Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

813results about How to "Improve peeling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

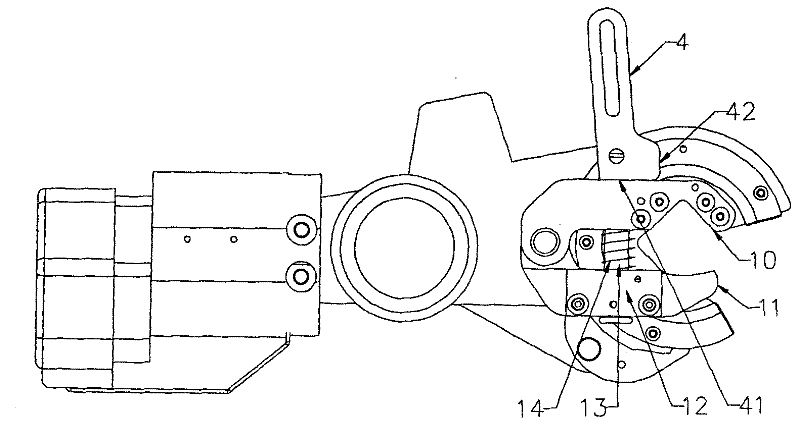

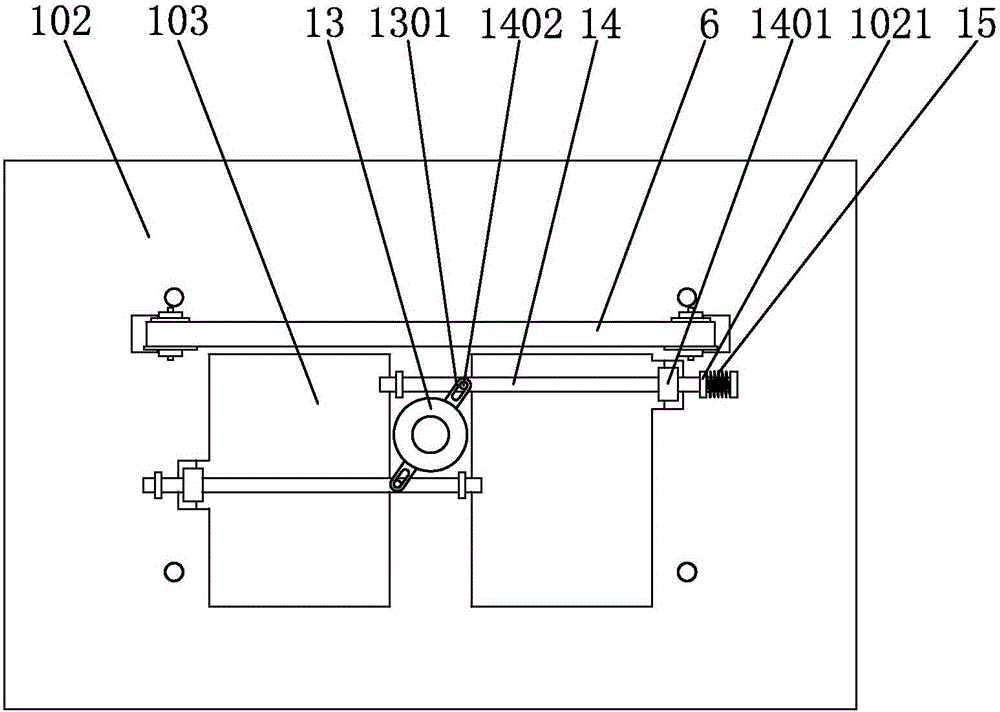

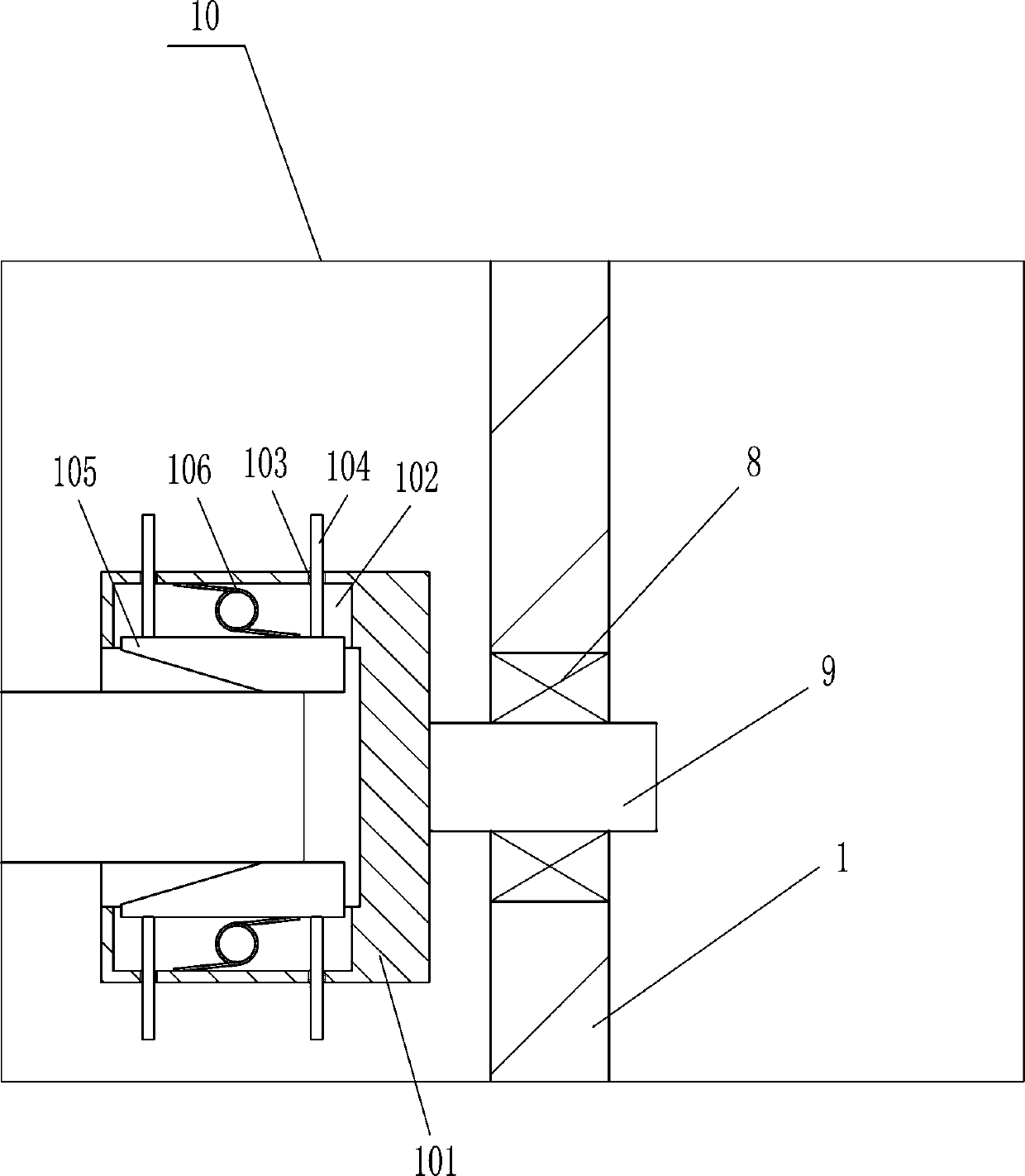

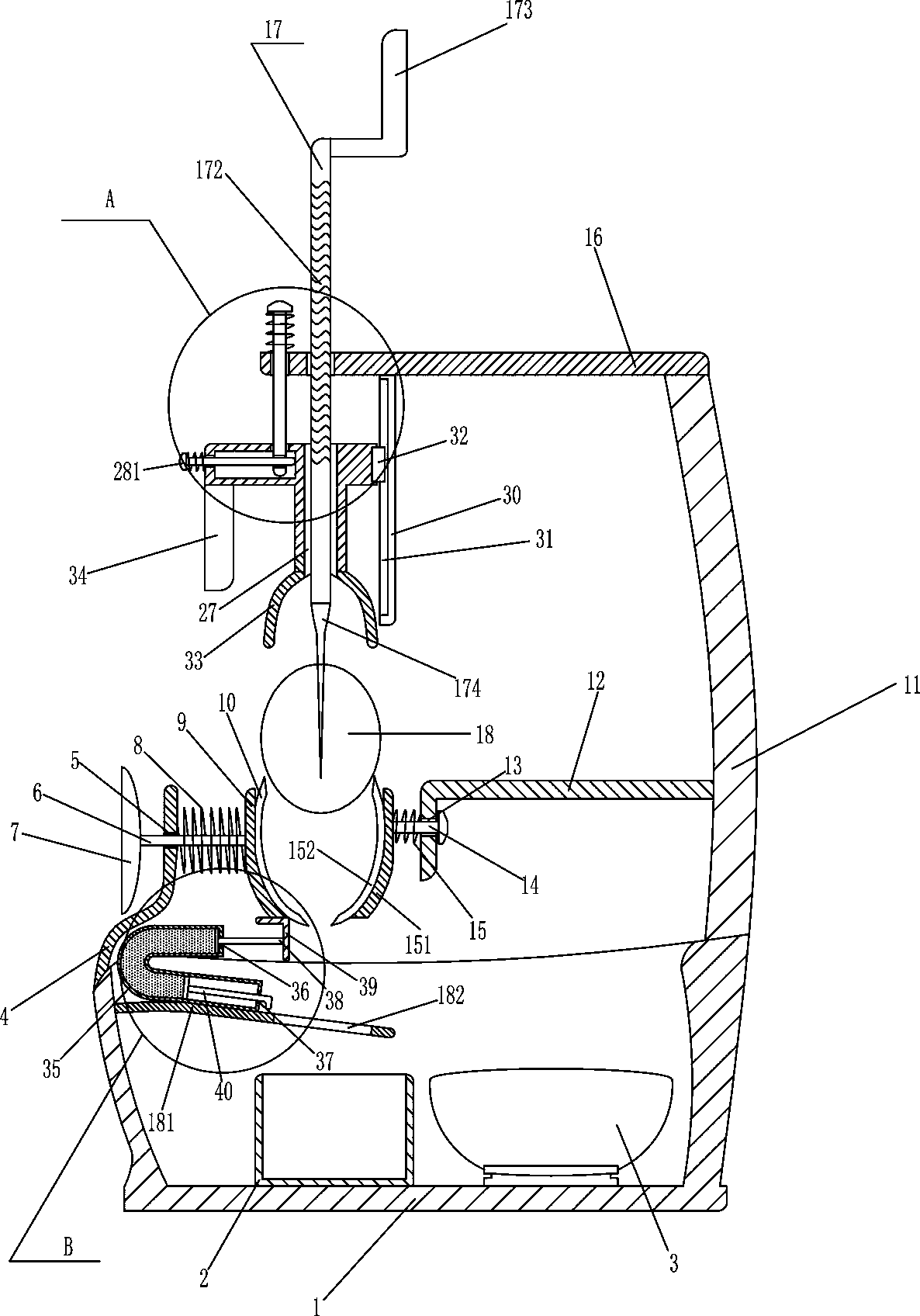

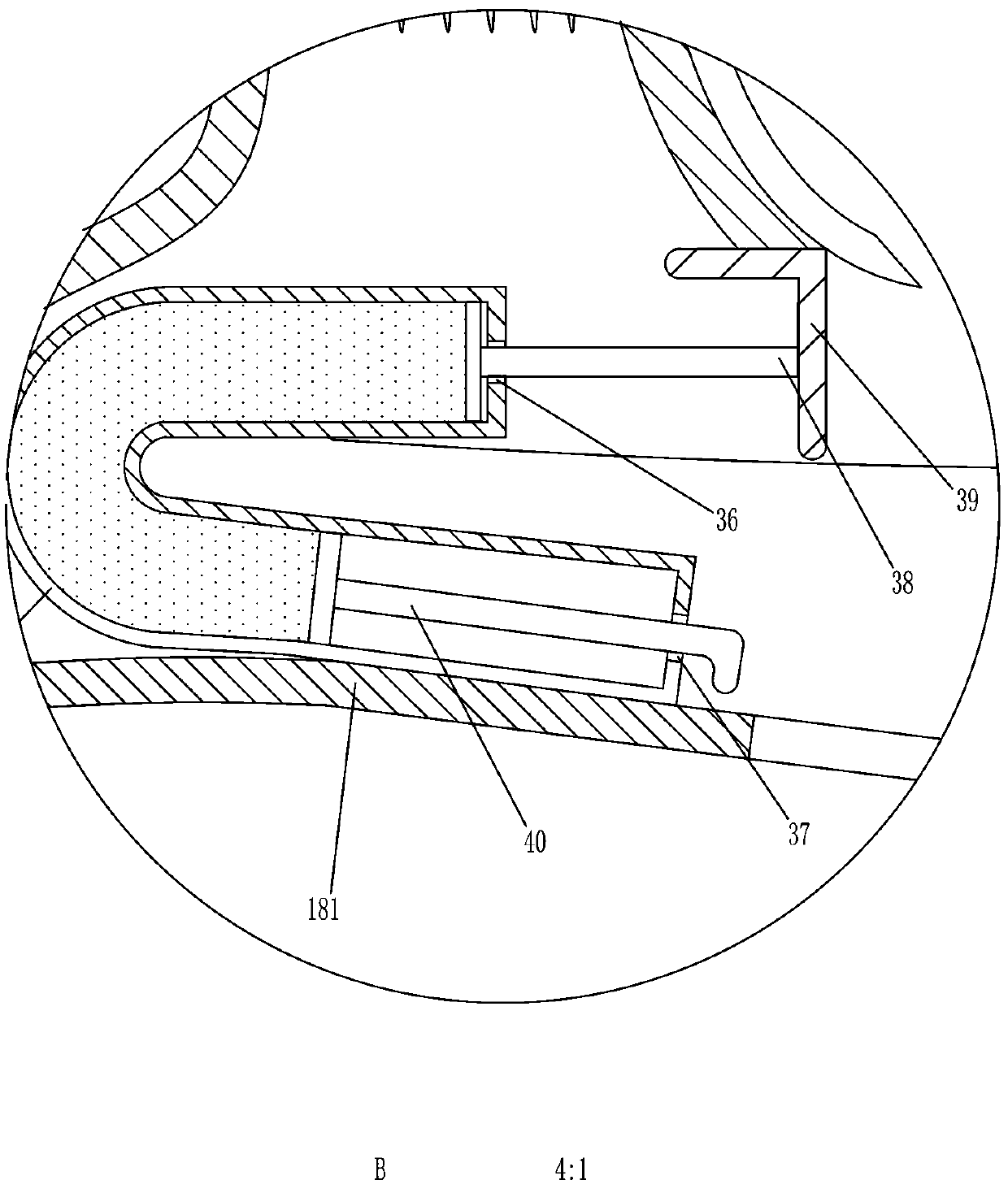

Sugarcane peeling and splitting machine

InactiveCN105058487AImprove peeling efficiencySimple structureCleaning using toolsVegetable peelingEngineeringMechanical engineering

The invention relates to a sugarcane peeling and splitting machine which comprises a peeling mechanism. The peeling mechanism comprises a cutting motor, a cutting quantity auxiliary protection plate, a tape spool and a sleeve. The tape spool is located on the sleeve in a rotating mode and in transmission connection with a main motor. A round groove is formed in the spool surface of the tape spool. The cutting motor is matched with the round groove to limit a rotation seat in a movable mode. The output end of the cutting motor is connected with a cutter shaft. The cutting quantity auxiliary protection plate is fixed to the outer side of the cutting motor. Moreover, an arc plate is arranged on the front portion of the cutter shaft and shields a part of the cutter shaft in the direction that sugarcane enters the cutter shaft. The non-shielded part of the cutter shaft is used as a cutting part for cutting the sugarcane, and the arc surface of the arc plate guides the sugarcane to enter the cutter shaft. The end of the cutting quantity auxiliary protection plate is movably connected with a balance block through a tension spring. The balance block is fixed to the tape spool. The cutting surface of the cutter shaft is made to be close to the axis of the sleeve under the effect of the tension spring. The sugarcane peeling and splitting machine is simple in structure, small in size, low in weight, high in peeling efficiency, good in effect and suitable for sugarcane peeling.

Owner:宁波市奉化奇佳机械设备有限公司

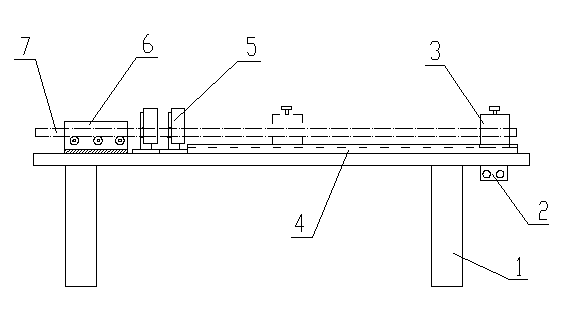

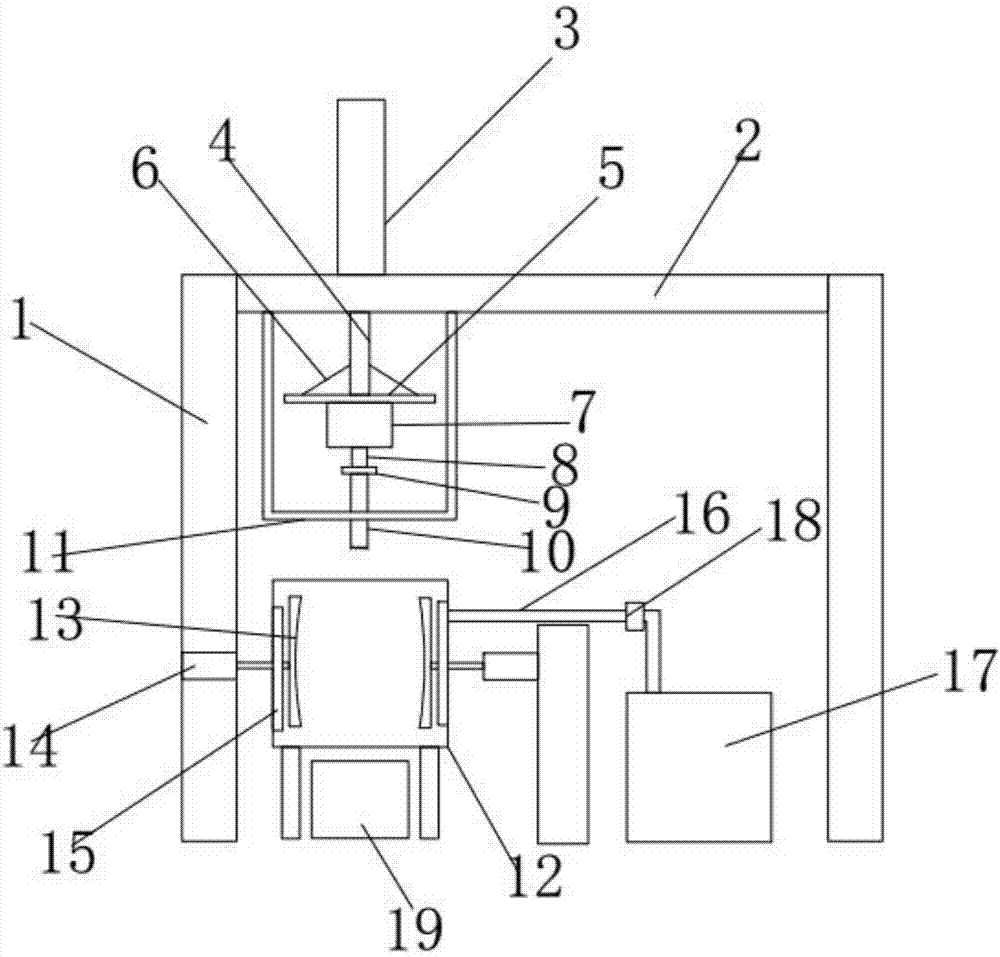

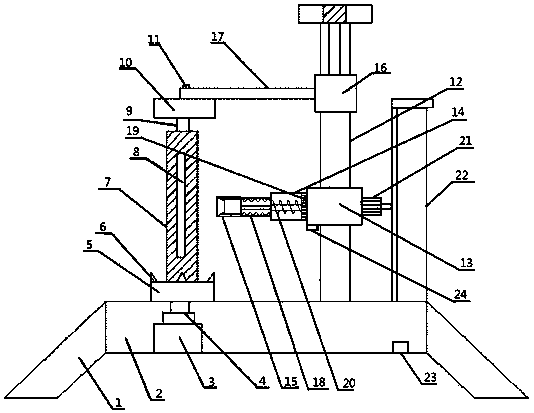

Automatic sugarcane peeling and cutting machine

ActiveCN104643268AIn line with expectationsEasy to acceptVegetable peelingMetal working apparatusLinear motionEngineering

