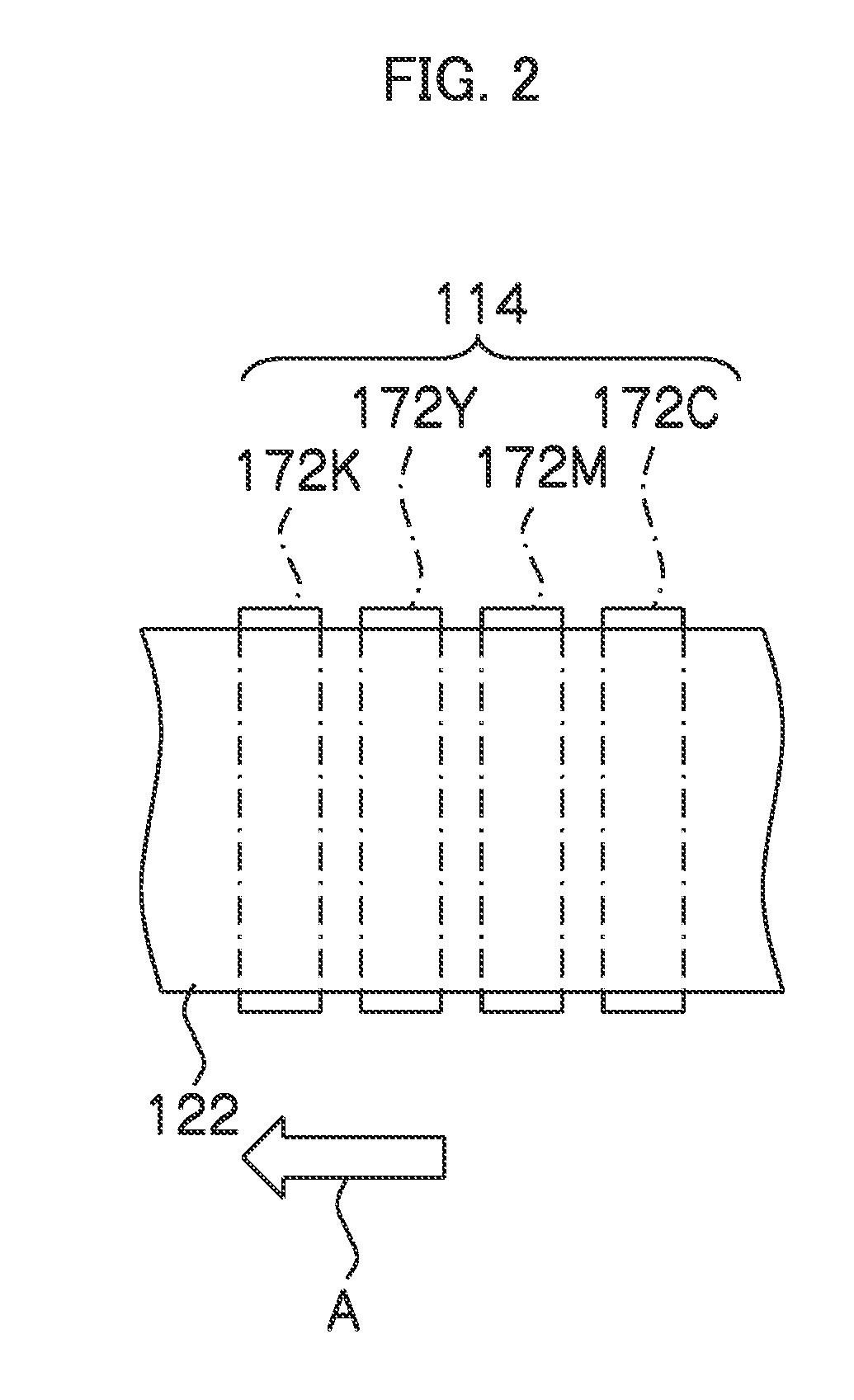

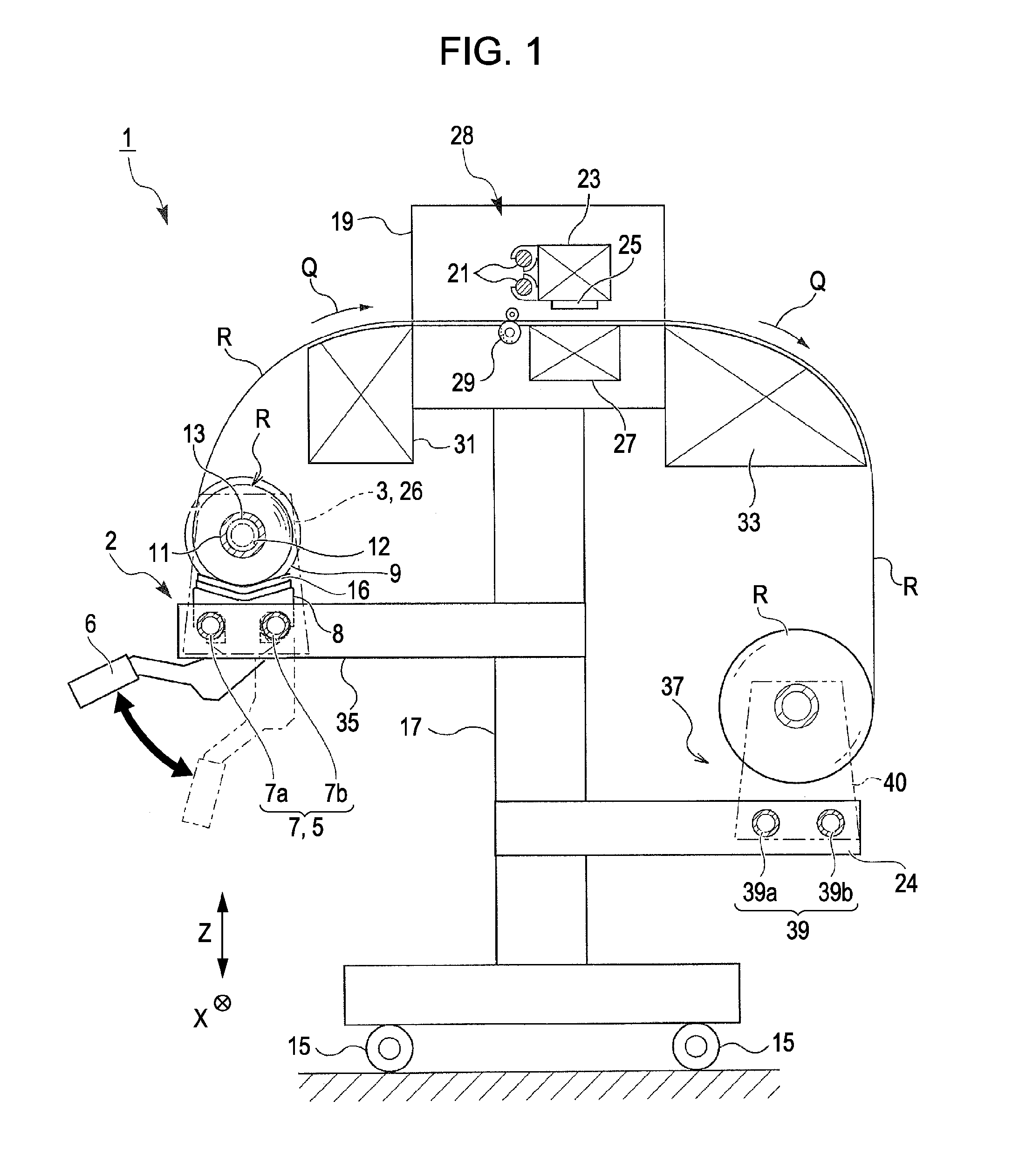

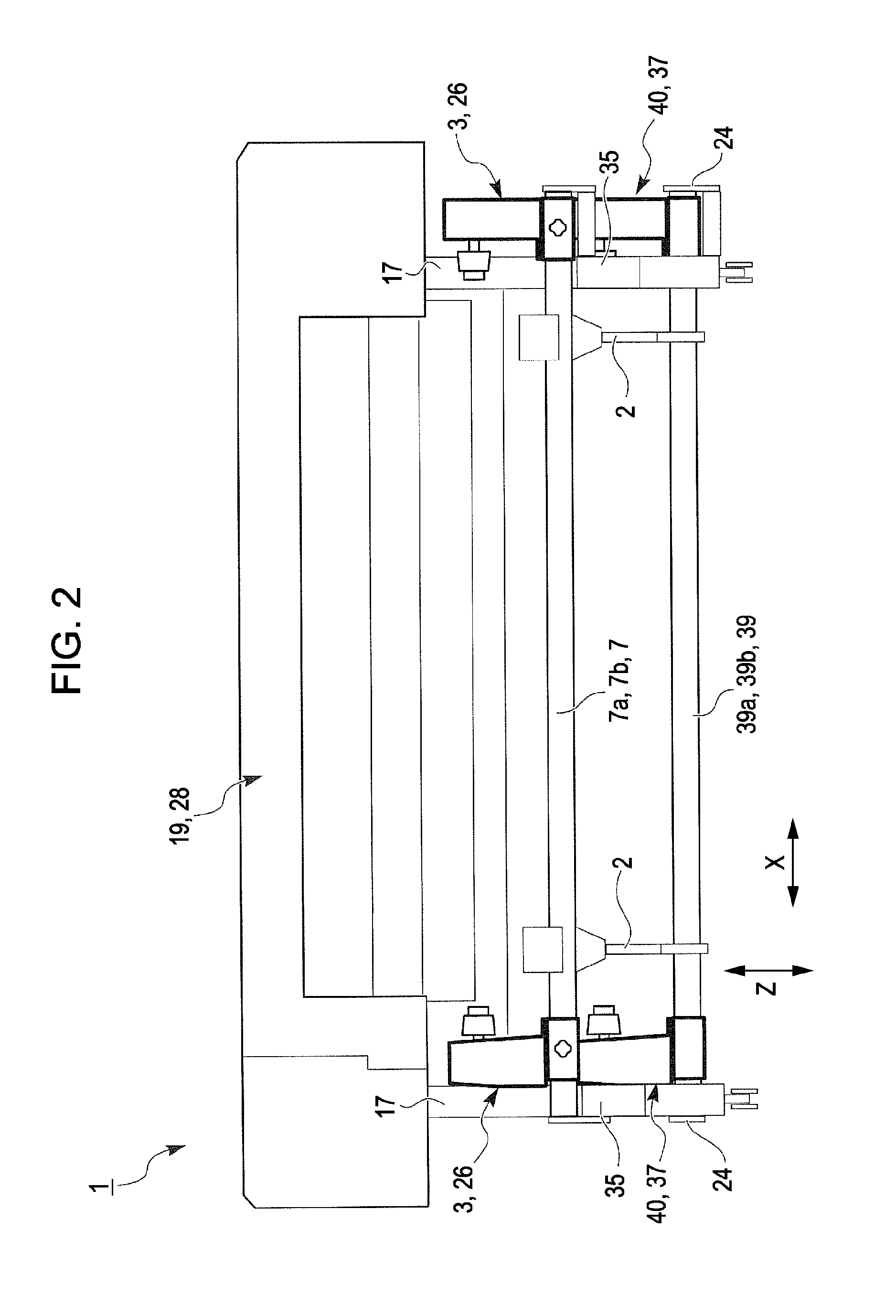

Recording apparatus

InactiveUS20110069103A1Not to produce severeSuppress wrinklesOther printing apparatusFlexural rigidityRecording media

The recording apparatus includes: an image forming device which deposits ink onto a recoding medium to form an image; a conveyance device which conveys the recording medium in a recording medium conveyance direction at a recording medium conveyance speed; a pressing member which presses the recording medium on which the ink has been deposited, onto the conveyance device; and a pushing device which pushes the pressing member to press the recording medium to suppress cockling occurring in the recording medium on which the ink has been deposited, the pushing device having a spring constant k that satisfies48EI(1 / f)3<k<v·2At·48EI(1 / f)3,where EI is a flexural rigidity of the recording medium, t is a thickness of the recording medium, v is the recording medium conveyance speed, A is an amplitude of the cockling in the recording medium, and f is a frequency of the cockling in the recording medium along the recording medium conveyance direction.

Owner:FUJIFILM CORP

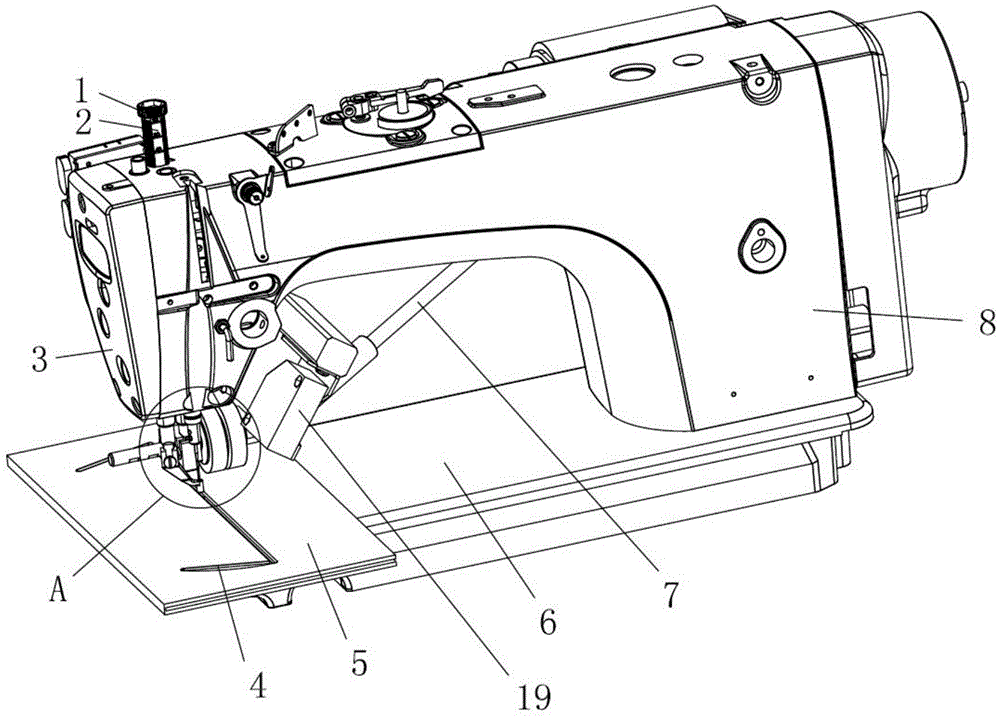

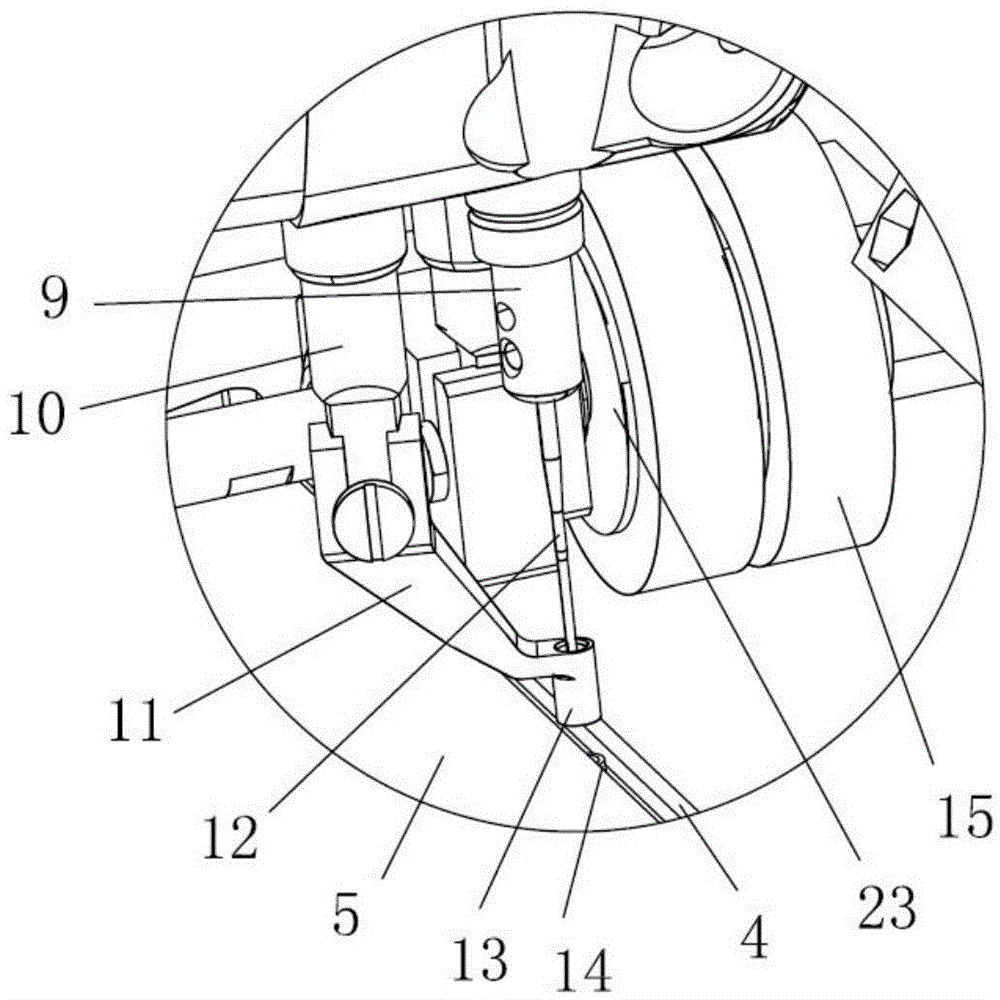

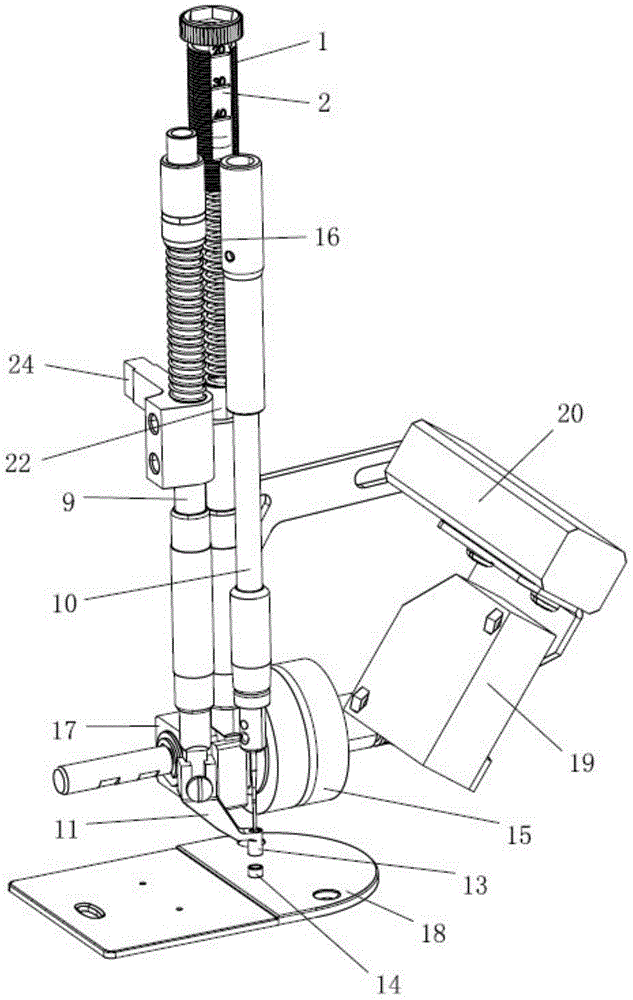

Novel intelligent template sewing machine and automatic induction sewing method

ActiveCN104911826AAvoid wrinklesAvoid tearingProgramme-controlled sewing machinesPressersMotor driveControl signal

The invention belongs to the technical field of sewing machines and particularly relates to a novel template sewing machine. The novel template sewing machine comprises a machine shell, the machine shell is provided with a cloth drag mechanism, a template photoelectric sensor and a controller, a needle plate of the template sewing machine is provided with a lower guide sleeve, a sewing needle penetrates through the lower guide sleeve, a thread is hooked by the lower guide sleeve, and the lower guide sleeve can be embedded in a guide groove in a template to be adapted. The novel template sewing machine further comprises an induction device. The induction device is used for sending out a control signal to the controller when it is detected that the sewing needle penetrates out of cloth upwards, and the controller controls a stepping motor of the cloth drag mechanism to be started according to the signal; the induction device sends out a control signal to the controller when the sewing needle penetrates into the cloth downwards, the controller controls the stepping motor of the cloth drag mechanism to be suspended according to the signal, and a motor shaft of the stepping motor drives a drag wheel to rotate through a universal coupling. When the sewing needle penetrates into the cloth, the cloth drag mechanism can be controlled by the controller to be suspended, so that cloth tear caused by non-correspondence of the cloth drag mechanism and the sewing needle is avoided.

