Lens driving device

A lens driving device and lens technology, applied in electromechanical devices, installation, optics, etc., can solve problems such as shaking and image blurring, and achieve the effects of reducing the occupied area, improving the yield, and having a reasonable and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

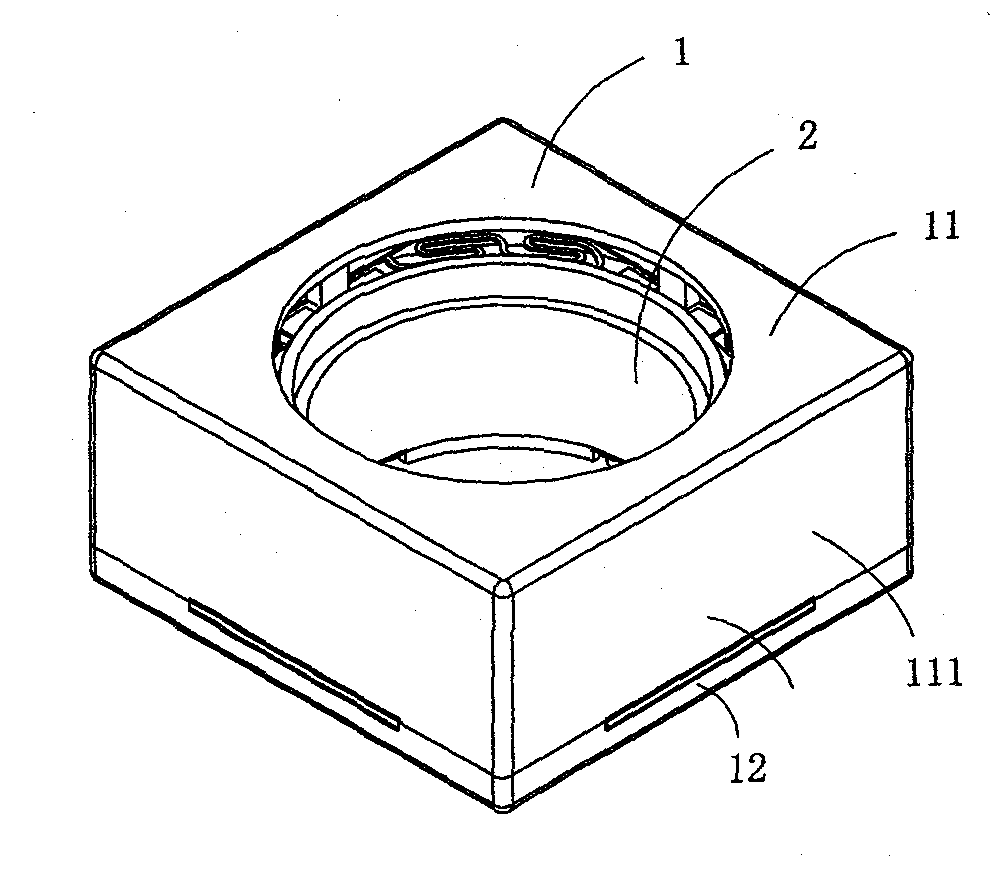

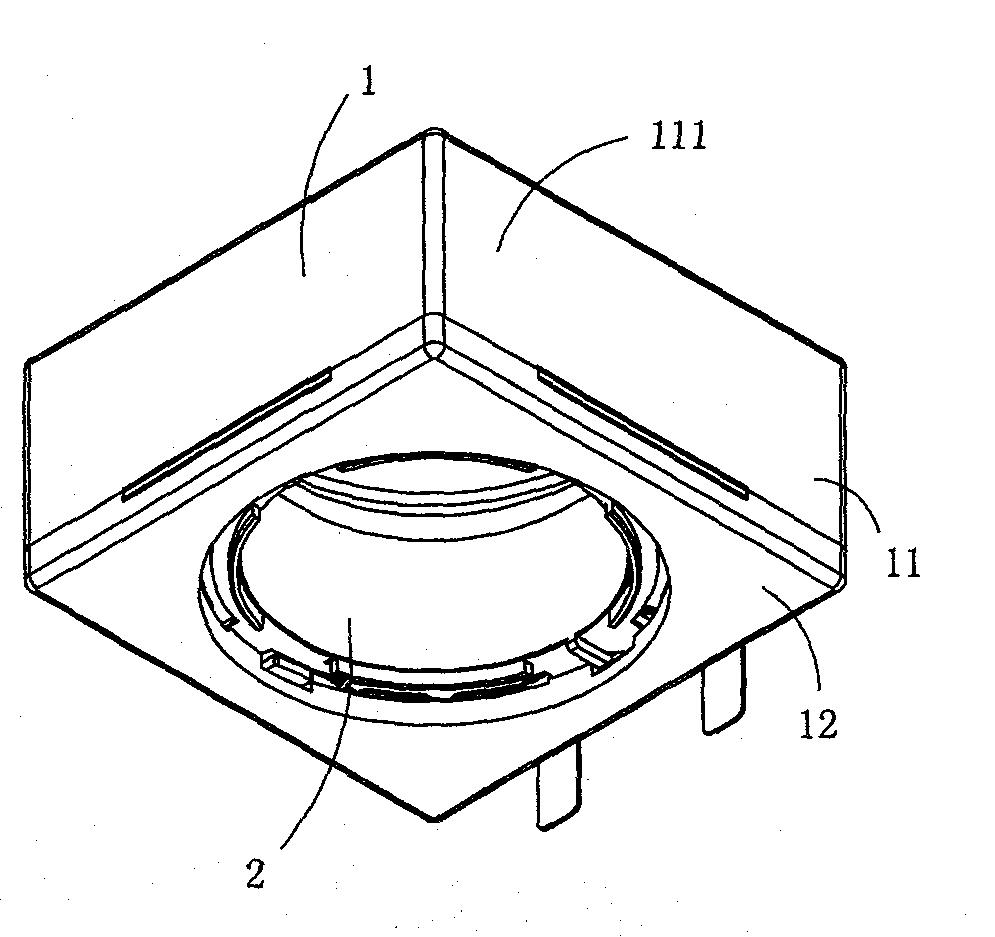

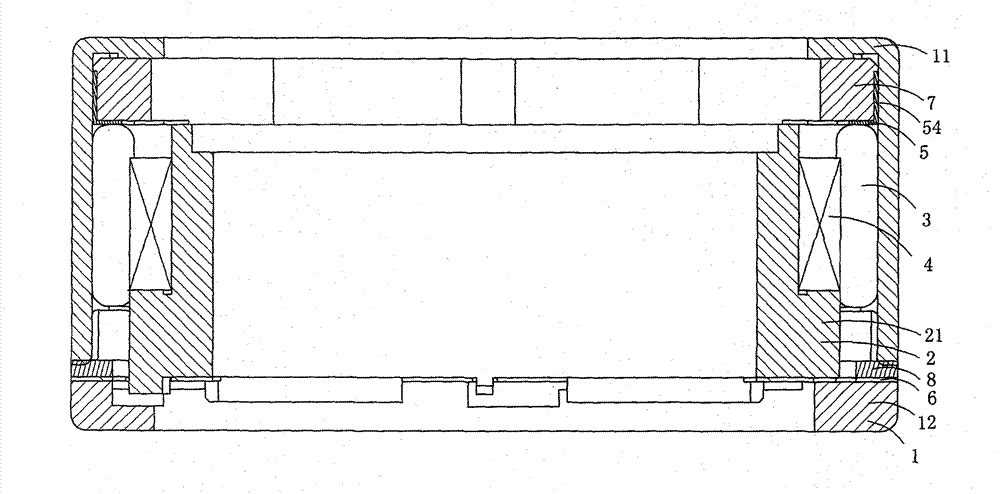

[0024] Figure 1 to Figure 5 A first embodiment of the invention is shown, in which figure 1 It is a schematic diagram of a three-dimensional structure of the first structure of the present invention; figure 2 for figure 1 A schematic diagram of the three-dimensional structure of the voice coil motor when viewed from another angle; image 3 for figure 1 A cross-sectional view of the voice coil motor shown; Figure 4 for figure 1 An exploded view of the voice coil motor shown; Figure 5 for figure 1 A schematic diagram of the three-dimensional structure of the upper shrapnel in the voice coil motor shown.

[0025] This embodiment is a lens driving device, see Figure 1 to Figure 5 , including a housing 1, and a lens carrier 2, a magnet assembly 3, a coil 4, an upper elastic piece 5, a lower elastic piece 6, an upper elastic piece bracket 7 and a lower insulating gasket 8 arranged in the housing 1; the lens carrier 2 is set Between the upper elastic piece 5 and the low...

Embodiment 2

[0036] Figure 6 It is a schematic three-dimensional structure diagram of the upper elastic piece in the second structure of the present invention, showing a second specific embodiment of the present invention.

[0037]This embodiment is basically the same as Embodiment 1, except that: the upper elastic piece 5 is no longer provided with a connection area 55 for connecting two adjacent fixing areas 51, and a connecting area 55 for connecting two adjacent fixing areas 51 is provided between the fixing areas 51. A gap 511 separating two adjacent fixing regions 51 . In addition, the specific shape of the upper elastic piece 5 is also different from that of the first embodiment.

[0038] Above-mentioned embodiment 1 to embodiment 2 have the following advantages:

[0039] (1) The structure is relatively reasonable and compact, and the magnetic conducting ring in the traditional lens driving device is no longer needed, so as to avoid the disadvantage of lens carrier eccentricity c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com