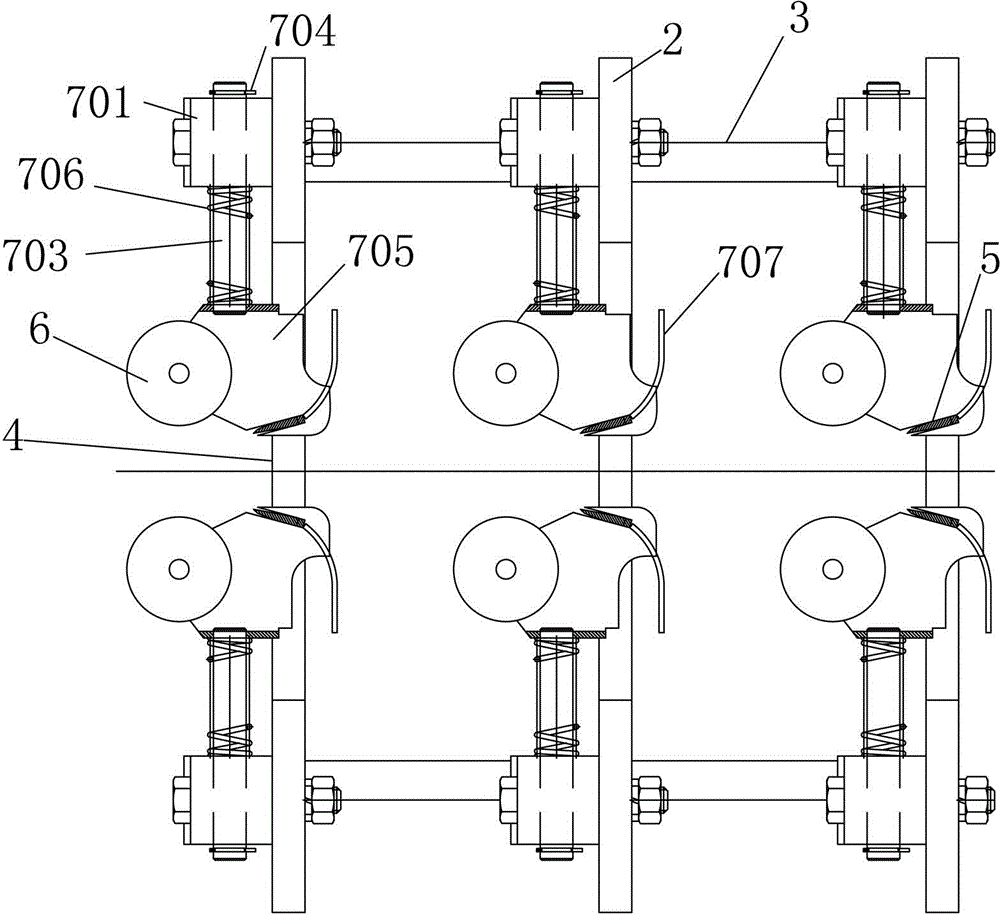

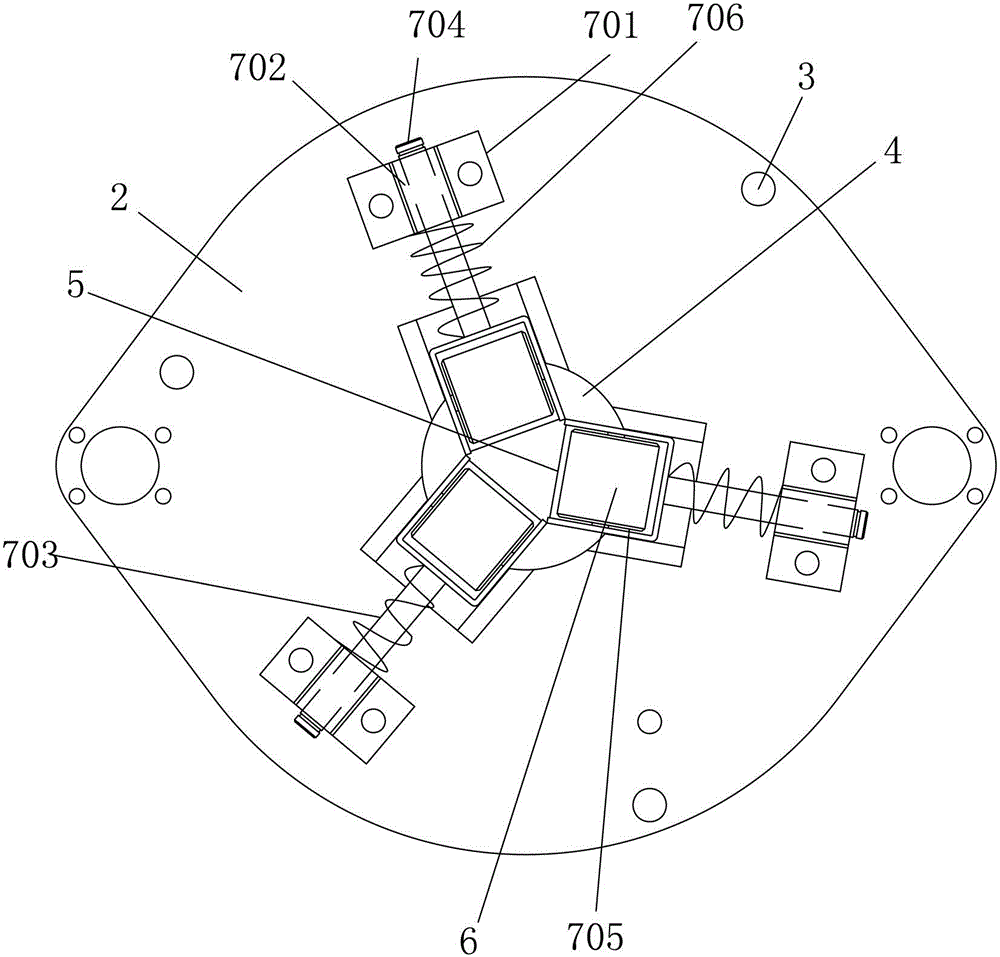

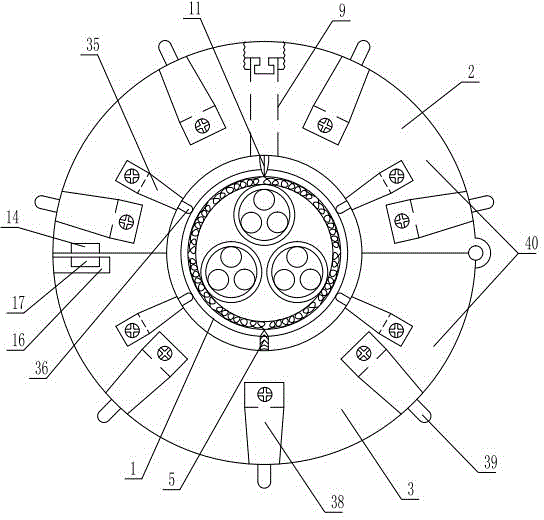

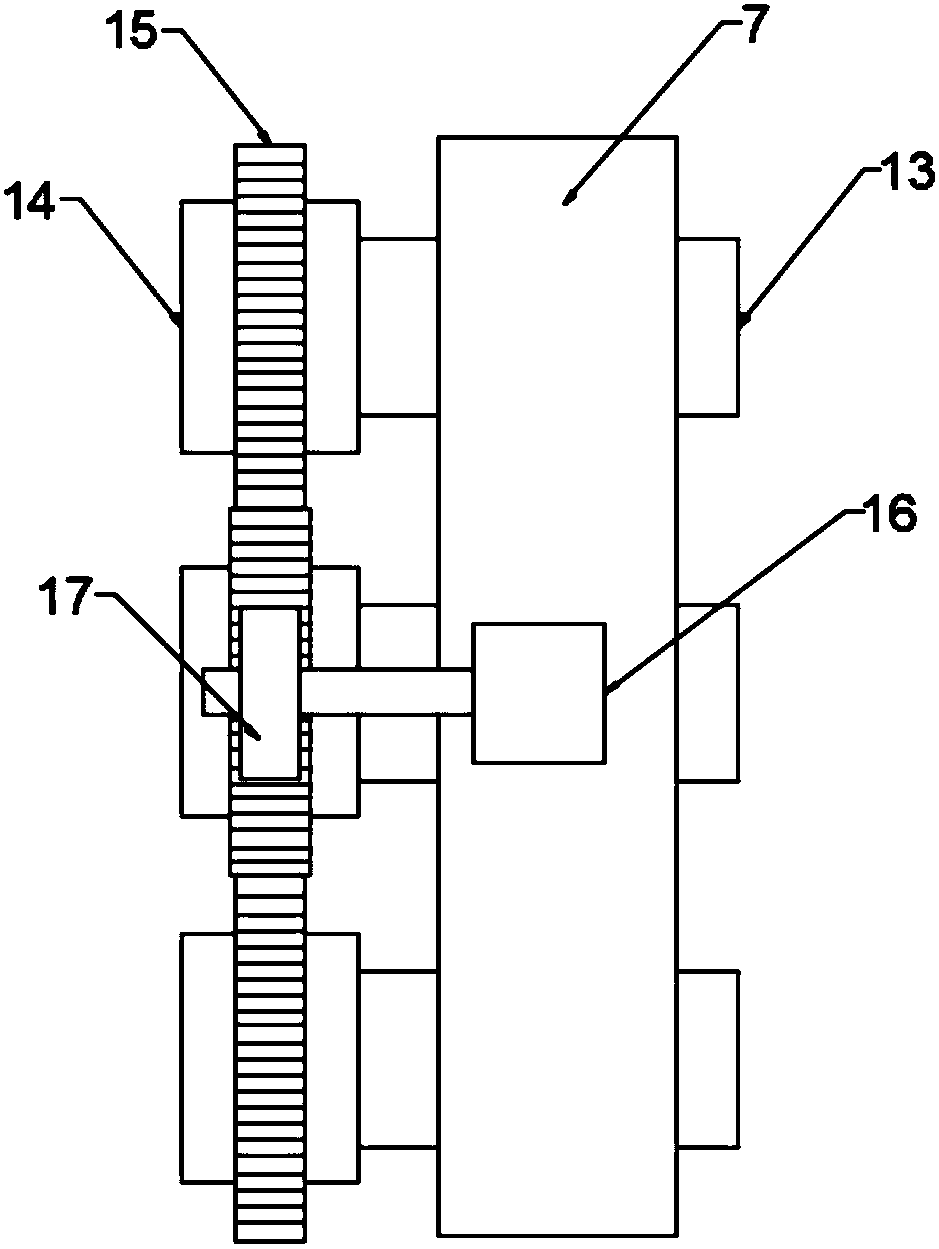

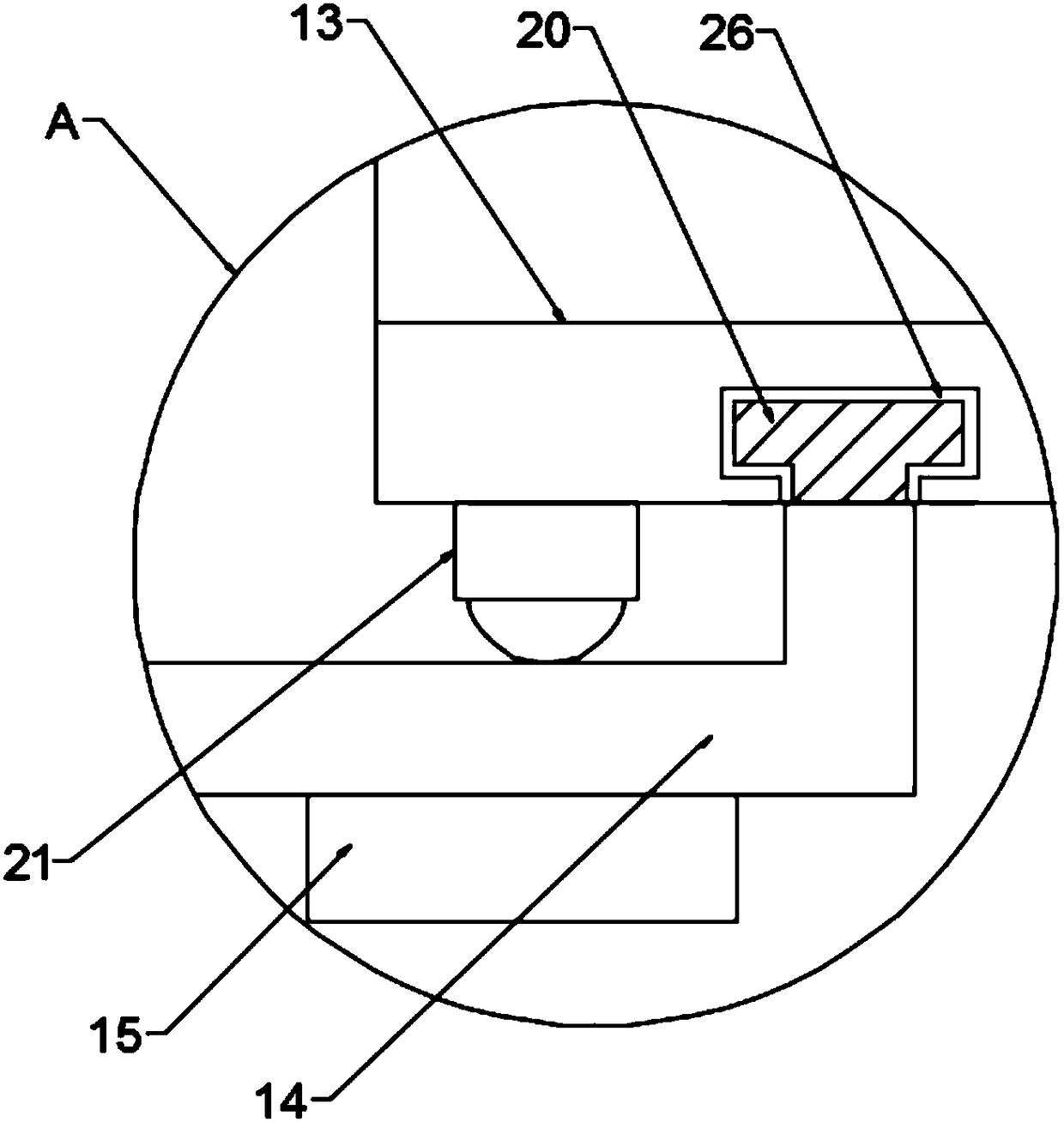

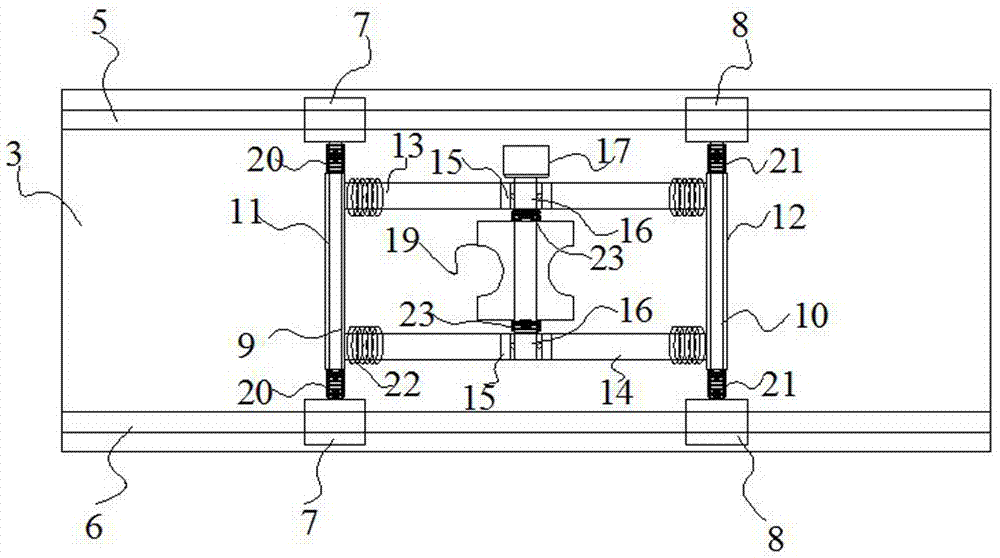

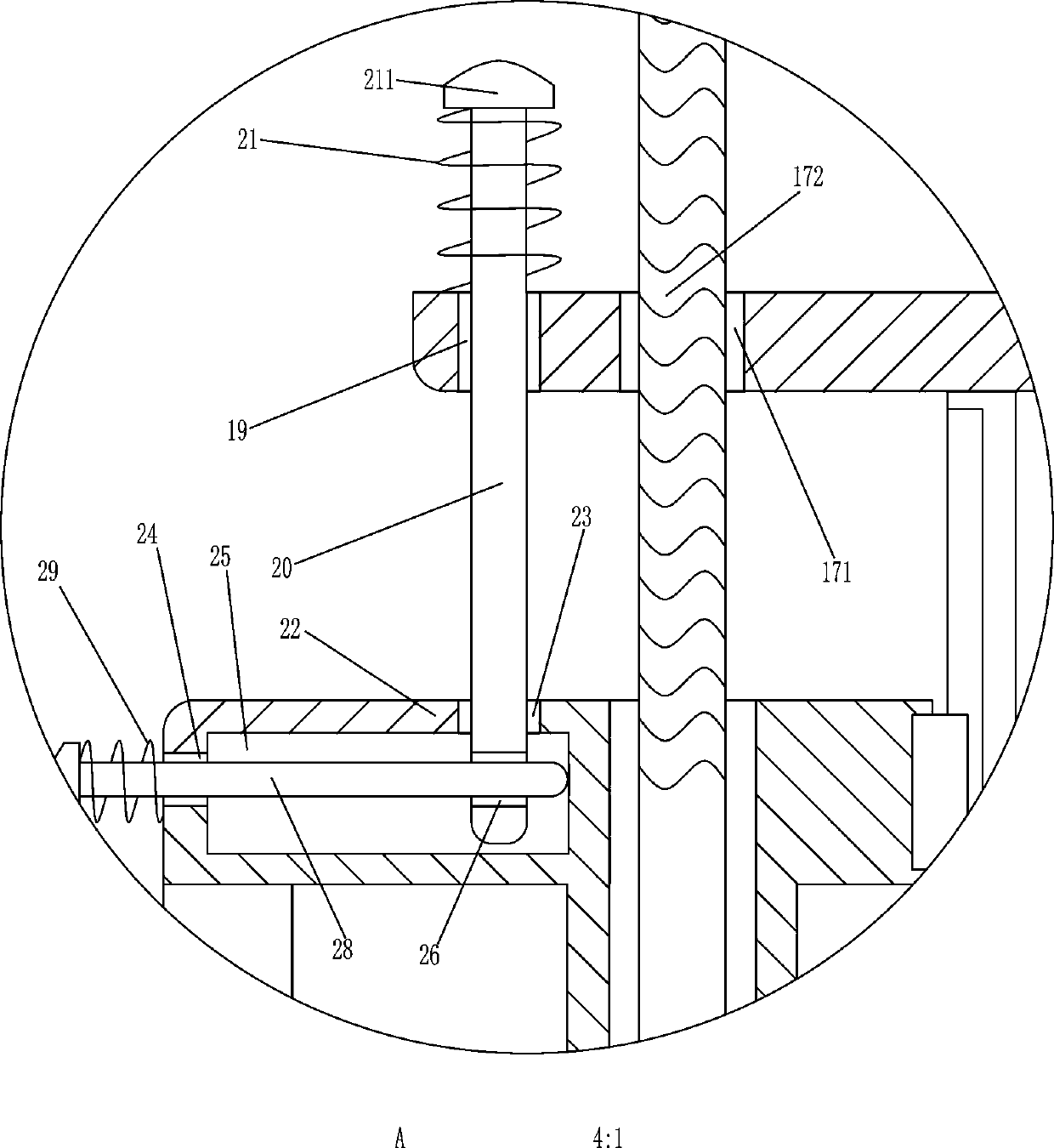

The invention relates to an automatic sugarcane peeling and cutting machine. The technical scheme is that the automatic sugarcane peeling and cutting machine comprises a frame, wherein multiple knife rests are arranged transversely on the frame at intervals and are connected with one another by virtue of multiple connecting shafts, a sugarcane passing hole is formed in the center of each knife rest, multiple peeling blades uniformly distributed around the circumference of each sugarcane passing hole are arranged on the knife rests, a guide roller is rotatably arranged on each knife rest at one side, facing a sugarcane inlet, of each peeling blade, an elastic part which is used for limiting each peeling blade at a position for doing linear motion towards the center of each sugarcane passing hole is fixed between each peeling blade and the corresponding knife rest, a holding device is arranged at the outer side of each of the two end knife rests, and a sugarcane traction device is arranged on each holding device in a direction facing a sugarcane outlet. The automatic sugarcane peeling and cutting machine is produced according to a principle of simulating artificial sugarcane peeling, and the appearance of a peeled sugarcane finished product achieves or superior to that obtained by artificial peeling, accords with expectations of people and is beneficial to be accepted by the masses. The automatic sugarcane peeling and cutting machine can well adapt to sugarcanes with different thickness diameters and bending degrees, the complete peeling rate reaches 95% or more than 95%, and the artificial peeling can be completely replaced.

Owner:关永刚

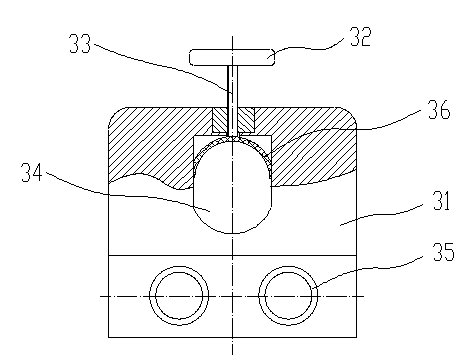

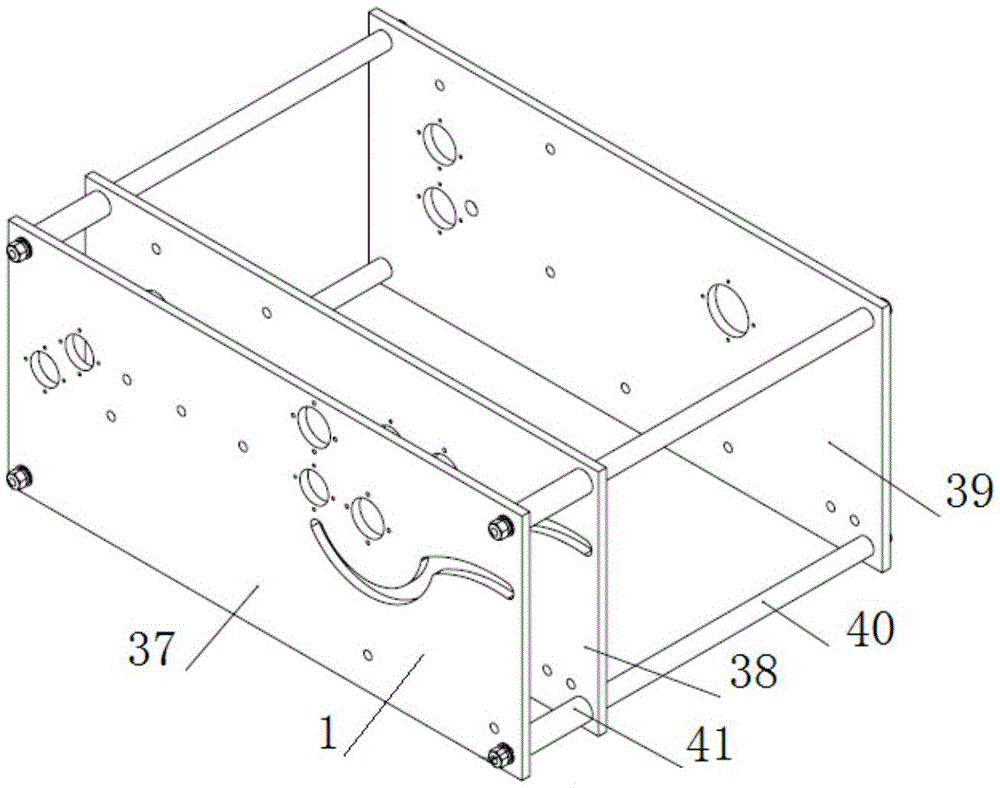

Cable sheath removal and recycling device

InactiveCN107482541AImprove work efficiencyImprove peeling efficiencyFilament handlingApparatus for removing/armouring cablesEngineeringElectric wire

The invention discloses a cable peeling recovery device, which comprises a device outer frame and supporting legs arranged at the bottom of the device outer frame, a cable inlet is opened on the left side wall of the device outer frame, and the inside of the device outer frame is installed in sequence from left to right There are: the first guide wheel is used to guide the cable to move to the right; the pressure plate is used to press the cable and remove the stain on the cable surface, and the lower end of the pressure plate is fixed with a cleaning block; the cutter device is used to cut the cable skin; the second guide wheel is used for Fix the cable above the cutter device and guide the cable to move to the right; the cable skin recovery wheel and the cable core recovery wheel are used to strip the cable inner core from the cable skin and recover the cable inner core and cable skin. The invention solves the problems that the existing electric wire recycling device cannot peel and classify the electric wires, is not suitable for recycling cables with different diameters, and has low working efficiency.

Owner:邹晶明

Continuous rolling tube high-pressure water spraying walnut kernel peeling device

InactiveCN102763887ASave resourcesImprove peeling efficiencyHuskingHullingWater resourcesHigh pressure water

The invention relates to a continuous rolling tube high-pressure water spraying walnut kernel peeling device, which comprises a material inlet hopper, a rolling tube, a high-pressure water pipe, a material outlet hopper, a motor, a water collecting hopper and a water collecting tank, wherein a spiral scraping plate is arranged in the rolling tube, walnut kernels are pushed from a material inlet to a material outlet, the high-pressure water pipe is arranged in the axial direction of the rolling tube and is positioned above the axial direction, a plurality of high-pressure water spray openings are symmetrically arranged under the water pipe, and the rolling tube is driven by a motive power system. The water collecting bank is positioned under the rolling tube, a filter net is arranged on the water collecting tank, the walnut kernel flushing and spraying is completed through high-pressure water, the water enters the water collecting tank through the water collecting hopper and the filter screen, the water in the water collecting tank enters the high-pressure water pipe arranged in the rolling tube after the pressure boosting via a centrifugal pump, and the water consumption circulation is formed. The continuous walnut kernel peeling can be realized, the peeling efficiency is high, the daily yield is high, the peeling is thorough and uniform, in addition, the peeling, the separation and the cleaning are combined, the production steps are saved, meanwhile, the circulation water is adopted, the water resource saving is realized, and the device is suitable for industrial mass walnut kernel peeling production.

Owner:食品行业生产力促进中心

Waste electric wire stripping and core-taking apparatus

ActiveCN107658077AEasy to manufactureLow costBasic electric elementsApparatus for removing/armouring cablesCopperElectric wire

The invention discloses a waste electric wire stripping and core-taking apparatus. The waste electric wire stripping and core-taking apparatus comprises a paying-off mechanism, a straightening and guiding mechanism, a cutting mechanism, a flying shear mechanism, a stripping mechanism and a wire-collecting mechanism arranged on a working table in sequence. By virtue of the waste electric wire stripping and core-taking apparatus, the problems of difficulty in stripping and not high stripping efficiency caused by the fact that the conventional electric wire cutting apparatus only cuts one surfaceof an electric wire, and the problem of not high recycling rate caused by easy breaking of a copper core can be solved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Method for peeling off walnut kernel pellicle by ultrasonic waves

InactiveCN101961130AHigh peeling efficiencyGuaranteed qualityHuskingHullingWrinkleUltrasonic generator

The invention discloses a method for peeling off walnut kernel pellicle by ultrasonic waves, which is characterized by comprising: firstly, placing walnut meat in 50 to 75 DEG C hot water and completely immersing the walnut meat in the hot water for 5 to 20 minutes; secondly, placing the heated walnut meat in a cold water container, and immersing the walnut meat in the water completely; thirdly, applying ultrasonic waves at a frequency of 1 to 10KHz and a sound intensity of 0.2 to 10W / cm<2> to the cold water for performing ultrasonic treatment for 4 to 20 minutes by using a piezoelectric ultrasonic generator to remove the pellicle on the surface of the walnut meat; and finally, manually removing the residual pellicle in the wrinkles of the walnut meat and obtaining clean hulled walnut meat. The method of the invention is efficiency, pollution-free, economic and practical, is applicable to almonds, ginkgo nut pip, pine nut pip, hazelnut pip, pea nut pip and other nut pips and suitable for industrial production and has very high promotion value.

Owner:HEFEI UNIV OF TECH

Camellia oleifera fruit huller

The invention discloses a camellia oleifera fruit huller, belonging to the technical field of hulling machinery. The camellia oleifera fruit huller comprises a rack, a turning box, two tooth rollers, a main roller, a strip sieve, a semi-circular sieve and a fan, wherein a feed port is arranged at the top end of the rack; the two tooth rollers rotating relative to each other are arranged opposite to the feed port in the rack; the two tooth rollers are connected with the turning box respectively; a transmission roller, the semi-circular sieve and the strip sieve are sequentially arranged below the two tooth rollers; one end of the main roller shaft is connected with the turning box; the fan is arranged on one side of the strip sieve; and a power machine is connected with the main roller and the fan respectively. According to the invention, two tooth rollers rotate relatively to remove the hulls of the camellia oleifera seeds, and the seeds and hulls are separated by a mesh sieve and a fan to realize hulling of the camellia oleifera seeds, the hulling efficiency is high and the separation of seeds and hulls is easy. The distance between two tooth rollers is adjusted according to the fruit size, and the camellia oleifera seeds are easily peeled with little damage.

