Automatic huller for Chinese chestnuts

A technology of shelling machine and chestnut, which is applied in the field of agricultural machinery harvesting, can solve the problems of damage to fruit grains, failure to guarantee the naturalness and hygiene of fruit grains, and increase the direct contact between people and chestnuts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

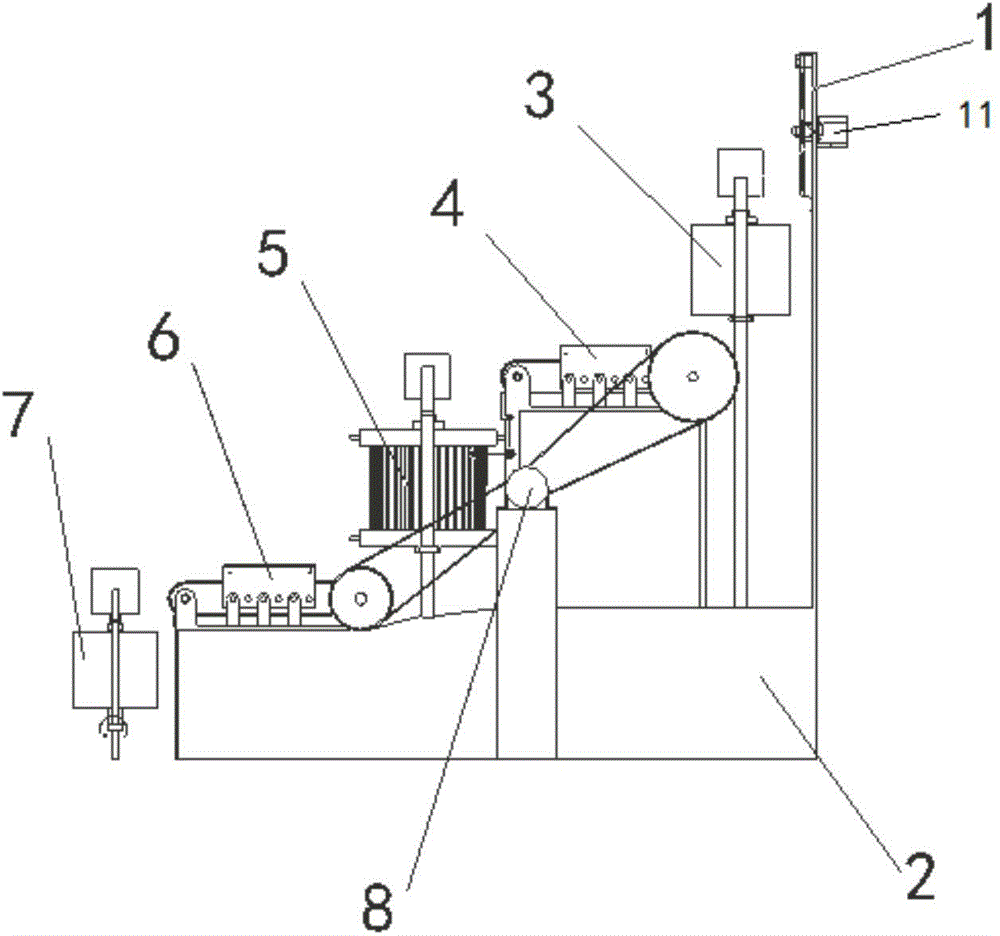

[0023] see figure 1 , a chestnut automatic shelling machine comprising a single grain picking device 1, an incision device 3, a primary drying device 4, a primary peeling device 5, a secondary drying device 6, a secondary peeling device 7, a transmission device 8, and a discharging device device; wherein, the single-grain picking device 1, the incision device 3, the primary drying device 4, the primary peeling device 5, the secondary drying device 6, the secondary peeling device 7, and the discharging device are arranged in sequence, and the single-grain picking device 1 , cutting device 3, primary drying device 4, primary peeling device 5, and secondary drying device 6 are arranged on the fuselage 2, and the transmission device 8 is used for conveying chestnuts.