Owner:佛山市朗宸机械有限公司

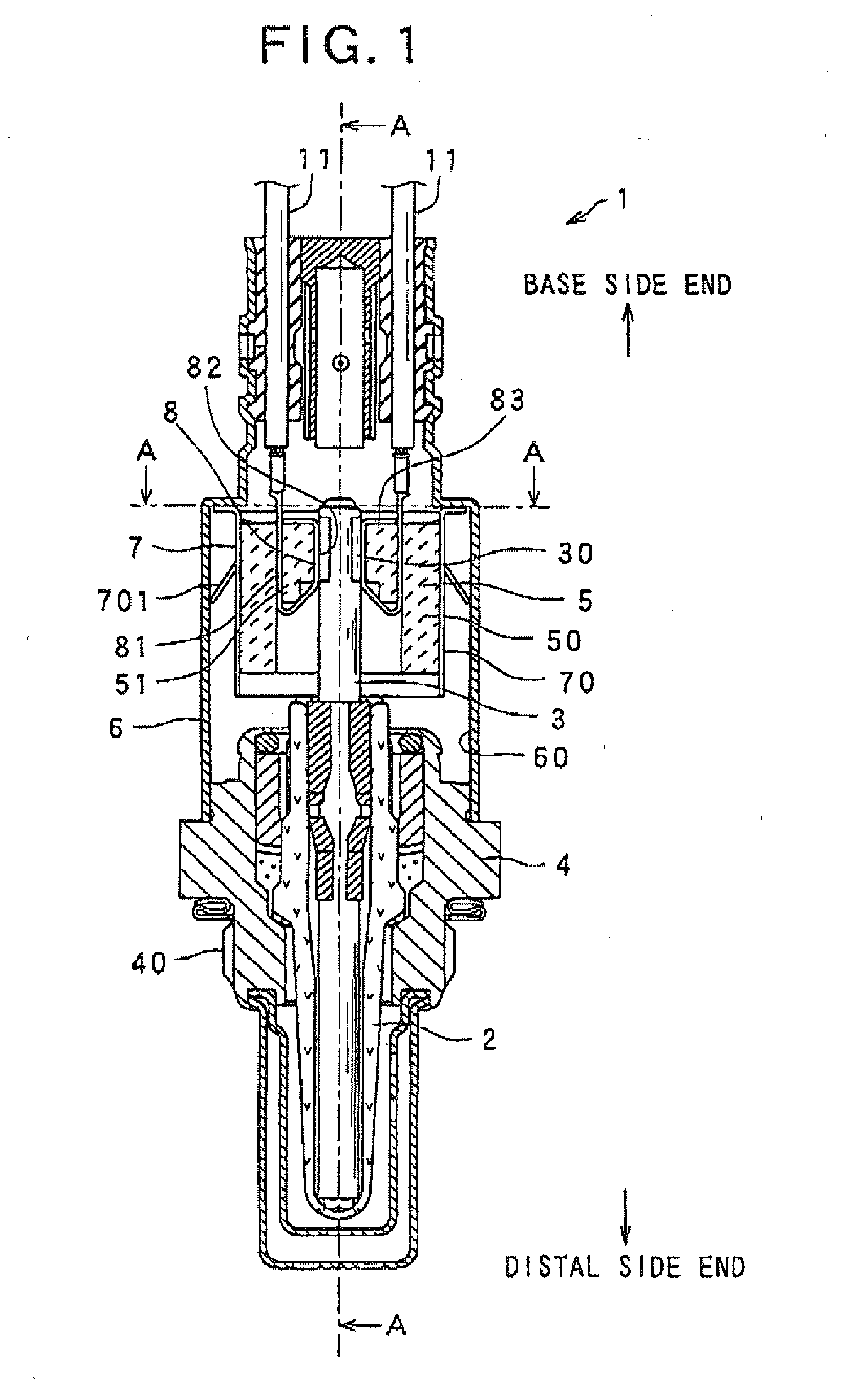

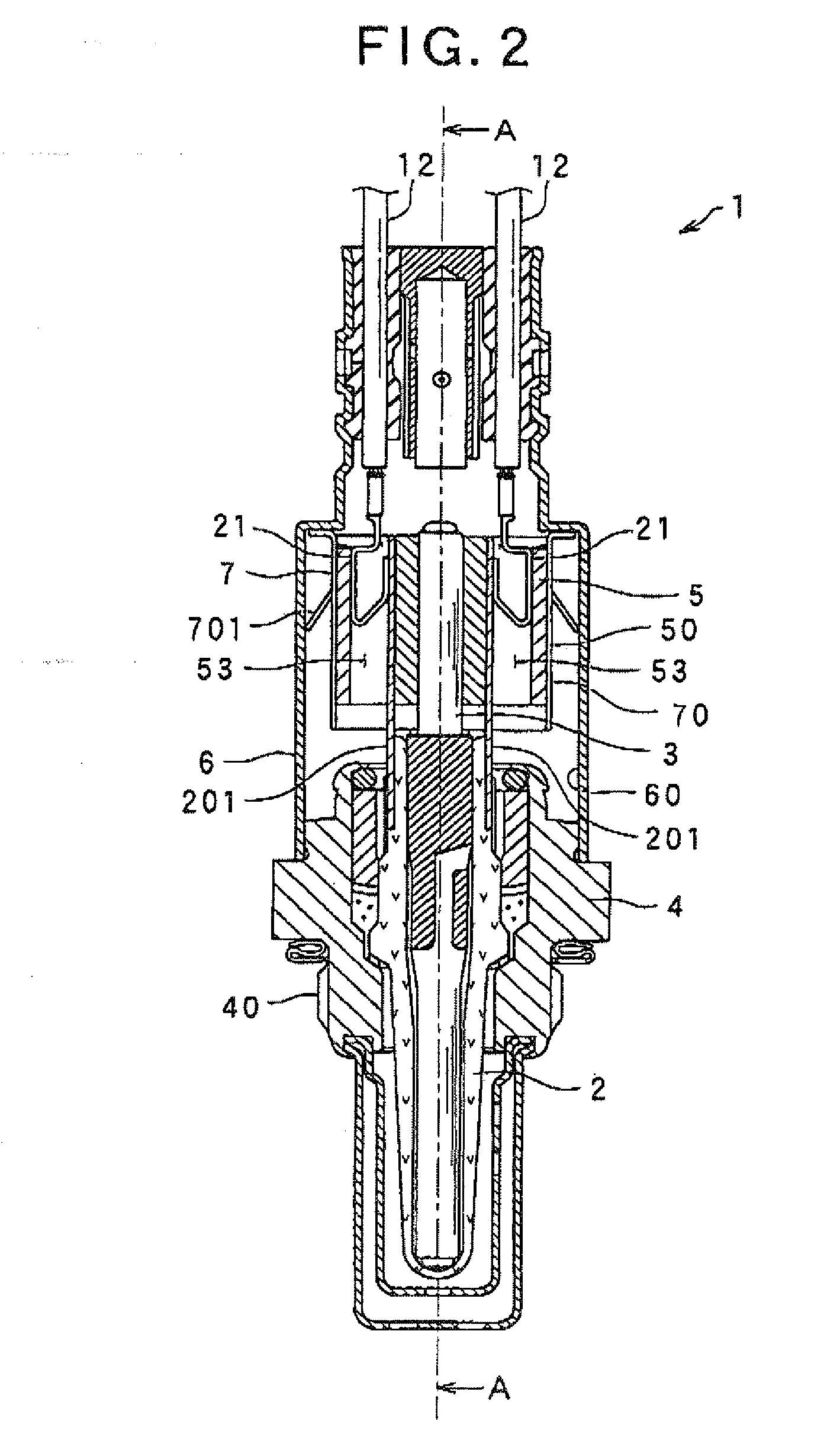

Gas sensor having insulator assembly for supporting heater

InactiveUS20080295576A1Adjustable pressing forceEasily boundedMaterial analysis by electric/magnetic meansElectricityEngineering

There is provided a gas sensor that includes a sensor element, a heater that comprises an electrode, a housing that holds the sensor element therein, an insulator assembly that surrounds a part of the heater and is constituted of a plurality of insulators, an electric terminal member that is located between the one of the plurality of the insulators and the electrode of the heater, a cover that covers the insulator assembly, a holder for holding the insulator assembly, and an elastic member that is located between the holder and the cover to generate elastic force which is applied at least to the one of the plurality of the insulators to pinch the heater between the one and another one of the plurality of the insulators via the holder so as to bring the electric terminal member into constant electric contact with the electrode of the heater.

