High-whiteness formaldehyde-free non-ironing cellulose fiber fabric finishing liquid, and application thereof

A cellulose fiber and fabric finishing technology, applied in fiber processing, plant fiber, fiber affecting crease behavior, etc., can solve the problem of low whiteness increase value, achieve high whiteness, short process flow, and good non-iron effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

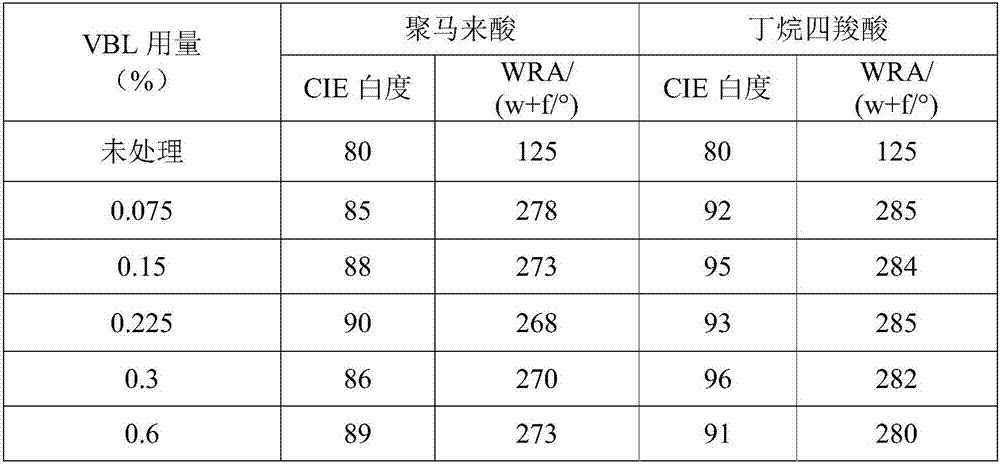

[0020] Butane tetracarboxylic acid and C.I. fluorescent whitening agent 351 non-ironing and whitening finishing process in the same bath

[0021] The working solution is made by physically mixing the components of the following concentrations:

[0022] According to mass percentage, butane tetracarboxylic acid 6%; C.I. fluorescent whitening agent 351 0.1%; sodium hypophosphite 3%; organic silicon softener 2%; penetrating agent JFC 0.2%; the rest is water.

[0023] Technological process: two dipping and two rolling (residual rolling rate: 80%), drying (80°C×3min), baking (180°C×1.5min), washing with water.

Embodiment 2

[0025] Polymaleic acid and C.I. fluorescent whitening agent 351 non-ironing and whitening finishing process in the same bath

[0026] The working solution is made by physically mixing the components of the following concentrations:

[0027] According to mass percentage, polymaleic acid 9%; C.I. fluorescent whitening agent 351 0.1%; sodium hypophosphite 3%; polyethylene softener 2%; penetrating agent JFC 0.2%; the rest is water.

[0028] Technological process: two dipping and two rolling (residual rolling rate: 80%), drying (80°C×3min), baking (170°C×2min), washing with water.

Embodiment 3

[0030] Citric acid and C.I. fluorescent whitening agent 351 non-ironing and whitening finishing process in the same bath

[0031] By mass percentage, citric acid 12%; C.I. fluorescent whitening agent 351 0.15%; xylitol 1.5%; sodium hypophosphite 7%; organic silicon softener 2%; penetrant JFC 0.2%; the rest is water.

[0032] Two dipping and two rolling (residue rate: 80%), drying (80°C×3min), baking (175°C×3min), washing with water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com