Chlorine-resistant polyamide composite reverse osmosis membrane and preparation method thereof

A technology of chlorine-resistant polyamide and reverse osmosis membrane, applied in the field of separation membrane, can solve problems such as poor chlorine resistance, and achieve the effects of excellent chlorine resistance, cheap raw materials and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

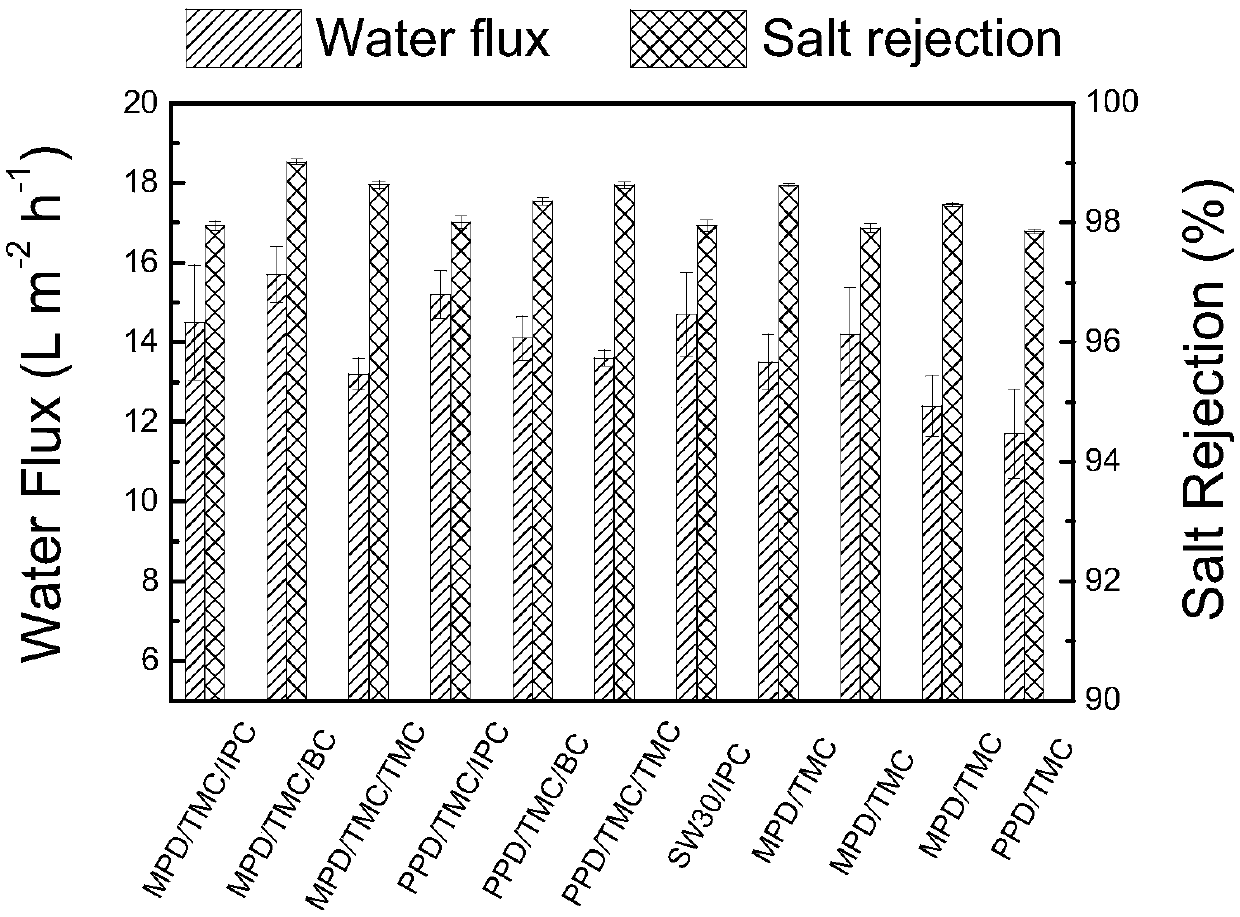

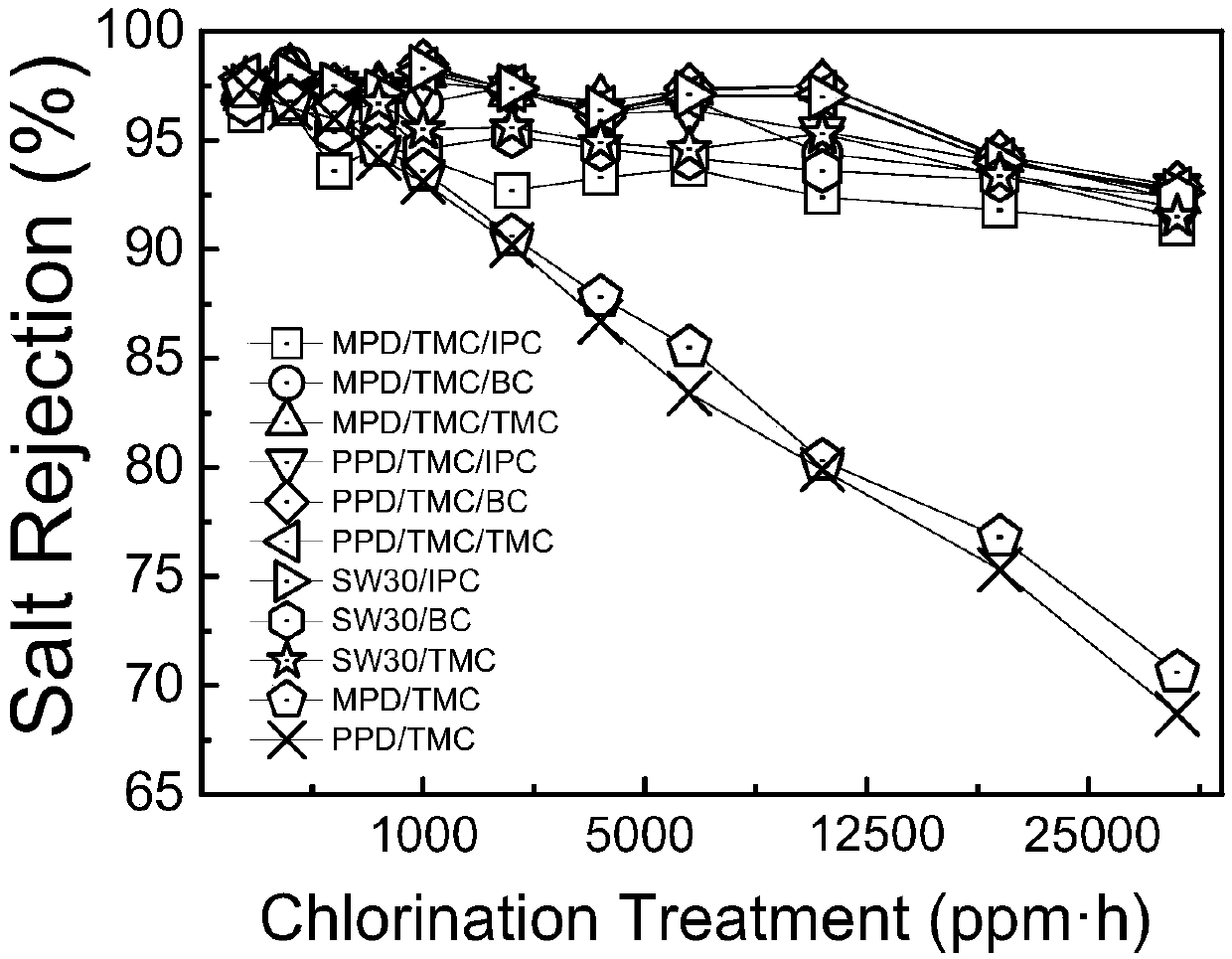

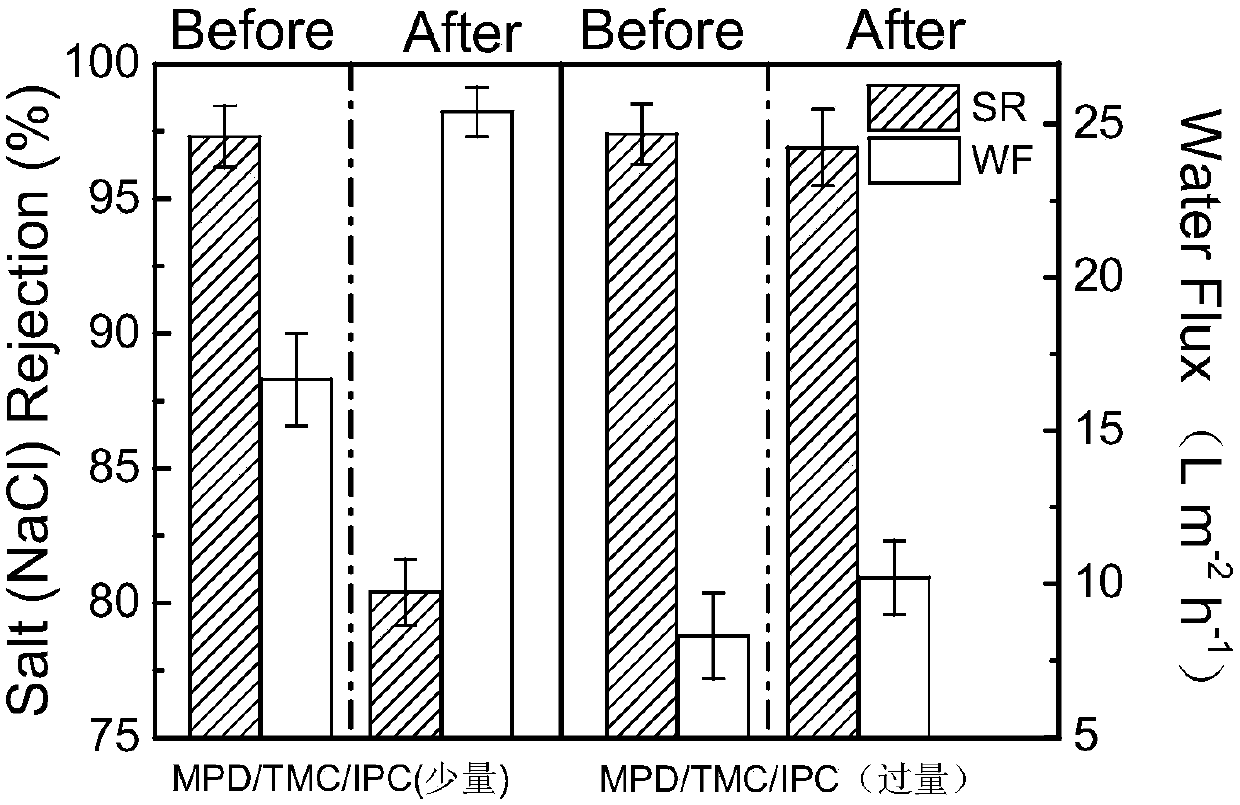

[0032] Embodiment 1 Preparation of MPD / TMC / IPC chlorine-resistant reverse osmosis membrane

[0033] The preparation process of the IPC-terminated MPD / TMC membrane is similar to that of the MPD / TMC reverse osmosis membrane in Comparative Example 1. The difference is that immediately after the n-hexane solution cleaning treatment, 100mL n-hexane solution containing 2wt% IPC was poured on the membrane surface again to carry out the