Owner:DENSO CORP

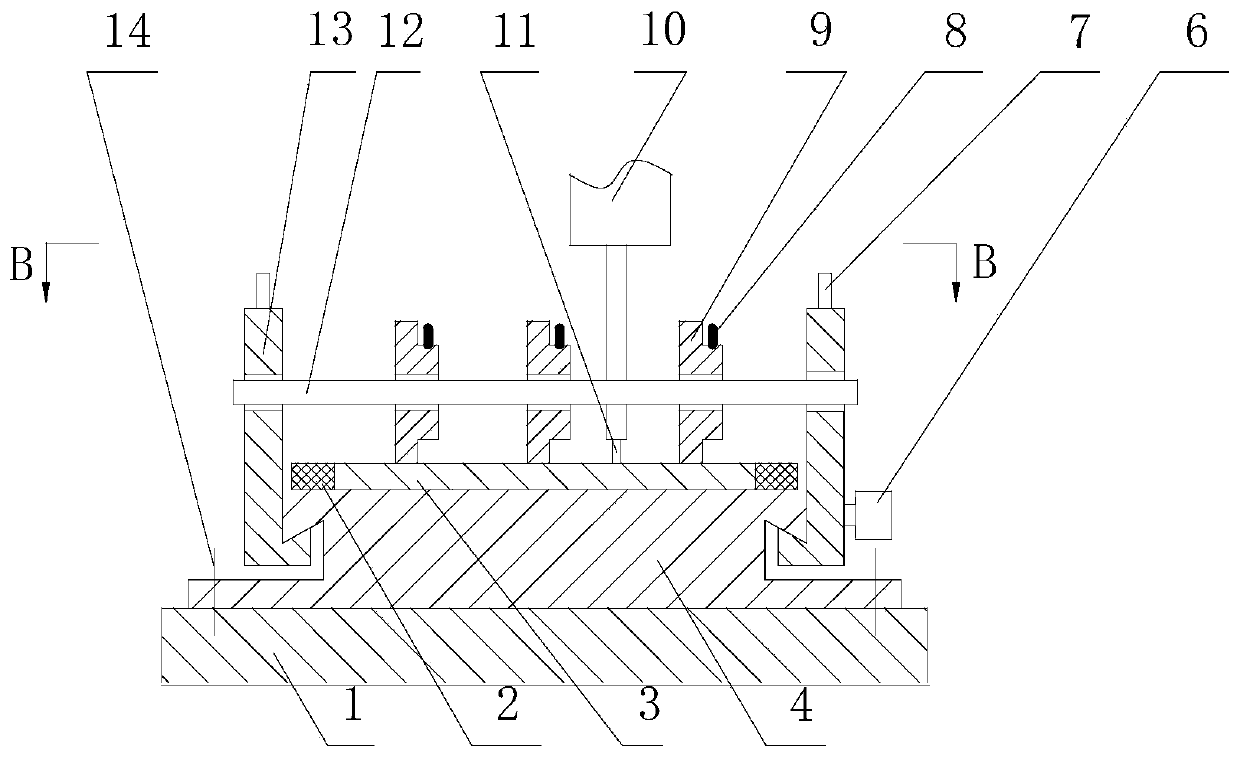

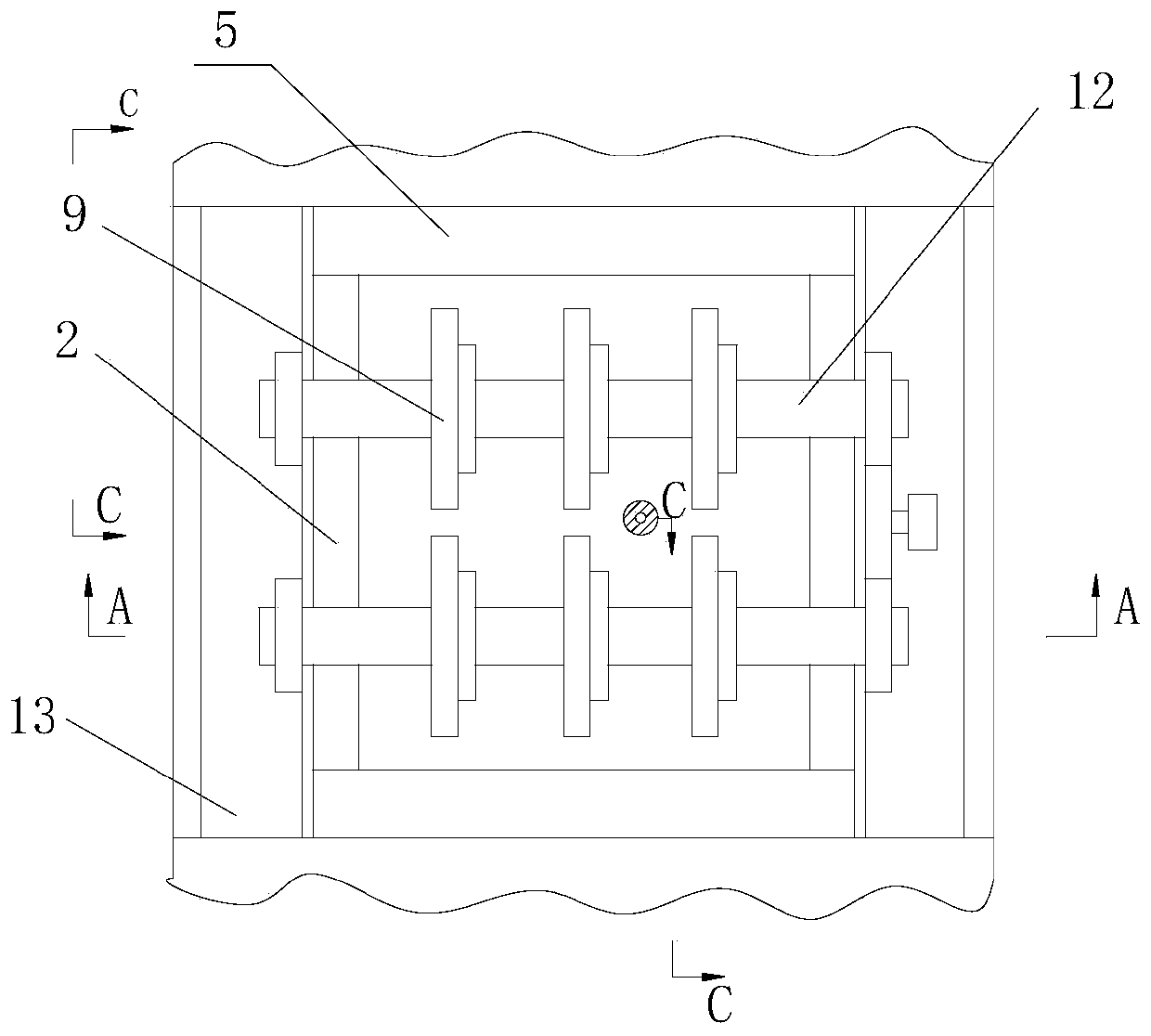

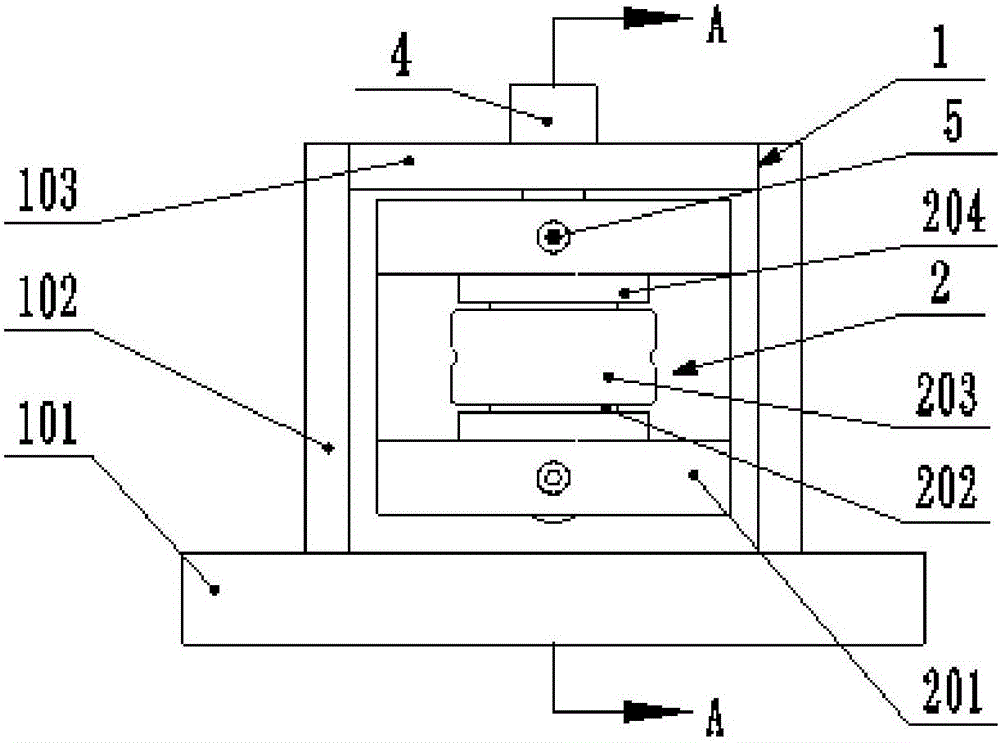

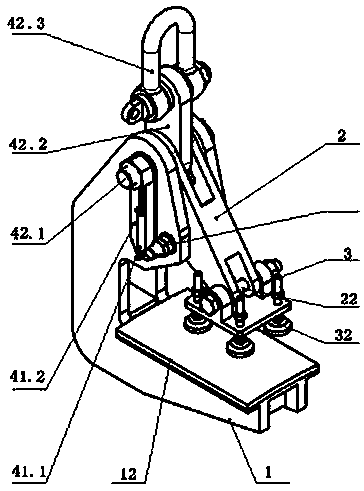

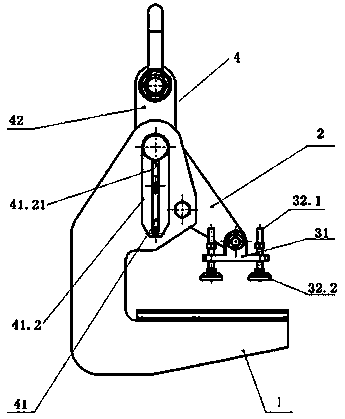

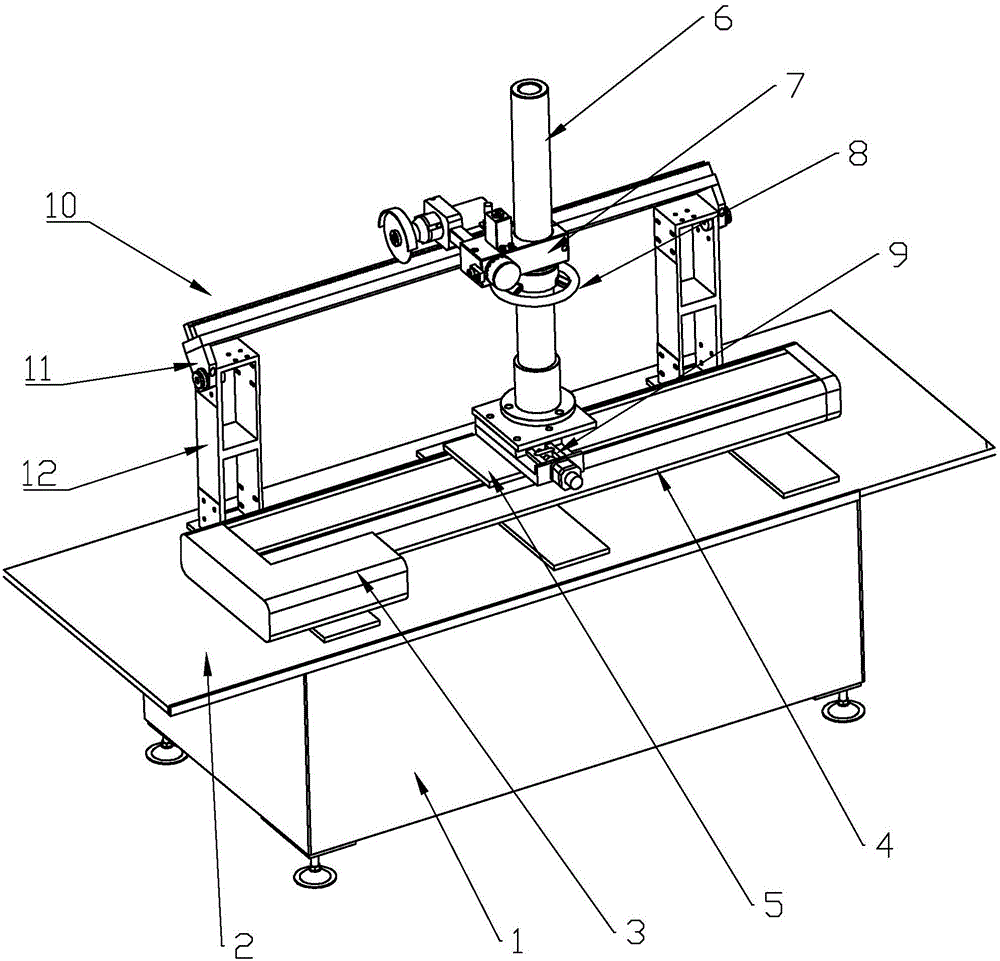

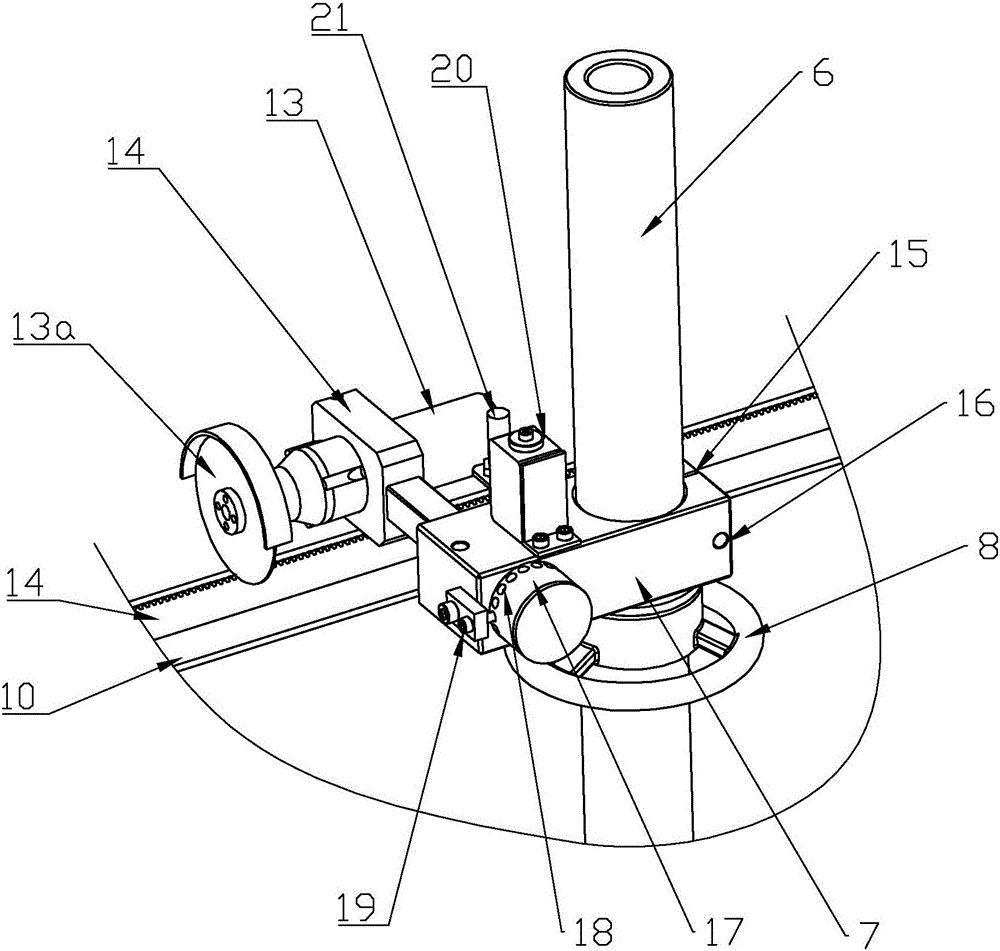

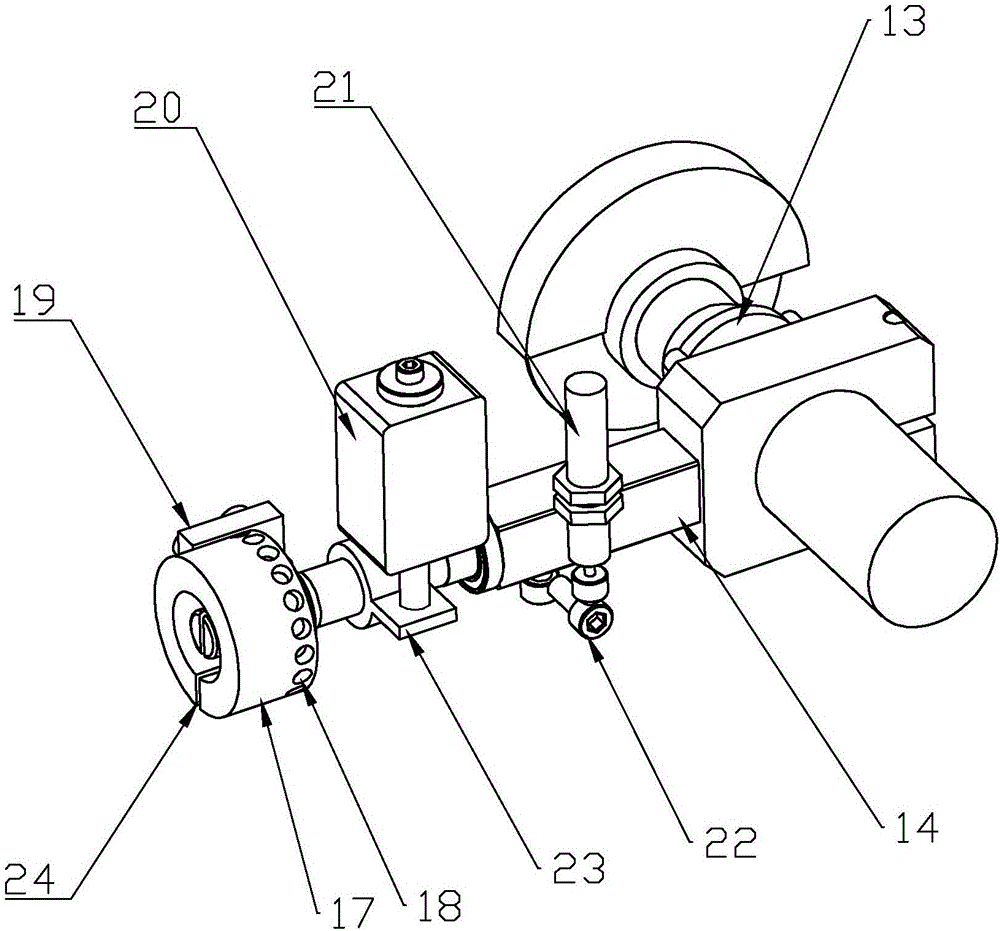

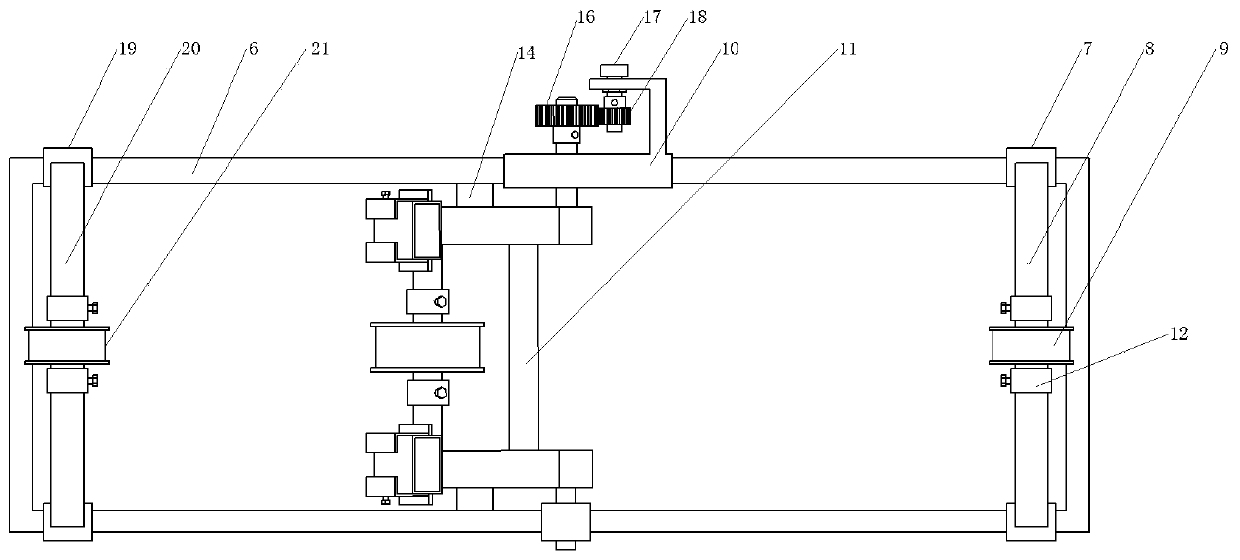

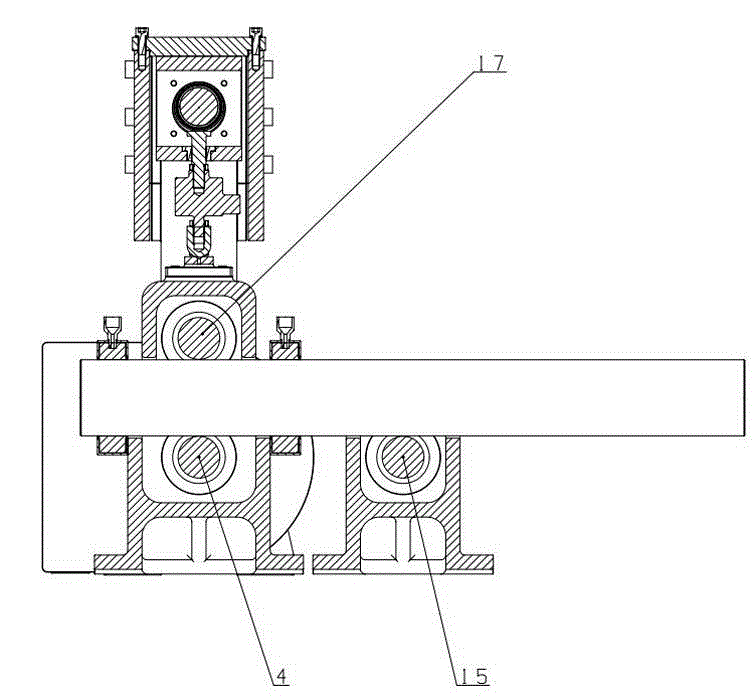

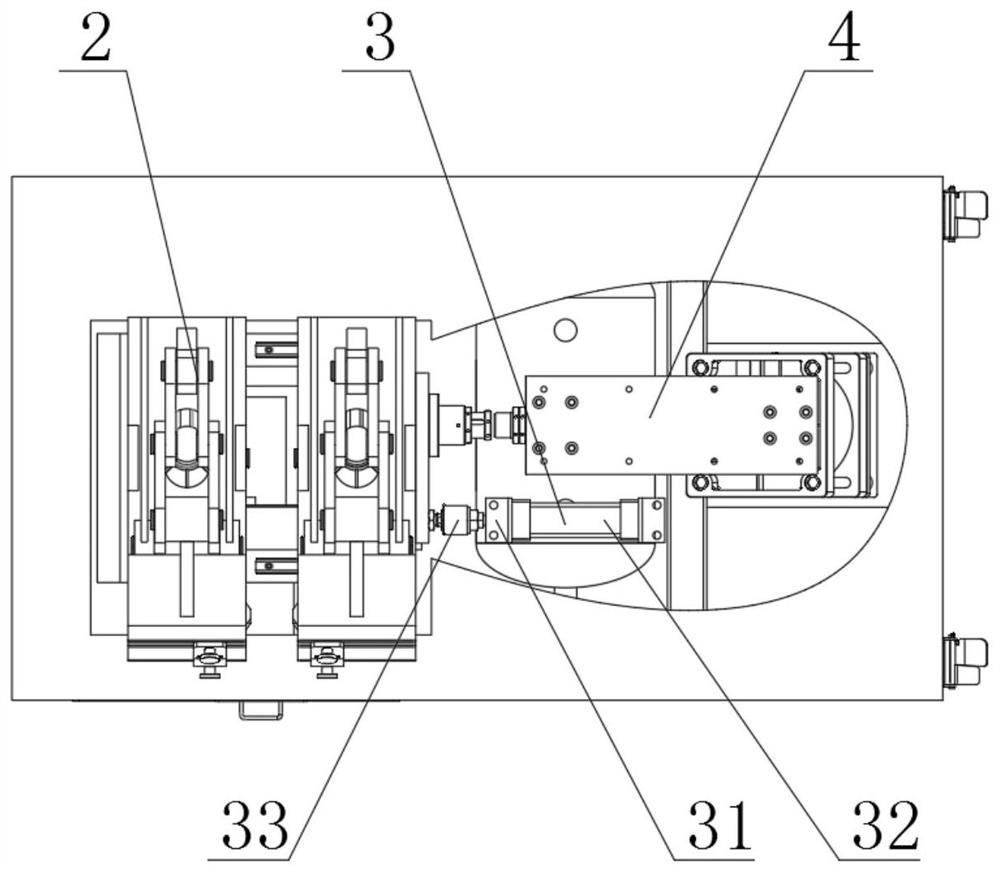

Special tool clamp for friction stir welding of complex welding seam aluminum alloy

PendingCN110434453AGuaranteed distanceAdjustable pressing forceNon-electric welding apparatusFriction stud weldingFriction stir welding

The invention relates to a special tool clamp for friction stir welding of complex welding seam aluminum alloy. The special tool clamp comprises a friction stir welding workbench, a friction stir welding machine head and a stirring head, wherein: a clamp base is fixedly connected to the friction stir welding workbench; the clamp base is provided with an X / Y axis direction limiting mechanism; a welded workpiece is placed in the X / Y axis direction limiting mechanism; the upper surface of the welded workpiece is in rolling pressure connection with a workpiece pressing mechanism; the workpiece pressing mechanism slides on the clamp base along the X-axis direction of the friction stir welding; and the workpiece pressing mechanism is driven by a variable speed and adjustable speed motor. The special tool clamp for friction stir welding of complex welding seam aluminum alloy, provided by the invention, has the advantages that: a plurality of pressing wheels which can roll on the surface of the welding seam for pressing are adopted, the pressing force and the pressing position of the pressing wheels are adjustable, and the pressing wheels can move along with the movement of the stirring head, thereby ensuring the distance between the pressing point and the welding seam and ensuring that the pressing wheels do not interfere with the stirring head; and special tool clamp for friction stir welding of complex welding seam aluminum alloy can make the welding seam continuous, and improve the welding seam quality and the processing efficiency.

