Sugarcane peeling and splitting machine

A technology of slitting machine and sugar cane, which is applied to the peeling of vegetables or fruits, metal processing, chemical instruments and methods, etc., can solve the problems of complex transmission structure, large volume, inconvenient use, etc., and achieves simple overall structure and small volume. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now in conjunction with accompanying drawing, the present invention will be further described.

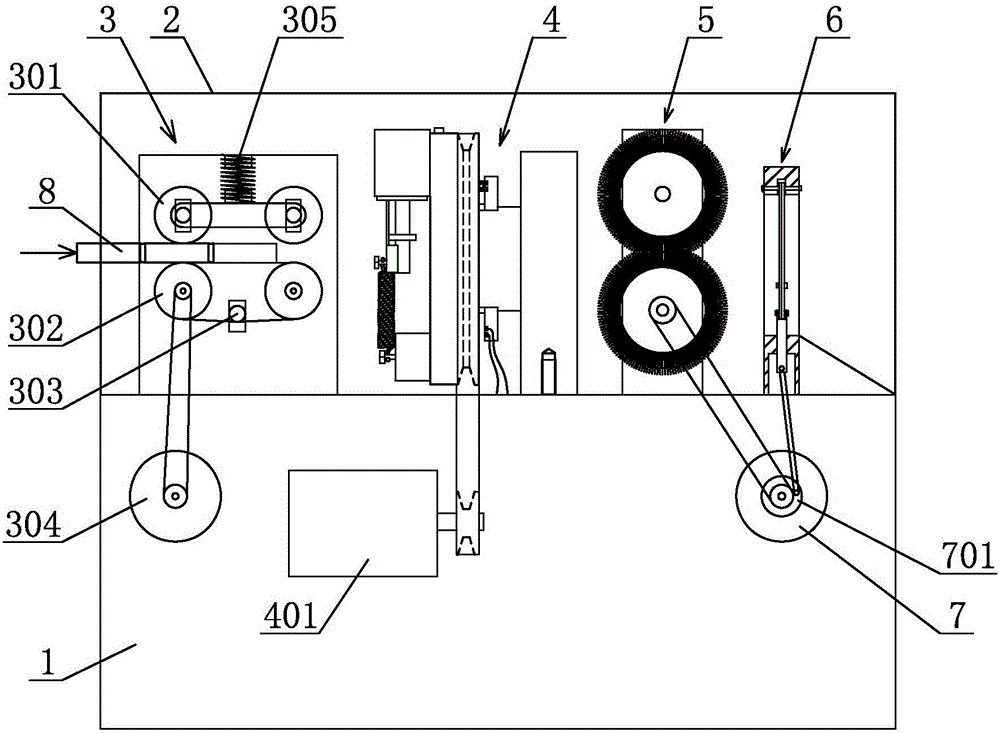

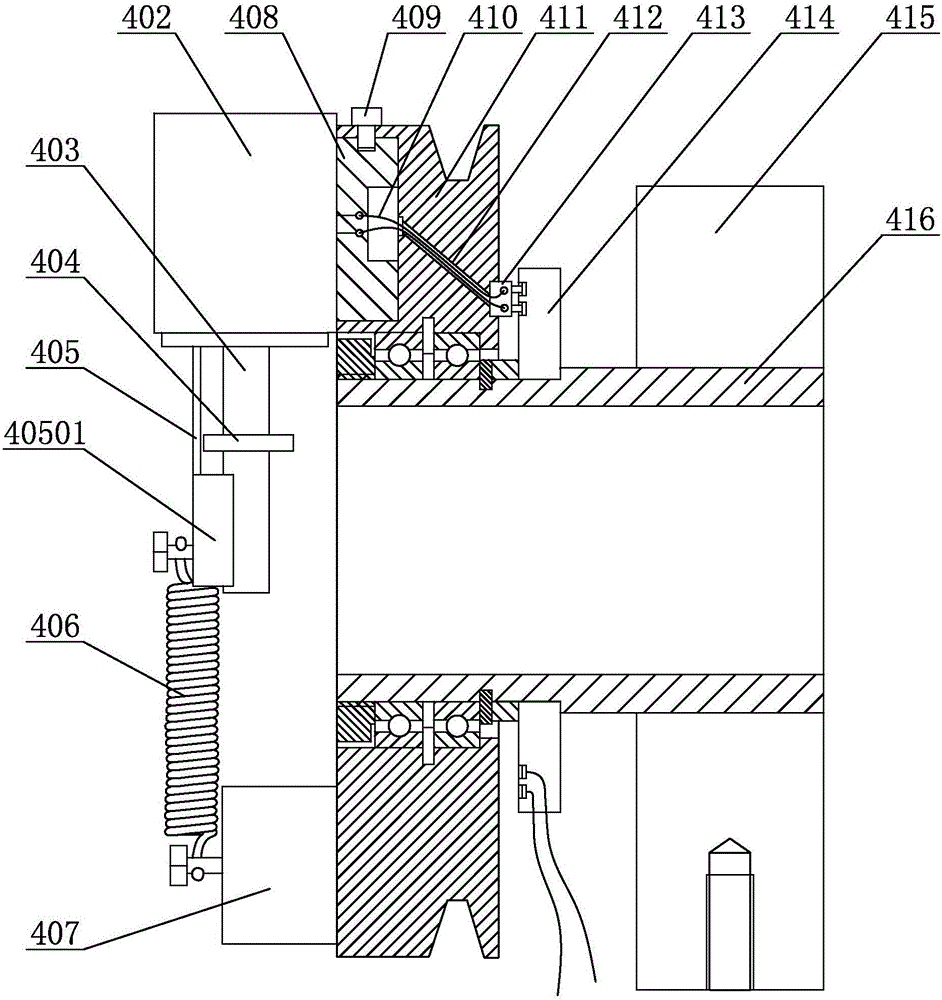

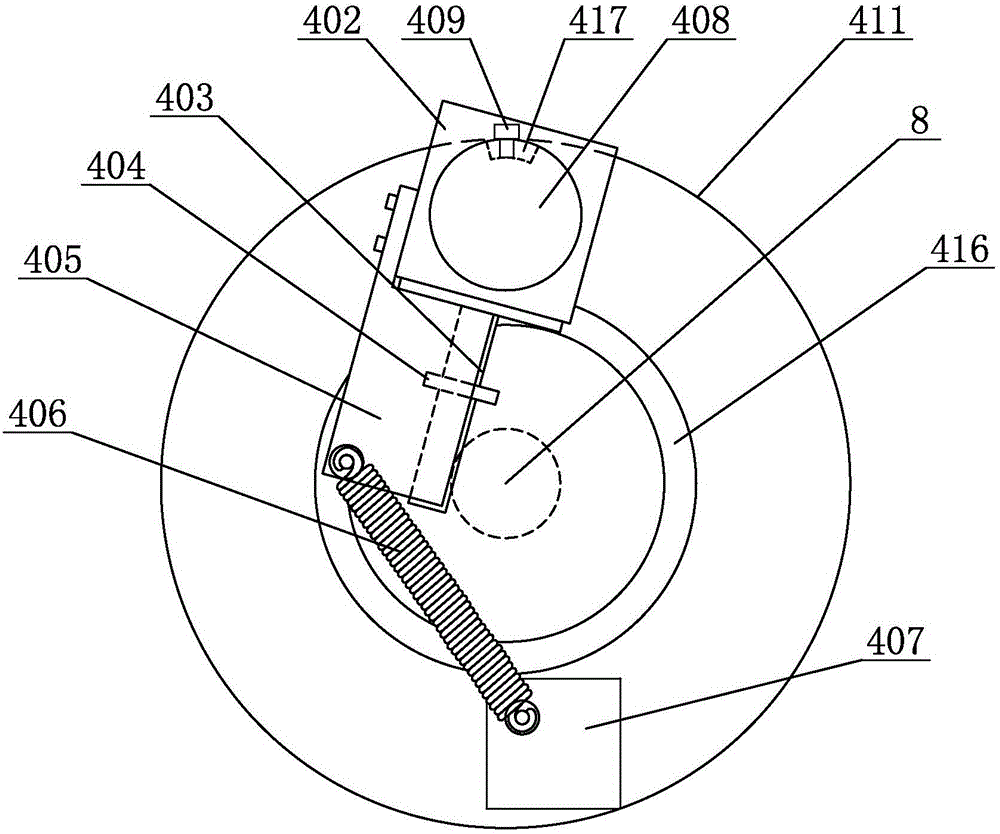

[0028] Such as figure 1 As shown, the sugarcane peeling and cutting machine includes a body 1, a machine cover 2, a feeding and advancing mechanism 3, a peeling mechanism 4, a cleaning mechanism 5, and a cutting mechanism 6. The body is used to set the electric control part and the power part, and the upper end of the body is used to fix the feeding propulsion mechanism, the peeling mechanism, the cleaning mechanism, the cutting mechanism, and the cover covering these mechanisms.

[0029] The feeding propulsion mechanism comprises shell, push motor 304, upper push runner 301, and lower push runner 302, and the push motor is connected with the upper push runner or the lower push runner transmission by a transmission belt, and the upper push runner and the lower push runner are all provided with There are two, and the two upper push wheels are fixed on the same bracket. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com