Owner:丹东先科液压设备有限公司

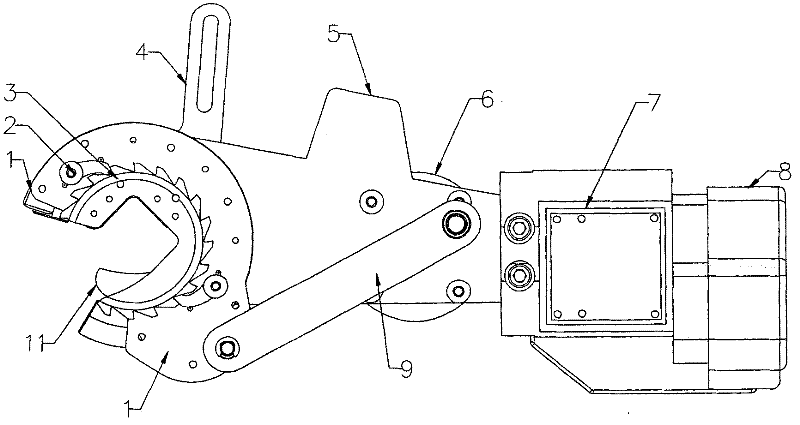

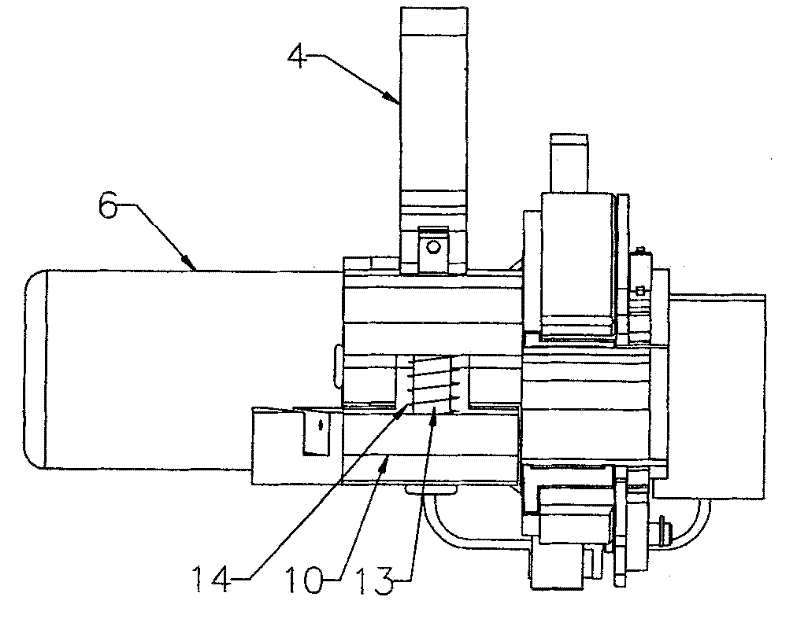

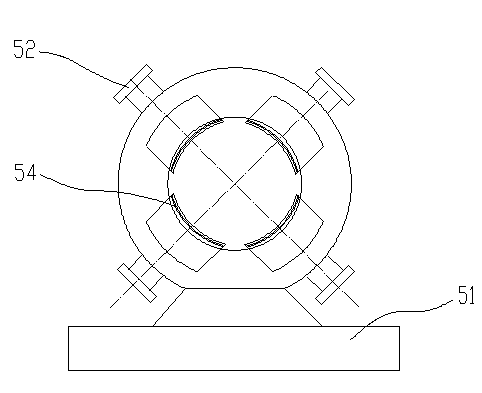

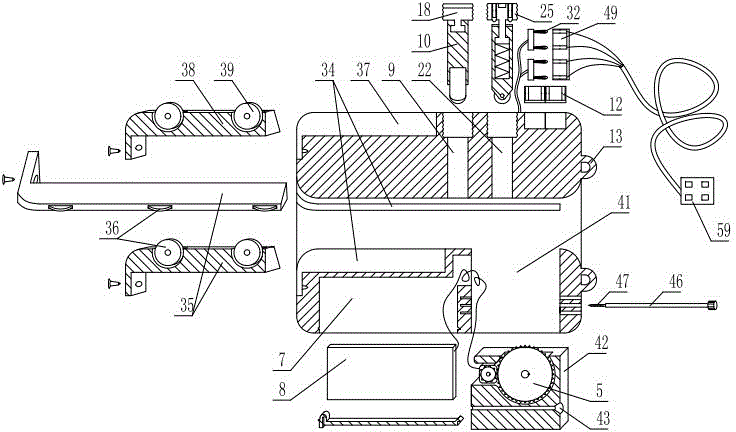

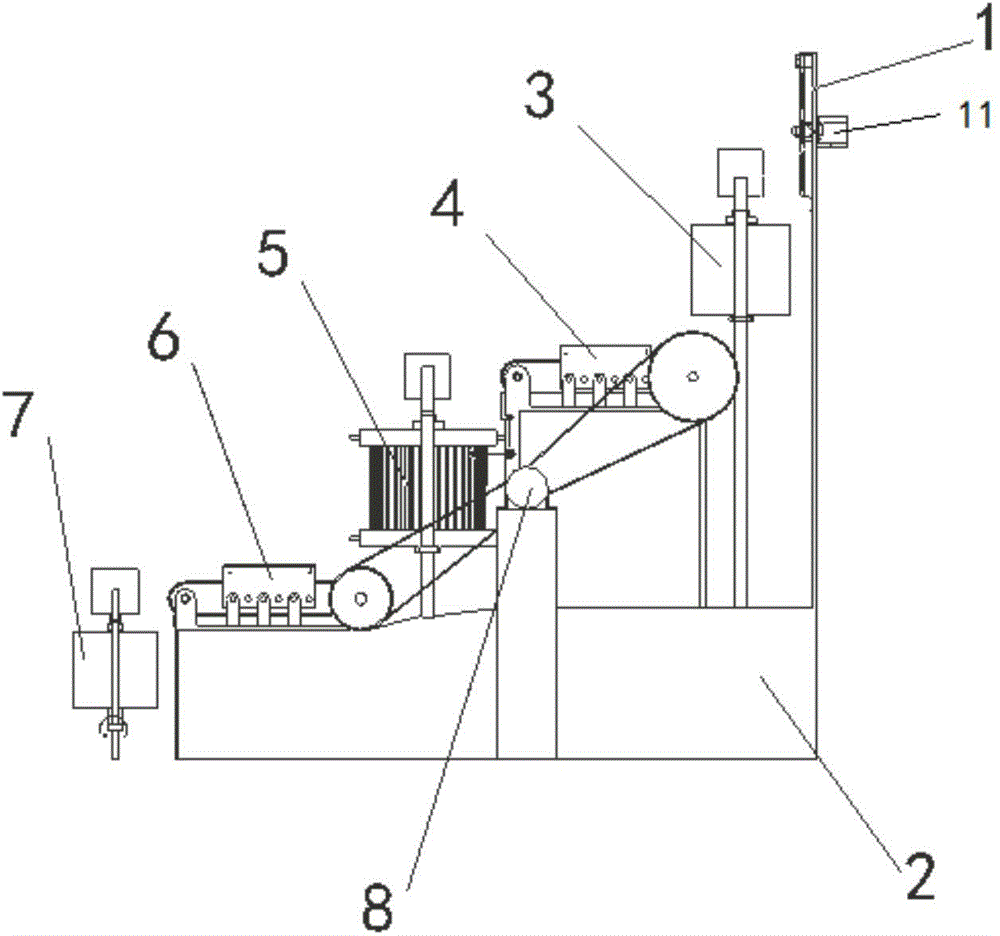

Cable stripping machine

ActiveCN101752809AImprove peeling efficiencyEasy to realize intelligent operationLine/current collector detailsApparatus for removing/armouring cablesEngineeringHigh pressure

The invention relates to a cable stripping machine. The cable stripping machine comprises a blade, a fixing bracket, a blade fixing device, a gear motor, a transmission mechanism, a cable clamping device and an electronic control device, wherein the blade fixing device drives the blade to rotate around a cable to realize ringcutting movement and is arranged on the front end of the fixing bracket; the gear motor is used to drive the blade fixing device to move and is fixed on the fixing bracket; the cable clamping device is used to clamp the cable and is arranged on the fixing bracket or on the blade fixing device; and the electronic control device is used to control the on and off of the gear motor and the revolution of the gear motor and is connected with a power supply. The invention uses the gear motor to drive the blade so as to avoid the problem that a manual stripping tool needs the user to wind the cable by hands, increase the cable stripping efficiency, reduce the labor intensity and facilitate the operation. The intelligent operation of the robot and the like can be conveniently realized by using the cable stripping machine. The cable stripping machine is used for stripping the sheath of the high voltage cable conductor, in particular for stripping the sheath of overhead high voltage cable conductor.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

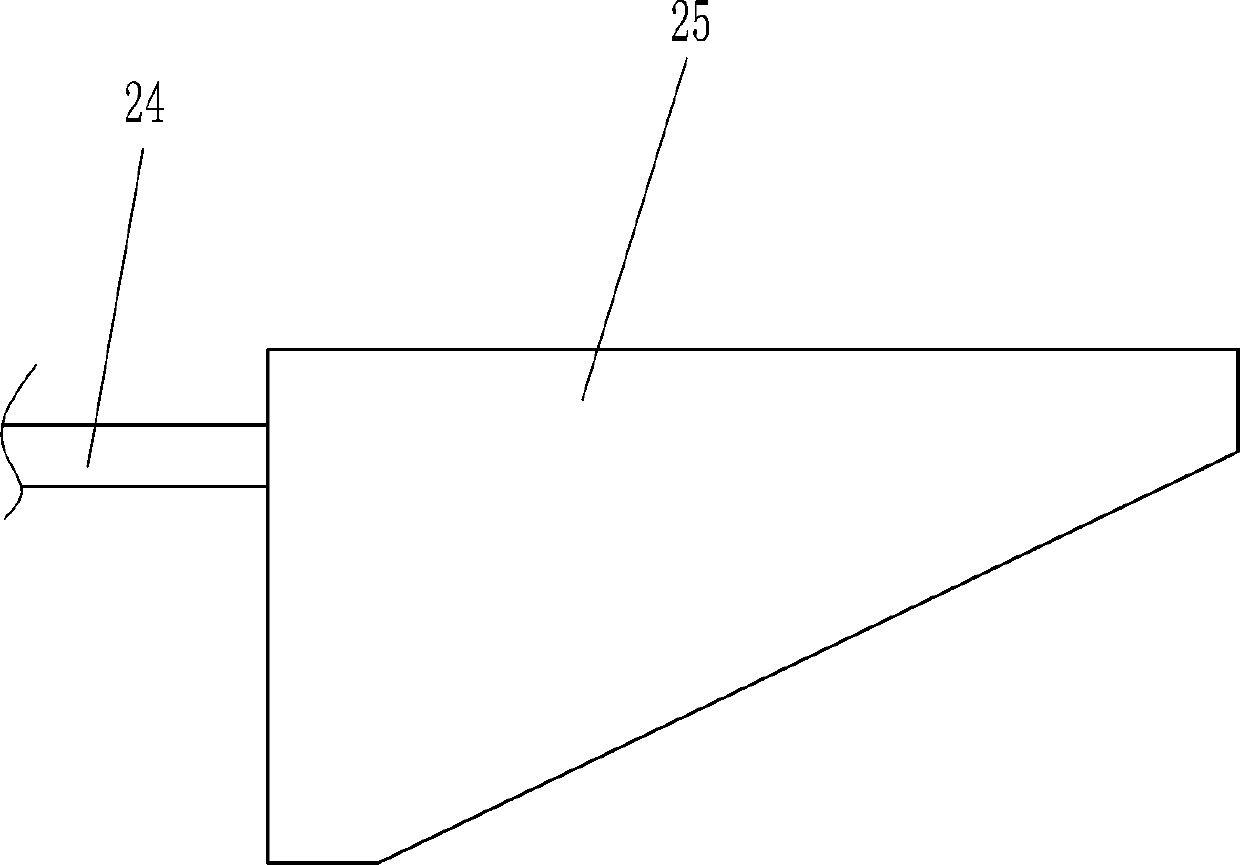

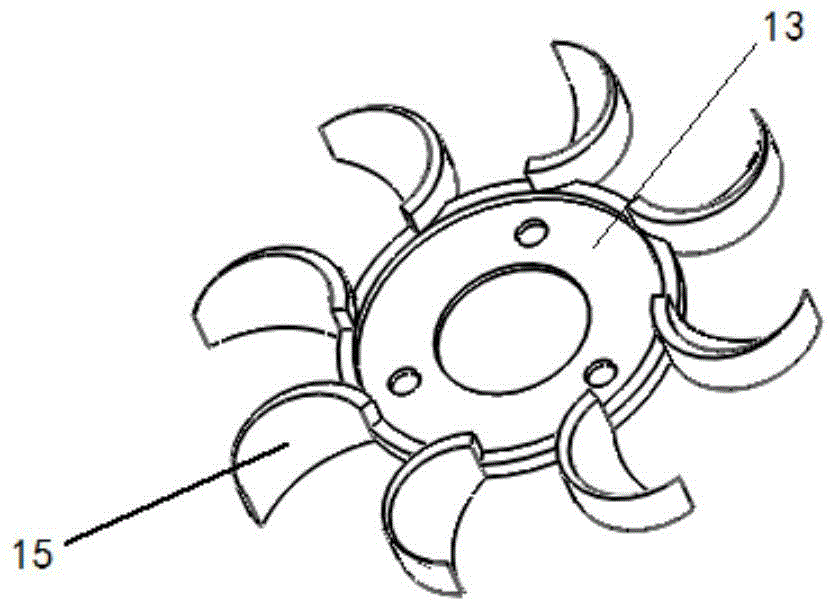

Automatic sugar cane peeler

The invention relates to an automatic sugar cane peeler for solving the problem of unsafety and low efficiency caused by manpower adopted by an existing sugar cane peeler device. The automatic sugar cane peeler comprises a clamping device and a cutter, and is characterized in that the clamping device is located on a linear guide, the clamping device is provided with a sugar cane porous base, the cutter is composed of a plurality of cambered blades, the cambered blades are arranged on an elastic adjustment device inside the cutter, and the cambered blades are provided with cambered surface for guiding scraps. The automatic sugar cane peeler has the characteristics that the plurality of repeated circular blades are designed to make peel more clean, the cutter can be used for peeling but is not easy to abrade, the peeler can operate only by clamping one side with low labor intensity, the peeler operates in a linear motion with high peeling efficiency, the peeler is suitable for sugar cane with a long fiber shell characteristic and is smooth in peel discharge, the structure of whole device is simple, the motion is safe and reliable and the operation is convenient.

Owner:余萱

Cable stripper

InactiveCN105281258ASmooth peelingQuick peelApparatus for removing/armouring cablesEngineeringBlade handle

The invention discloses a cable stripper. The cable stripper includes a main half tube and an auxiliary half tube which are locked together through a locking device so as to form a sleeve; a power gear which is in press fit with the outer sheath of a cable and a motor for driving the power gear to rotate are arranged in a power cavity of the sleeve; the outer wall of the sleeve is provided with a switch for controlling the on-off of the power source of the motor; the cross section of a blade cavity of the sleeve is a regular polygon; the edges of the polygon are an positive integer times of four; a blade handle is slidingly inserted in the blade cavity; a blade which can longitudinally cut the cable is fixedly arranged in the inner end of the blade handle; the outer section of the blade cavity is in threaded connection with a positioning device for axially positioning the blade handle; and an end portion of the sleeve is fixedly provided with a connecting ring. With the cable stripper adopted, axial longitudinally-cutting stripping and transverse annularly-cutting stripping can be both realized, and stripping can be initially performed on any portion of the cable, and cable stripping can be performed in a pipeline, and stripping depth can be adjusted. The cable stripper has the advantages of automatic stripping and time-saving and labor-saving operation.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

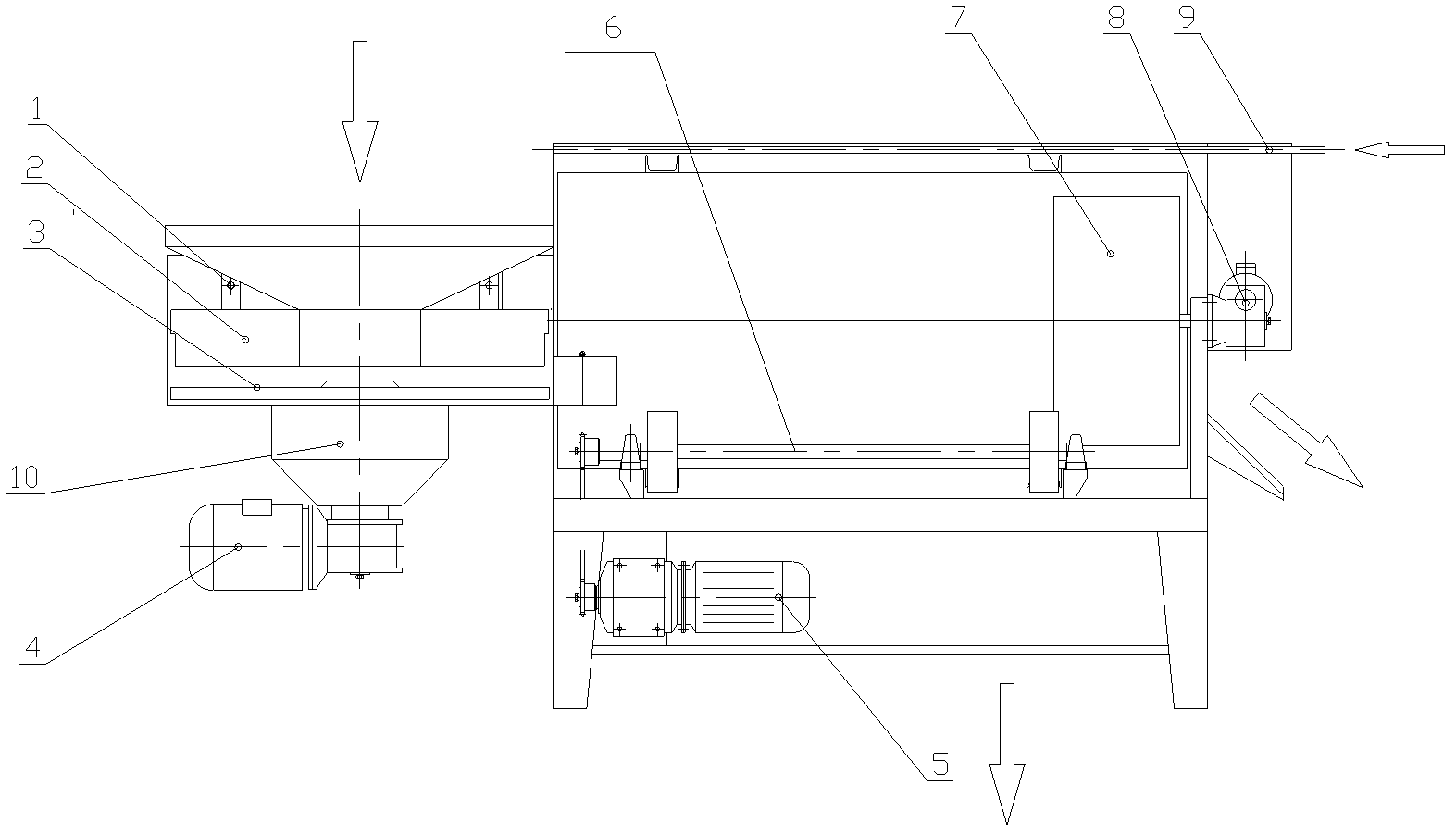

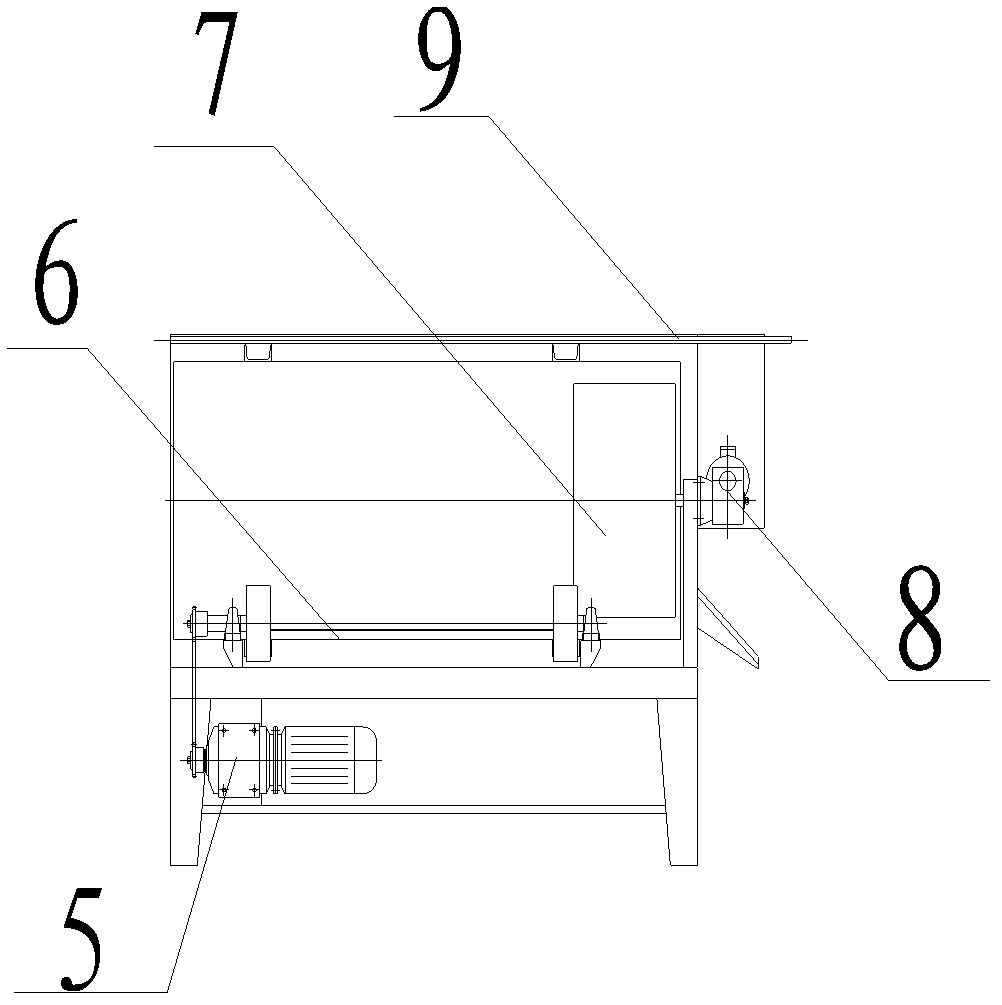

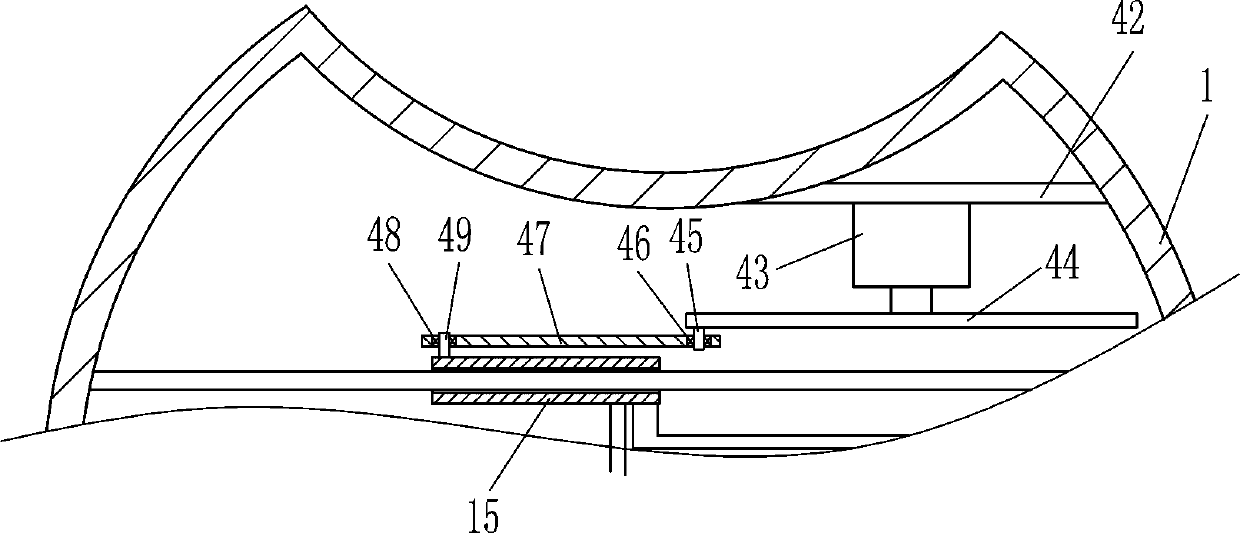

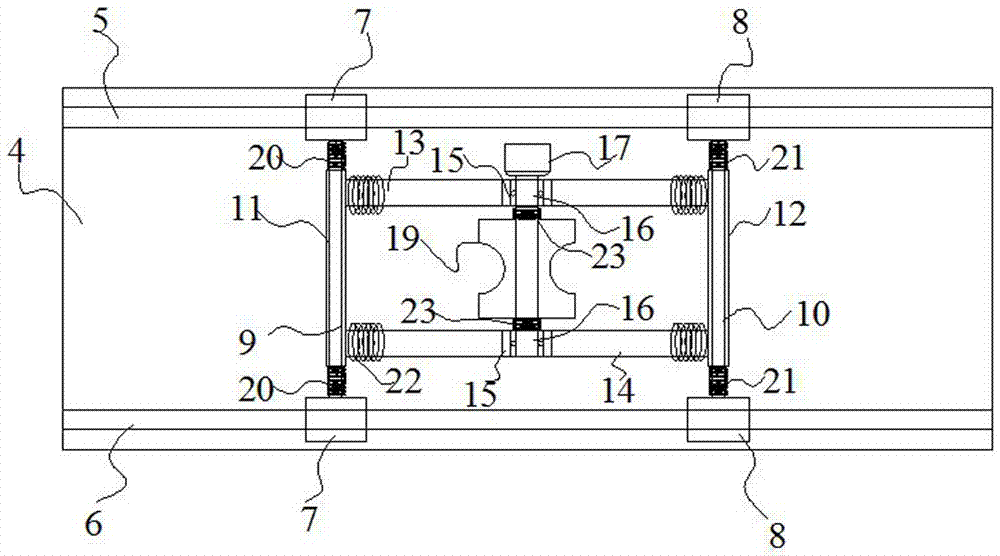

Sugarcane peeling and section cutting device

PendingCN108284478AImprove peeling efficiencyIntegrity guaranteedVegetable peelingMetal working apparatusEngineeringUltimate tensile strength

The invention discloses a sugarcane peeling and section cutting device, and belongs to the field of agricultural product processing. The sugarcane peeling and section cutting device is composed of a support, a device rack, a first sugarcane stop rod, a sharp tooth gear, a first baffle spring, a first baffle, first cutting-off tool springs, a second baffle, a first cutting-off tool, a second sugarcane stop rod, peeling tools, a second cutting-off tool, a storage bag supporting rod, a storage bag stop block, a second baffle spring, second cutting-off tool springs, peeling tool springs and a stepping motor. The sugarcane peeling and section cutting device is high in automation degree, the labor intensity is relieved, and the sugarcane peeling efficiency is improved; the integral design of thestructure is reasonable, the peeling and section cutting work of the whole sugarcane can be finished through one-time operation, the whole operation process is clean and sanitary, and direct usage cannot be influenced for eaters. According to the purpose of cooperation of the unique design of the first baffle and the second baffle and usage of tension springs, the sugarcane is downwards closely attached to a sugarcane positioning clamping arc step, the sharp tooth gear rotates and drives the non-peeled sugarcane to move inwards, and the attaching force is increased.