Owner:中色(天津)特种材料有限公司

Compressing device for single-side spot welding of stainless steel sidewall, spot welding machine and welding process

ActiveCN103567617AHeight adjustableImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesBeam crossingSpot welding

The invention relates to a compressing device for single-side spot welding of a stainless steel sidewall, a spot welding machine and a welding process. The spot welding machine comprises a welder gantry, a welding platform, and spot welding electrodes. The welding platform is used for holding a sidewall to be welded. The compressing device is disposed on the welding platform and comprises two vertical posts arranged on two sides of the welding platform, and a cross beam crossing over the welding platform and connecting the two vertical posts. The cross beam is provided with a plurality of compressing parts used for compressing the sidewall. The vertical posts are movably connected with the welding platform. A frame and a wallboard are integrally compressed with the compressing device, the frame is tightly attached to the outer face of the wallboard and the platform, corrugated deformation of a workpiece is eliminated by pressure of an air cylinder, the wallboard and the frame form a whole after spot welding, and the whole is higher in rigidity; after compressing force is removed, the outer surface can still be even and flatness is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

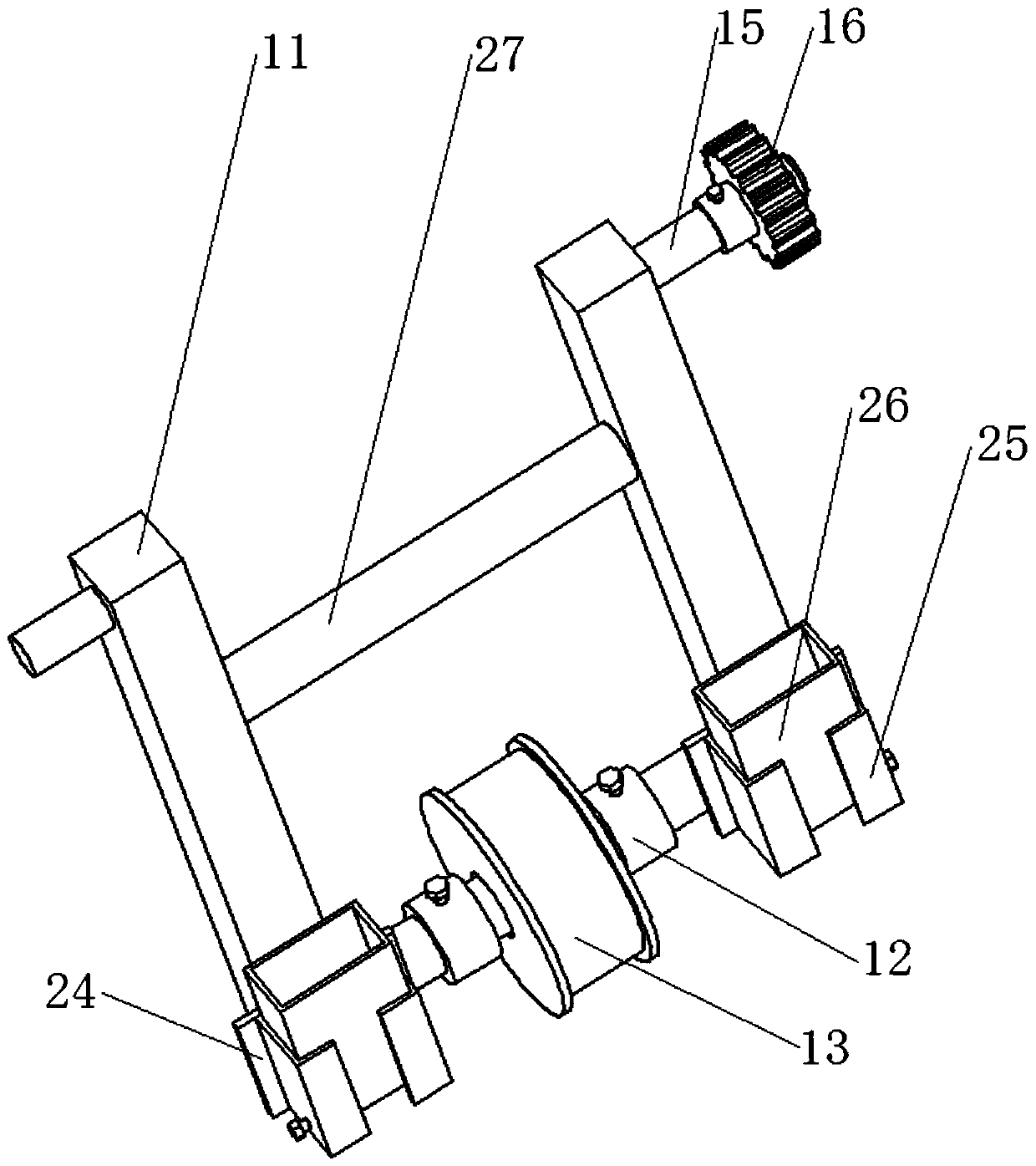

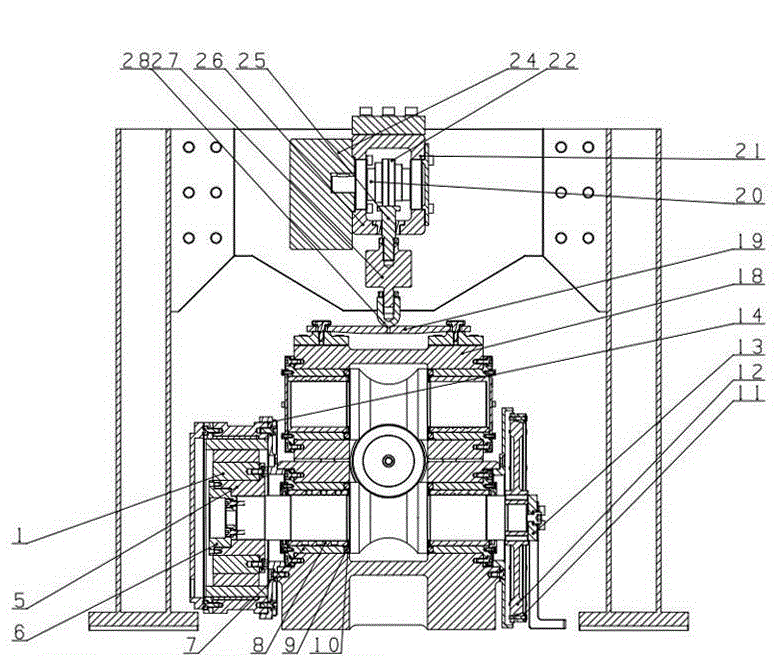

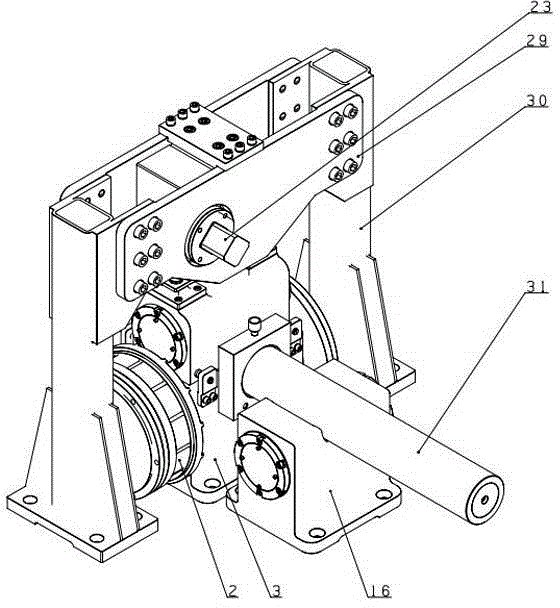

Roller adjusting device, adjusting method and application of device and bending machine comprising device

The invention discloses a roller adjusting device, an adjusting method and application of the device and a bending machine comprising the device, and belongs to the technical field of bending machines. The roller adjusting device is mounted on a cylinder of the bending machine; the roller adjusting device comprises a mounting base, a roller component and an adjusting component; the roller component is connected with the mounting base through the adjusting component; the adjusting component can be used for adjusting the roller component to move forwards and backwards relative to the mounting base; the roller component is in contact with a sliding block; the adjusting component comprises an adjusting thread sleeve, an adjusting screw nut and an adjusting screw; the adjusting thread sleeve is of a tubular structure and is in threaded connection with the mounting base; the adjusting screw nut sleeves the adjusting thread sleeve; the adjusting screw penetrates through the adjusting thread sleeve and is connected with the roller component. According to the adjusting method of the roller adjusting device, the roller component is adjusted by the adjusting component to move forwards and backwards so as to press the sliding block. By adopting the roller adjusting device, vibration of the sliding block can be alleviated in bending operation of a large-tonnage bending machine (the bending force is greater than 300t), the bending precision can be improved, the product pass percentage can be increased, and the service life of a cylinder can be prolonged.

Owner:ANHUI YAWEI MACHINE TOOL MFG

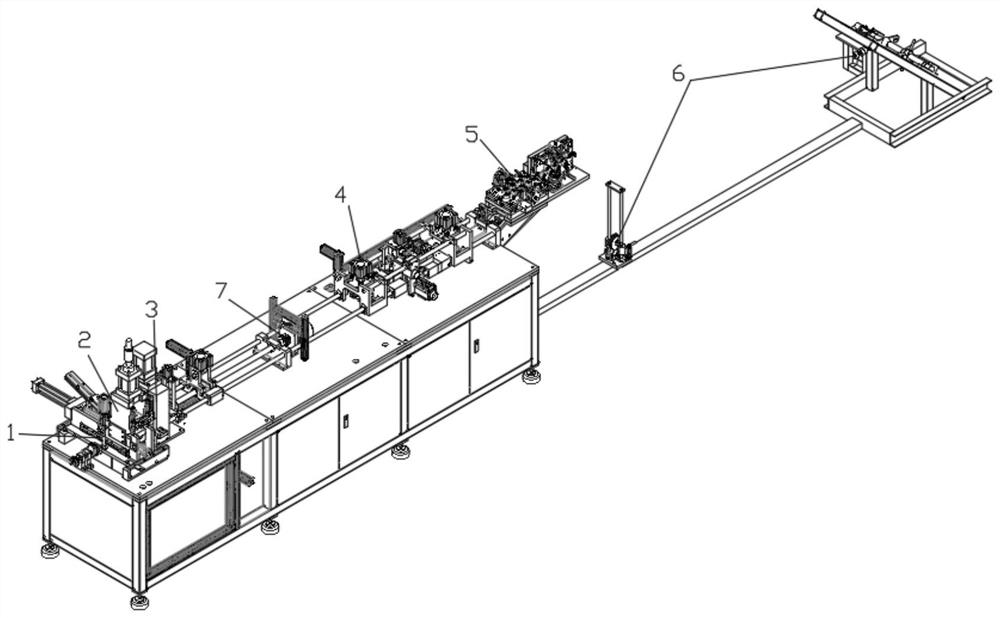

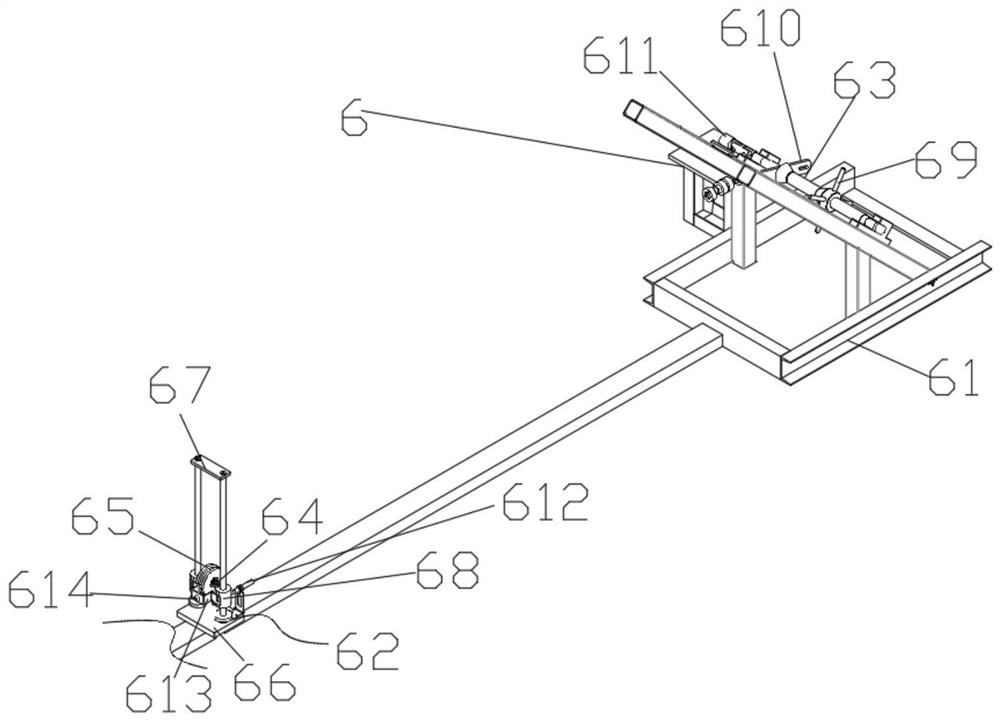

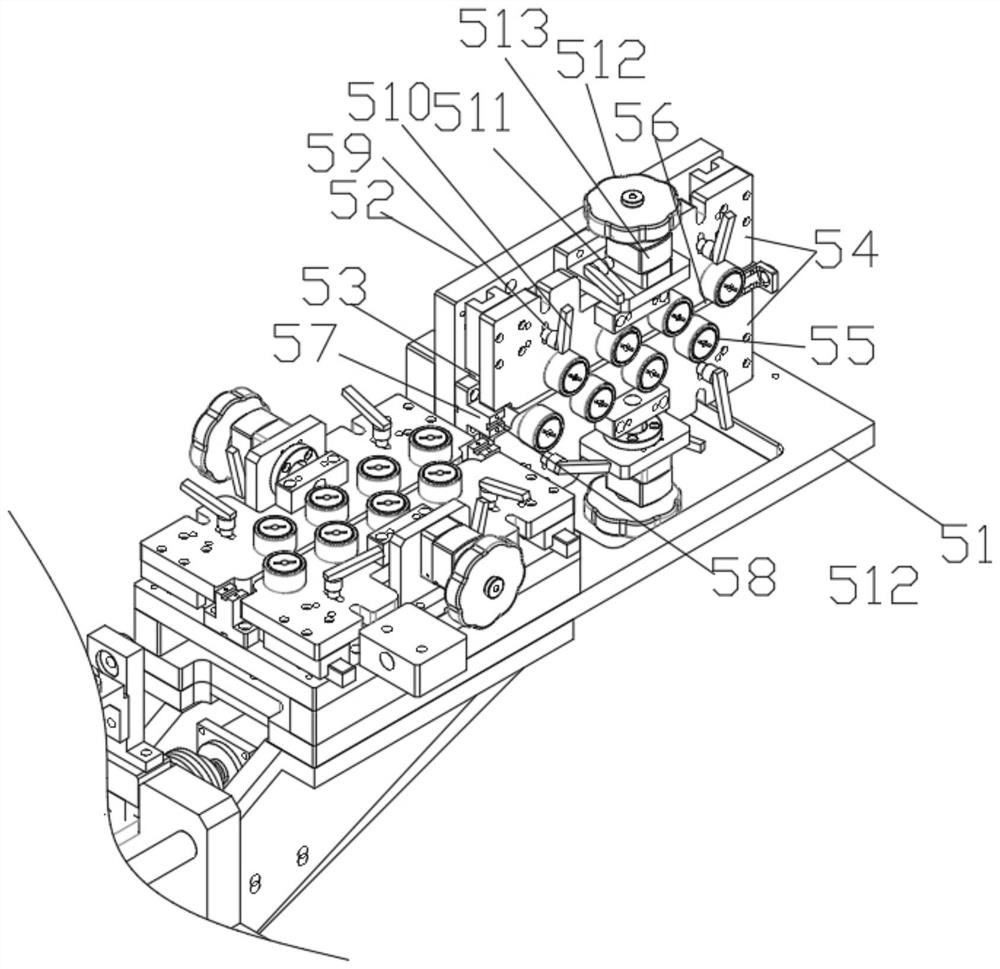

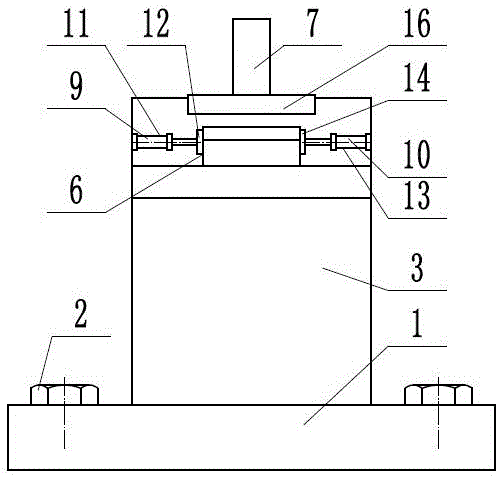

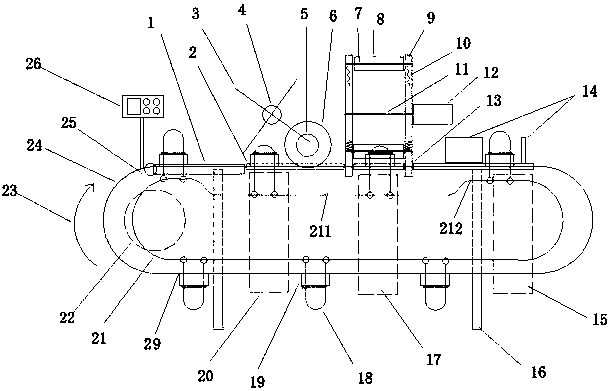

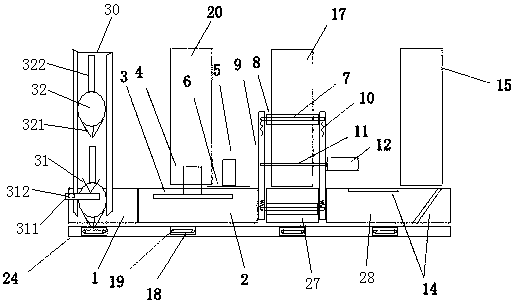

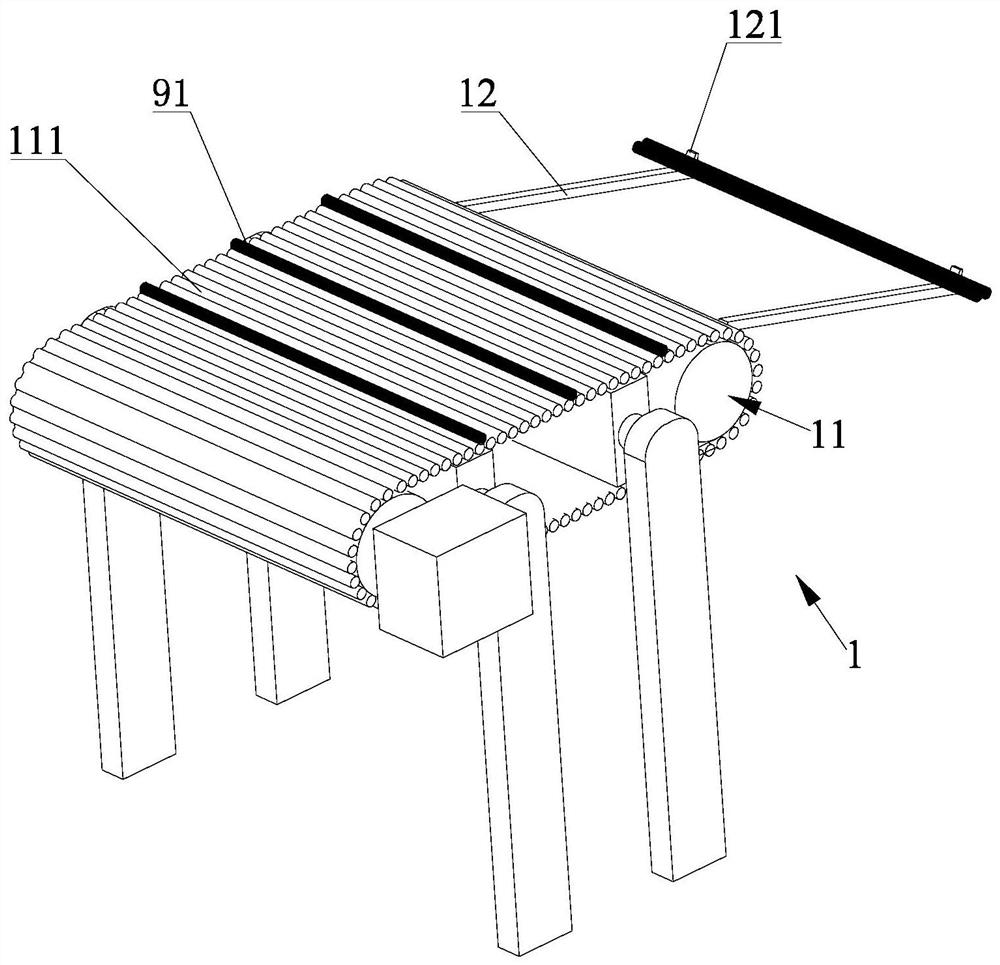

Flat wire automatic unloading forming machine of flat wire hairpin motor of new energy automobile

PendingCN112953140ARealize automatic feedingAvoid damageManufacturing dynamo-electric machinesNew energyElectric machine

The invention discloses a flat wire automatic unloading forming machine of a flat wire hairpin motor of a new energy automobile. An automatic wire pre-feeding mechanism, a flat wire straightening mechanism, a profiling cutter lossless enameled sheath removing mechanism, a flat wire feeding mechanism, a flat wire chamfering and primary cutting mechanism, a hairpin profiling equal-length positioning and rotary wire breaking mechanism and a hairpin profiling forming and automatic blanking mechanism are sequentially installed in the advancing direction of a flat wire. Automatic feeding, automatic straightening, automatic paint removing, chamfering, rotary wire breaking, forming and discharging of the flat wire are achieved, damage to the flat wire is small, the hairpin profiling length and shape of the flat wire are consistent, and the machining efficiency and quality of the flat wire are improved.

