Walnut splitting type shell-cracking kernel-taking machine

A walnut shell breaking technology, which is applied in the field of walnut splitting shell breaking machine, can solve the problems of low shell breaking rate, poor crushed kernels, and inability to guide and position walnuts, and achieve one-time shell breaking High efficiency, easy to use, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0029] Below in conjunction with preferred embodiment and accompanying drawing, the present invention will be further described:

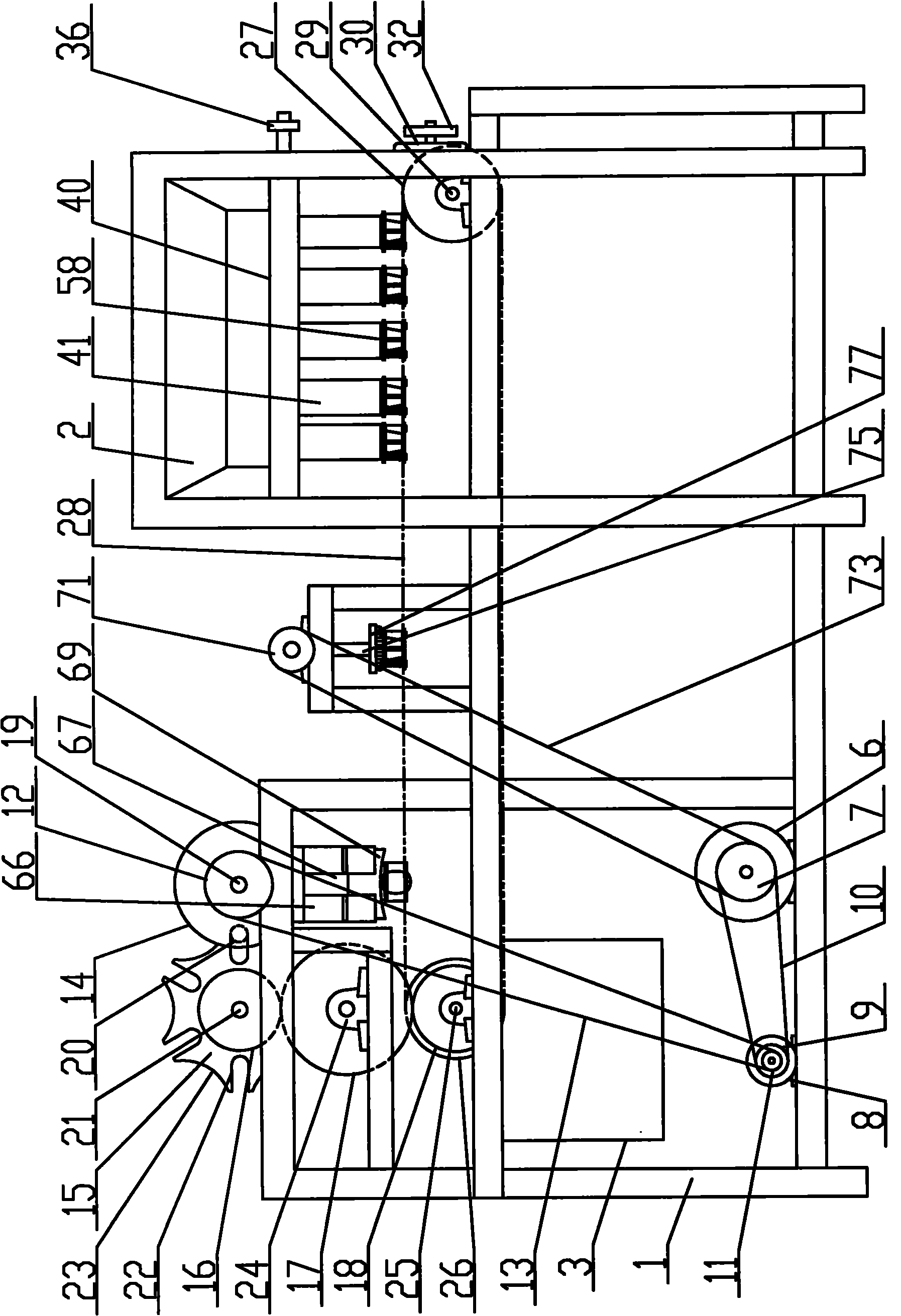

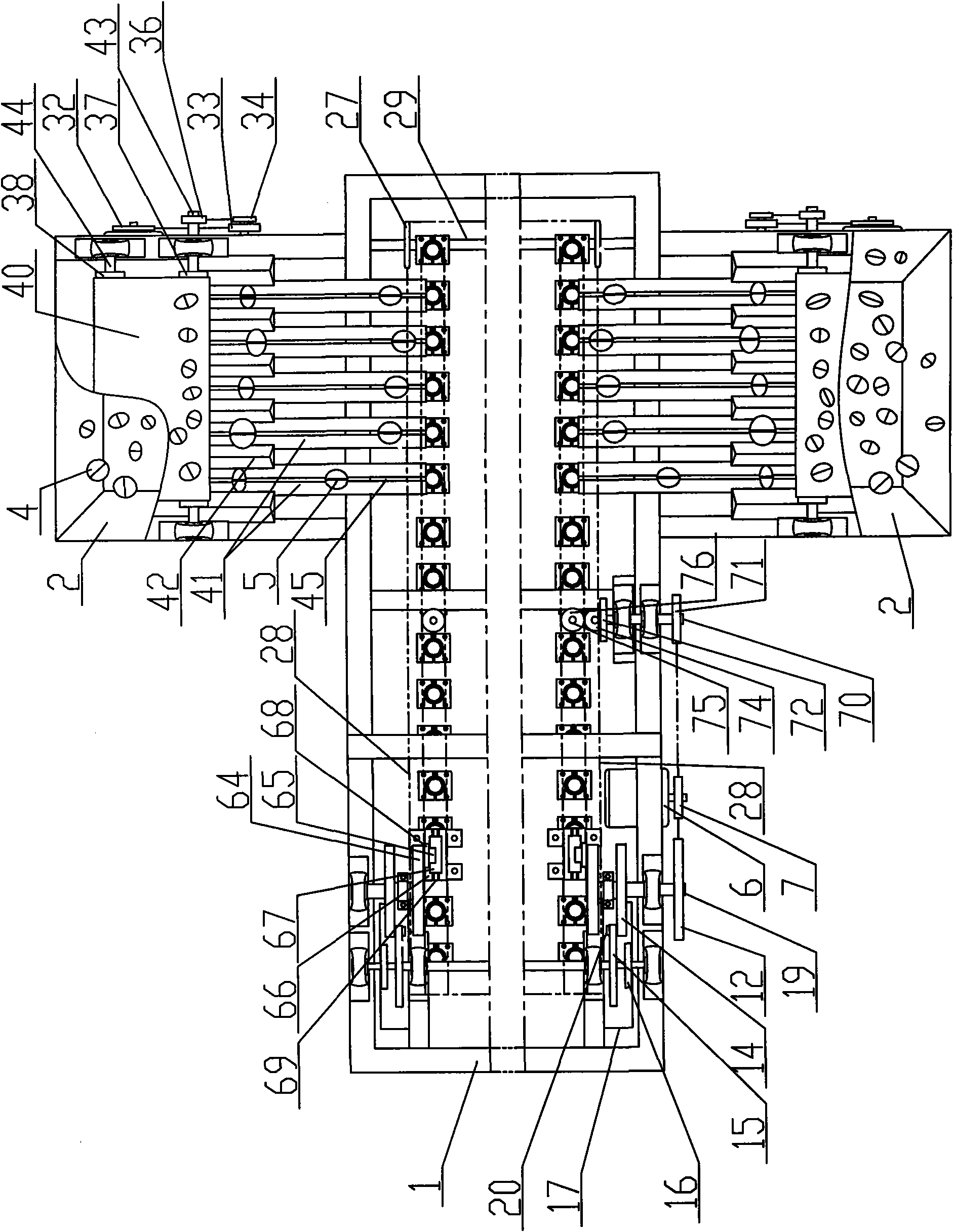

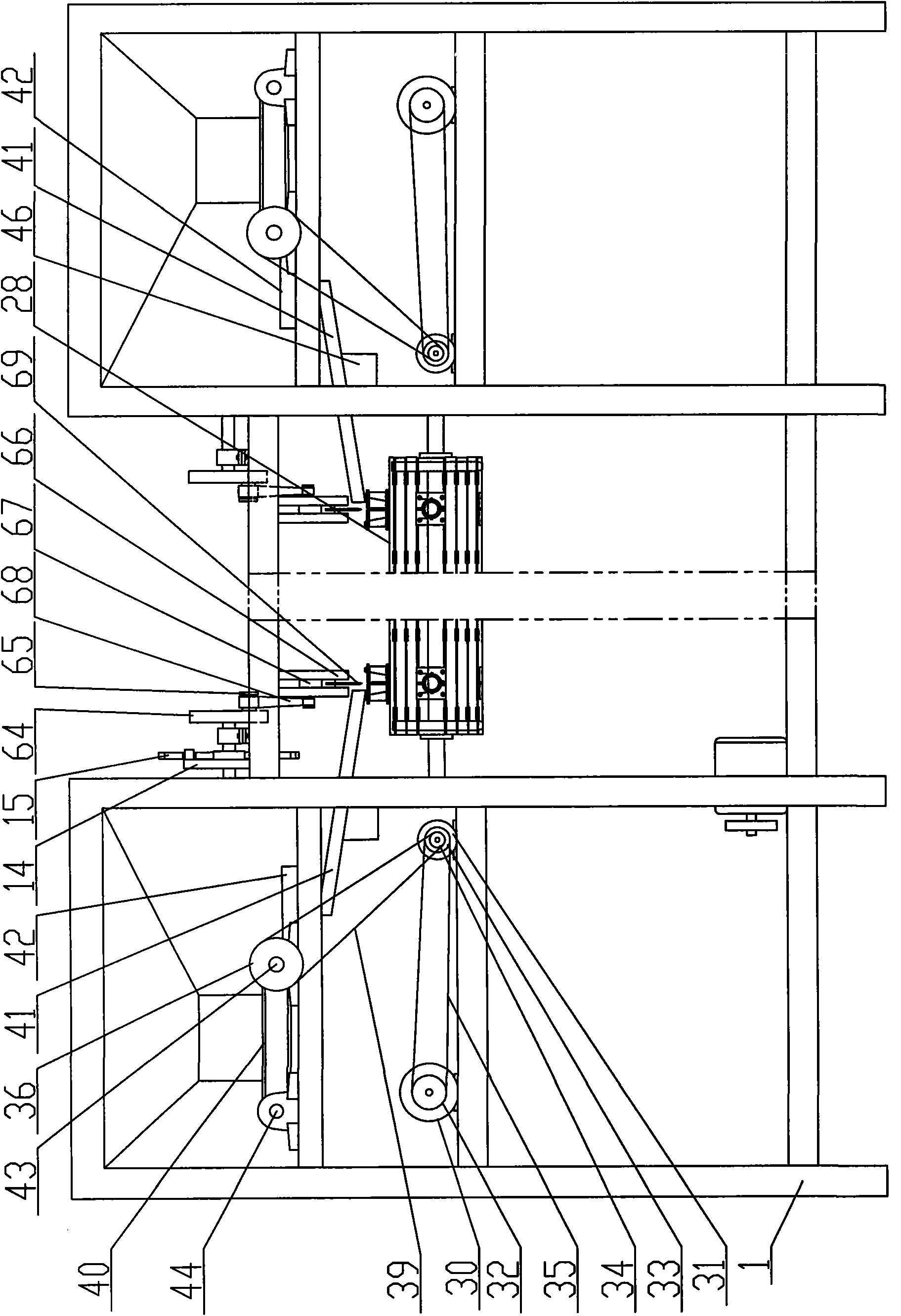

[0030] as attached figure 1 , 2 , 3, the walnut splitting type shell-cracking kernel machine includes a frame 1, a feeding box 2, a receiving box 3, a transmission device, a conveying device, a feeding guide and a cutting device; the front of the frame 1 Feeding boxes 2 are respectively fixed on the left and right sides of the upper part, and the receiving box 3 is fixed on the lower part of the rear of the frame 1. The transmission device is installed on the frame 1 and can drive the conveying device and the cutting device to work. The conveying device that moves intermittently is equipped with no less than two walnut jigs that can fix e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com