Owner:祝凯旋

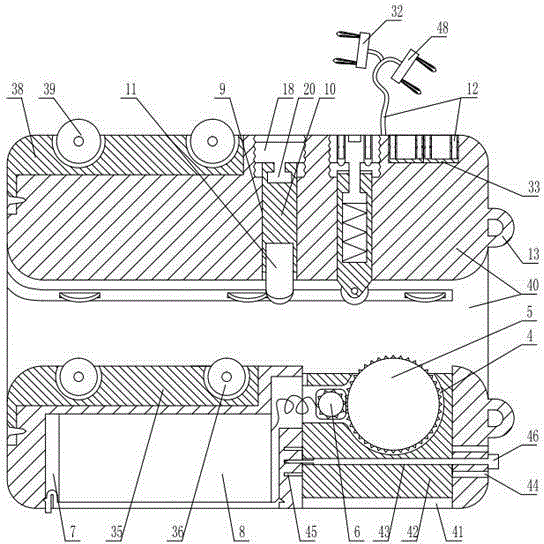

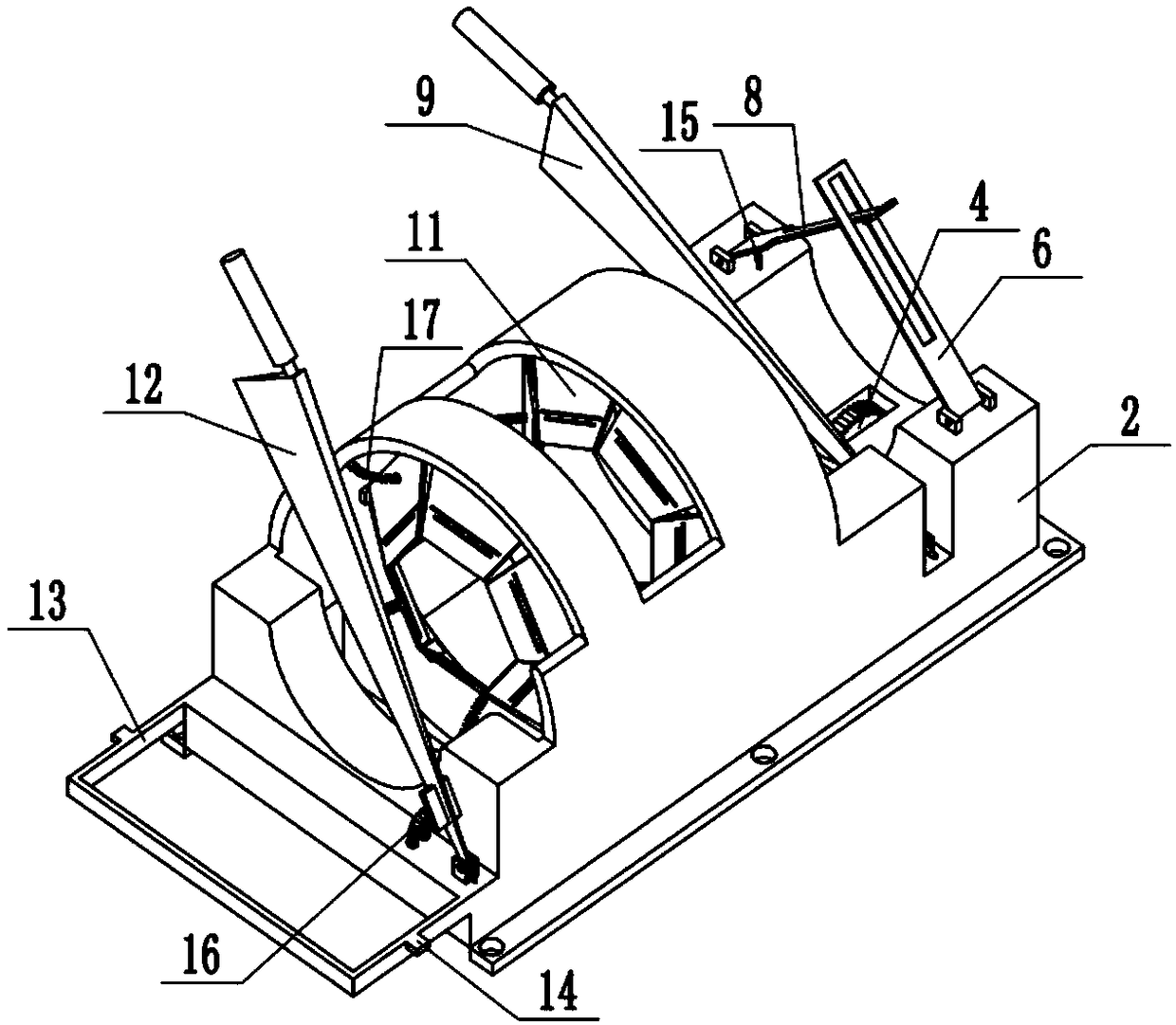

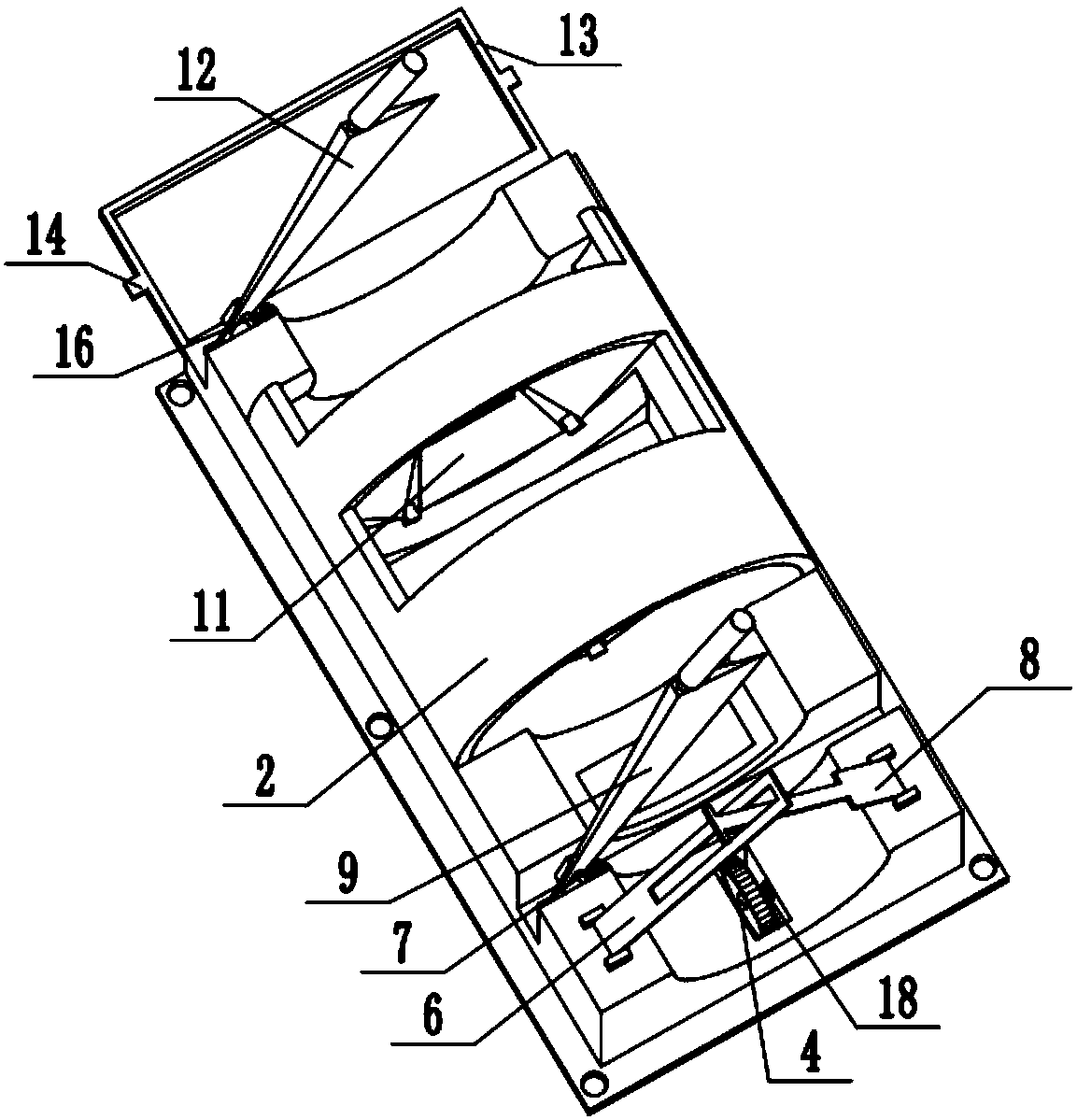

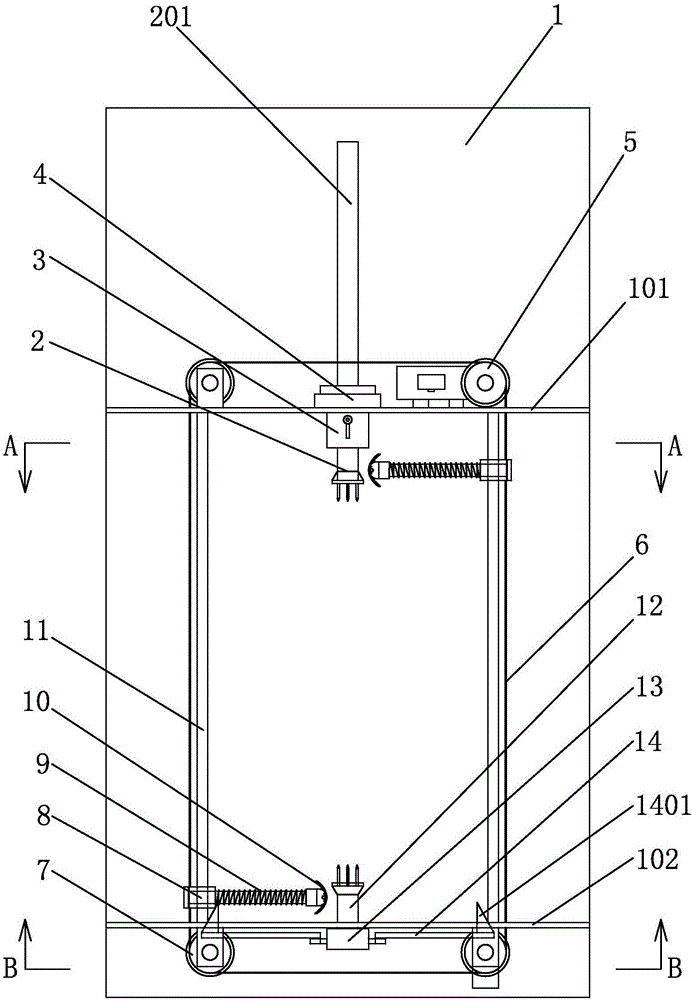

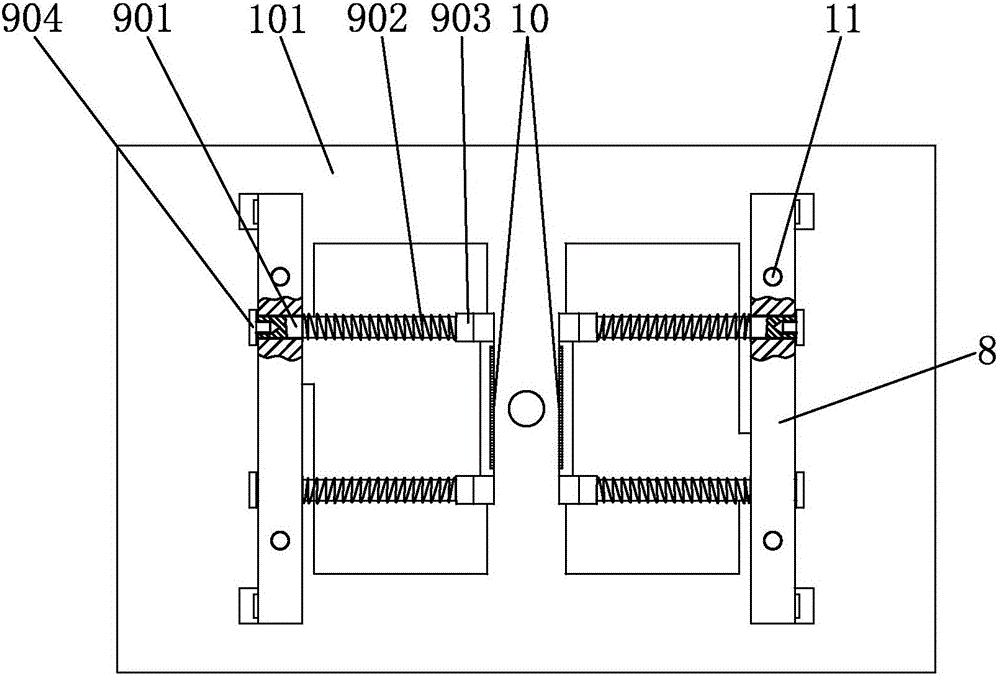

Manual-work-imitated melon/fruit peeling machine

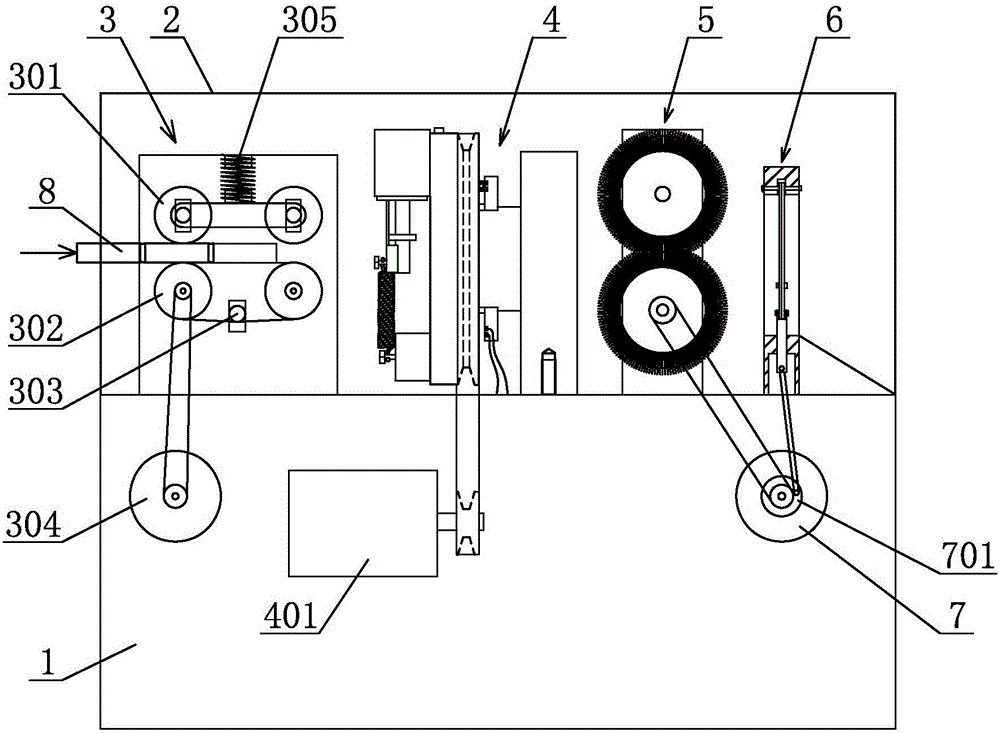

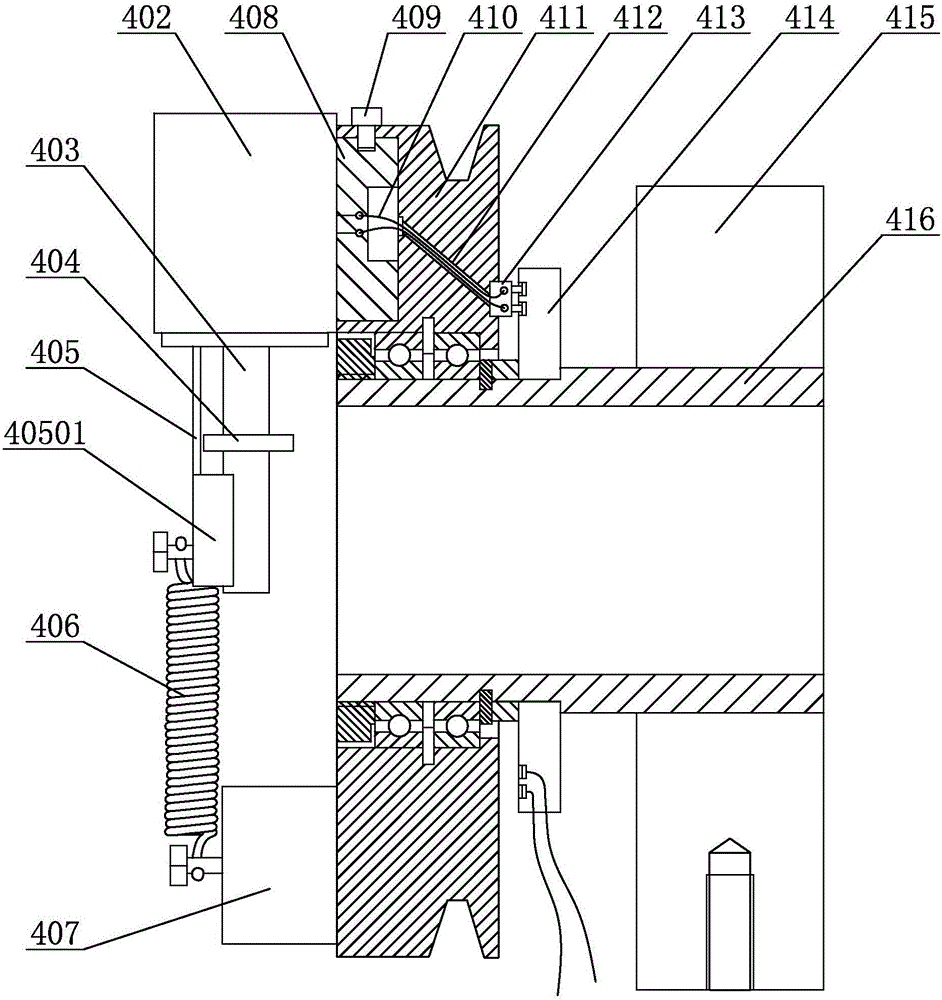

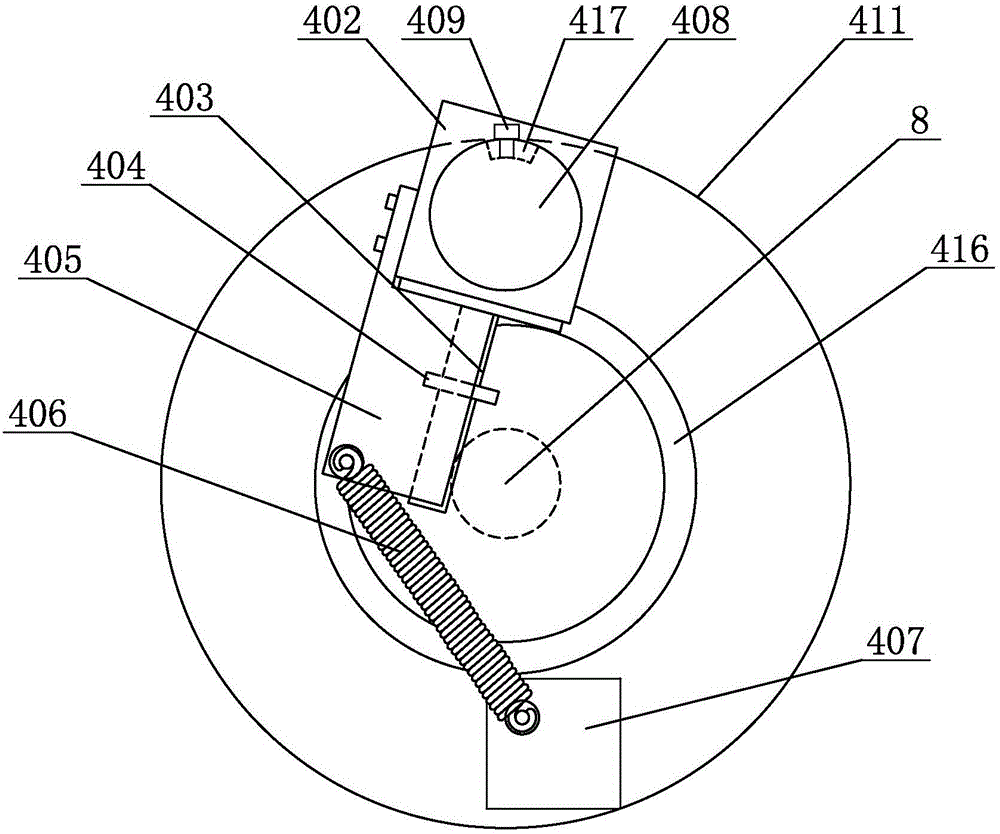

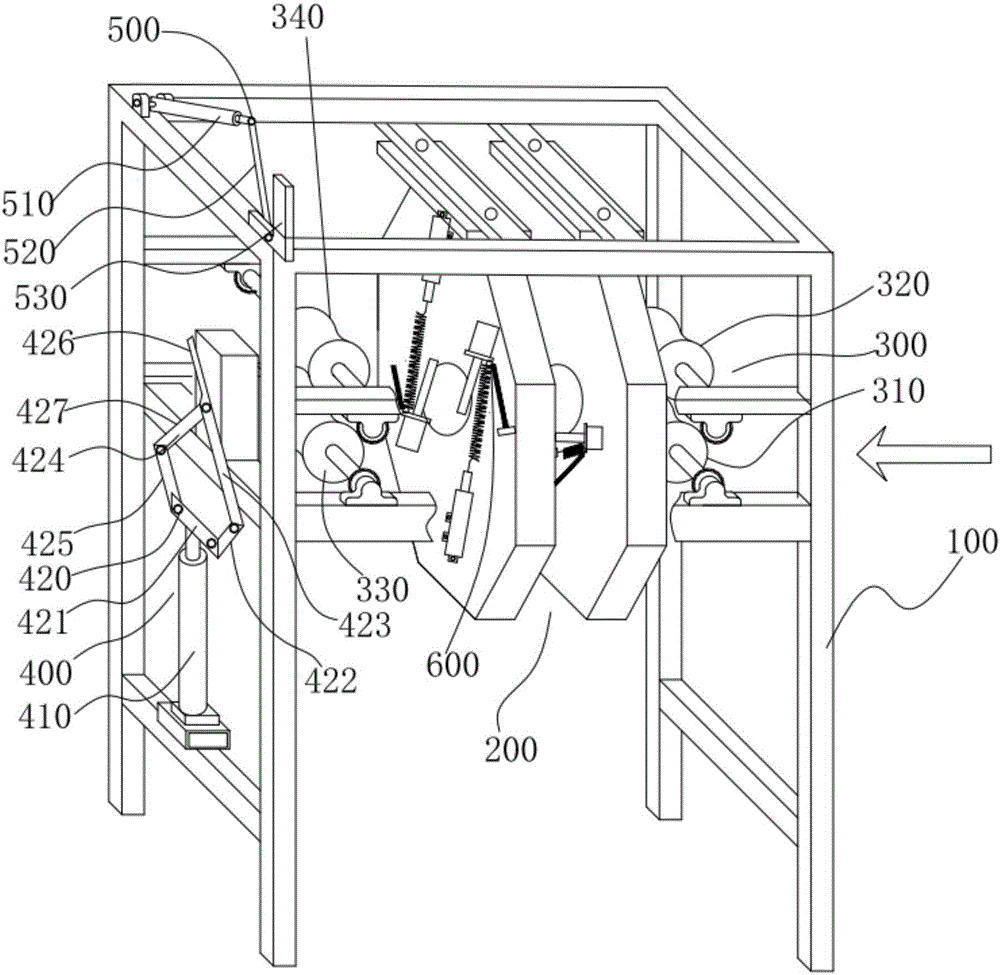

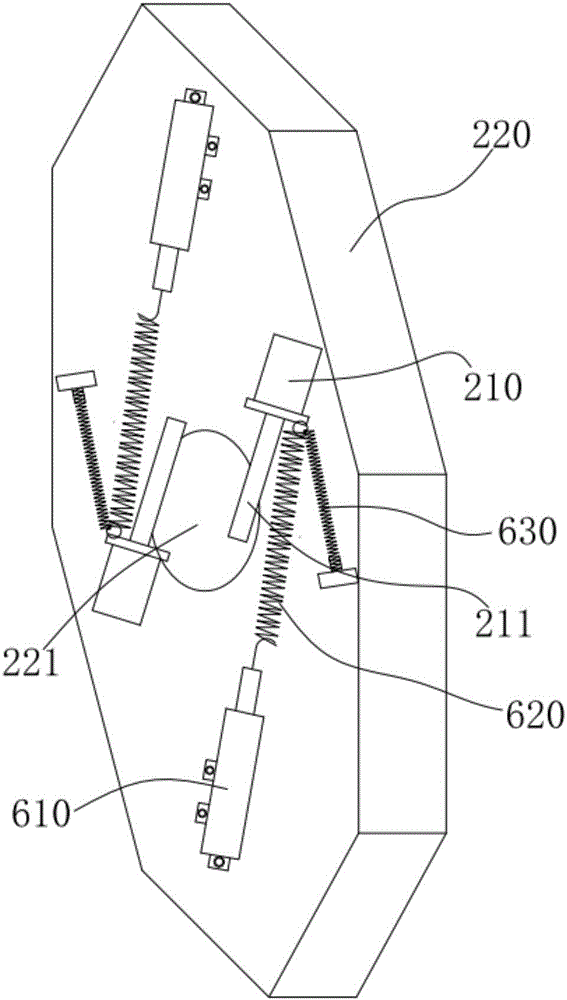

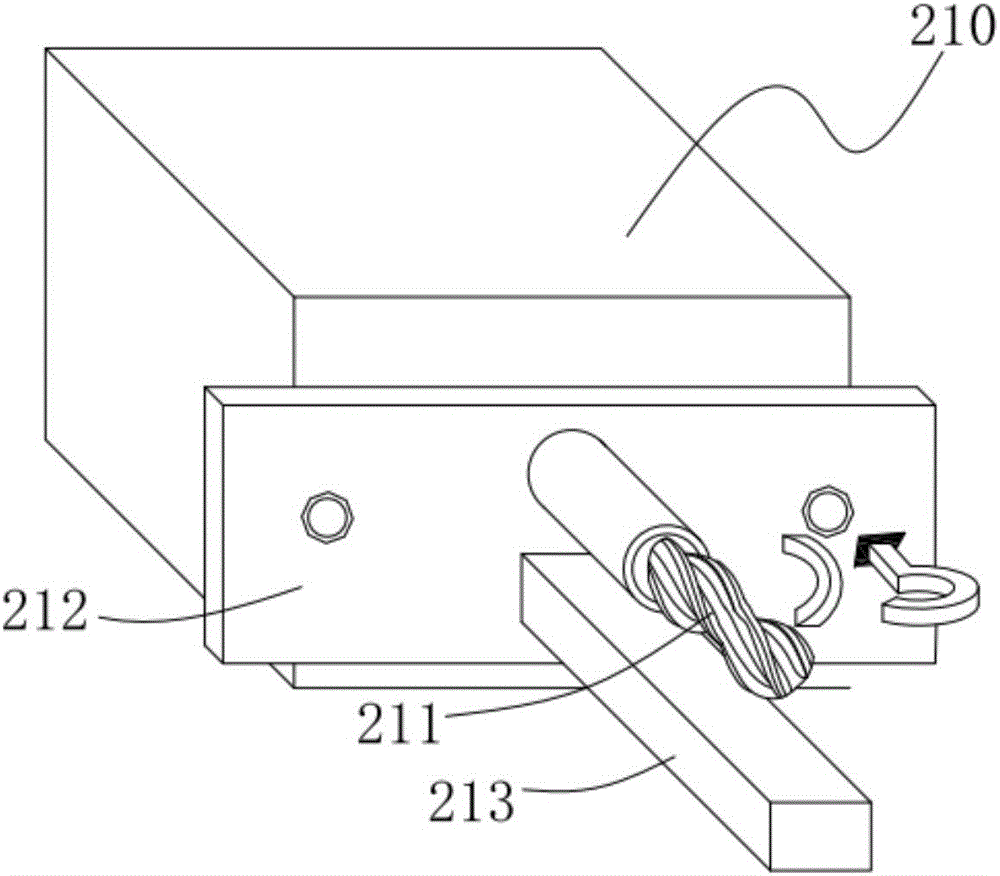

InactiveCN106072693ARealize automatic peelingImprove peeling efficiencyVegetable peelingTransmission beltEngineering

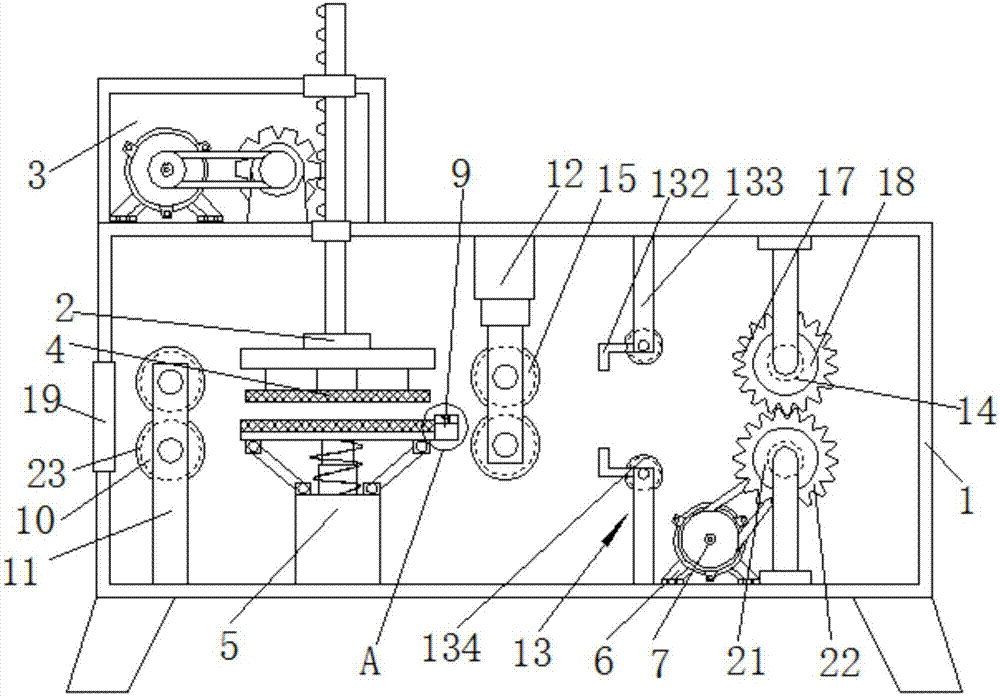

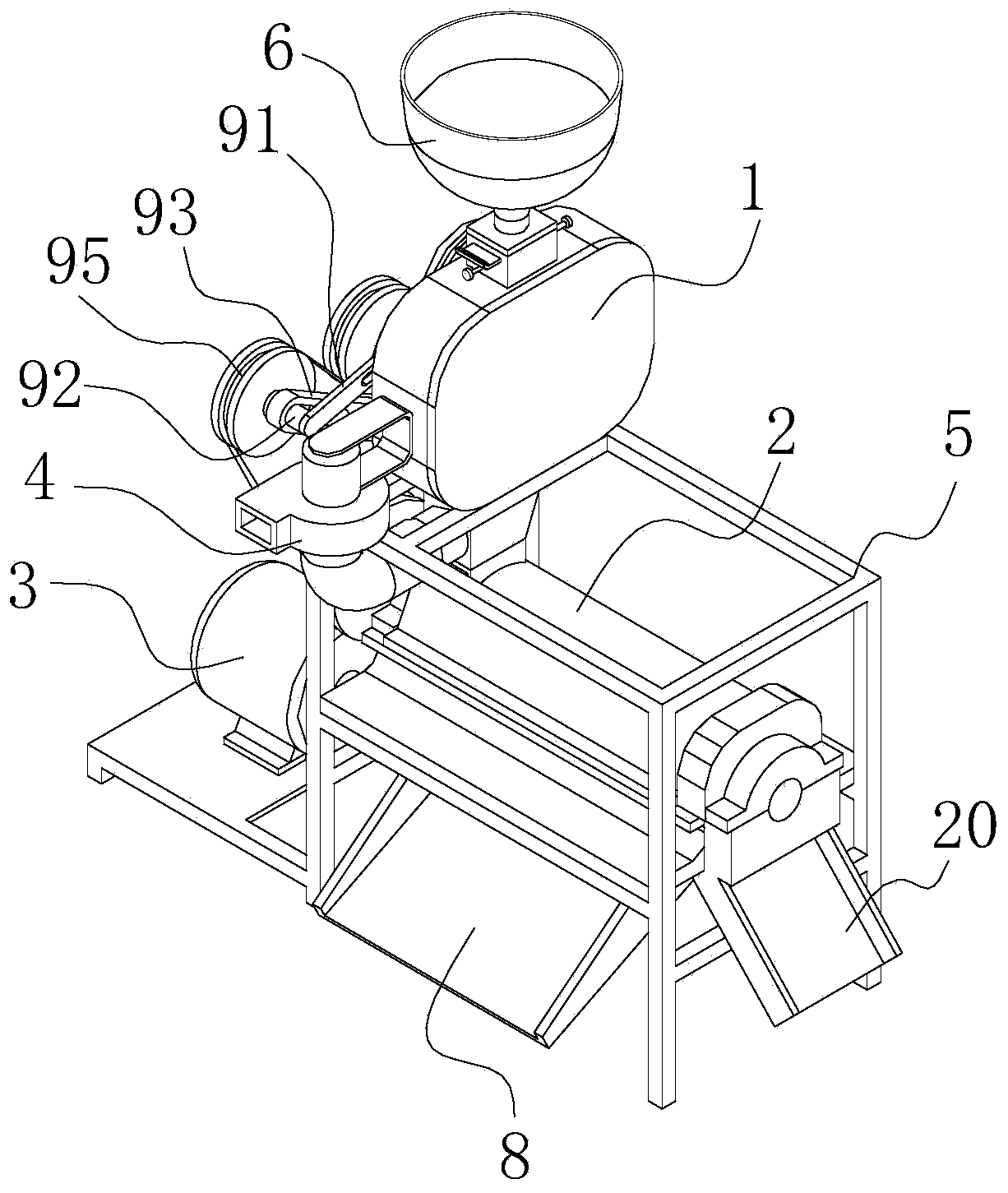

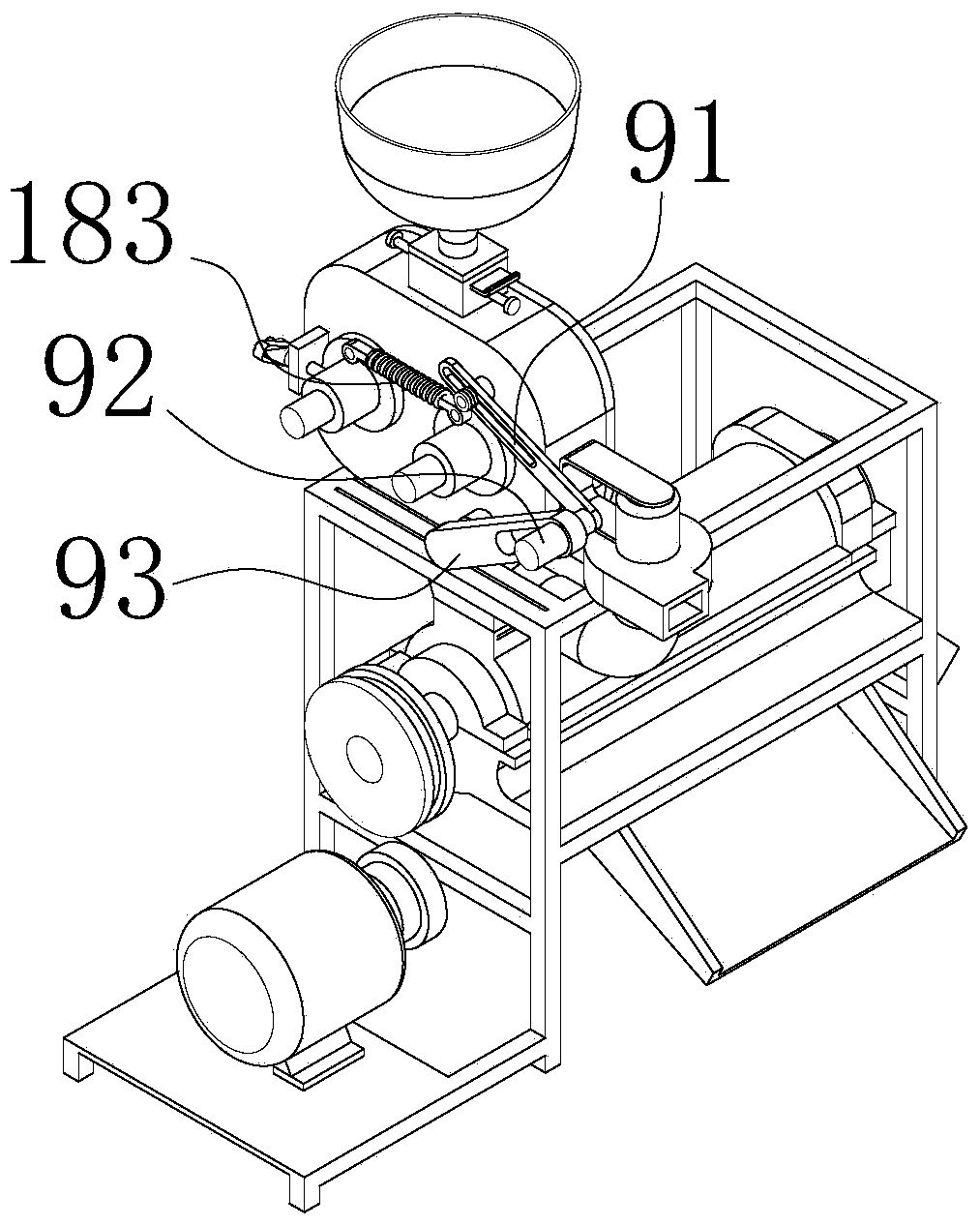

The invention relates to a manual-work-imitated melon / fruit peeling machine for peeling off fruits. The manual-work-imitated melon / fruit peeling machine comprises a rack, a clamping mechanism and a peeling mechanism, wherein the rack comprises an upper fixed plate and a lower fixed plate; a peeling working region is formed between the upper fixed plate and the lower fixed plate; an upper clamping part which rotates and can be adjusted in a lifting manner is arranged on the upper fixed plate; a lower clamping part capable of rotating in one direction is arranged on the lower fixed plate; an upper transmission belt wheel is arranged on the upper end face of the upper fixed plate and a lower transmission belt wheel is arranged on the lower end face of the lower fixed plate; the upper transmission belt wheel and the lower transmission belt wheel are connected through a transmission belt; the transmission belt vertically passes through the peeling working region; the peeling mechanism comprises a lifting bracket, an elastic bracket and a peeling knife; the transmission belt is fixedly connected with the lifting bracket; the lifting bracket is connected with the peeling knife through the elastic bracket, so that the peeling knife is self-adaptive to surfaces of melons and fruits in the peeling working region; and a guide rod which is used for limiting a lifting knife rest to slide in the vertical direction is arranged between the upper fixed plate and the lower fixed plate. The manual-work-imitated melon / fruit peeling machine is high in peeling efficiency, is safe and reliable, and is suitable for being used as peeling equipment for various types of fruits.