Owner:长沙华锐机电实业有限公司

Intermittent press-fitting device

InactiveCN106078603APressing to achieveReduce pinch injuriesWork holdersPress ramEngineeringCylinder block

The invention provides an intermittent press-fitting device and belongs to the technical field of machining. The intermittent press-fitting device comprises a press-fitting platform, a clamping mechanism and a press-fitting mechanism. The press-fitting platform is fixed to one side of a rack. A rear supporting cushion block of the clamping mechanism is fixed to the press-fitting platform and located behind a workpiece. A left clamping assembly and a right clamping assembly are symmetrically arranged on the left side and the right side of the workpiece. A driving cylinder of the press-fitting mechanism comprises a cylinder block, a piston rod, a connecting support lug and a lock nut. The lower end of the cylinder block is hinged to a cylinder supporting seat. The cylinder supporting seat is fixed to one side of a supporting base. The connecting support lug is in threaded connection with the upper end of the piston rod and is locked through the lock nut. The connecting support lug is hinged to one end of a pressing plate fulcrum bar. A pressing plate is arranged at the other end of the pressing plate fulcrum bar. The upper ends of two rocking bars are hinged to the pressing plate fulcrum bar. The lower ends of the rocking bars are hinged to the rack. The intermittent press-fitting device can conduct intermittent press-fitting on the workpiece, and is reasonable in structure, adjustable in press-fitting force and high in applicability.

Owner:徐晓杰

Throttle grip apparatus

ActiveUS8336423B2Small sizeNo uncomfortable feelingControlling membersCycle control systemsControl theoryThrottle

A throttle grip apparatus is provided with: a throttle grip (1) rotatably mounted on a leading end of a handle bar (H) of a vehicle; a magnet (6) rotatable together with the throttle grip (1); a detector (13) for detecting variations in a magnetic field of the magnet (6) in a non-contact manner to detect a rotation angle of the throttle grip (1); and a frictional plate (9, 10) for generating a rotation load of the throttle grip (1). An engine of the vehicle is controlled based on a detected value of the detector (13). The frictional plate (9, 10) is disposed within the handle bar (H).

Owner:ASAHI DENSO KABUSHIKI KAISHA

Tool holder

ActiveUS20110014854A1Low costReduce operational burdenEdge grinding machinesHoning toolsCoolant flowEngineering

A tool holder is provided with a main body, a taper cone, a working portion, a coolant flow passage, and an adjuster. The taper cone includes a taper portion and movable in an axial direction of the main body. The working portion is mounted on an outer peripheral portion of the main body and includes a taper bottom surface which engages with the taper portion. The taper bottom surface is movable in a radial direction of the main body based on a movement of the taper cone in the axial direction. A coolant flows through the coolant flow passage such that a part of the coolant presses and moves the taper cone in the axial direction and another part of the coolant flows out to an outside so as to adjust a pressing force. The adjuster is fitted into a hole penetrating the main body and includes a coolant flow-out hole for adjusting a flow-out of the coolant.

Owner:HONDA MOTOR CO LTD

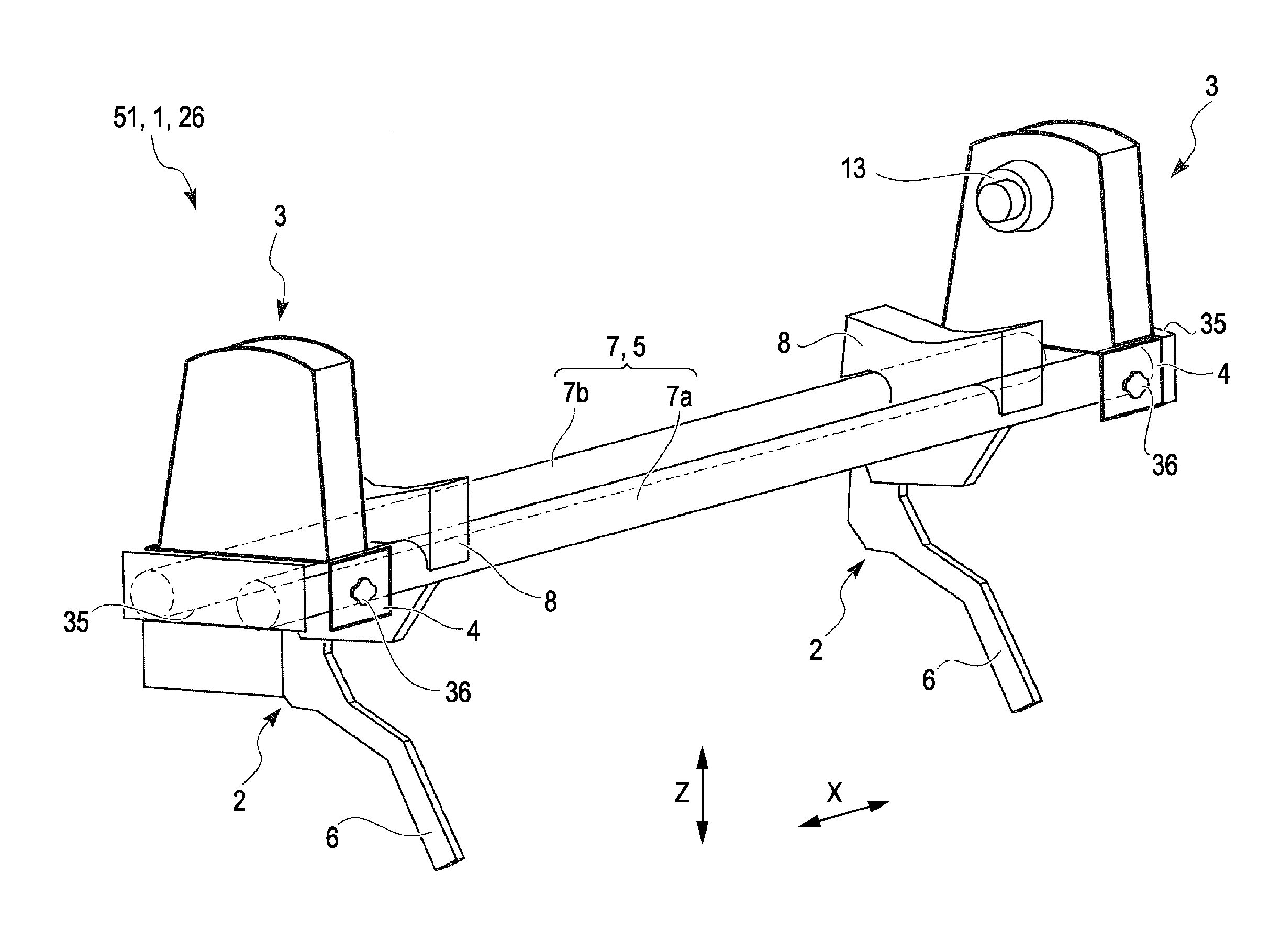

Wind power blade demoulding hoisting clamp and wind power blade demoulding method

ActiveCN111573494AImprove demoulding efficiencyImprove reliabilitySafety gearEngineeringStructural engineering

The invention provides a wind power blade demoulding hoisting clamp. The wind power blade demoulding hoisting clamp comprises a C-shaped seat, a pressing block connecting rod obliquely arranged and installed on the C-shaped seat in a swinging mode and a pressing block assembly installed at the lower end of the connecting rod and used for compressing a blade on the C-shaped seat. The wind power blade demoulding hoisting clamp is characterized by further comprising an elastic hoisting assembly capable of driving the pressing block connecting rod to swing, the elastic hoisting assembly is movablyinstalled on the C-shaped seat and enables the initial spacing between the pressing block assembly and the C-shaped seat to be the largest through an initial oblique angle of an elastic positioning pressing block connecting rod, the blade extends between the C-shaped seat and the pressing block assembly, blade gravity is located on the C-shaped seat with the upward hoisting of the elastic hoisting assembly, and the pressing block connecting rod swings downwards with the hoisting of the elastic hoisting assembly to enable the spacing between the pressing block assembly and the C-shaped seat tobe reduced and pressed on the blade. According to the wind power blade demoulding hoisting clamp, the blade is effectively protected from being damaged in the demoulding process due to clamping, thereliability and safety of the clamp are improved, the demoulding efficiency of the blade is improved, and the service life is long.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

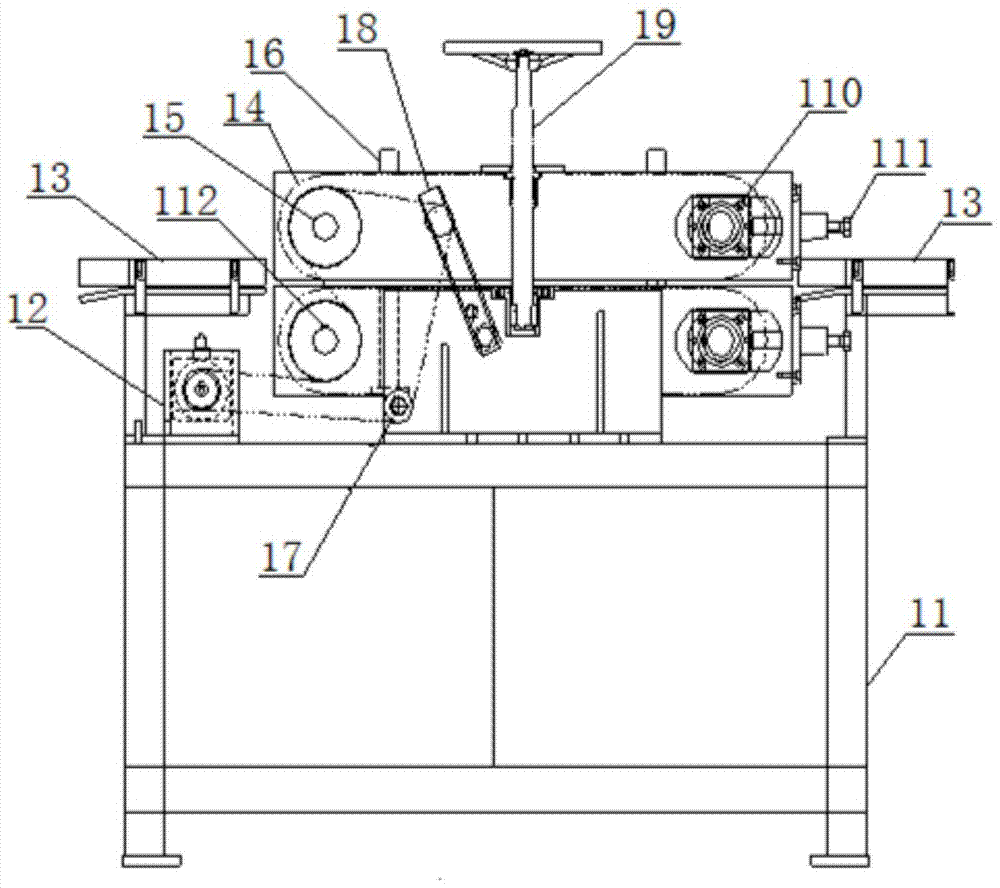

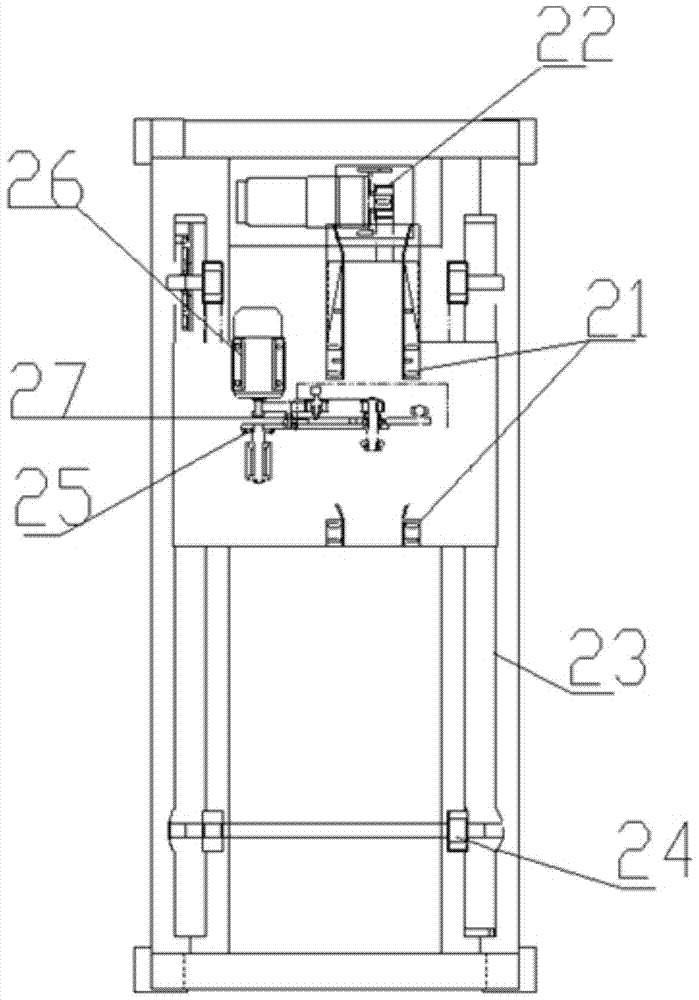

A traction cross-cutting machine for producing xps profiles

The invention relates to a traction cross-cutting machine for producing XPS profiles, which comprises a traction part and a cross-cutting part connected in sequence, a length calculation sensor is installed on the traction part, and the length calculation sensor is electrically connected with a transmission system servo motor on the cross-cutting part. Adopt custom thickened soft foam natural rubber crawler for traction. The cross-cut parts are cut according to the product length specifications, and the structure of the swing saw blade is used for its small cross-sectional area. The height between the upper and lower belts of the traction part and the pressing force can be adjusted. The cross-cutting part and the cross-moving knife table part adopt servo motors, and the structure is reliable and compact. The cutting mechanism of the cross-cutting part adopts the form of swing and saw blade cutting, the cutting cycle is short and the speed is fast, which effectively shortens the moving distance of the knife table and saves the equipment occupation area, and the cutting mechanism has few parts, compact, reliable and durable Good sex.

Owner:南京法宁格节能科技股份有限公司

Toothed rack angle lapping machine

InactiveCN106216776AOutstanding and Beneficial Technical EffectsGrinding to achieveGear-cutting machinesGear teethEngineeringBench grinder

A toothed rack angle lapping machine comprises a transverse traveling mechanism. A rack placement frame is arranged on one side of the transverse traveling mechanism and provided with a rack placement station parallel with the traveling direction of the transverse traveling mechanism. A grinding wheel machine is arranged above the rack placement station. The transverse traveling mechanism drives the grinding wheel machine to travel transversely. The grinding wheel machine is connected with a swinging shaft and controlled by elastic force. Under the action of the elastic force, the grinding wheel machine has the trend of rotating around the swinging shaft and enabling a grinding wheel piece to get close to the rack placement station. According to the toothed rack angle lapping machine provided in the scheme, a rack subjected to heat treatment is subjected to finish angle lapping by adopting a copying following principle, the machining accuracy is high, the consistency is high, and time and labor are saved.

Owner:TAIZHOU TAIPUNC EQUIP CO LTD

Rolled medium holder device and recording apparatus

InactiveUS20120199687A1Increase pressureReduce pressing forceFilament handlingFunction indicatorsMechanical engineeringEngineering

