Stiff wear-resistant and waterproof regenerated yarn-dyed fabric and production method thereof

A production method and fabric technology, applied in the direction of wear-resistant fibers, textiles, fabrics, etc., can solve the problems of fading, uneven reproducibility, and difficult control of fabric color fastness, so as to reduce consumption, use less, and resist The effect of pilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

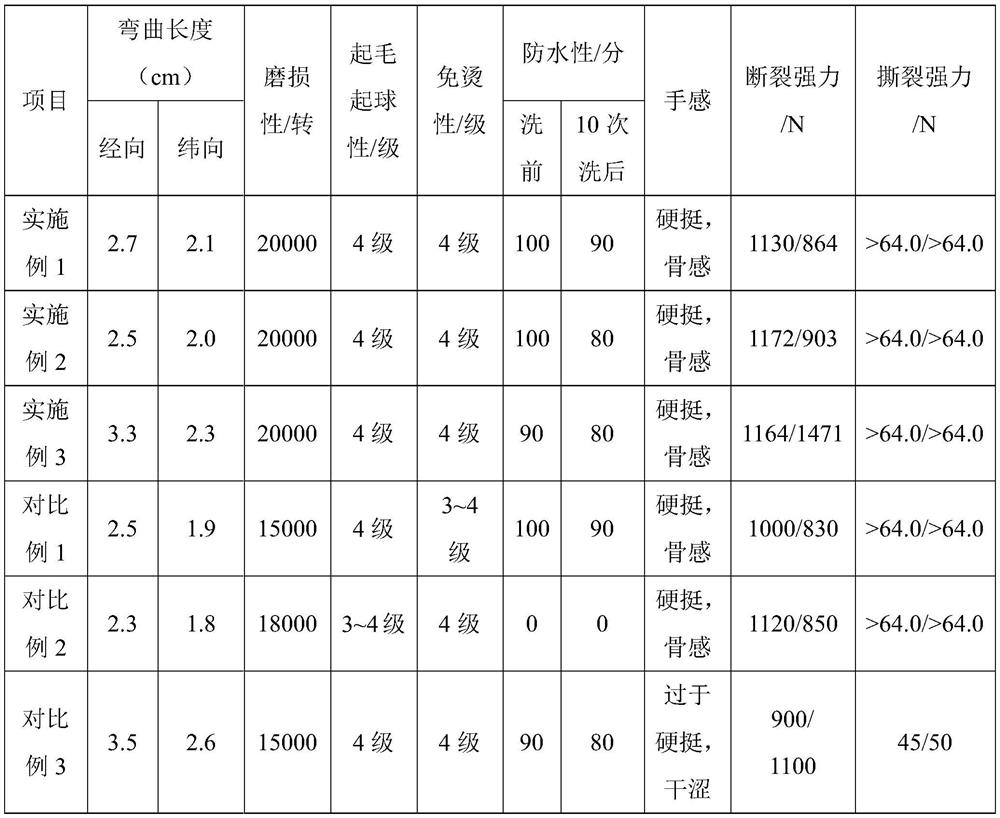

Examples

Embodiment 1

[0058] A kind of production method of stiff wear-resisting waterproof regenerated yarn-dyed fabric, comprises the following steps:

[0059] First, select the yarn raw material: the weight percentage of cotton and regenerated polyester is: 35% cotton fiber, 65% regenerated polyester fiber; the warp yarn is 32 / 2S; the weft yarn is 32 / 2S; The density is 80 threads / in, the weft density is 60 threads / in; the width is 57 / 58in;

[0060] Regenerated polyester staple fiber is Suzhou Youfu Textile Co., Ltd.;

[0061] Then, the warp yarns are dyed, then warped, sizing, reeded, and heald, and then interwoven with the weft yarns to form a gray cloth; the weft yarns are dyed, then wound, and then woven with the warp yarns to form a gray cloth;

[0062] Finally, finishing includes the following steps:

[0063] (1) singeing

[0064] Use one positive and one reverse, select the position of the burner to burn, the flame intensity is 10mbar, and the speed is 90m / min;

[0065] (2) Desizing

...

Embodiment 2

[0076] A kind of production method of stiff wear-resisting waterproof regenerated yarn-dyed fabric, comprises the following steps:

[0077] First, select the yarn raw material: the weight percentage of cotton and recycled polyester is: 35% cotton fiber, 65% recycled polyester fiber; the warp yarn is 32 / 2S; the weft yarn is 22 / 2S; Density is 70 / in, weft density is 60 / in; width 57 / 58in;

[0078] Regenerated polyester staple fiber is from Hangzhou Benma Chemical Fiber Spinning Co., Ltd.;

[0079] Then, the warp yarns are dyed, then warped, sizing, reeded, and heald, and then interwoven with the weft yarns to form a gray cloth; the weft yarns are dyed, then wound, and then woven with the warp yarns to form a gray cloth;

[0080] Finally, finishing includes the following steps:

[0081] (1) singeing

[0082] Use one positive and one reverse, select the position of the burner to burn, the flame intensity is 10mbar, and the speed is 90m / min;

[0083] (2) Desizing

[0084] Adopt ...

Embodiment 3

[0094] A kind of production method of stiff wear-resisting waterproof regenerated yarn-dyed fabric, comprises the following steps:

[0095] First, select the yarn raw material: the weight percentage of cotton and regenerated polyester is: 35% cotton fiber, 65% regenerated polyester fiber; the warp yarn is 30 / 2S; the weft yarn is 20 / 2S; The density is 70 threads / in, the weft density is 50 threads / in; the width is 57 / 58in;

[0096] Regenerated polyester staple fiber is from Suzhou Youfu Textile Co., Ltd.;

[0097] Then, the warp yarns are dyed, then warped, sizing, reeded, and heald, and then interwoven with the weft yarns to form a gray cloth; the weft yarns are dyed, then wound, and then woven with the warp yarns to form a gray cloth;

[0098] Finally, finishing consists of the following steps:

[0099] (1) singeing

[0100] Use one positive and one negative, choose the position of the burner to burn, the flame intensity is 12mbar, and the speed is 95m / min;

[0101] (2) De...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com