Continuous rolling tube high-pressure water spraying walnut kernel peeling device

A peeling device and technology for walnut kernels, which are applied in the fields of shelling, pod removal, food science, etc., can solve the problems of large water consumption, unsuitable for factory production, and unfavorable resource conservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

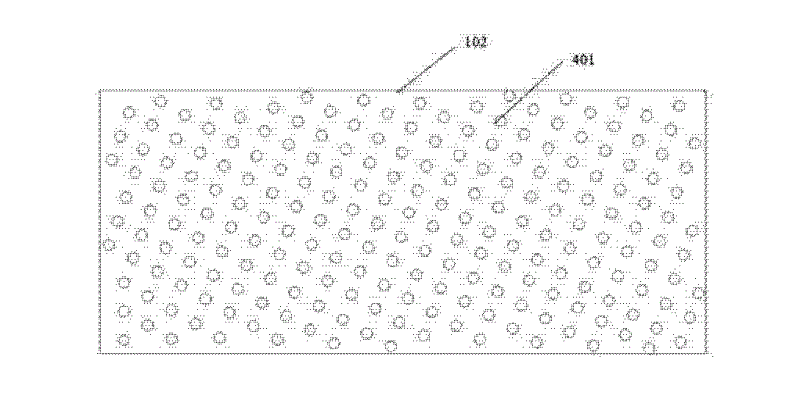

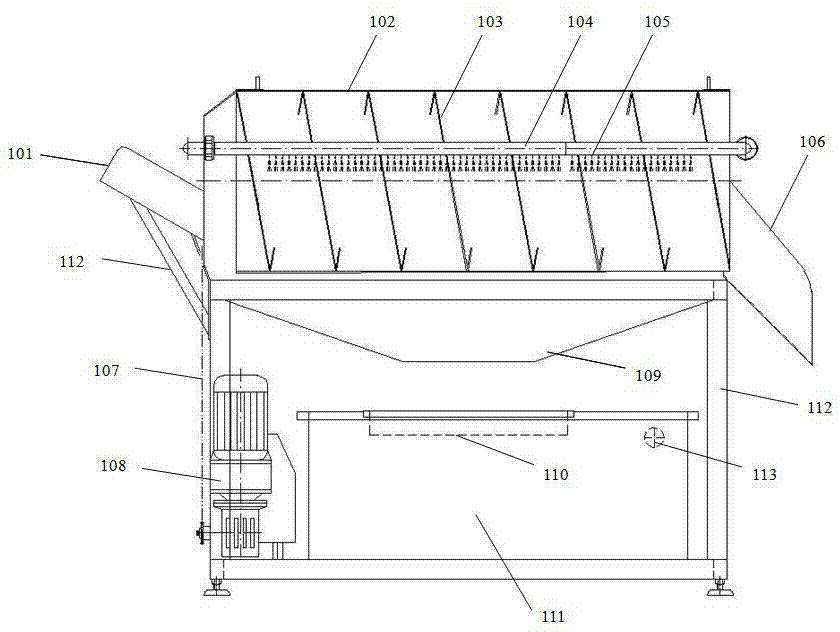

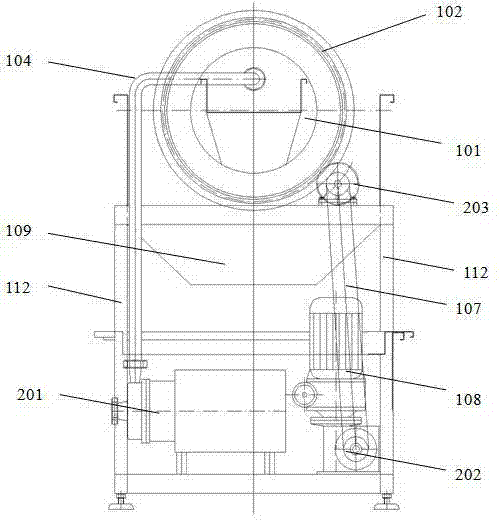

[0014] refer to figure 1 , figure 2 , image 3 , Figure 4 , the patent of the present invention is a continuous drum high-pressure water spray walnut kernel peeling device, which consists of a feed hopper 101, a drum 102, a high-pressure water pipe 104, a discharge hopper 106, a transmission device 107, a power device 108, a reducer 202, and a water receiving bucket. 109, a filter screen, a water collection tank 111, and a support system 112 are formed. Wherein the small holes 401 with an aperture of 3 mm are evenly distributed on the drum 102, and the net distance between the holes is 8 mm. A spiral plate 103 is arranged in the drum 102. The spiral plate 103 is a stainless steel plate with a thickness of 3 mm. The spiral plate 103 is connected on the drum wall, and the spiral Arranged continuously from the inlet to the outlet, pushing the walnut kernels from the inlet to the outlet; the high-pressure water pipe 104 is located along the axial direction of the drum and is ...

Embodiment 2

[0016] In this example, the motor 108 drives the gear 203 through the chain 107, and the gear 203 drives the drum 102 to rotate; the spiral plate 103 is a plastic plate with a thickness of 5mm; There are 4 rows of high-pressure water nozzles 105, and the high-pressure water nozzles 105 are square with a side length of 1.0mm. Other components and their connection relationship are the same as Example 1.

[0017] The working process of the patent of the present invention is as follows: open the power device 108, drive the drum 102 to rotate by the transmission device 107, then open the centrifugal pump 201, pump the clean water and the water in the water collection tank 111 to the high-pressure water nozzle 105 through the high-pressure water pipe 104, and keep The water pressure is 0.1-2.0MPa; put the walnut kernels from the feeding hopper 101, driven by the inner spiral plate 103 of the drum, the walnut kernels roll up and down and move along the rotation direction of the drum....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com