Owner:SEIKO EPSON CORP

Gordon enryale fruit shell peeler

Owner:CHUZHOU UNIV

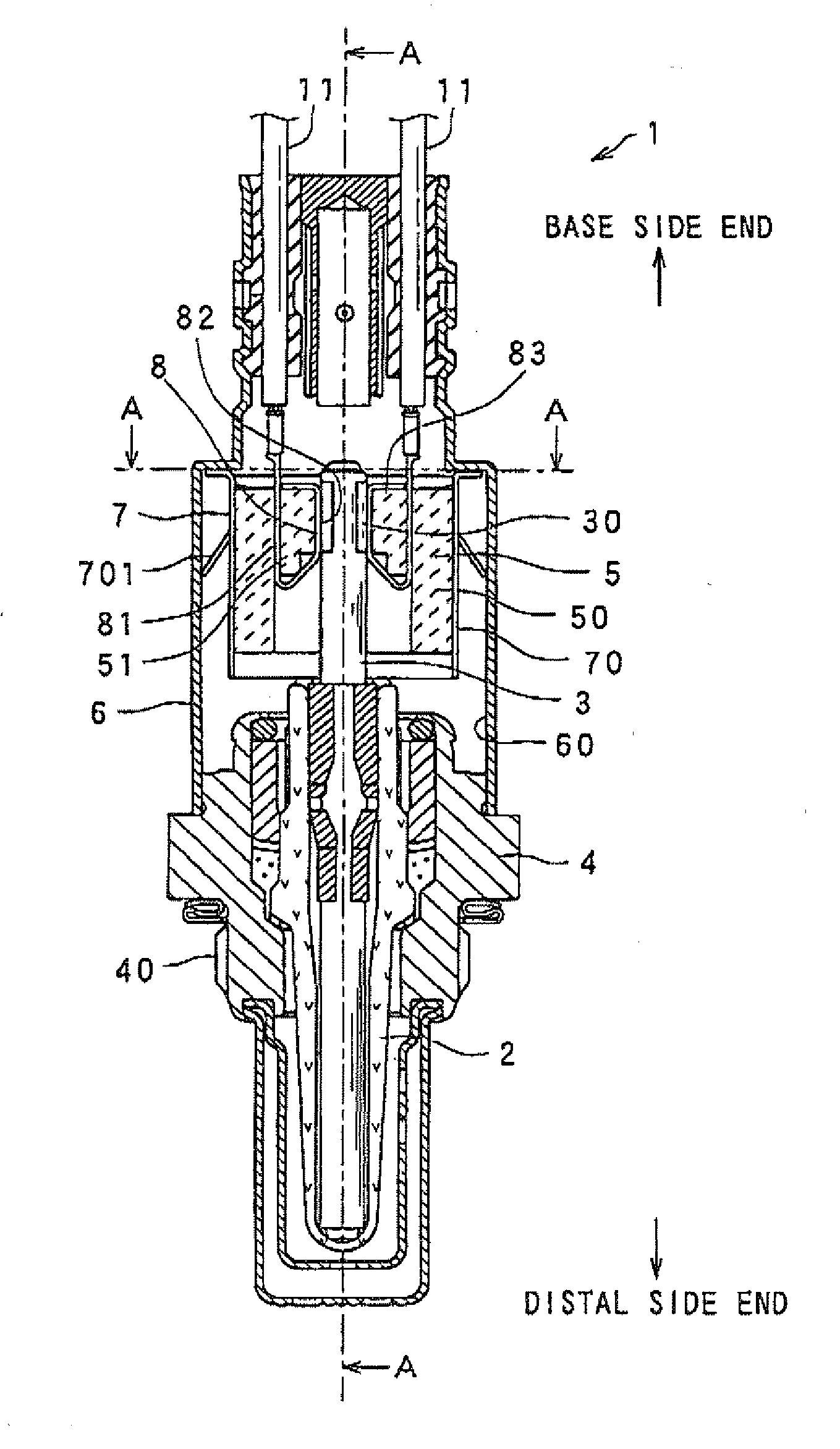

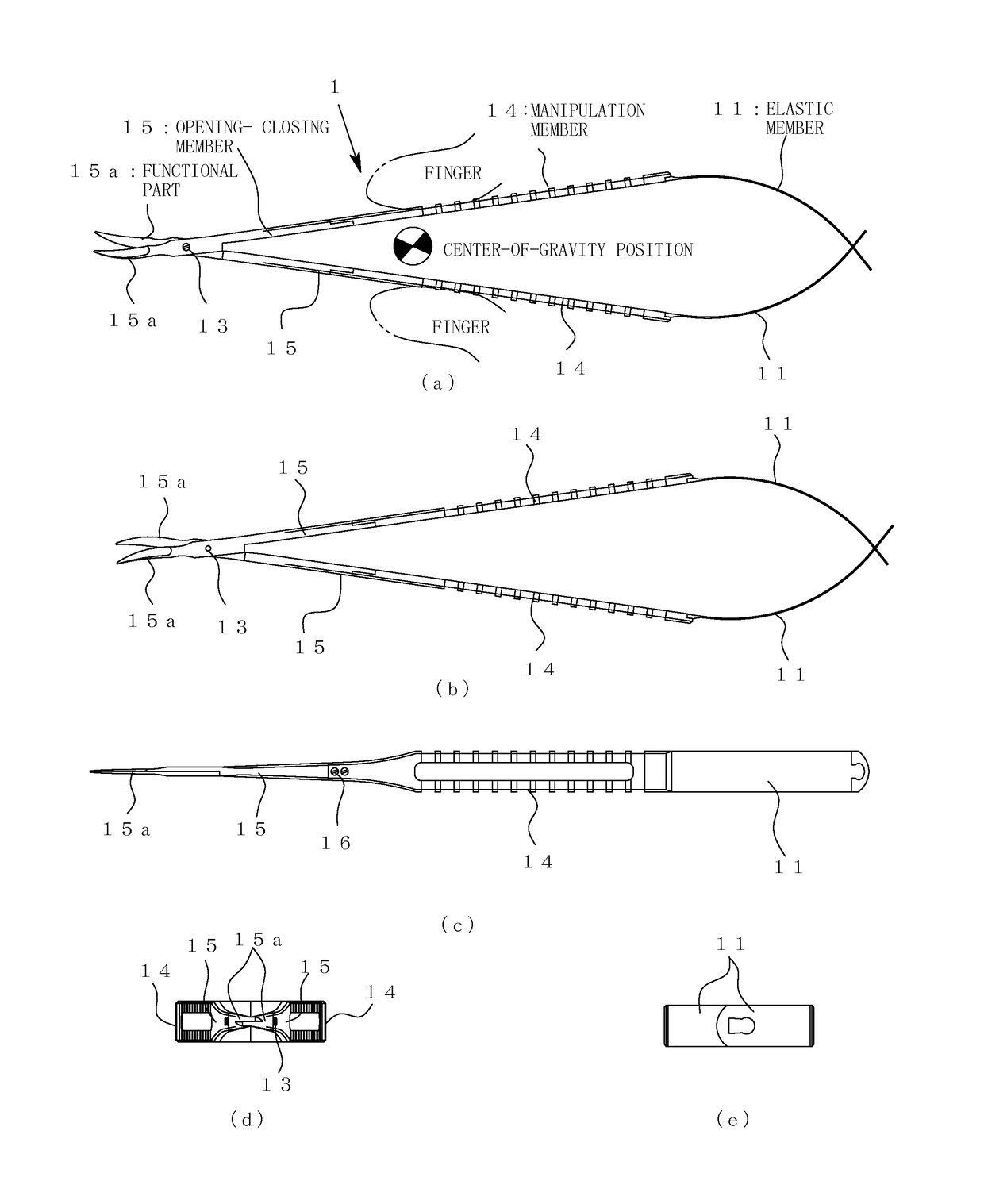

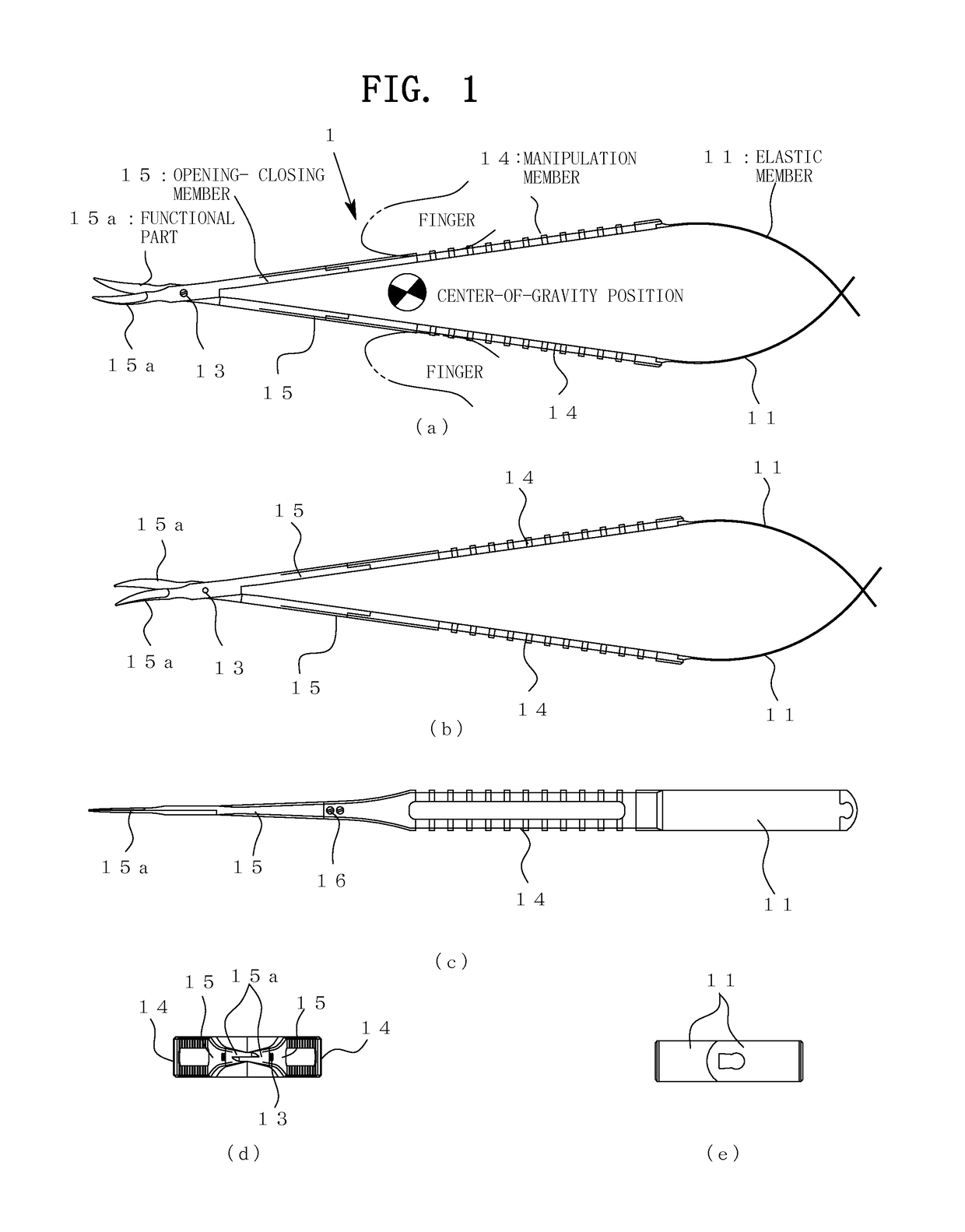

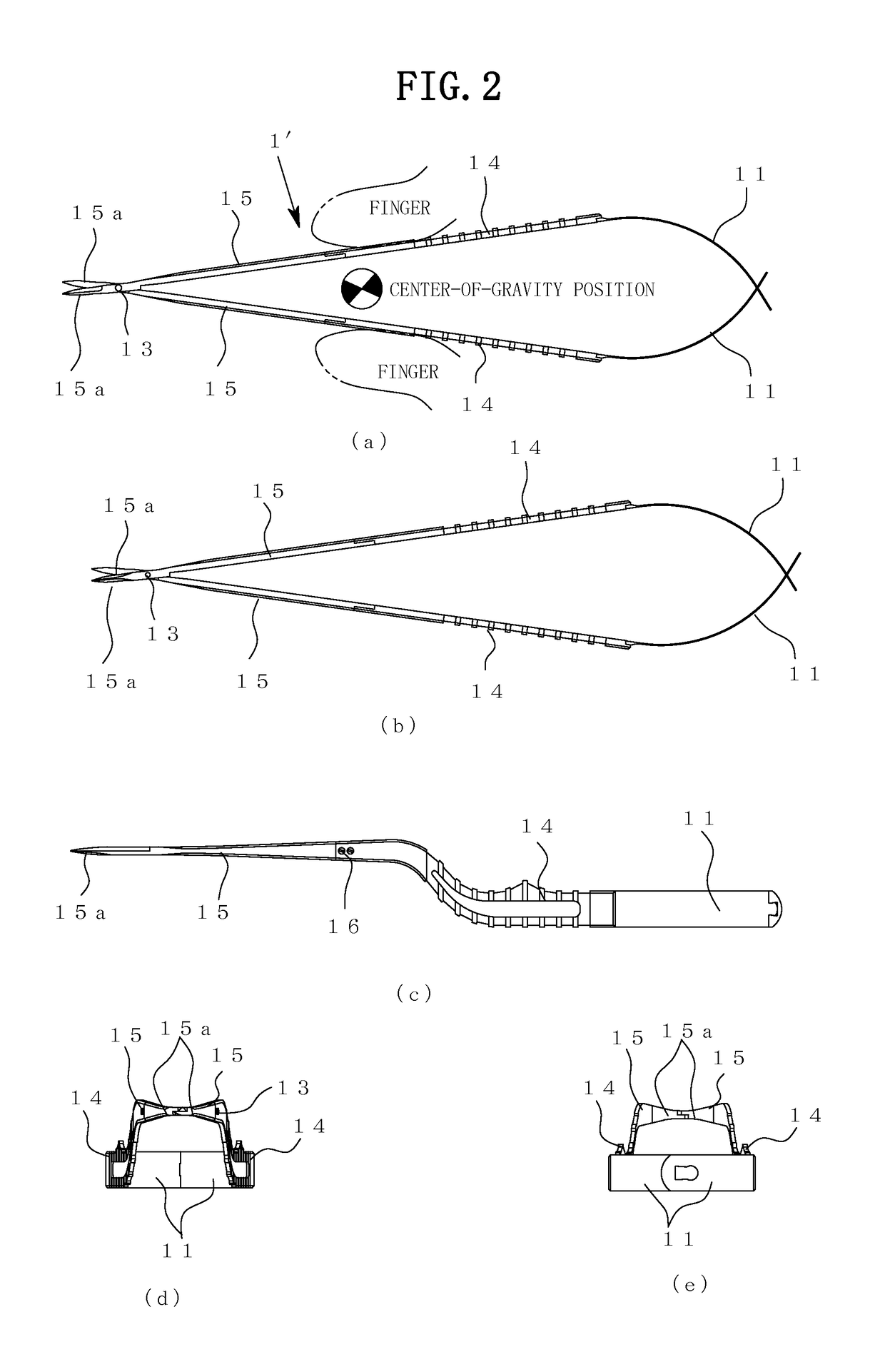

Medical instrument

ActiveUS9931130B2Adjustable pressing forceHair-singeingSurgical scissorsEngineeringMedical instruments

A medical instrument effectively suppresses a situation in which the edge of a blade springs immediately after completion of incision, excision, or the like. The medical instrument (1) includes manipulation members (14) that are held by a user, elastic members (11) that are respectively secured on one end of the manipulation members, and intersect each other at one end thereof, and opening-closing members (15) that are respectively secured on the other end of the manipulation members (14), and intersect each other at a pivot (13), functional parts (15a) for implementing a gripping operation, a holding operation, a cutting operation, or the like being respectively provided at one end of the opening-closing members (15), the functional parts (15a) being opened and closed by adjusting a pressing force applied to the manipulation members (14), the opening-closing members (15), the manipulation members (14), and the elastic members (11) being configured so that the pressing force applied to the manipulation members (14) and an opening-closing amount of the functional parts (15a) have a linear proportional relationship during a period in which the functional parts (15a) are operated.

Owner:CHARMANT

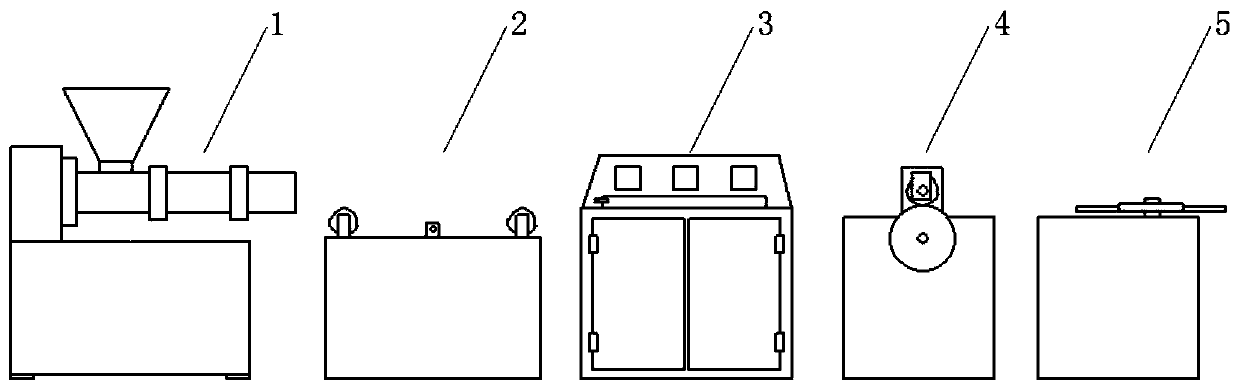

Magnetic rubber strip production line with magnetic rubber strip protection function

InactiveCN110600255AReduces the risk of twisting and breakingAvoid breakingInductances/transformers/magnets manufacturePotentiometerTraction motor

The invention discloses a magnetic rubber strip production line with a magnetic rubber strip protection function. The magnetic rubber strip production line comprises an extrusion molding device, a cooling device, a magnetizing device, a traction device and a reeling device, wherein the cooling device comprises a water tank; hinging frames are arranged at the middle part of the upper end surface ofthe water tank; a U-shaped frame is hinged onto each hinging frame; one hinging shaft of the U-shaped frame extends out to reach the outer side of the hinging frame; a first gear is arranged at the outer end of the hinging shaft; a potentiometer is arranged on the hinging frame; a second gear is arranged on a rotating shaft of the potentiometer; the second gear and the first gear are engaged witheach other; the traction device comprises a traction motor; the traction motor is connected with a traction frequency converter; and the traction frequency converter is connected with the potentiometer. The potentiometer is driven to rotate through the movement of the rubber strip per se; when the potentiometer rotates, the rotating speed of the traction motor is regulated by regulating the frequency of the traction frequency converter, so that the traction speed and the extrusion speed maintains dynamic balance; and the tensile failure of the rubber strip due to too high traction speed is prevented.

Owner:WENZHOU RENHE EDUCATION TECH CO LTD

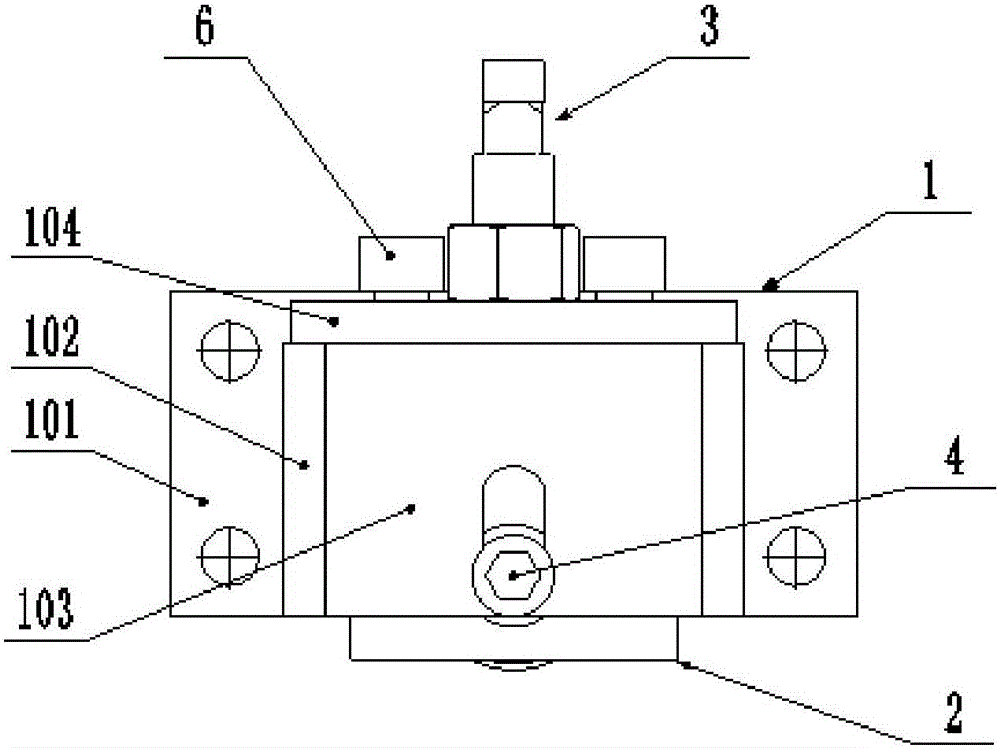

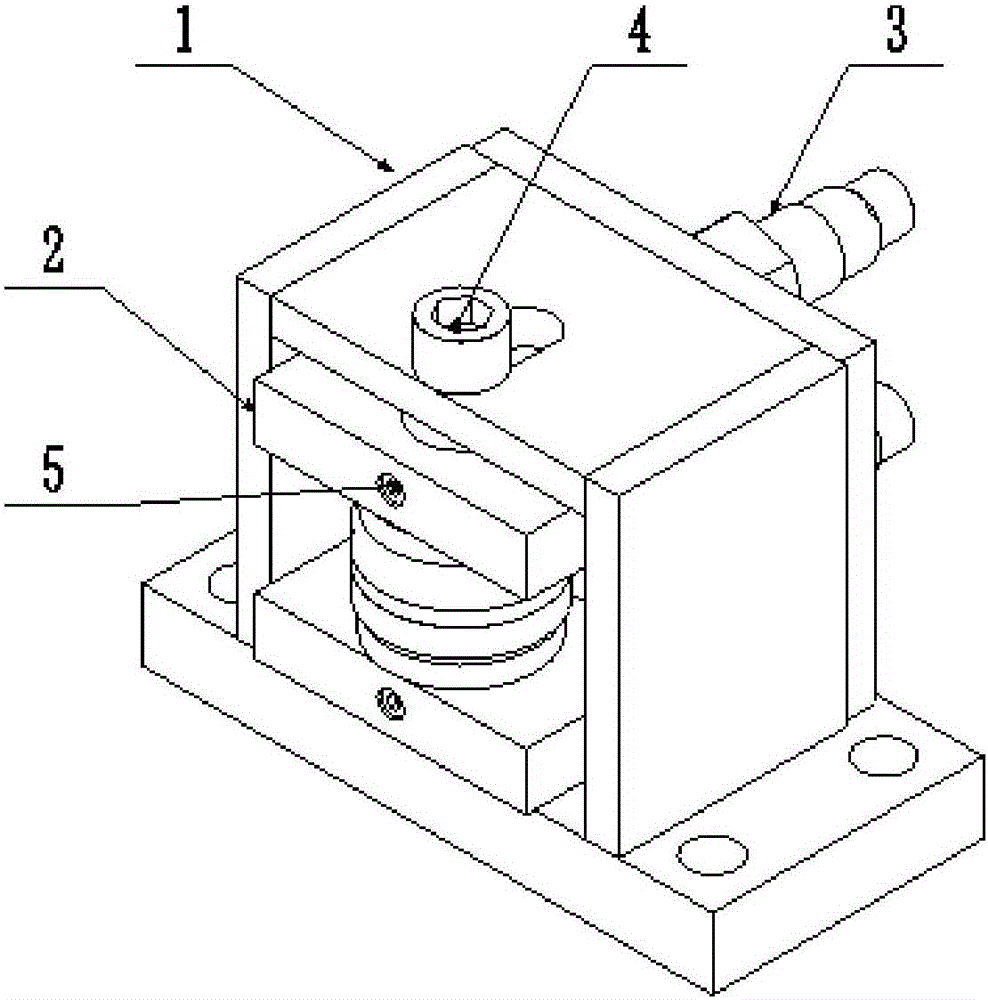

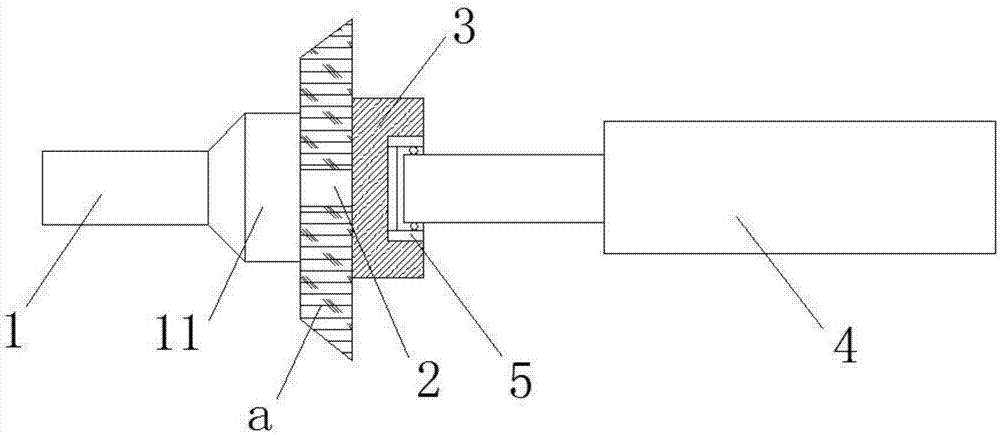

Ultraprecise friction driving mechanism

ActiveCN104405837AReliable preloadAdjustable pressing forceMechanical energy handlingFriction gearingsDrive wheelGrating