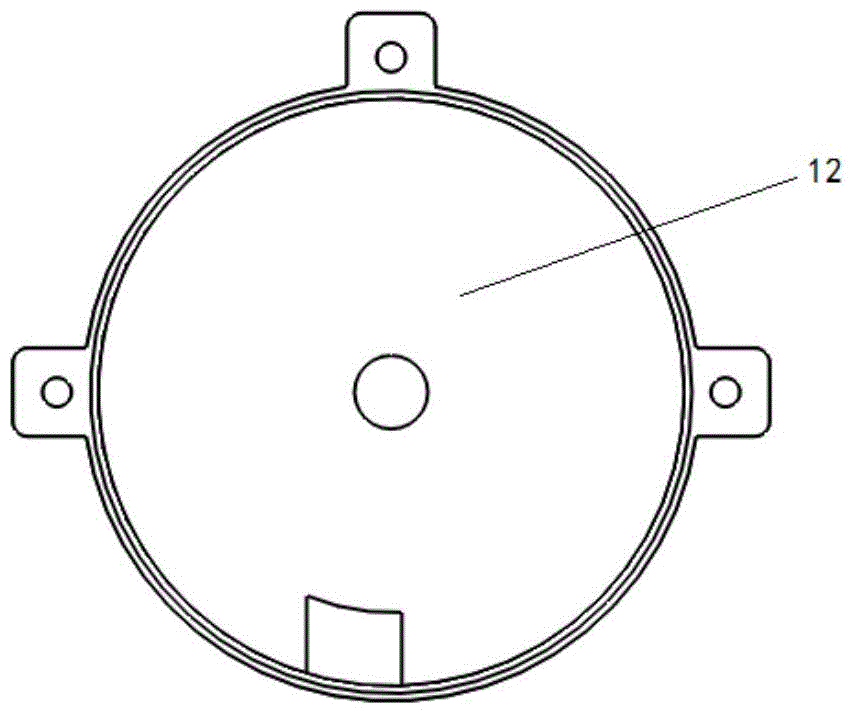

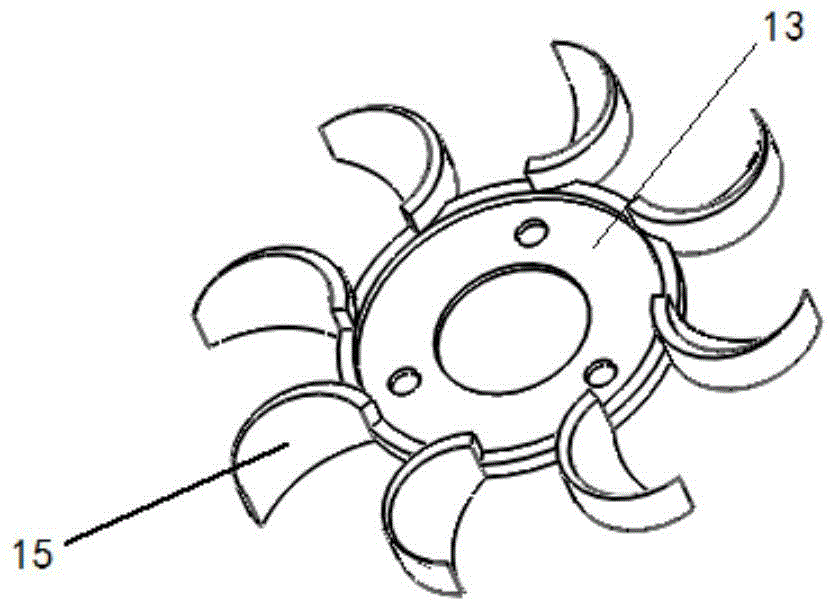

[0024] see Figure 2-5 , the single-grain picking device 1 includes a storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com