Owner:宁波市奉化奇佳机械设备有限公司

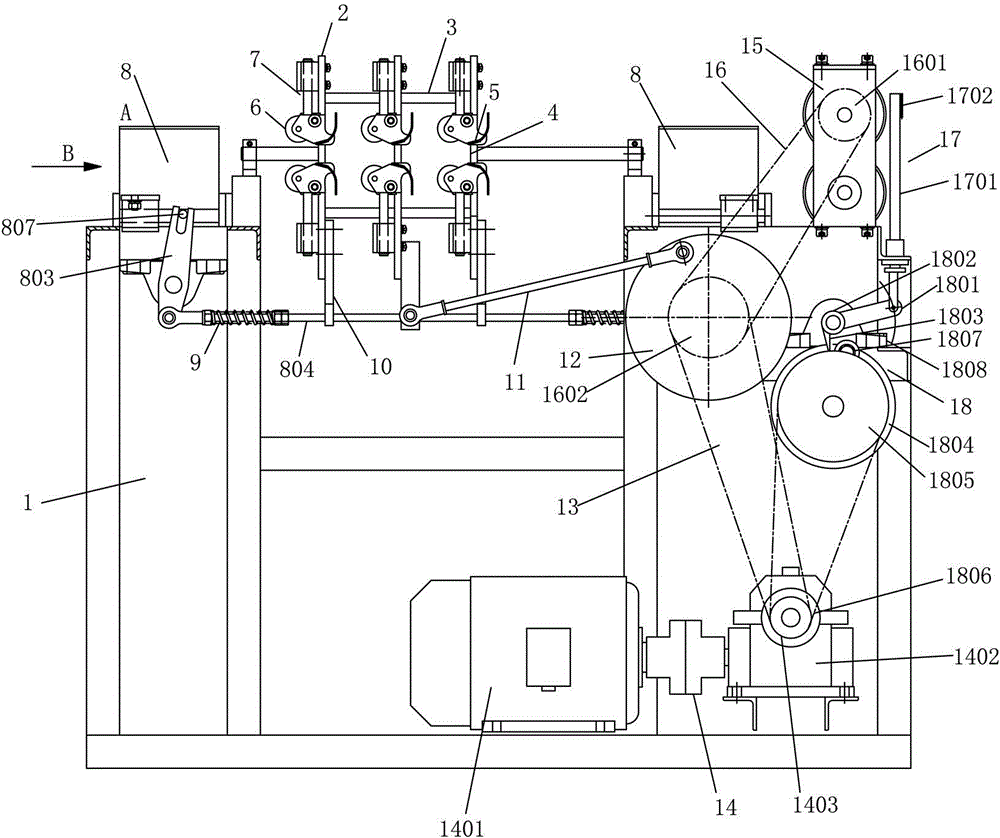

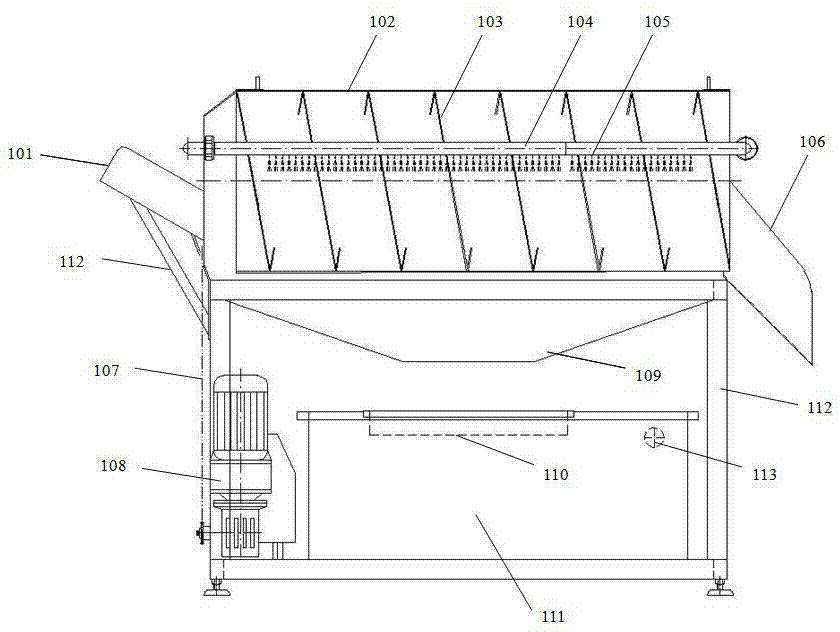

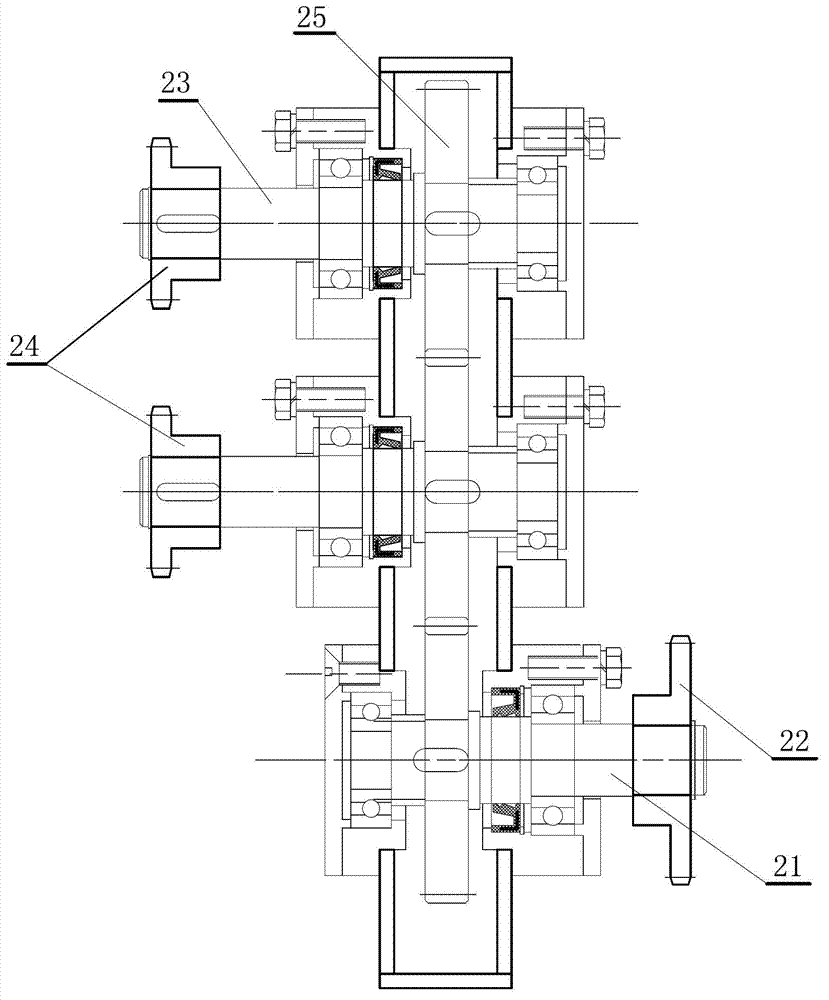

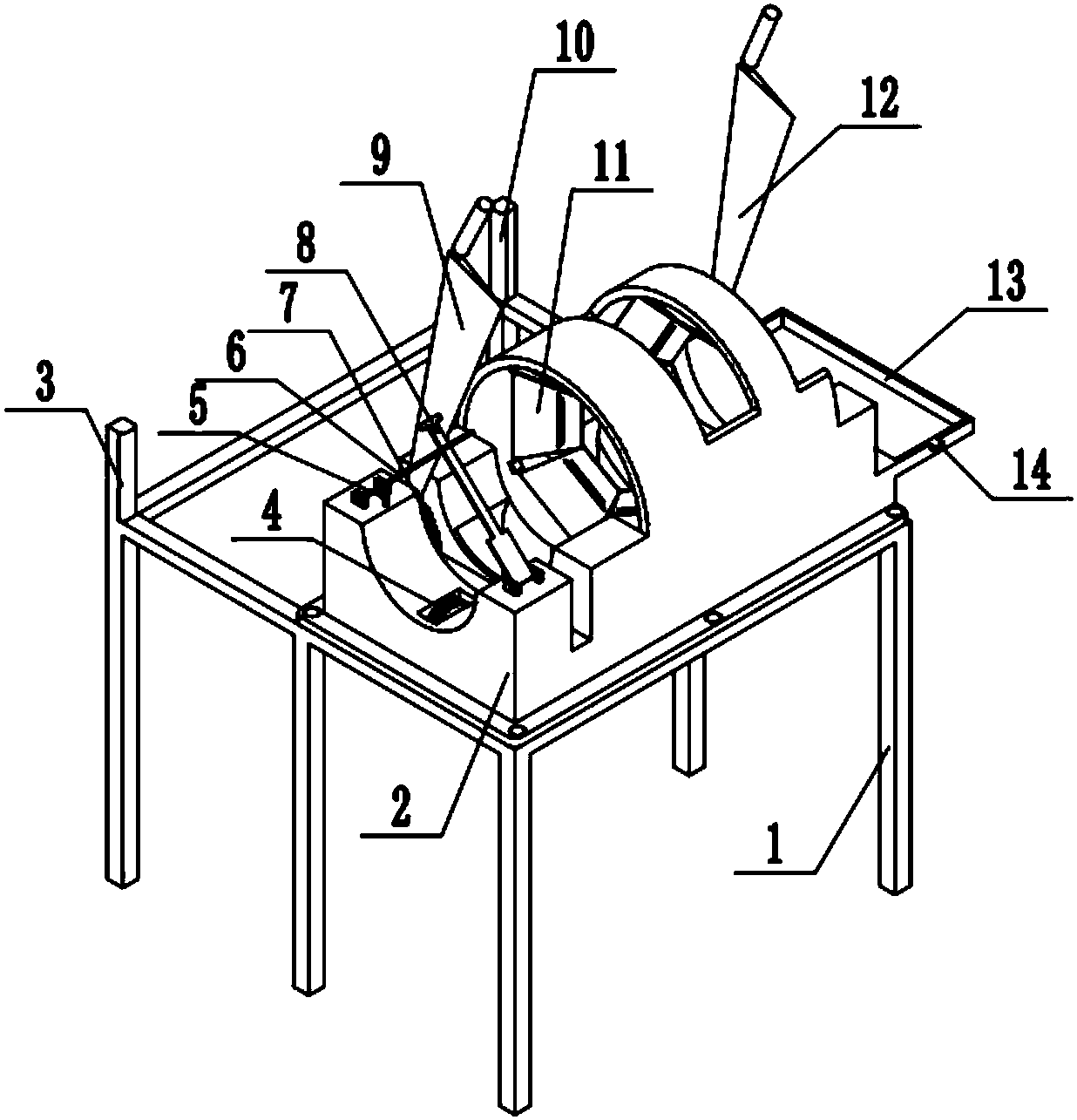

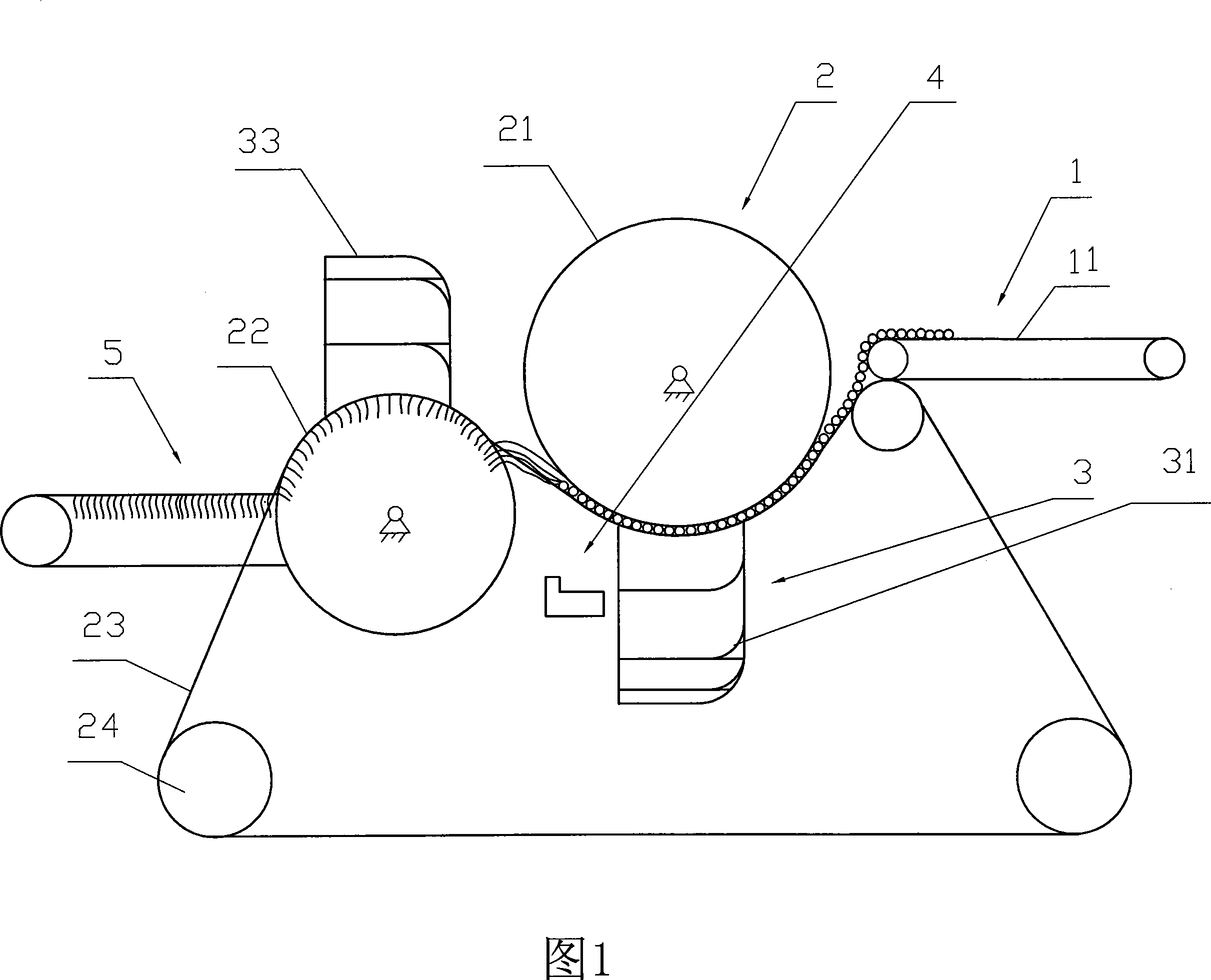

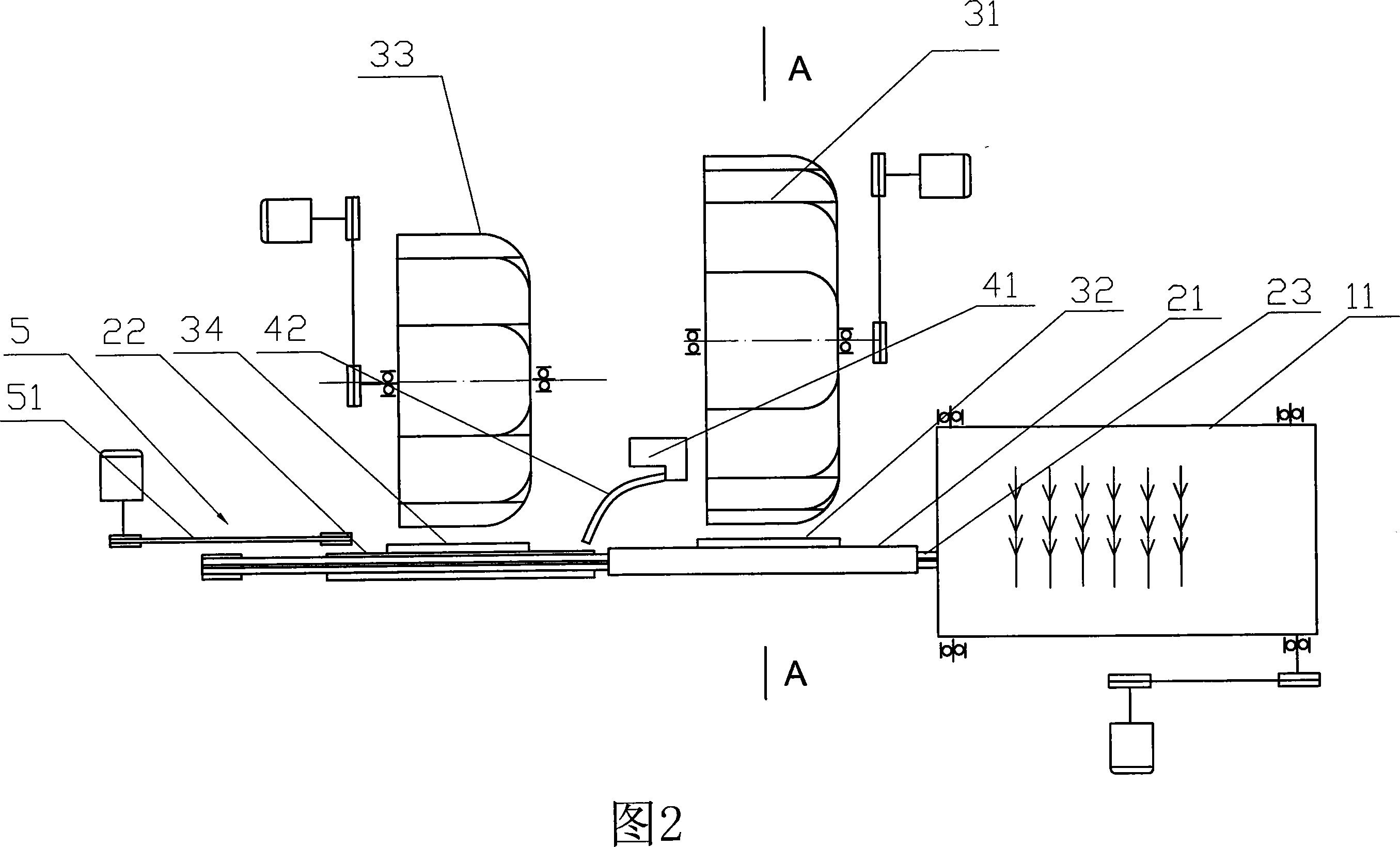

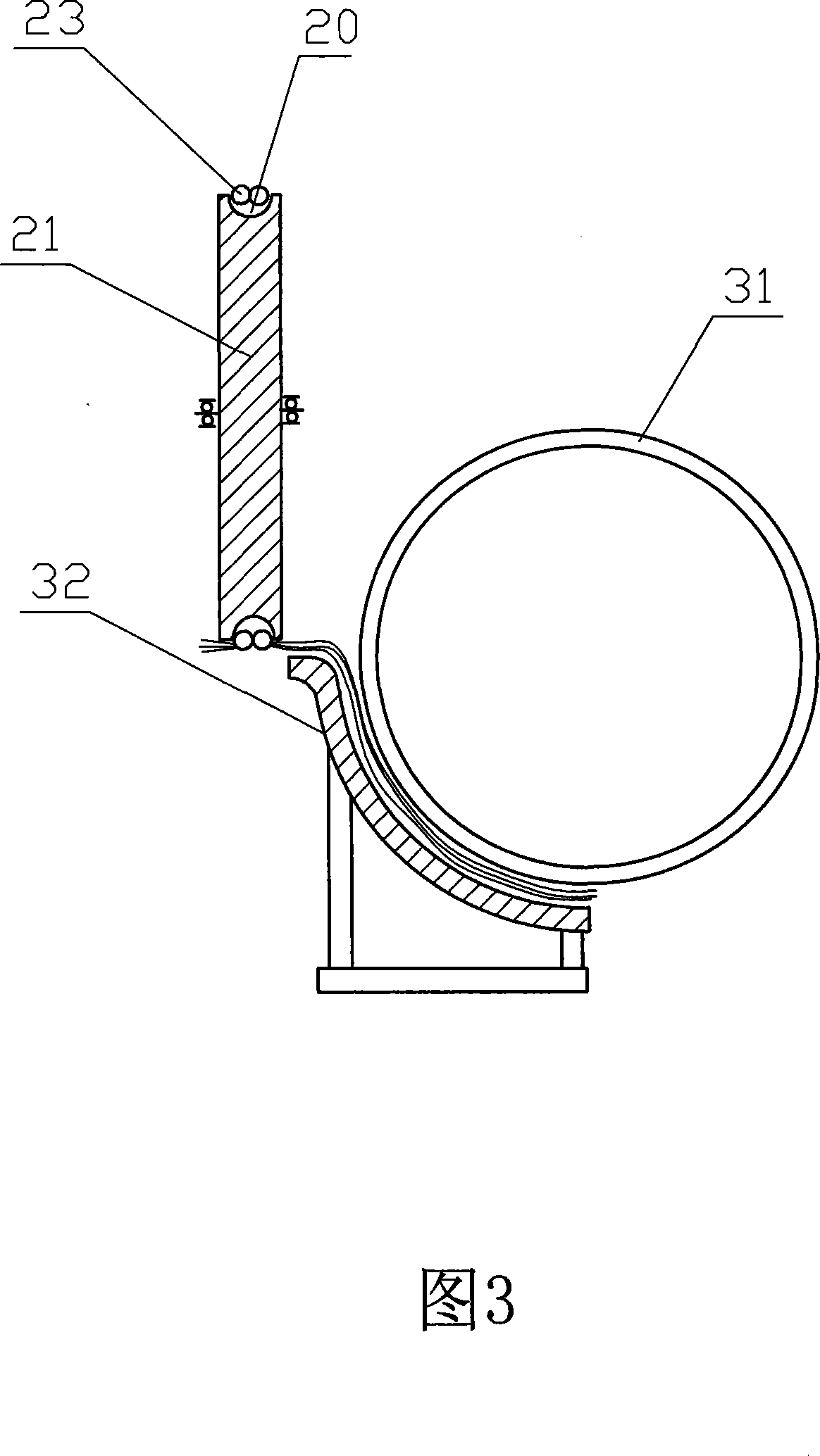

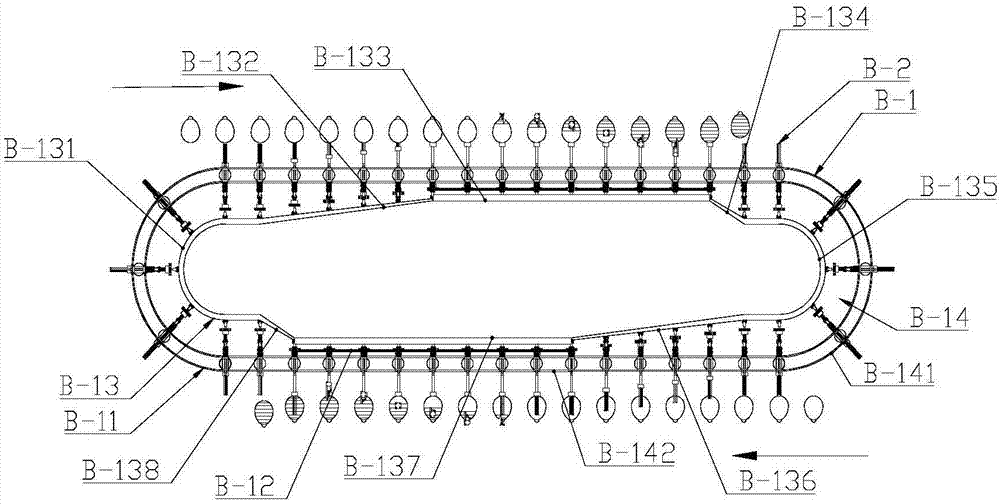

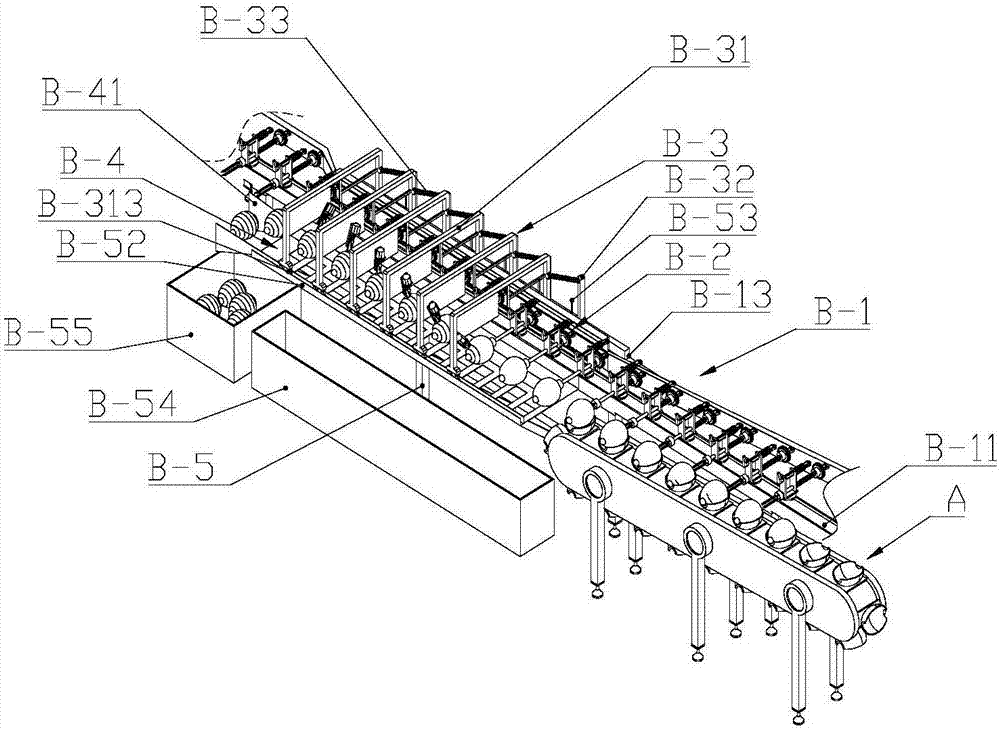

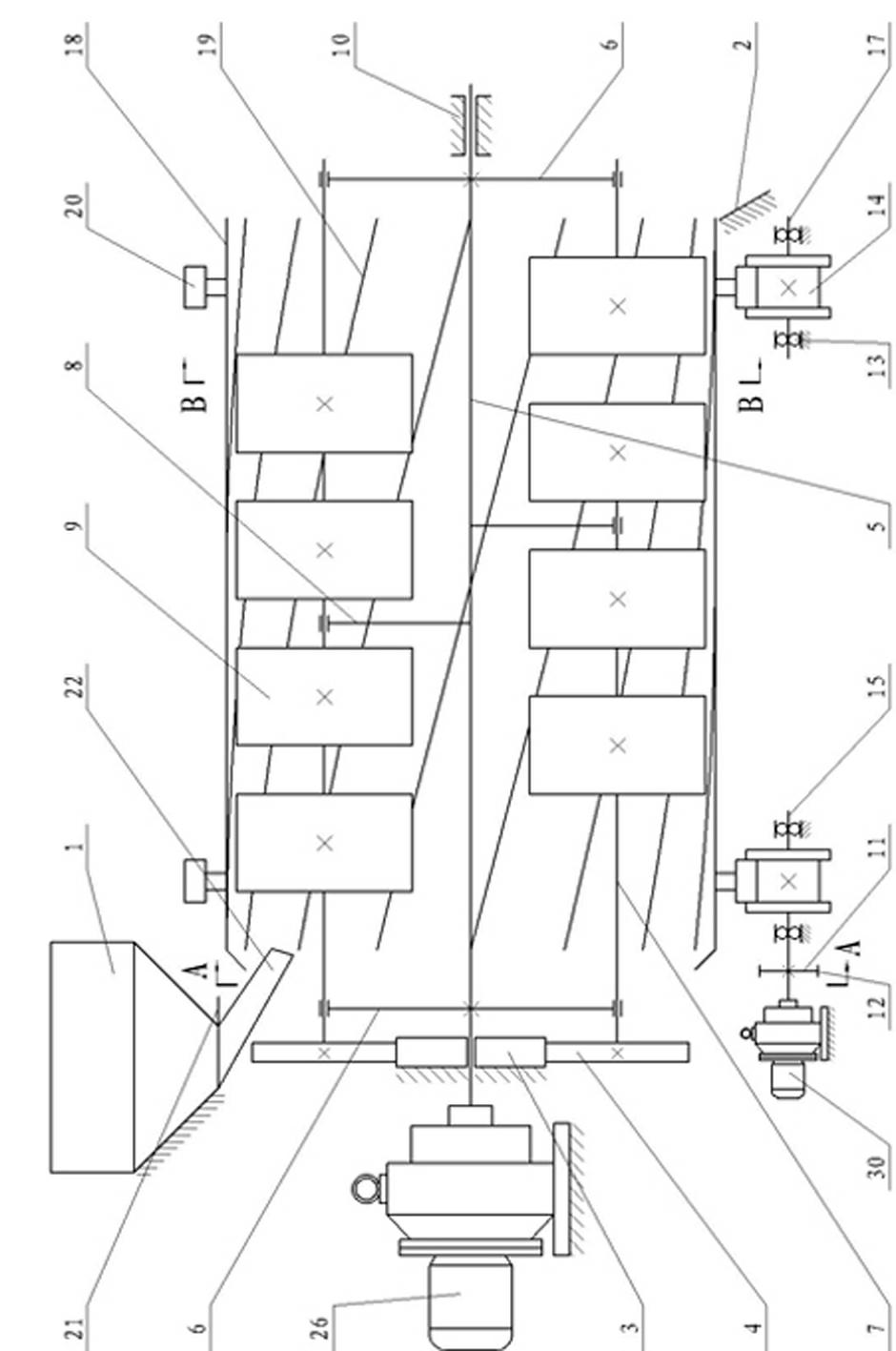

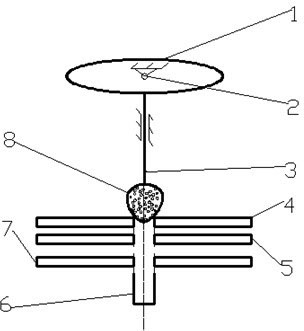

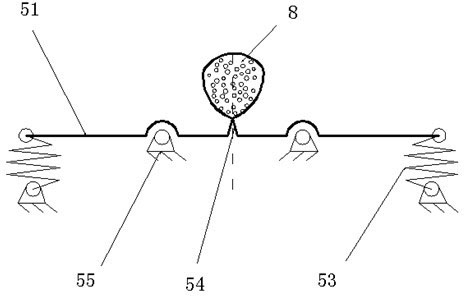

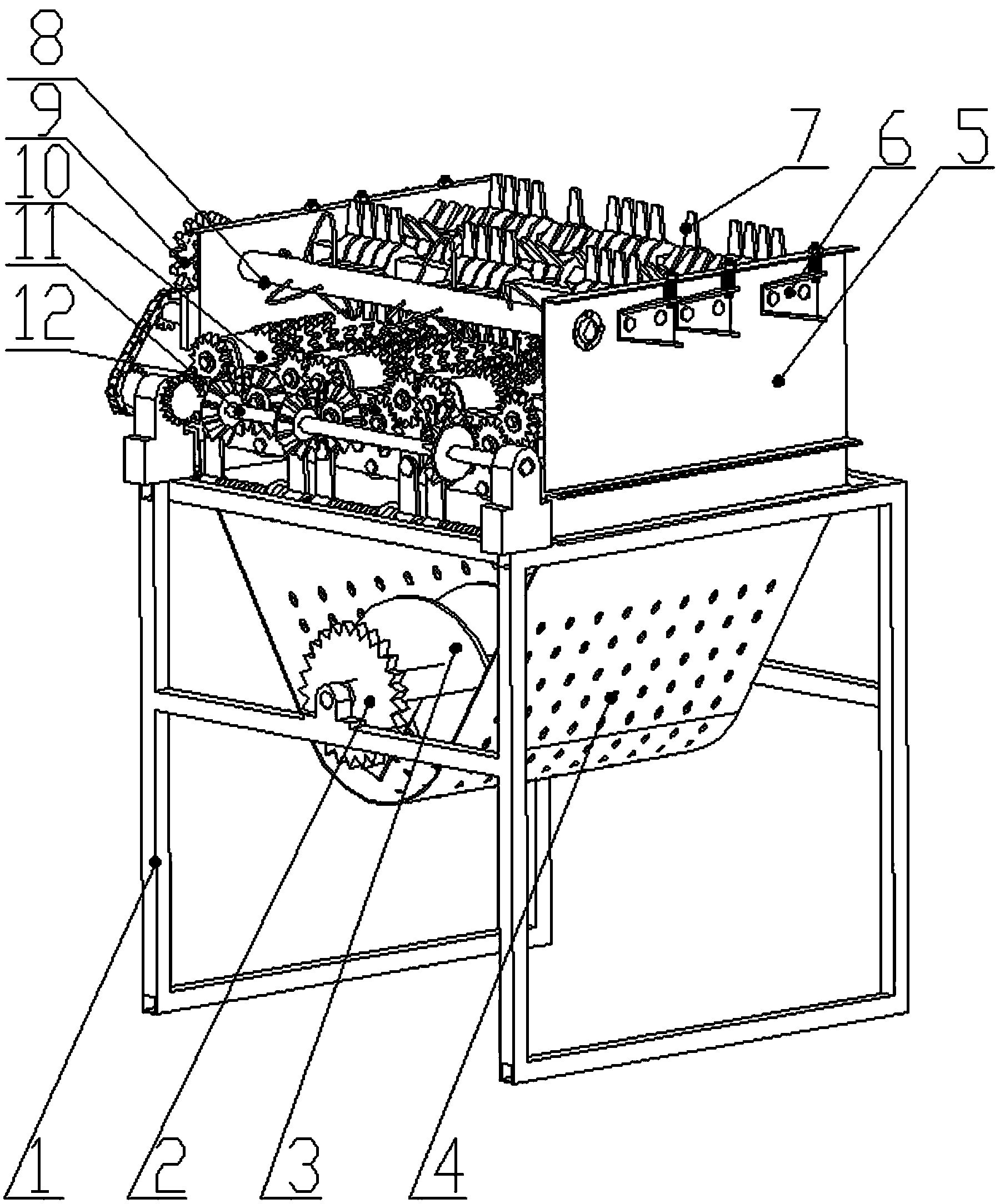

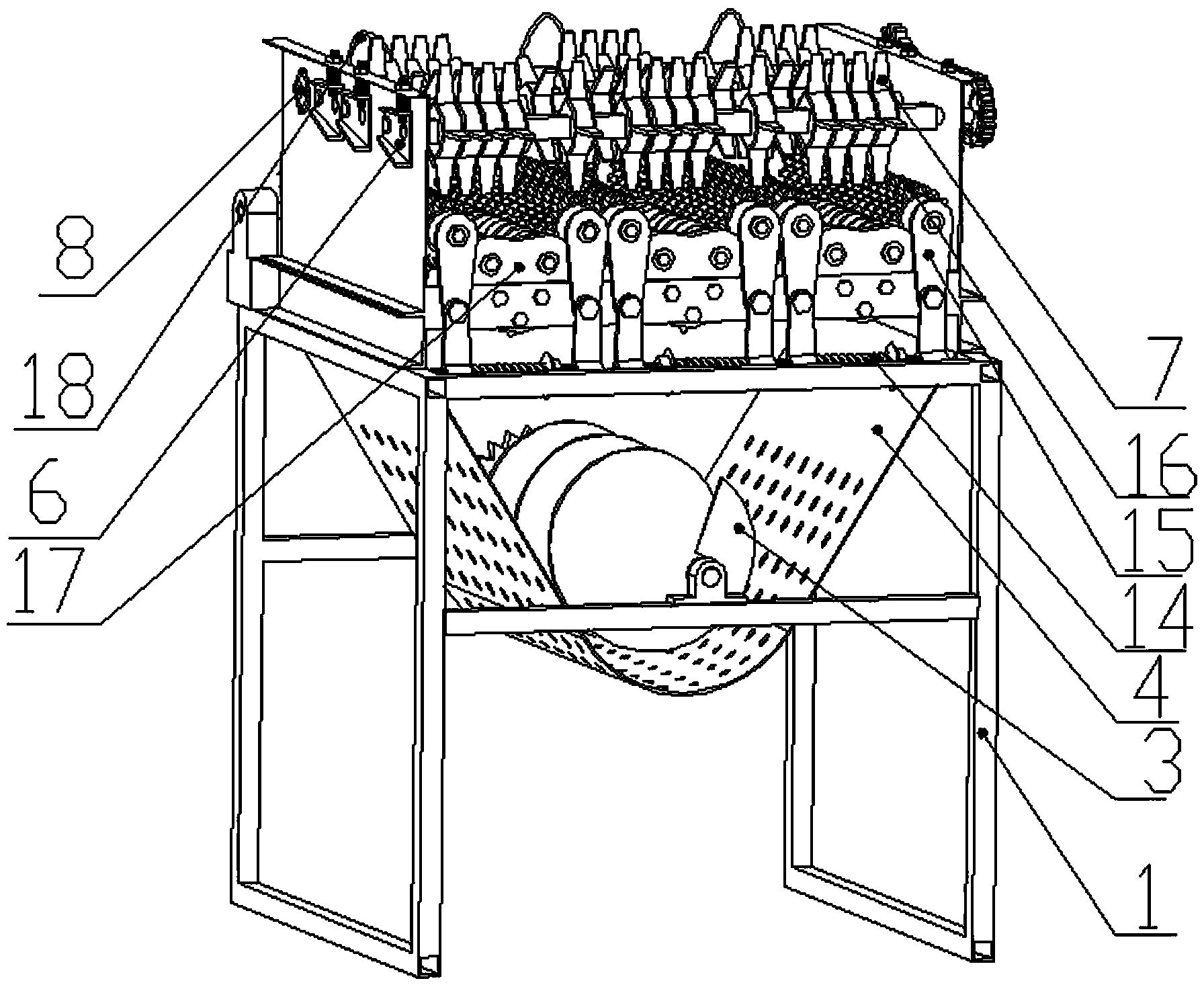

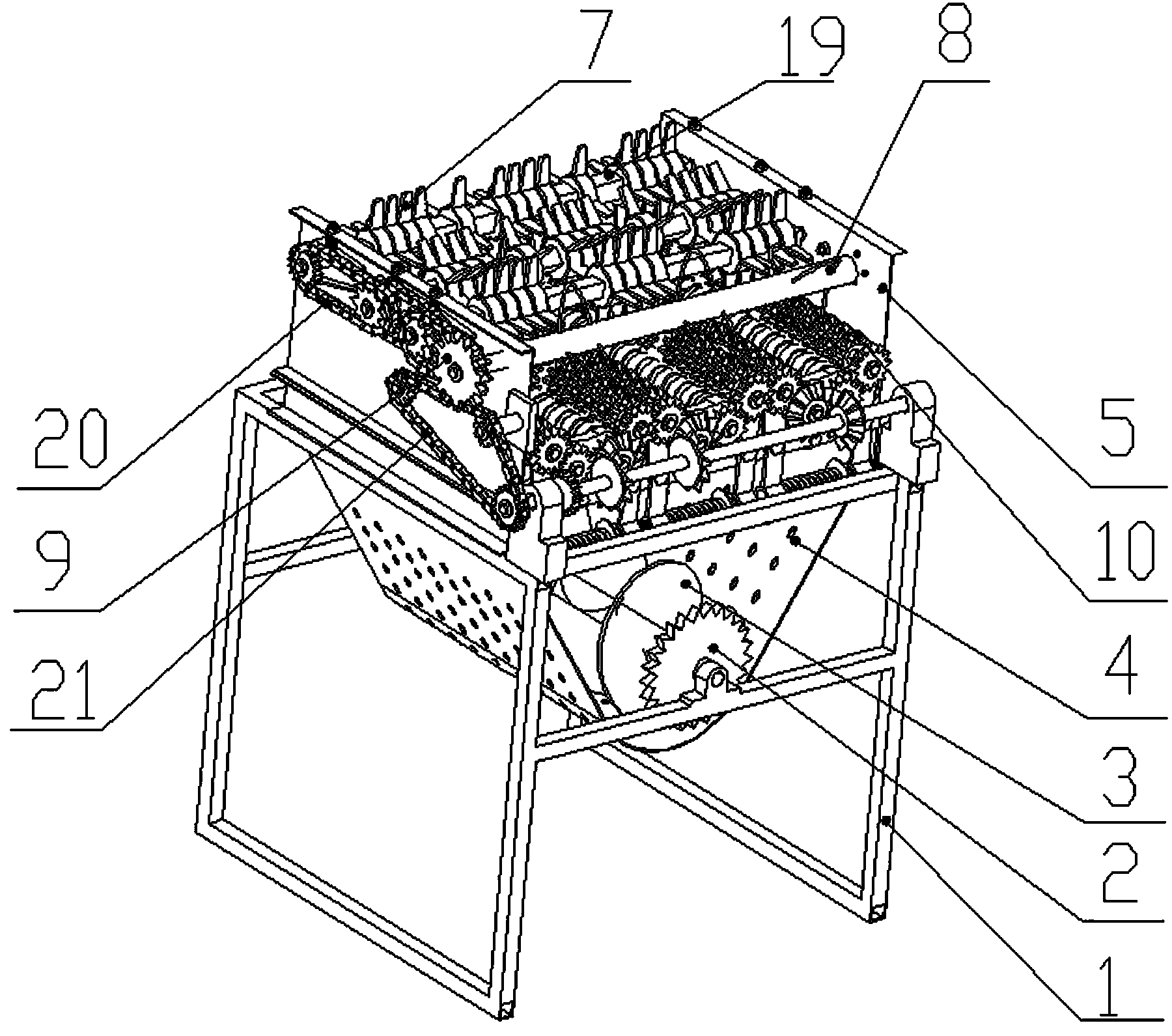

Ramie fibre decorticating method and transverse feeding type ramie raspador thereof

ActiveCN101168853ALow work efficiencyRealize automatic feedingMechanical fibre separationDecortication procedureEngineering

The invention discloses a ramie fiber stripping method and a transverse feeding type ramie stripping machine. The method is as follows: the ramie stems are stripped by transverse feeding, and the ramie stems are stripped in two stages. Make a section near the tip, and then peel off a section near the base. The ramie stripping machine includes a horizontal hemp feeding mechanism, a hemp clamping mechanism, a hemp scraping mechanism, a guiding mechanism, and a hemp receiving mechanism; wherein the horizontal hemp feeding mechanism is mainly composed of a conveyor belt; the hemp clamping mechanism is mainly composed of a primary hemp clamping wheel, a secondary Clamping wheel and clamping hemp rope are composed, and clamping hemp rope forms an S shape between the two clamping hemp wheels and bypasses the two clamping hemp wheels; The secondary hemp stripping hob and its matching concave plate are composed of the primary hemp clamping wheel corresponding to the position of the primary hemp stripping hob, and the secondary hemp clamping wheel is corresponding to the position of the secondary hemp stripping hob; the guide mechanism is mainly composed of The slightly end of the hemp stripped by the hob is blown to the blower on the secondary hemp wheel and the corresponding hemp guide plate; the hemp receiving mechanism is mainly composed of a conveyor belt. The invention can automatically feed and strip, thereby greatly reducing the labor intensity and improving the work efficiency of stripping hemp.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Integrated fruit-and-vegetable automatic peeling machine

The invention discloses an integrated fruit-and-vegetable automatic peeling machine. The machine comprises a rack, a guide rail set, a material feeding mechanism, a material inserting and delivering mechanism, a peeling mechanism and a material unloading mechanism; the guide rail set comprises an annular baseboard, a vertical blocking rail and a locating guide rail, the material feeding mechanism comprises a first delivery belt conveying mechanism and a material fixing base, the material inserting and delivering mechanism comprises multiple material inserting mechanisms and first conveying mechanisms, each material inserting mechanism comprises a needle inserting mechanism, a linkage mechanism and a locating block, each needle inserting mechanism comprises an inserting needle, a first connecting rod and a gear; each linkage mechanism comprises a first stopping block, a second connecting rod, a first spring and a first idler wheel; the peeling mechanism comprises multiple cutting mechanisms, each cutting mechanism comprises a knife rest, a fixed pillar and a second spring, each knife rest is provided with a knife feeding mechanism, an uplifting block is arranged on the vertical blocking rail, and the material unloading mechanism comprises a separation plate. The peeling device can carry out multiple tasks of peeling fruit and vegetables simultaneously.

Owner:江苏绿能汽配科技有限公司

Rapid cable stripping and rolling device for communication engineering

InactiveCN108539670AAvoid breakingWon't breakApparatus for removing/armouring cablesArchitectural engineeringScrew thread

The invention discloses a rapid cable stripping and rolling device for communication engineering. The device comprises a base plate, an installation rod frame and two support rod frames are arranged on the upper surface of the base plate, installation screws arranged in an annular shape and cooperated with threads are arranged in a right-end port of a first leading cylinder, the inner side of eachinstallation screw is fixedly connected with a blade, one support rod frame is fixedly connected with an installation clamping frame, the inner side of the installation clamping frame is provided with second leading cylinders, the sidewall in a left-end port of each second leading cylinder is provided with fixing screws, one end of each fixing screw is fixedly provided with a stripping cutter,, the outer wall of each leading cylinder is provided with a rotating gear, and the base plate is provided with a waste material collecting groove. The whole device is higher in stripping efficiency, theworkload of an operator is lower, operation is convenient, multiple cables can be stripped at the same time, the efficiency is higher, the cable is prevented from fracture due to being drawn too tightly during stripping, and the practicality is higher.

Owner:ZIBO TRICKS EDUCATION TECH CO LTD

A sugarcane peeling machine

InactiveCN106072690ATo achieve the purpose of peelingSimple structureVegetable peelingElectric machineryEngineering