The invention discloses an ultraprecise friction driving mechanism. The mechanism mainly comprises a driving part, an auxiliary support part, a pressing part and an eccentric pressing part, wherein stable and precise rotation positioning is provided by the driving part, a torque motor is directly connected with a friction driving shaft, a driving error caused by intermediate transmission links is reduced, a circular grating is connected to the other end of the driving shaft, and the angular precision of a driving wheel is measured; through the auxiliary support part, the deflection deformation of the tail end of a driven rod is reduced, the position precision of the driven rod is guaranteed, so as to achieve the effects of auxiliary support and fine-tuning positioning, wherein the displacement output by an eccentric wheel structure is converted into pressing force by a pressure reed, and a driving wheel system and a friction guide rod are pressed through a prepressing wheel system; through the eccentric pressing part, accurate displacement output can be provided for the pressure reed, the pressing force can be conveniently adjusted, and the change of the pressing force can be monitored in real time by a pressure sensor installed on an eccentric wheel driven component, so as to satisfy the controllable requirement on the pressing force.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

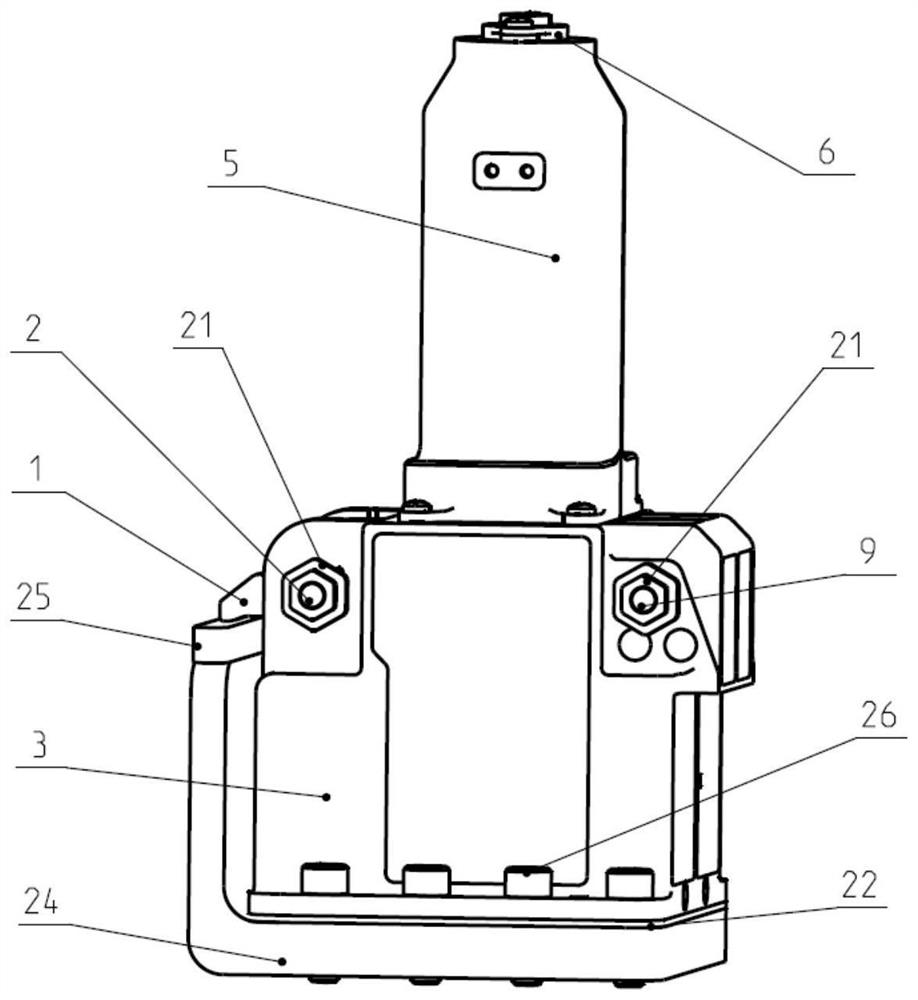

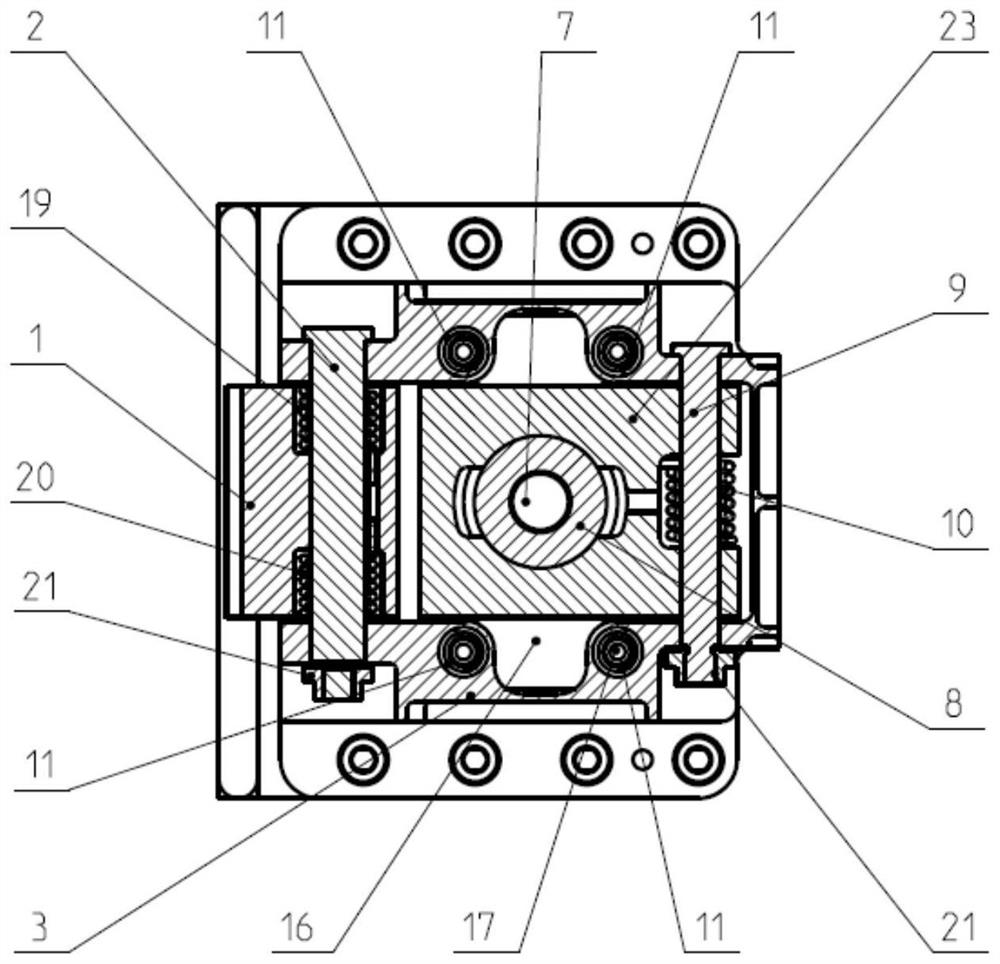

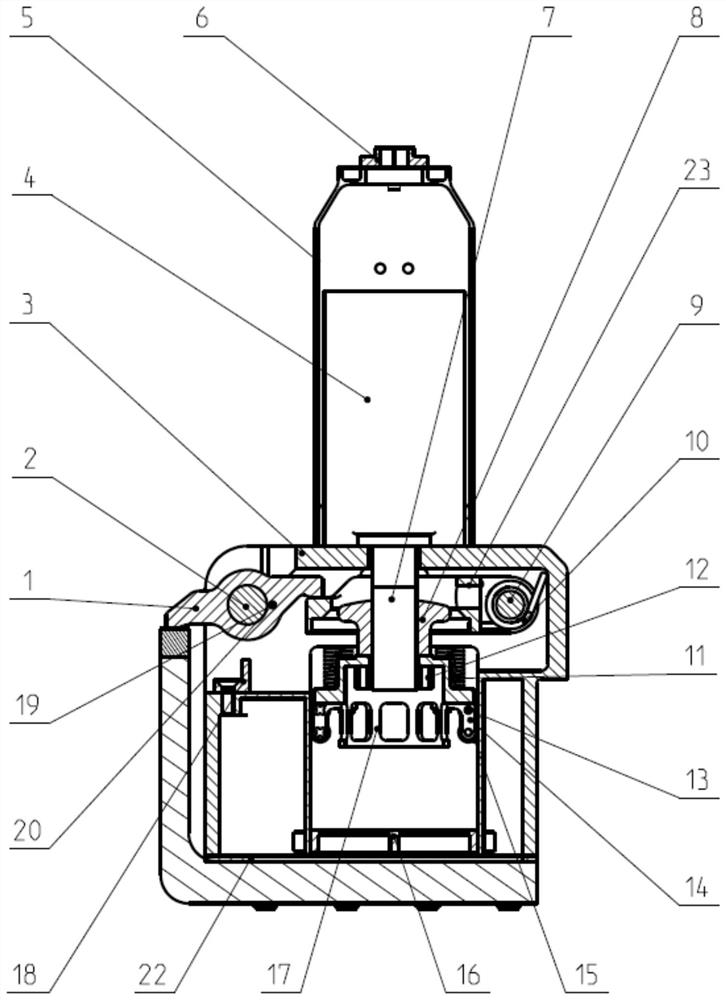

Rotary clamping assembly

InactiveCN107363599AHigh precisionGuaranteed accuracyWork clamping meansPositioning apparatusMachine partsEngineering

Owner:台山市兰宝磨具有限公司

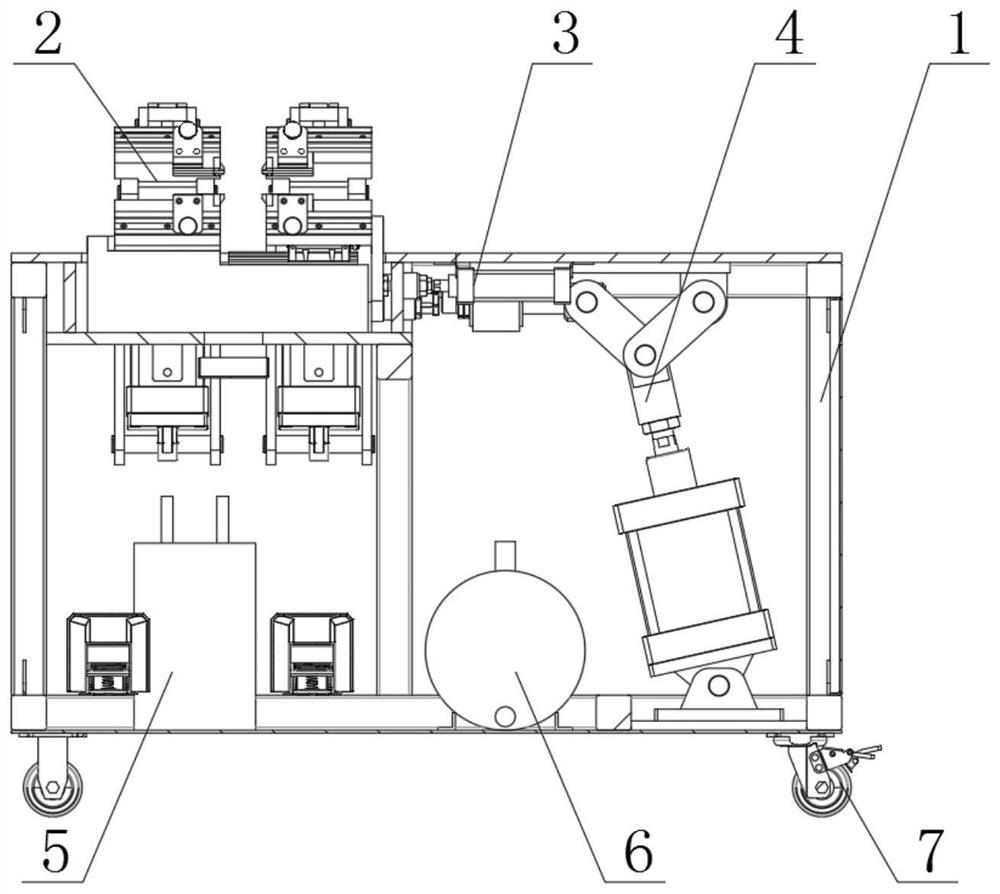

Automatic brazing equipment for copper pipes and joints and its control method

ActiveCN111283289BPrecise positioningAccurateMetal working apparatusSoldering auxillary devicesEngineeringMaterials science

The invention discloses an automatic brazing equipment for copper pipes and joints and a control method thereof. Welding machine; the copper tube delivery mechanism is used to deliver the copper tube to each station; the copper tube positioning mechanism includes a positioning plate and a pressing device for positioning and pressing the copper tube; the joint feeding and assembly The mechanism is used to grab the joint and put the joint on the end of the copper pipe; the socket detection mechanism is used to detect the socket effect of the sleeve joint operation; the high-frequency brazing machine is installed on the brazing machine sliding platform The outer side of the copper tube positioning mechanism is located at the brazing station. The invention can realize a series of operation processes such as automatic feeding and positioning of copper pipes, automatic grasping of joints, detection of sockets and defective sockets, and automatic brazing after that, so as to ensure the welding of copper pipes and joints during the automatic brazing process quality and easy operation.

