Preparation method of polyurethane modified non-ironing resin with improved strong hand feeling

A polyurethane modified, non-ironing resin technology, applied in the direction of improved hand feel fiber, textile and paper making, fiber treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

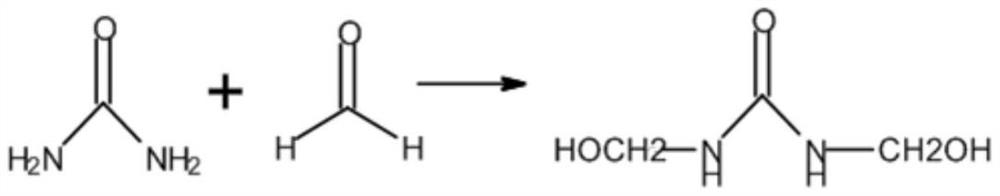

[0031] (1) Add 70.0g of urea and 189.2g of 37% formaldehyde to a container equipped with a thermometer, agitator, reflux device, and pH probe, raise the temperature and keep it at 50°C, and maintain pH 7.5 with 4.3g of 20% sodium hydroxide solution React under the condition of ~8.0 for 4 hours to obtain a colorless solution; the solution crystallizes at a low temperature of <10°C, filters and dries to obtain dimethylolurea;

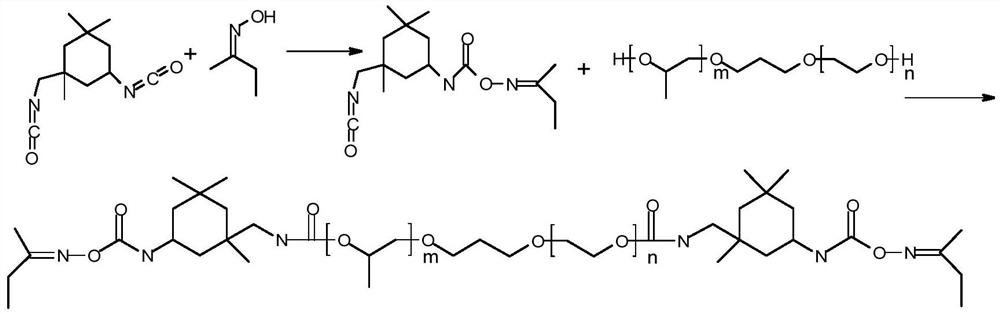

[0032] (2) In a container equipped with a thermometer, a stirrer, and a reflux device, add 225.0 g of isophorone diisocyanate, 89.9 g of methyl ethyl ketone oxime, and 19.2 g of acetone, and react at 50° C. for 5 hours to obtain a polyurethane prepolymer;

[0033] (3) In a container equipped with a thermometer, a stirrer, and a distillation device, add 2900.0g propylene glycol polyoxyethylene polyoxypropylene ether (the polyoxyethylene ether part accounts for 60% of the total polyether moles), heat to 160°C and Vacuum distillation for 4 hours, then lower ...

Embodiment 2

[0038] (1) Add 70.0g of urea and 189.2g of 37% formaldehyde to a container equipped with a thermometer, stirrer, reflux device, and pH probe, raise the temperature and keep it at 45°C, and maintain pH 8.0 with 4.6g of 20% sodium hydroxide solution Reaction under the condition of ~8.5 for 5 hours, a colorless solution was obtained; the solution was crystallized at a low temperature <10°C, filtered and dried to obtain dimethylolurea;

[0039] (2) Add 170.0g of hexamethylene diisocyanate, 99.1g of 3,5-dimethylpyrazole, and 33.2g of acetone into a container equipped with a thermometer, a stirrer, and a reflux device, and react at 50°C for 4 hours to obtain Polyurethane prepolymer;

[0040] (3) In a container equipped with a thermometer, a stirrer, and a distillation device, add 4000.0 g of propylene glycol polyoxyethylene polyoxypropylene ether (the polyoxyethylene ether part accounts for 70% of the total polyether moles), heat to 160 ° C and Vacuum distillation for 3 hours, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com