The invention provides a sugarcane peeling machine comprising a rack and a peeling mechanism arranged on the rack. The peeling mechanism comprises motors and installing plates; the peripheral side of an output rotating shaft of each motor is provided with cutter teeth; the middle portion of each installing plate is provided with a through hole used for entry and exit of sugarcanes; the multiple motors are hinged to two side surfaces of the installing plates; the output rotating shafts of the motors are arranged to surround the peripheral edges of the through holes; each motor makes the corresponding output rotating shaft get close to the axis of the corresponding through hole via an elastic part. The cutter teeth on the output rotating shafts of the multiple motors work on the peripheral side of a sugarcane entering the through holes, so that the sugarcane is peeled. The peeling mechanism employed by the sugarcane peeling machine is fixed and sugarcanes are peeled through the rotation of the output rotating shafts of the motors in different directions; the sugarcane peeling machine is simple and effective in structure, high in peeling efficiency and convenient to use.

Owner:上海傻海食品机械有限公司

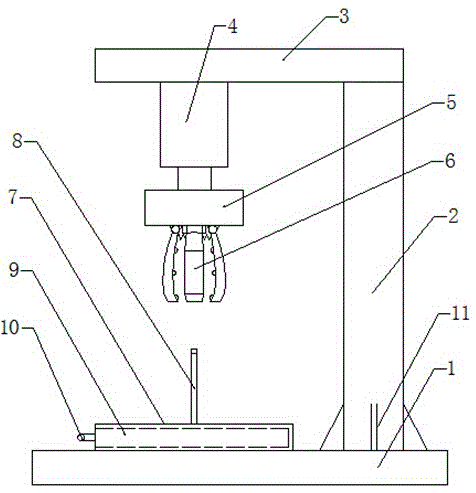

Orange and tangerine peeling machine

InactiveCN105533769AHigh degree of automationImprove peeling efficiencyVegetable peelingEngineeringCantilever

The present invention discloses an orange and tangerine peeling machine in the field of orange and tangerine processing. The orange and tangerine peeling machine includes a supporting device, a peeling device and a waste collection device. The supporting device includes a base, a vertically arranged support column on the upper end of the base, and an overhanging rail transversely arranged at the top end of the support column. The peeling device includes a cylinder, a peeling claw and a support base. The support base is fixed on the base at one side of the support column, a thimble is arranged at the upper end of the support base, the cylinder is vertically arranged at the lower end of the overhanging rail, the peeling claw is mounted on an output end of the cylinder, and the peeling claw and the thimble are oppositely arranged. The waste collection device comprises a collection box in a slide connection with the support base, the thimble is in a cylindrical shape, and the thimble bottom end is connected with the collection box. The program aims at the location of oranges and tangerines and removal of fruit stems. By using the cylinder to drive the peeling claw to conduct peeling of oranges and tangerines, the orange and tangerine peeling machine has a high degree of automation and a high peeling efficiency, only needs workers to load and unload oranges and tangerines, and is low in labor intensity and more convenient in orange and tangerine peeling.

Owner:CHONGQING PINGWEI CHAOYANG AGRI DEV CO LTD

Green walnut debarking cleaning device

The invention discloses a green walnut debarking cleaning device, which comprises a debarking component and a cleaning component, wherein the debarking component comprises a brush disc, a turntable and a first motor, the brush disc is positioned at the supper part of the turntable, the turntable disc is connected with the first motor, the bottom of the brush disc is provided with a brush wire, a material inlet hole is arranged on the brush disc, the cleaning component comprises a separation rolling tube and a hair brush roller, the separation rolling tube comprises an inlet, an outlet and connecting pipes, a plurality of connecting pipes are connected between the inlet and the outlet, the inlet of the separation rolling tube is arranged at the outlet part of the turntable, and the outlet of the separation rolling tube is provided with the hair brush roller. The green walnut debarking cleaning device has the advantages that the turntable is driven through the motor, so green walnuts to be debarked on the turntable are debarked through the brush disc, the green walnuts and the walnut barks are separated through the rotation of the separation rolling tube, green bark juice and the like can be cleanly cleaned by a hair brush and spraying water through the cleaning by the hair brush roller and the liquid water washing, and the contact between the human body and the walnut juice is avoided.

Owner:URUMQI ZHONGKAIDA ELECTROMECHANICAL

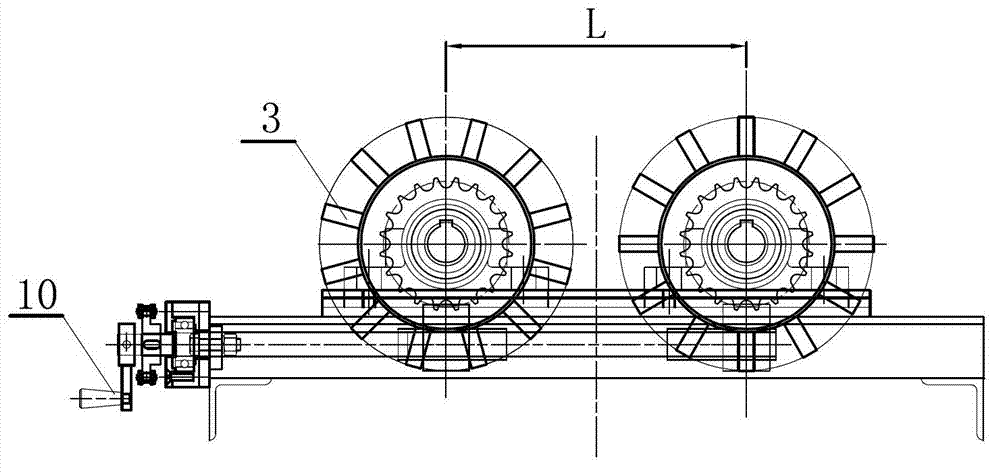

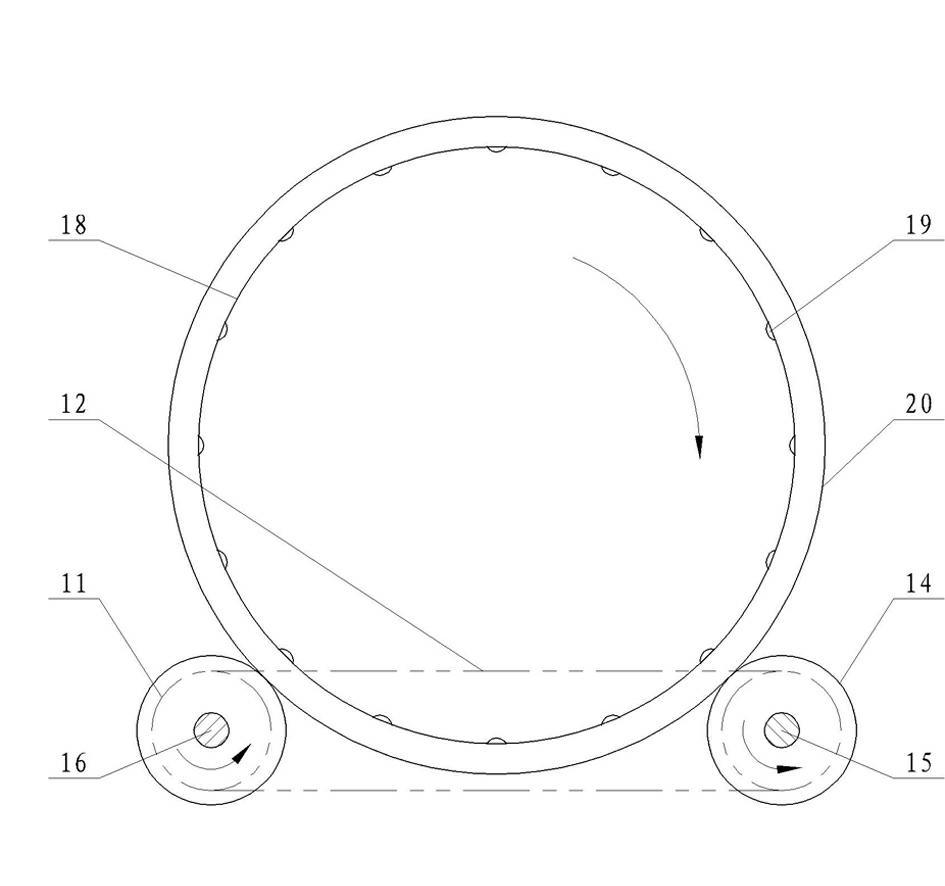

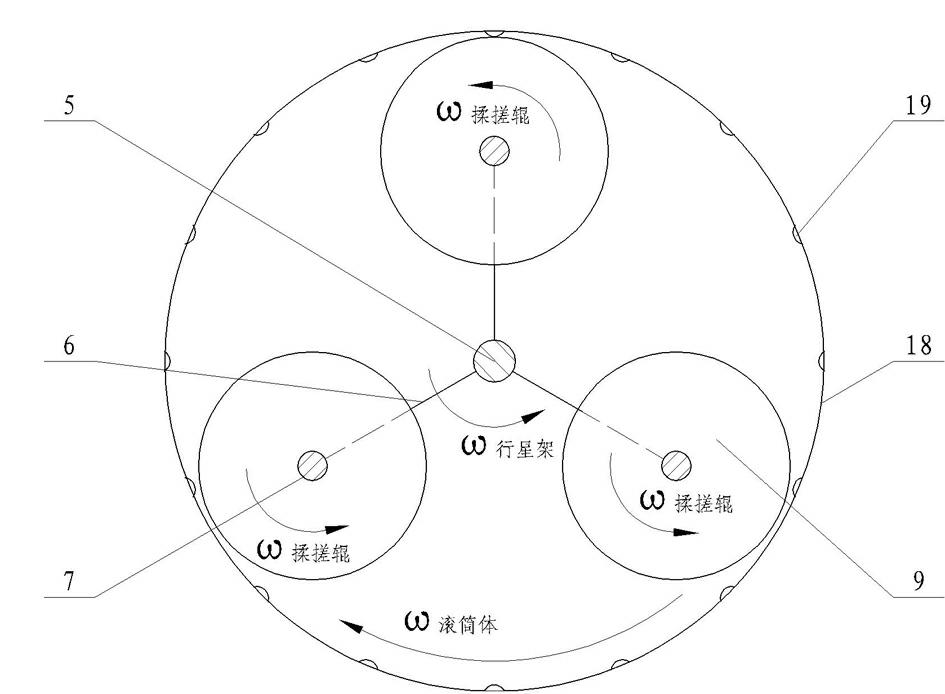

Split driving type pea peeling machine

The invention provides a splitting driving type pea peeling machine. The splitting drive type pea peeling machine is characterized in that: two ends of a main driving shaft are respectively supported in a sun wheel and a hole of a bearing I; the main driving shaft is connected with a planet driving device; two planet carriers are respectively fixed at two ends of the main driving shaft; after a planet shaft penetrates through a hole of one planet carrier, a planet wheel which is engaged with the sun wheel is arranged at one end of the planet shaft and the other end of the planet shaft is supported in the hole of the other planet carrier; a kneading roller is fixedly arranged on the planet shaft; a drive carrier roller mechanism, a driven carrier roller mechanism and two sets of support carrier roller mechanisms are respectively and symmetrically arranged at two sides below two ends of the main driving shaft; chains wheels on which a same chain is suspended are installed at the outer ends of a drive shaft and a driven shaft; the outermost end of the drive shaft is connected with a carrier roller driving device; an edge framework is arranged on the inner surface of a rotary drum, and two ends of an external circle of the rotary drum are supported on a carrier roller through an idler wheel; and a feeding hopper is located at a feeding end of the rotary drum and a discharging opening is arranged at the other end of the rotary drum. The splitting driving type pea peeling machine provided by the invention can meet the requirements of different pea varieties on the relative rotary speed between the planet carriers and the rotary drum and is advantaged in stable performance and reliable work.