Owner:XIAMEN UNIV OF TECH

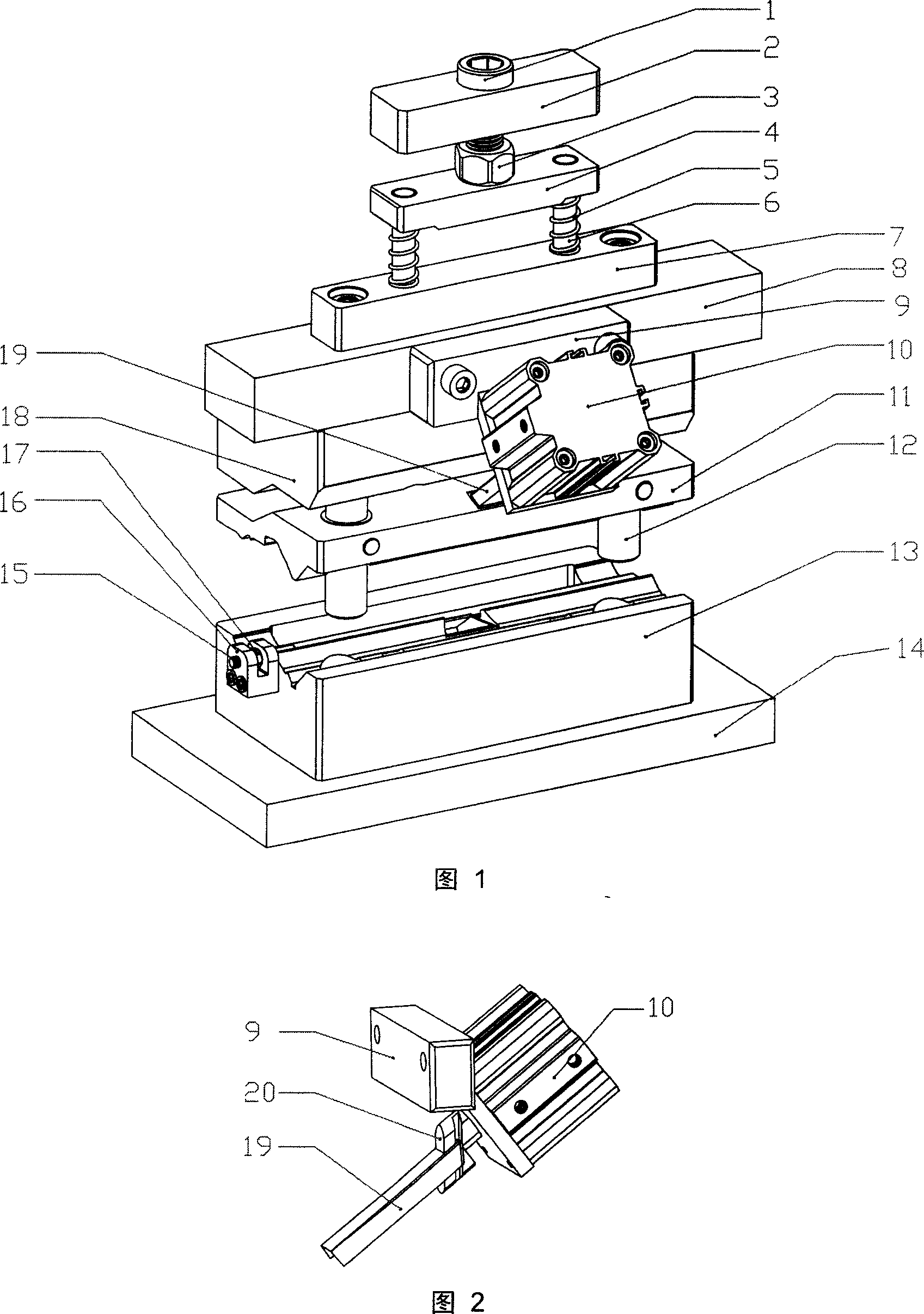

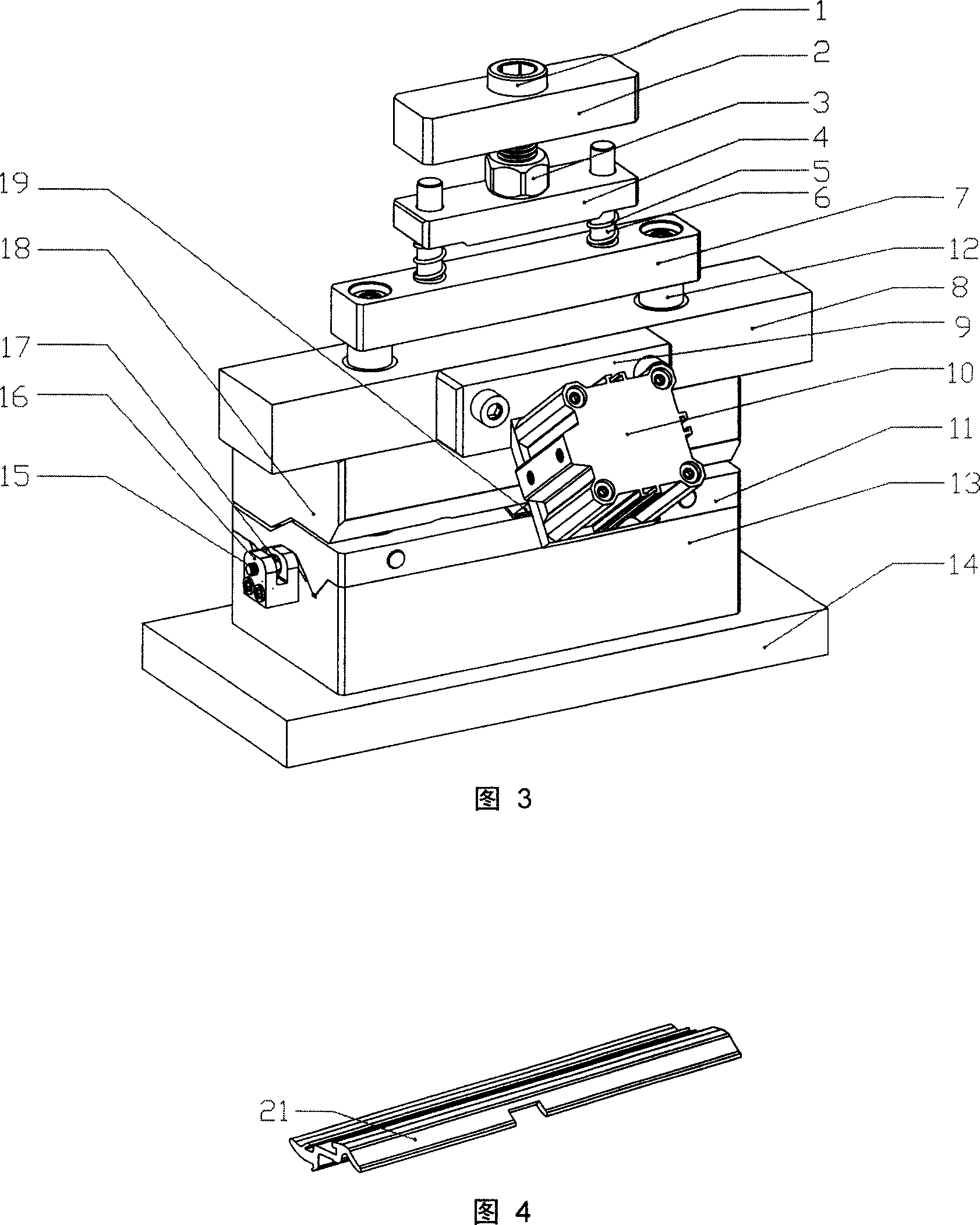

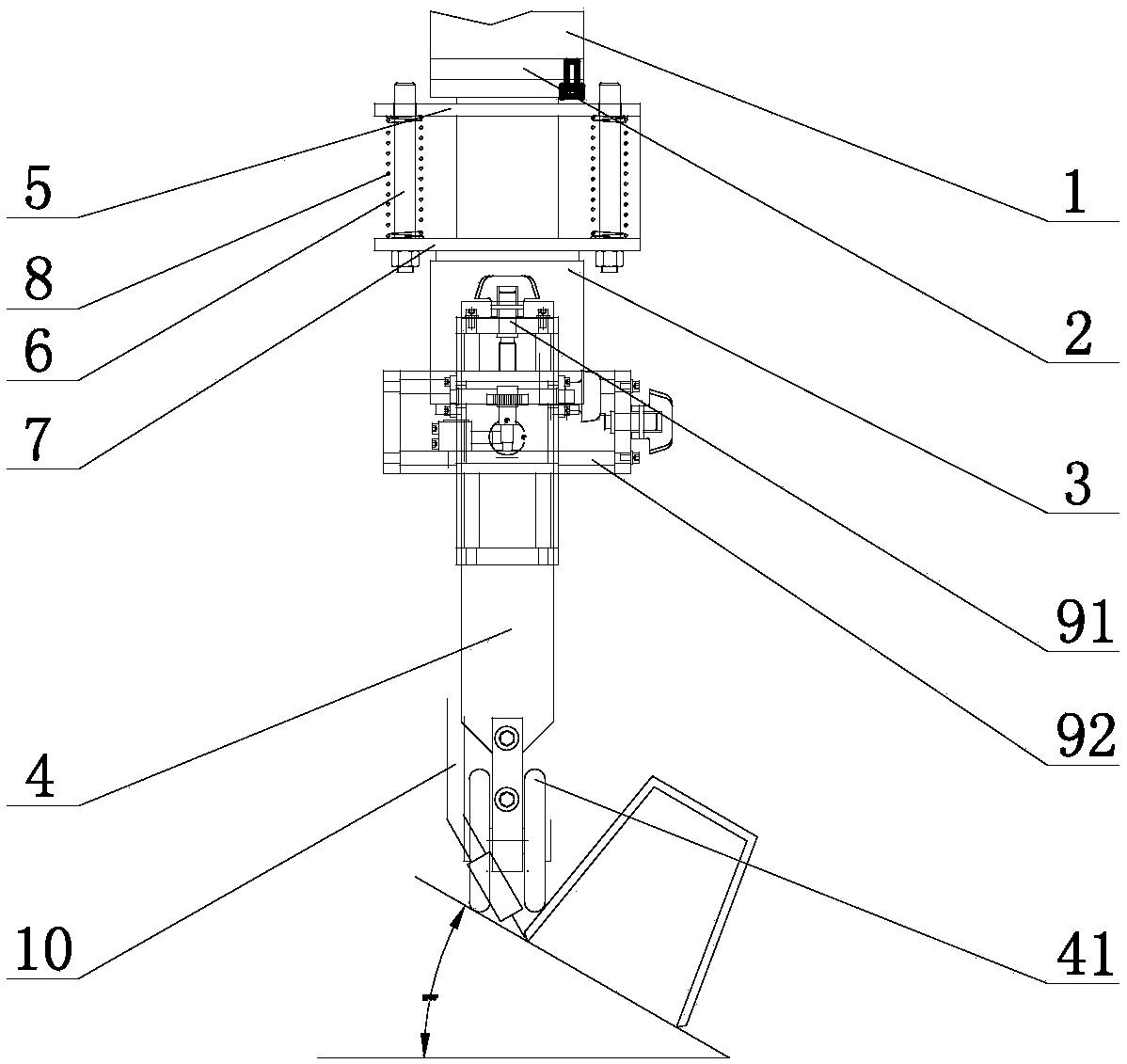

Apparatus for blanking and processing profile notches of rubber sealing strip

InactiveCN1321785CAvoid interferenceGuarantee subsequent punching processing actionMetal working apparatusPunchingOblique cutting

This invention discloses a device for blanking and processing rubber sealed strip-type slot; essentially composed by counter die part, upper die part and oblique cutting part. It is characterized in adopting work piece outline of the counter die's surface and its end face's lateral positioning machine to actualize rapid and accurate position for work piece's feeding; the outline of pressing plate and counter die's surface individually furring with upper and lower surfaces of sealing strip to prevent its surface from destroying; pressing device of upper die mainly comprising adjusting screw rod, packing force adjusting nut, spring block, spring guide and connecting block, and being able to adjusting packing force of work piece; using inclined punching guiding block of the oblique cutting part to avoid interference of upper die to oblique punching tool. The invention has the advantages of simple structure, high processing quality and efficiency.

Owner:SHANGHAI JIAOTONG UNIV

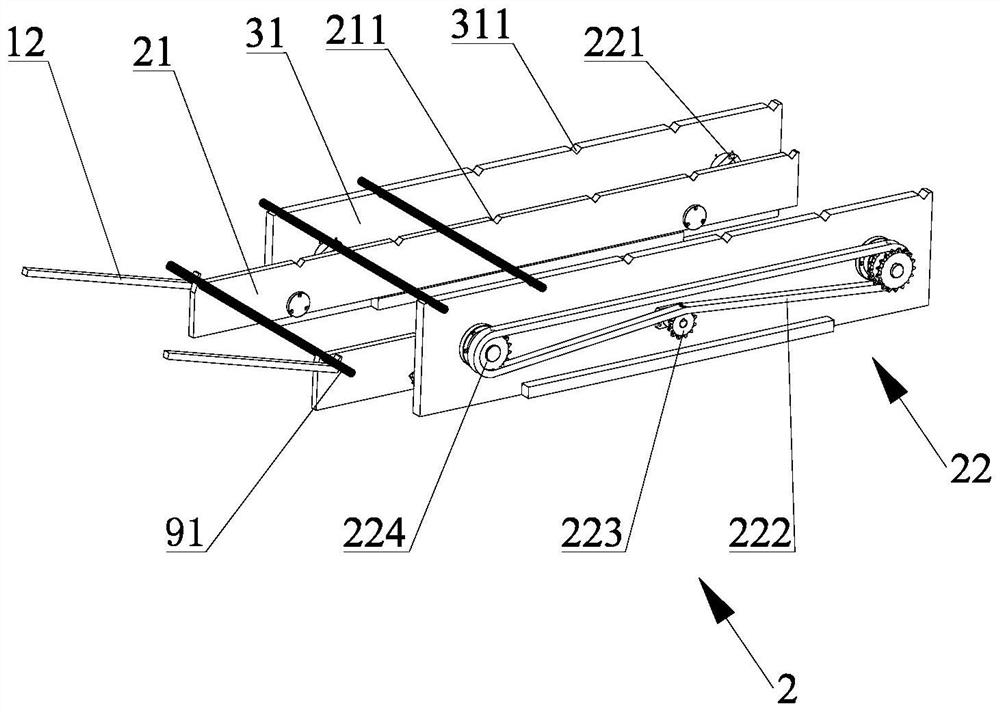

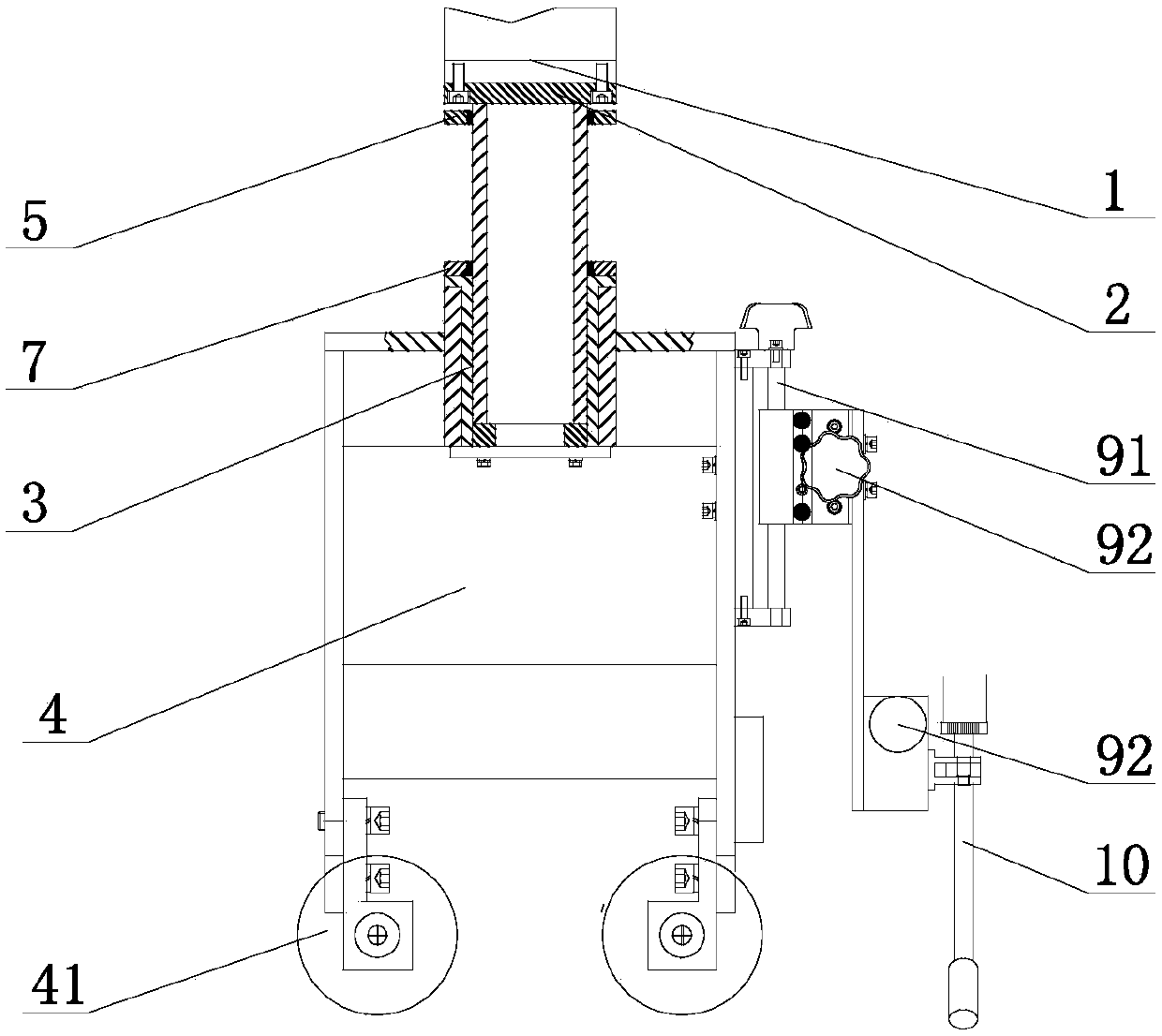

Weld joint tracking welding device for U-shaped rib plate

InactiveCN107790854AStrong impact resistanceLow guiding resistanceElectrode supporting devicesWelding accessoriesEngineeringWelding joint

The invention relates to a U-shaped rib seam tracking welding device, which includes a lifting welding arm and a welding torch adjustment device. A sliding shaft is fixed under the lifting welding arm. The lower end of the sliding shaft is connected to the arc guide frame through a guide sleeve. Fix the guide post mounting plate, guide posts are installed on both sides of the guide post mounting plate, the lower end of the guide post is fixedly connected with the guide post fixing plate connected to the guide sleeve, a compression spring is fixed on the outside of the guide post, and the The guide wheel is installed at the lower end of the arc guide frame, the welding torch adjustment device is fixed on one side of the arc guide frame, the welding torch is fixed on the welding torch adjustment device, the welding seam tracking welding device of the U-shaped rib plate is used, and the lifting welding arm adopts a square guide rail to prevent Impact, strong impact resistance, the arc guide frame is pressed by springs, the pressing force is adjustable, the tracking is sensitive, the guide wheel guide resistance is small, the welding torch is connected through the welding torch adjustment device, and the welding torch can be quickly adjusted. The whole mechanism has no electrical parts. Simple structure and easy maintenance.

Owner:WUXI YANGTONG MACHINERY EQUIP

Space compressing and releasing device

ActiveCN113184230AHighly integratedAdjustable pressing forceCosmonautic vehiclesCosmonautic component separationDetonationSpring force

The invention discloses a space compressing and releasing device. The device comprises a pressing plate, a pressing plate rotating shaft, a shell, a separation nut, an outer cover, a wire clamping plate, a screw, a locking nut, a hanging plate rotating shaft, a hanging plate torsion spring, a pressure spring, a nut, a pin shaft, a roller support, a roller, a bottom cover, a guide support, a baffle, a right pressing plate torsion spring, a left pressing plate torsion spring, a limiting nut, a hanging plate, a fixed base and a pressing piece. According to the space compressing and releasing device, a product with functions of manual compressing, manual releasing and space initiating explosive releasing can be achieved, a mechanism, a spring and an initiating explosive device are highly integrated by the product, and the mechanism is driven by the spring force to reliably release a compressing piece after initiating explosive detonation. The problem that ground test verification is difficult to achieve due to one-time work of an existing product is effectively solved.

Owner:SHANGHAI AEROSPACE SYST ENG INST

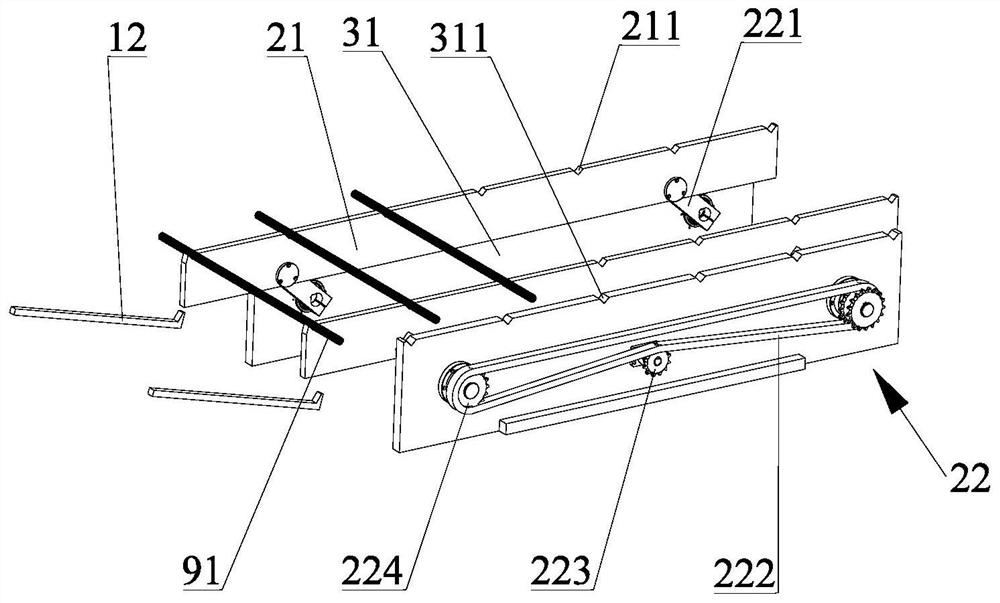

Vertical butt welding machine

InactiveCN113275722AGuaranteed StrengthReduce weightResistance electrode holdersWelding/cutting auxillary devicesStructural engineeringManufacturing engineering

The invention relates to a vertical butt welding machine. The vertical butt welding machine comprises a rack (1), a welding clamp assembly (2) is arranged on the rack (1), a feeding assembly (3) and a push rod impacting assembly (4) are arranged on the right side of the welding clamp assembly (2), and the feeding assembly (3) and the push rod impacting assembly (4) are arranged in a front and back manner. According to the vertical butt welding machine, the concentricity and precision of butt welding materials can be effectively guaranteed, the butt welding pressing force is adjustable, and the surface quality of the butt welding materials can be effectively guaranteed.

Owner:无锡颐和德昌电力机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com