secondary interfacial polymerization reaction. After standing and soaking for 5 minutes, pour out the solution again, and rinse the surface with fresh n-hexane to remove unreacted acid chloride monomers. Finally, the MPD / TMC / IPC chlorine-resistant reverse osmosis membrane was air-dried and stored in deionized water for testing.

Embodiment 2

[0034] Embodiment 2 Preparation of MPD / TMC / BC chlorine-resistant reverse osmosis membrane

[0035] The preparation process of the BC-capped MPD / TMC membrane is similar to that of the MPD / TMC reverse osmosis membrane in Comparative Example 1. The difference is that 100 mL of n-hexane solution containing 3wt% BC was immediately poured on the surface of the membrane after the n-hexane solution was cleaned to carry out the secondary interfacial polymerization reaction. After standing and soaking for 10 minutes, pour out the solution again, and rinse the surface with fresh n-hexane to remove unreacted acid chloride monomers. Finally, the MPD / TMC / BC chlorine-resistant reverse osmosis membrane was air-dried and stored in deionized water for testing.

Embodiment 3

[0036] Embodiment 3 Preparation of MPD / TMC / TMC chlorine-resistant reverse osmosis membrane

[0037] The preparation process of the TMC-capped MPD / TMC membrane is similar to that of the MPD / TMC reverse osmosis membrane in Comparative Example 1. The difference is that immediately after the n-hexane solution cleaning treatment, 100mL n-hexane solution containing 1.5wt% TMC was poured on the membrane surface again to carry out the secondary interfacial polymerization reaction. After standing and soaking for 10 minutes, pour out the solution again, and rinse the surface with fresh n-hexane to remove unreacted acid chloride monomers. Finally, the MPD / TMC / TMC chlorine-resistant reverse osmosis membrane was air-dried and stored in deionized water for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com