Owner:SHANDONG UNIV OF TECH

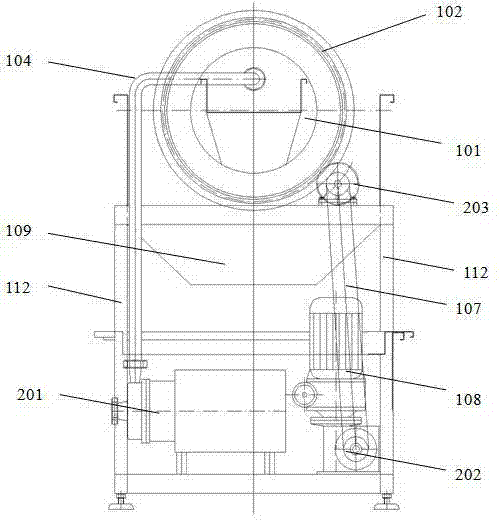

Litchi peeler

InactiveCN102318877AKeep it originalImprove peeling efficiencyVegetable peelingLychee fruitAgricultural engineering

The invention discloses a litchi peeler. The peeler comprises a cam, a frame, a push rod, a feeding plate, a cutting mechanism, a peeling mechanism and a fruit receiving device, wherein the cam is arranged on the frame, one end of the push rod is connected with the cam, and the other end of the push rod is adapted with a litchi positioning elastic hole in the feeding plate; the feeding plate is connected with a transmission mechanism; the cutting mechanism is positioned below the feeding plate, and a blade in the cutting mechanism corresponds to the litchi positioning elastic hole; and the peeling mechanism is arranged below the cutting mechanism, and the fruit receiving device is arranged below the peeling mechanism. By using the peeler, the original taste of the litchi can be kept, the peeling efficiency of the litchi is high, and the obtained finished product has good completeness.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

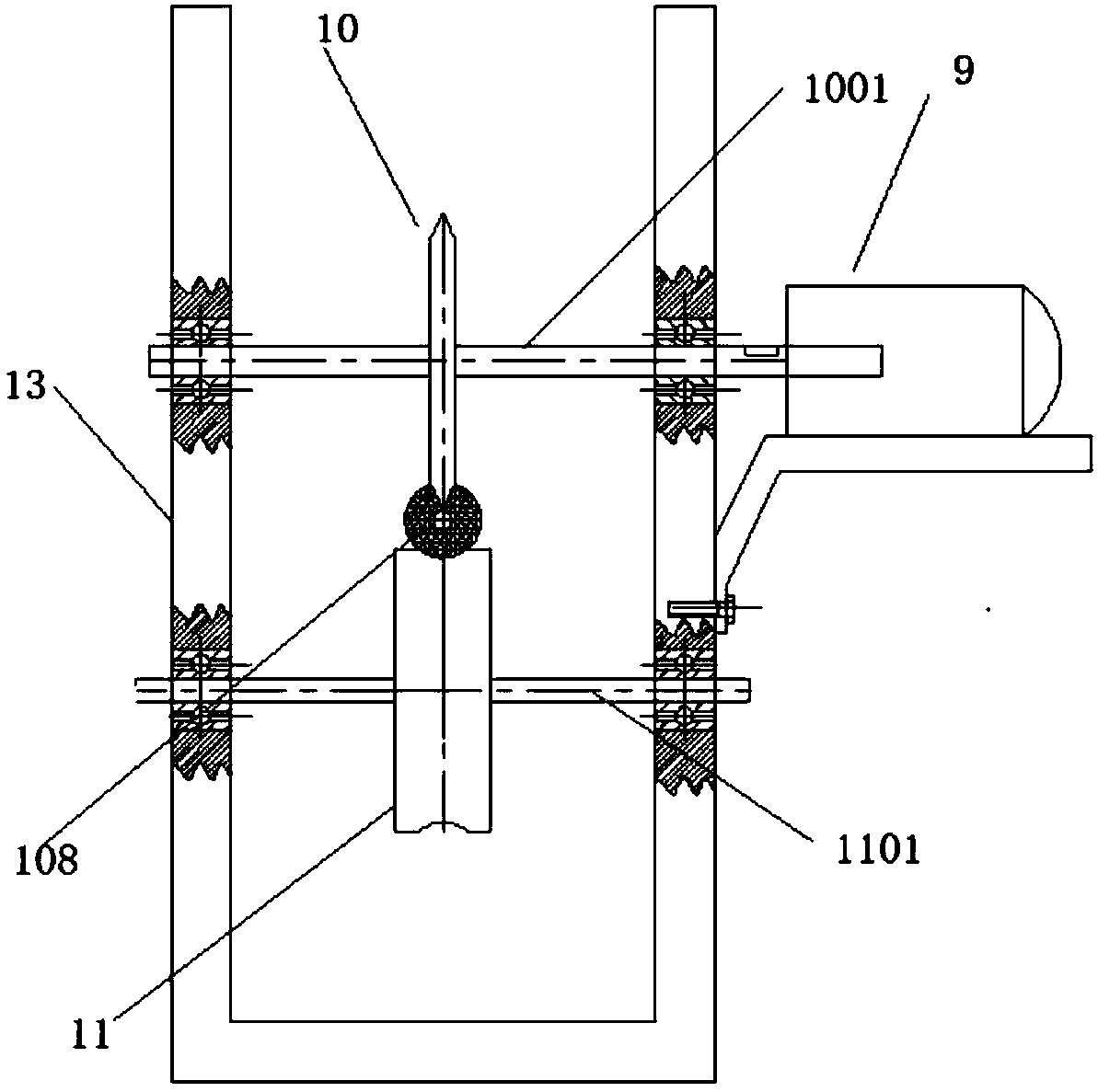

Bamboo peeler

Owner:江西新生命制药有限公司 +1

Corn husker

The invention relates to the technical field of agricultural machinery, particularly to a corn husker. According to the corn husker, scale roll sets and spiral conveying roll sets are arranged in a staggered manner, and installation positions of the scale roll sets are higher than those of the spiral conveying roll sets so as to form V-shaped conveying grooves; one end of each scale roll set is connected with a rack through swing arms and a tension spring; and the swing arms are driven to rotate by certain angles through changing of extension lengths of the springs, so that the positions of the scale roll sets are changed, and the husker is adapted to the husking operation of corn with different varieties and sizes. One end of each spiral conveying roll set is connected with the rack through a roll-aligned connecting plate, and each scale roll set is meshed with the other end of each spiral conveying roll set through gears, so that synchronous rotation is realized. One spiral conveying roll of each spiral conveying roll set is provided with a bevel gear and connected with a power distribution shaft through the bevel gear, and the power distribution shaft can be connected with a plurality of scale roll sets and spiral conveying roll sets, so that the single-pass processing capability is improved.

Owner:酒泉市铸陇机械制造有限责任公司

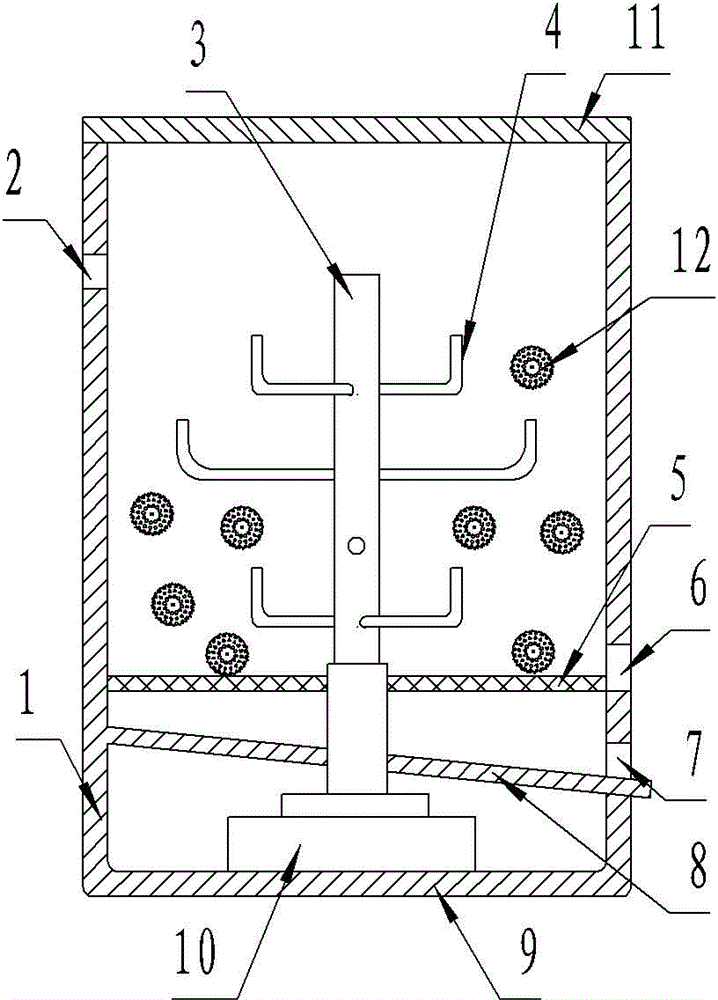

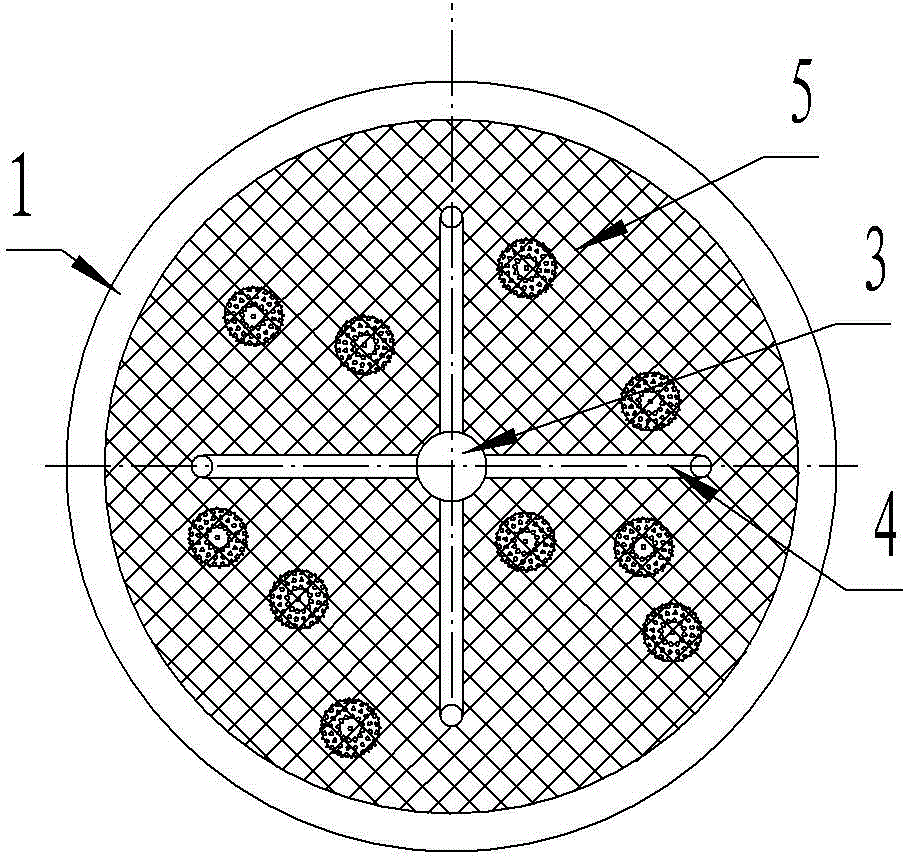

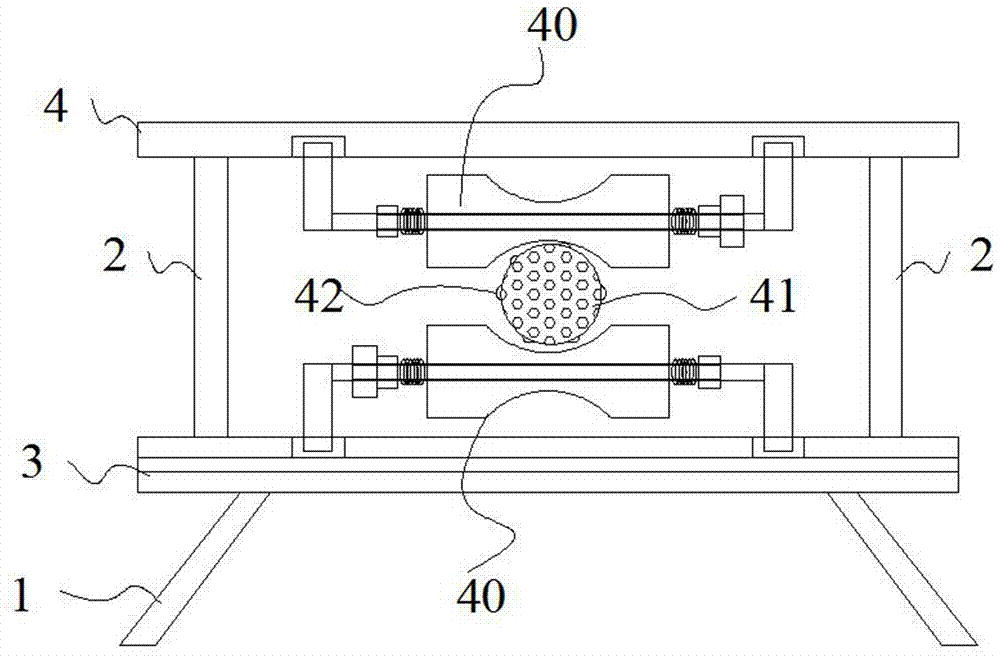

Water chestnut peeling machine

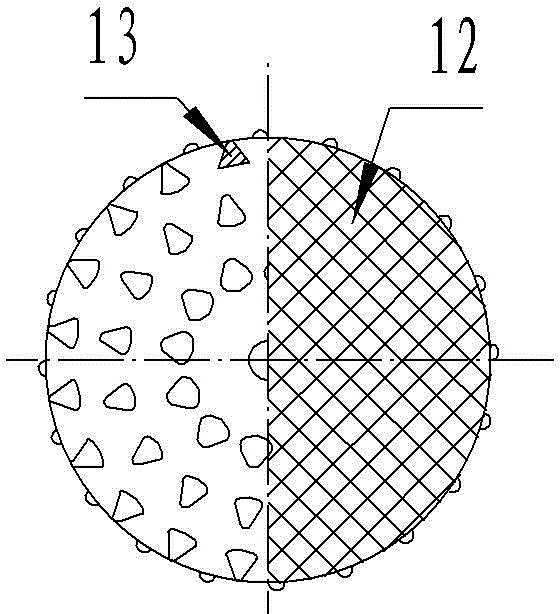

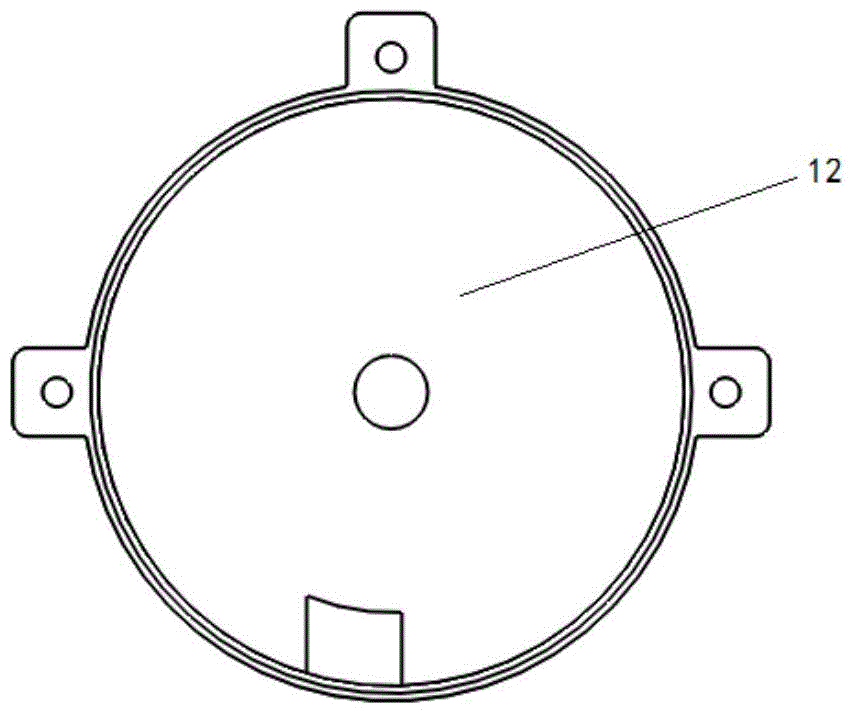

ActiveCN104473305AThoroughly peeledImprove peeling efficiencyVegetable peelingWater ChestnutsPower output

The invention discloses a water chestnut peeling machine comprising a cylinder. The cylinder is provided with an upper bottom and a lower bottom. A horizontal motor is arranged between the upper bottom and the lower bottom. A power output shaft of the horizontal motor extends upward to penetrate the upper bottom to be connected with a vertical shaft. The vertical shaft is driven by the power output shaft and uniformly provided with multi-row stirring bar sets. Each stirring bar set comprises at least two stirring bars which are radially mounted on the vertical shaft. The tails of the stirring bars bend downward. A screen is arranged between the lowest stirring bar set and the upper bottom which is obliquely arranged. A slagging outlet and a discharging outlet are formed in the wall of the cylinder. A plurality of flexibly peeling balls with metal protrusions are arranged upon the upper bottom in the cylinder. By the use of the water chestnut peeing machine, the problems that the conventional water chestnut peeling is difficult and low in efficiency and deep-processed product development of the water chestnuts is limited can be solved.

Owner:钦州市钦南区金窝工业园管理委员会

Mechanical pineapple peeling machine

InactiveCN105581621AImprove peeling efficiencyFor precise clampingFruit coringPeelersEngineeringElectrical and Electronics engineering

The invention discloses a mechanical pineapple peeling machine which comprises a machine frame. A positioning clamp and a black core removing structure are arranged on the machine frame. Two opposite pineapple insertion tables are arranged on the opposite sides of the machine frame. One pineapple insertion table is telescopic and is connected with a gear shifting mechanism through a main transmission mechanism, the gear shifting mechanism is connected with a handle and a black core removal transmission mechanism, the main transmission mechanism is connected with a peeling transmission mechanism, the peeling transmission mechanism is connected with a lead screw a, the lead screw a is connected with a peeling adjustable cutter, the positioning clamp and the peeling adjustable cutter are located between the two opposite pineapple insertion tables, the black core removal transmission mechanism is connected with the black core removing structure, and the black core removing structure is opposite to the peeling adjustable cutter. The mechanical pineapple peeling machine completes the peeling step and the black core removing step through one-time clamping, and pineapple peeling efficiency is greatly improved.

Owner:XIAN UNIV OF TECH

Automatic huller for Chinese chestnuts

The invention relates to an automatic huller for Chinese chestnuts. The automatic huller comprises a single grain pick-up device, an opening cutting device, a primary drying device, a primary peeling device, a secondary drying device, a secondary peeling device, a transmission device and a discharging device, wherein the single grain pick-up device, the opening cutting device, the primary drying device, the primary peeling device, the secondary drying device, the secondary peeling device and the discharging device are sequentially arranged, and the transmission device is used for conveying Chinese chestnuts. The huller is reasonable in structure, integrative in the functions of Chinese chestnut feeding, single grain separation, progressive cutting, primary drying, primary peeling, secondary drying, secondary peeling, electric transmission, discharging and the like, convenient to use, high in mechanical degree and high in peeling efficiency, can carry out continuous operation, reduce the production intensity of workers and provide reliable equipment guarantee for the peeling deep processing of the Chinese chestnuts, and has wide prospect of being popularized in the Chinese chestnut industry.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Efficient peeler for pineapples

The invention discloses a pineapple high-efficiency peeling machine, which includes a main support, the main support is composed of a column and a beam, the beam is equipped with a push-down electric cylinder, and the lower part of the push-down electric cylinder is connected to a vertically arranged pressure rod through transmission. The bottom end of the pressure bar is fixedly connected to the motor fixing plate, the motor is fixed on the bottom surface of the motor fixing plate, and the motor shaft of the motor is connected to the vertically arranged slotting knife through a coupling, and the pineapple is fixed by the slotting knife; Pass through the through hole on the horizontal plate, and the horizontal plate is fixedly connected to the cross beam through the mounting frame; a peeling barrel that runs through the structure up and down is provided below the insertion knife, and multiple groups of vertically arranged peeling barrels are installed on the peeling barrel. The knife set and the peeling knife set are respectively driven and connected to their respective horizontal adjustment structures. This invention can not only protect the worker's hands from being stabbed, but also has an excellent overall effect, very high peeling efficiency, and has the integrated function of cleaning and peeling. After the processing is completed, it can be directly packaged, and the residue can also be collected and utilized.

Owner:湖南天爱农业科技有限公司

Peeling mechanism for irregular sugarcanes

The present invention discloses a peeling mechanism for irregular sugarcanes. The peeling mechanism comprises a machine frame, stand columns, a bottom plate and a top plate. The bottom plate is arranged on the machine frame, a plurality of the stand columns are arranged on the machine frame, the top plate is arranged on the stand columns, peeling units are arranged between the bottom plate and top plate, and the peeling units are symmetrically arranged between the bottom plate and top plate. The peeling mechanism for the irregular sugarcanes is novel in structure, high in peeling efficiency, easy for realization, and suitable for large-area production, promotion and use.

Owner:桐乡市易尔顺科技信息咨询有限公司

Rice husking polisher

InactiveCN103920556AGood quality riceLess broken grainsGrain huskingGrain polishingRice grainEngineering

The invention discloses a rice husking polisher through which rice quality can be improved, and rice grain rate in rice is improved. The rice husking polisher comprises a driving device, a transmission device, a machine frame, a husking mechanism and a polishing mechanism. The husking mechanism, the polishing mechanism and the driving device are arranged on the machine frame. The husking mechanism is placed above the polishing mechanism. The driving device is in transmission connection with the husking device through the transmission device. The driving device and the polishing mechanism are in transmission connection. The polishing mechanism comprises an upper machine shell, a lower machine shell, a rice roller, an upper half roller and a lower half roller. The upper half roller is arranged in an upper half roller mounting groove. The lower half roller is arranged in a lower half roller mounting groove. The upper machine shell and the lower machine shell are buckled together. The rice roller is arranged in a cylindrical cavity formed by the upper half roller and the lower half roller. According to the rice husking polisher, after husking and polishing are carried out on rice, obtained rice is good in quality, the number of broken grains in rice is small, and rice grain rate is high.

Owner:乐山市五通桥百泰机电厂

Raw taro peeler

InactiveCN109875065AImprove peeling efficiencyGood for fallingVegetable peelingMechanical engineeringEngineering

Owner:曾广银

Induction-type fruit peeling machine

InactiveCN107744155AEasy to fixImprove practicalityFruit stoningVegetable peelingMotor driveArchitectural engineering

The invention discloses an induction type fruit peeling machine, which comprises legs, a base, a motor, a telescopic rod, a supporting plate, a shelling tube, a connecting rod, a turntable, a rotating shaft, a peeling knife and a support rod, and the two sides of the base are The shock-absorbing outriggers are welded, the base is equipped with a motor, and the surface of the base is provided with a support plate. The center of the bottom of the support plate is connected to the motor transmission inside the base through a telescopic rod. The limited teeth are welded on the board around the nuclear removal tube, the top of the nuclear removal tube is threadedly connected with a connecting rod, and the connecting rod is fixedly connected with the turntable through the rotating shaft, and a pillar is welded on the side of the supporting plate on the base, and the supporting rod is provided with The casing, the casing and the turntable are connected by connecting cross bars, the support rod is provided with a movable casing, the movable casing is provided with a fixed pipe, the fixed pipe is provided with a propulsion motor, and the peeling knife is arranged on the movable pipe. The invention not only can better fix the fruit, but also allows the blade to cling to the surface of the fruit, thereby improving the practicability and peeling quality.

Owner:陈建霖

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com